The most popular way to maintain heat in the rooms of a private house is heating associated with the movement of water through pipes. There are many types of structures that allow you to conduct and install heating in a house. Practical owners choose a double-circuit heating system for a private home. It fully pays for the money spent on it and effectively heats the premises.

In our article we will analyze in detail what two-pipe heating is, why people install this system, what heating installation schemes exist. We will also touch on the topic of installing a double-circuit boiler that runs on gas.

What is dual-circuit heating?

Double-circuit heating (two-pipe) is the most popular pipe layout for heating a house. A double-circuit heating system is better than a single-circuit heating system due to the rational and efficient distribution of the coolant.

The two pipes connected to the radiator perform different functions. Water heated by the boiler to the required temperature flows through one pipe. On the other, the cooled coolant is discharged. Then it goes back into the boiler for further heating, but does not flow into the next radiator. The water in both pipes often moves in the same direction, although with a certain installation design it can move in opposite directions.

A double-circuit heating system requires more pipes than a single-circuit heating system, but it is more efficient and much more practical.

Thanks to the two-pipe system, you can maintain a comfortable temperature in a specific room, and not in the entire house at once. It's also more economical. A two-circuit system can be automated so that it can heat a room to a certain temperature, turn itself off, and then turn on again when the temperature drops to a certain point. These are not the only advantages of such heating.

Calculation of boiler power and boiler capacity

The temperature in the combustion chamber should not exceed 90 degrees with correct power calculation.

With the correct power of the heating unit, the temperature in the combustion chamber will not rise above 90°C, which significantly increases the service life of the equipment.

The simplest calculation method:

Q=S×A×k

- Q – thermal power (Watt);

- S – internal area of the structure (m²);

- A – the number of watts from the total power of the heating system per 1 m² (usually 100 - 150 watts);

- k – safety factor for extreme cold (1.2 or 1.25).

If the total area of the heated room is about 100 m2, the maximum power cannot exceed 38 kW. As a rule, two values are indicated on the boiler. The first shows energy consumption in heating mode, the second shows the power for quickly heating water.

The boiler capacity must be calculated based on future consumption: on average 10 liters for washing dishes, 30 liters for taking a shower, 100 liters for a bath and a large wash.

Why do people choose a dual-circuit system?

This type of wiring has advantages that need to be mentioned in order to understand why home owners choose it. These include:

- Parallel connection of radiators. This allows you to maintain different temperatures in a single room. This allows the system to be used in multi-storey buildings. Plus, if one or more radiators break down, the system will continue to function. With a single-circuit system this is impossible.

- Possibility of connecting a large number of radiators. The temperature of the water entering each radiator will be the same, regardless of how far it is located from the boiler.

- Possibility of installing a thermostat. The system monitors the temperature itself and automatically turns on when needed. The owner only needs to set the temperature range.

- Low heat loss. Almost all the heat generated is not lost, but is used to heat the room. In single-circuit systems it is wasted.

Of the minuses: many note the long length of pipes and the high cost of installing double-circuit heating in a private house. In fact, a double-circuit system is not more expensive than its single-pipe counterpart due to the small diameter of the pipes themselves. And there are much more benefits from it.

Where to go for installation?

Our company professionally installs heating systems in buildings for various purposes. We recommend placing an order for comprehensive services. It will include:

- Creation of a heating system project for a specifically specified room (building, industrial facility). Our specialists will conduct a full analysis of the areas and calculate the amount of heat required. They will not make mistakes in calculations, as otherwise the system will not work correctly. We do not want our clients to pay additional costs for repair work. Therefore, we do everything accurately, efficiently and on time.

- Purchase of necessary components. We are also ready to take on this concern. We have been working with reliable suppliers of high-quality materials for heating networks for a long time. The customer himself will choose the model of the boiler, radiators, and pipeline fittings. Our craftsmen will deliver and install everything within the agreed time frame.

- Installation of a boiler in a private house. Carried out after completion of preparatory work. We will install and adjust the operation of each element, carry out pressure testing and hydraulic tests.

We guarantee high-quality performance of all work. A technical passport is issued for the heating system, indicating the wiring method, brands of components and other technical characteristics.

Many years of experience of our company’s craftsmen allows them to quickly and effectively deal with any problem. Industrial enterprises with developed infrastructure and owners of private country cottages cooperate with us. We install heating systems in houses of various types: retail outlets, residential premises, administrative buildings. By cooperating with us, clients save time and money.

We recommend that after installing the heating system, you enter into a service agreement with our company. Periodic technical inspection will help extend the life of the system. Maintenance also includes current and major repairs. We promptly respond to every call from our regular customers. We do not inflate prices, but make them optimal for each customer.

Dual-circuit heating schemes

An example of a two-pipe heating scheme for a house

A double-circuit heating system can be installed in different ways. The choice depends entirely on the decision of the home owner. In order not to miscalculate and understand which of them is necessary in a given situation, we will dwell on them in more detail. The most common of them will be:

- Open wiring.

- Closed wiring.

- Upper wiring.

- Bottom wiring

- Dead end.

So, let's start in order.

Correcting the system operation

Scheme of water heating of a private house.

To achieve the desired operating mode of the system, some of its parameters should be adjusted. To do this, the limiters (chokes) of each battery must be adjusted. You need to start with the first battery in the direction of liquid movement from the boiler. This procedure will reduce the supply of coolant immediately after heating and increase its flow at the extreme points of the system. In detail, the operation is as follows: we gradually close the valves on the radiators and control the temperature change at the extreme points of the system; a simple touch is enough to feel the slightest fluctuations. Consistently carry out the procedure with all battery chokes in the selected direction.

It is necessary to remember a couple of important conditions that will accompany the process of adjusting the operation of a double-circuit heating system. Namely, that it will take a significant period of time to achieve satisfactory results in setting the desired temperature regime, since after pressing each throttle you should wait until the entire system adapts to the changes in the regime and displays the result. For more sensitive tuning, all operations must be carried out in a timely manner. The cold season is not suitable for temperature correction.

https://youtube.com/watch?v=xqjR5Zpjhpw

In modern times, many different innovations have appeared, including coolants that can remain in a stable state of aggregation even with a sharp drop in temperature. That is, they do not freeze or expand. Using a non-freezing coolant will require some financial costs, but it will save time on seasonally emptying and filling the heating system.

Open wiring

This implies the presence of an expansion tank that is not sealed. It has a lid, but it does not close the tank tightly, which allows the liquid in it to communicate with the atmosphere.

Install it at the highest point of the system. It is located in attics or directly under the ceiling of a building. In the first case, it is necessary to maintain heat in the attic, otherwise the coolant may freeze, and in the second, such a design looks untidy. Installation at this point in the house is necessary to ensure that water does not overflow from it.

The tank can only be filled with water. Other coolant fluids will not work. The system communicates with the atmosphere and some of the water regularly evaporates. Owners of such heating systems must monitor the water level in open wiring. If there is insufficient coolant, the entire heating system will fail.

The system is the easiest to install, does not pose any particular threat to humans and does not require additional components.

Connecting the gas equipment system

You can install the entire system with your own hands, but the actual gas connection can only be carried out by a specialist. Even if you have all the necessary knowledge, you cannot work with gas pipes without special permission. Otherwise, the inspector will demand an explanation when putting the equipment into operation, and you will have to pay a large fine.

To connect new equipment, you need to do the following:

- Contact the BTI so that the appropriate changes are made to the technical passport of the house. The plan should show the boiler room and make appropriate notes.

- An application is submitted to the gas service, to which the technical passport of the purchased boiler is attached. It is worth purchasing all the equipment in advance.

- Carry out installation of equipment, except for direct connection. How to do this is described in detail in the next paragraph.

- Invite a specialist from the gas service to connect the equipment. At the same time, an application is being submitted to put it into operation.

- Obtain permission from the gas inspector. He will check the correct connection, draw up the necessary documents, and after that gas will be released into the system.

Installation can only be carried out by a specialist!

Note. The meters are installed and sealed immediately so that they can start working immediately after the equipment is put into operation.

Closed wiring

The system is based on an expansion tank. Inside it is divided transversely into two parts by an elastic partition, which is called a membrane. The required pressure is maintained in the upper part, and the volume of water is maintained in the lower part. The lower part is connected to the heating system through a pipe.

Water and any ethylene glycol-based liquid are suitable for filling a closed dual-circuit system. The advantage of the latter is that it does not freeze even at fairly low temperatures. Disadvantage: it is not egological and requires disposal. And there are problems with this in the CIS countries.

An expansion tank with a membrane can be installed anywhere in your home, not necessarily at the highest point.

A sealed tank is more dangerous than a leaking one. The pressure can increase greatly, and gases, having no outlet, accumulate. Therefore, a closed system must be carefully monitored and air vents installed.

Installation methods and installation

First of all, you need to decide on the choice of energy source. The most common energy sources for a private home are electricity and natural gas, which provide various features for the installation and operation of thermal equipment.

Piping of a double-circuit boiler.

If the first does not require a lot of space and special safety measures, then the second requires a special room in which natural ventilation must be provided and a chimney must be installed. According to safety rules, a gas boiler can only be installed there. The heating system, the circuit of which has two circuits, can be located both vertically and horizontally.

Selecting a connection method

The pipeline connection can be top or bottom. The first method allows water to circulate naturally inside the battery, from top to bottom. The expansion tank is placed at the highest point of the heating distribution. The second scheme makes it possible to run pipes along the basement ceiling for batteries on the first floor or inside the ceiling for the second.

Selection and placement of radiators

You should also choose the type of radiators, which often determines the method of their installation. If they are aluminum, steel or bimetallic, then they can be hung on the wall using special brackets. It is more reliable to install cast iron radiators on special floor mounts.

Batteries are usually located in the center of the window openings of a private house, under the window sills. The distance of radiators from the floor, window sill and wall should not be less than 5 cm. Pipelines can be either steel, metal-plastic or plastic. The pump is installed simultaneously with the laying of pipes. All control and measuring devices are installed in the upper part of the installed pipeline.

Heating a private house with a double-circuit boiler is a fairly common solution. This type of equipment allows you to heat all rooms in the building and heat water for various household needs. With the help of a double-circuit boiler, you can provide a high level of comfort in your home and at the same time do without purchasing additional equipment. However, you need to know the features and disadvantages of such equipment in order to install the most efficient and reliable system.

Upper wiring

Pipes supplying coolant are installed at the top of the room. Most often closer to the ceiling, above the windows. This contributes to the appearance of high pressure in them. The pipes supplying coolant back to the boiler run along the bottom of the room, as close to the floor as possible.

A two-pipe heating system for a private house with overhead wiring requires an expansion tank. Sealed or not is the owner's choice.

The disadvantage of the top wiring is that some of the heat goes up. It is not intended for heating large areas. But the coolant is transferred at high speed.

Types of wiring for a two-pipe system

Regardless of what type of two-pipe heating system you choose for your own home, there is another system for dividing it - according to the principle of organizing the wiring. In the photo you can see two different wiring diagrams. Each has its own advantages and disadvantages of a two-pipe heating system.

Bottom wiring. In this case, the pipeline with hot coolant is laid in the basement or basement. It is also possible to lay pipes underground. With this type of installation, it should be taken into account that the pipes for returning the waste coolant back to the boiler must be located even lower. Using the principle of horizontal wiring requires some deepening of the boiler - only in this case will water move from the radiators to the heating element as quickly as possible. In addition, there is a need to connect an additional line - an overhead line - to the circuit. With its help it will be possible to remove air from the system.

Bottom wiring

Upper wiring. To construct it, it is necessary to place the expansion tank at the highest point of the pipeline. The branching of the system is also carried out there. Being more practical, overhead wiring cannot be installed in buildings that do not have an attic.

You can choose the most suitable type of wiring, regardless of what type of supply pipe arrangement is used in your home.

However, there are some requirements that should definitely be taken into account. In particular, for houses in which a two-pipe vertical heating system is installed, the most appropriate is to use lower wiring. This is explained by the fact that two-pipe heating with bottom wiring makes it possible to make maximum use of the pressure that arises in the system when there is a fairly large difference between the coolant and waste liquid. Of course, if the architectural features of the building do not allow the use of lower wiring, the use of upper wiring is acceptable.

Upper wiring

It should be borne in mind that the use of upper wiring both to supply coolant to the radiators and to return the return to the boiler is not the best solution, since sludge may accumulate in the lower elements of the system.

In fact, the classification of a two-pipe heating system is very multifaceted.

Another principle of separation is the direction of coolant flow. According to this criterion, the system can be:

Heating system of a two-story house. We are looking for the best option

- direct flow. In this case, the direction of movement of the coolant and return coincide.

- dead end. When using a scheme such as a two-pipe dead-end heating system, the hot and waste coolant move in different directions.

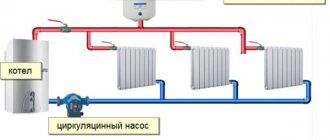

Modern systems can be equipped with a special pump, thanks to which the coolant moves more actively. At the same time, natural circulation systems are also often used, in which no additional equipment is used. If you plan to use a two-pipe system in a two-story house, then such double-circuit heating should certainly be equipped with a pump.

Heating system with circulation pump

But when installing a two-pipe heating system in a one-story room, you can do without a pump, using some laws of physics to move the coolant naturally. It is important to take into account that for more active natural circulation of the coolant, it is necessary to lay heating pipes with a slope directed towards the heating boiler.

However, regardless of the system you use (with forced and natural circulation), a slope must be present.

For systems with forced circulation, it is necessary in case of an unexpected power outage or pump breakdown. In this case, the slope allows the coolant to circulate naturally.

Bottom wiring

Here the coolant-conducting pipe is installed directly under the window sill, and the return pipe is installed near the floor.

The pressure in the pipes is not very high, so pumps have to be used. Airing is possible. To avoid this drawback, Mayevsky cranes should be installed on the floor. If the house is multi-story, then this tap should be located on each floor.

The wiring can be laid only to the doorway or two heating systems independent of each other can be installed on both sides of the door.

The expansion tank is easy to install anywhere. If it is closed, then it can be placed in rooms rather than in the attic, which is convenient. The lower wiring is not noticeable. This is important if you care about the wiring fitting into the decor of your room.

Advantages and disadvantages

Wooden houses require special attention to safety.

Now let's look at the pros and cons of using a dual circuit system.

Let's start with the positive points:

- A noticeable saving of space in the house is achieved: due to the absence of an additional boiler, the size of the boiler room can be made smaller. This is especially true for small houses where space is already limited. In the case of constructing a special extension for a heating point, savings in costs and materials are added;

- The cost of a double-circuit unit is significantly lower than the cost of a boiler with a boiler or two boilers;

- Connecting a second boiler or indirect heating boiler significantly complicates installation work and requires additional fittings and pipelines, automation and control equipment;

- In the case of using gas, you do not need to connect two devices with obtaining permits and commissioning work, which should be carried out with the help of specialists.

Compact size and low cost are the main advantages.

Important! The main criterion for choosing such devices is saving space and money. People call such units “boilers for the poor,” but, as you know, poverty is not a vice

Now let's discuss the negative aspects of this scheme:

- Devices with instantaneous water heating are not very convenient to use: it is quite difficult to regulate the water temperature, especially when the pressure changes. This effect is familiar to owners of old-style geysers;

- A coaxial heat exchanger can operate for either heating or heating. This leads to the fact that with prolonged use of hot water, the house can noticeably cool down;

- If the combined heat exchanger breaks down, the heating will not work until it is replaced;

- Heating running water requires a doubling of power, and this leads to an increase in the dimensions and weight of the product;

- Electric boilers in running water heating mode will also operate with double power, and this will require connection to a three-phase 380 V network, which is not available everywhere.

To stabilize the temperature of running water, you can use a heat accumulator.

Important! Obviously, the scheme is quite contradictory, and only you can decide here. Of course, if buying more convenient and expensive equipment is beyond your means, then the choice here is predictable

Heating the house with a double-circuit gas boiler

If you are looking for a universal way to provide your home with heat, then you should think about purchasing a double-circuit gas boiler. It can not only heat the room, but also heat water for domestic needs.

It is worth keeping in mind that boilers are not entirely suitable for large houses. The heating capacity of hot water in double-circuit boilers allows servicing only one point. If you plan to have several bathrooms, then the power will not be enough. In such cases, you should resort to indirect heating boilers or conventional heating element tanks.

Heating system installation

We will begin the description of installation work with the installation and piping of the boiler. In accordance with the rules, units whose power does not exceed 60 kW can be installed in the kitchen. More powerful heat generators should be located in the boiler room. At the same time, for heat sources that burn different types of fuel and have an open combustion chamber, it is necessary to ensure a good air flow. A chimney device is also required to remove combustion products.

The location where the heat generator will be located must be selected taking into account the minimum permissible distances to walls or other equipment. Typically these intervals are specified in the manual supplied with the product. If this data is not available, then we adhere to the following rules:

- passage width on the front side of the boiler is 1 m;

- if there is no need to service the unit from the side or rear, then leave a gap of 0.7 m, otherwise - 1.5 m;

- distance to the nearest equipment – 0.7 m;

- when placing two boilers next to each other, a passage of 1 m is maintained between them, and opposite each other - 2 m.

Double-circuit heating combined with heated floors

Closed options for double-circuit heating of a private house can be easily combined with a water heated floor system. It is important to consider that underfloor heating is a low-temperature system, and radiators are a high-temperature system. Therefore, it is necessary to provide underfloor heating so that the temperature drops from 60-80 degrees to a more comfortable 45-50.

If you want to heat all one room with a water floor, then this module will be useful to you:

The module has a thermal head, which, depending on the temperature, opens or closes the coolant supply to the system. The module is connected to the return of the dual-circuit system.

If you want to implement a solution: one floor has floors, another has radiators, then it’s worth distributing the coolant in the boiler room.

Parallel connection of boilers

When switched on in parallel (if the automation of one of the boilers is turned off), water from the return flow passes through the switched off boiler, overcoming the hydraulic resistance of its circuit, which means additional electricity consumption for the circulation pump. Plus, the return flow (cooling), having passed through the non-working boiler, is mixed with the supply from the boiler that remains in operation, which, in turn, has to increase power in order to compensate for the mixture from the return flow. To prevent this from happening, the master plumber has to shut off the pipelines manually (using valves) or install automation equipped with servo drives.

What to do if the house is large in area

Plan of a two-pipe system.

- For a large two-story building with a large number of separate rooms, a two-pipe heating scheme is best suited. It must have a top spill and permanent radiator wiring.

- Directly from the heat generator, the heated water flows up the supply pipe. It goes around the building along its attic or along the ceiling of the upper floor.

- Next, the water enters the risers, and batteries are connected to them. They do not completely open the riser. Each device is equipped with an adjustable throttle and jumper.

- It is advisable to install a shut-off valve on the second branch of the supply pipeline. You can install only one valve for bleeding air and screw it to the expansion tank in the upper section of the circuit.

- Through the second (lower) pipe, which goes around the building through the basement or the floors of the first floor, water flows back into the boiler.

That is, a system with such a scheme can operate without electricity-dependent units (for example, a pump). Based on this, if force majeure arises, you will never freeze.

Increasing the thermal inertia of the system

Cast iron floor battery.

You can increase the thermal inertia of the heating system with your own hands.

- It is convenient to do this by choosing a slightly larger cross-section of contour pipes than is necessary for the project.

- You can also replace aluminum batteries with cast iron counterparts. They have an expanded internal volume of sections, which increases the thermal conductivity and heat capacity of the material. There is an opinion that all cast iron radiators for heating systems have an ugly design. However, it is not. Yes, their obsolete Soviet-era models are still being produced. But in addition to them, the market also offers modern analogues. For example, beautiful floor radiators made of wrought iron or wall-mounted radiators with flat, aesthetic shapes.

Heating system with two boilers.

- Often the attic or second floor of a house is needed only from time to time in winter, for example, to accommodate guests. Then the best option is to use a heating circuit with two heat generators and separate single-pipe circuits for each floor.

- In this case, the boiler at the top will operate most of the time in economical mode, i.e. Maintain temperatures around +5 degrees.

The cheapest way to overcome all problems

System with storage tank.

- You can independently improve the heating network, increasing its thermal inertia many times over.

- To do this, you need to add a thermal energy accumulator (storage tank) to the circuit. It is a container with a volume of 300/2000 l, which has two connecting pipes. The tank should be well insulated to reduce heat loss.

- The container is used to accumulate large volumes of heated water. If the boiler stops, the heat reserve from this tank is wasted. It is clear that the larger the tank, the slower the radiators will cool.

- The heat accumulator can be placed on any part of the heating system. You can mount it in the basement. To do this, you need to open the lower circuit with two pipes. It is possible to place the unit in a storage room. An interesting option is to turn the device into the basis of a warm bed. After all, it will inevitably release some heat into the atmosphere.

- The battery will compensate for temperature changes in the coolant while the boiler warms the water for domestic hot water. It is very beneficial if the boiler runs on electricity.

Features of a two-pipe connection diagram

Then we move on to the next room, calculate the coolant flow for it, sum it up with the flow rate for the calculated room and determine the diameter of the pipe.

For example, a single-pipe structure is installed on the second floor in the form of a water-heated floor, and a two-pipe structure is installed on the first floor.

Natural circulation systems with connections at the bottom are used very rarely, since they require a large number of risers, and the point of inserting pipes in this way is to reduce their number to a minimum.

With natural circulation Scheme with natural circulation The coolant is heated in the boiler, expands and becomes lighter, and rises to the highest point. Comfort in the house and an acceptable microclimate can be set with both single-pipe and two-pipe wiring, but in the first case you will have to constantly monitor the process yourself, but with a two-pipe system there are more opportunities to automate the process. Polypropylene Polypropylene pipelines are mounted using a special soldering device. If one or even several radiators fail, the system can continue to operate.

The choice of a particular option depends on the consumer, his wishes and financial situation. Possibility of connecting and operating the heating system until construction or repair work is completed. Thus, each radiator is equipped with an individually adjustable coolant supply, which makes it possible to organize heating as efficiently as possible.

Advantages and disadvantages of single-pipe and two-pipe heating systems

Heating boiler;

2. In addition, connecting pipes for overhead lines means placing risers from floor to ceiling in each room, which eliminates all the advantages of the lower connection. But at the same time, they forget about the drop in water temperature, as a result of which it is necessary to increase the power of the radiators, that is, add sections. Next, you should agree on the installation of the heating system in the project documentation and begin purchasing the necessary materials, devices, and preparing tools. The systems belong to the double-circuit category, according to which the boiler is installed in the central section of the network and divides it into two circuits approximately equal in length. The appearance of a room with pipes laid under the ceiling is not aesthetically pleasing.

The return line is laid with an inclination only from the distant radiator down to the boiler, promoting circulation. In this case, you can even combine the distribution tank responsible for the presence of hot water and the expansion tank. A two-pipe heating system is more difficult to install, but it has many undeniable advantages - this is what we will talk about in our review. Next, the air enters the expansion tank, from where it is removed. It is advisable to install temperature sensors - with their help you can monitor temperature indicators and regulate them. How to connect a heating boiler wiring diagram

What to do if the house is large in area

Plan of a two-pipe system.

- For a large two-story building with a large number of separate rooms, a two-pipe heating scheme is best suited. It must have a top spill and permanent radiator wiring.

- Directly from the heat generator, the heated water flows up the supply pipe. It goes around the building along its attic or along the ceiling of the upper floor.

- Next, the water enters the risers, and batteries are connected to them. They do not completely open the riser. Each device is equipped with an adjustable throttle and jumper.

- It is advisable to install a shut-off valve on the second branch of the supply pipeline. You can install only one valve for bleeding air and screw it to the expansion tank in the upper section of the circuit.

- Through the second (lower) pipe, which goes around the building through the basement or the floors of the first floor, water flows back into the boiler.

Note! Such piping of a double-circuit heating boiler has one important advantage. If necessary, it is able to function thanks to the natural circulation of the coolant. A pipe for water flow to the upper bottling area will act as an accelerating manifold.

A pipe for water flow to the upper bottling section will act as an accelerating manifold.

That is, a system with such a scheme can operate without electricity-dependent units (for example, a pump). Based on this, if force majeure arises, you will never freeze.

Increasing the thermal inertia of the system

Cast iron floor battery.

You can increase the thermal inertia of the heating system with your own hands.

- It is convenient to do this by choosing a slightly larger cross-section of contour pipes than is necessary for the project.

- You can also replace aluminum batteries with cast iron counterparts. They have an expanded internal volume of sections, which increases the thermal conductivity and heat capacity of the material. There is an opinion that all cast iron radiators for heating systems have an ugly design. However, it is not. Yes, their obsolete Soviet-era models are still being produced. But in addition to them, the market also offers modern analogues. For example, beautiful floor radiators made of wrought iron or wall-mounted radiators with flat, aesthetic shapes.

Heating system with two boilers.

- Often the attic or second floor of a house is needed only from time to time in winter, for example, to accommodate guests. Then the best option is to use a heating circuit with two heat generators and separate single-pipe circuits for each floor.

- In this case, the boiler at the top will operate most of the time in economical mode, i.e. Maintain temperatures around +5 degrees.