To ensure proper functioning of the chimney, care must be taken to ensure that it is securely fixed. For chimneys made of brick or ceramics, the role of the retainer is played by the cement foundation into which the chimney pipe is built. Modern chimney sandwich pipes, due to their low weight, do not require pouring a foundation, and the stability of the entire structure is achieved using wall brackets.

What is

The device is designed for attaching both a stove and a boiler chimney to the wall and holding it in a vertical position. It protects the pipe from displacement along the vertical axis under the influence of wind loads.

It consists of two triangular structures made of steel guides, connected by jumpers at the base and a ring for fixing the chimney.

The chimney pipe is held either by a platform with a hole to match the diameter of the channel, or by a clamp, or by cantilever guides. To provide additional strength, the fasteners are equipped with a rubber seal.

At the other end, the cantilever device is attached to a vertical surface with anchors, bolts or studs.

Differences in designs

The most visible and main difference between the two methods of exhausting a chimney is the location of the pipes: one is located inside, the other outside the room.

Other differences in the designs of both chimneys:

- The external chimney has many angles, bends and slopes in its structure. And the pipe that runs inside the building and then exits through the roof is strictly straight.

- The outlet on the external facade is carried out through a hole in the wall, and another way is through the ceiling, roof and roof of the building.

- When the pipe is routed through the ceiling, the small outer part of the pipe is practically not damaged by climatic conditions. In the case of an external method, the structure may suffer from dampness and strong winds. There are cases when structures could not withstand the weight of wet snow adhering to them.

Both options, despite their differences, advantages and disadvantages, are widely used in the construction of houses, cottages or baths.

Both structures may suffer from exposure to adverse weather

Advantages and disadvantages

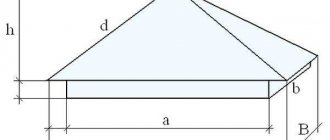

The starting or support bracket is made of two strong cantilever structures that are connected at the base by jumpers. To a certain extent, it also carries a power load, since it serves as a support for the entire vertical mass of the chimney and is installed at the point where the chimney exits to the street.

The wall bracket is used to fix the smoke exhaust duct along its entire length, both vertically and horizontally. Able to withstand quite a large weight, create rigid support, and is easy to install.

The disadvantages include the fact that its fastening ring has a certain, unregulated cross-sectional size.

The clamps differ in the form of fastening the chimney ducts in them - instead of a closed ring, two tightening brackets are used.

As a budget option, ordinary clamps are used, attached to the walls with studs.

The main advantage of the telescopic bracket is its sliding design, which allows you to adjust the distance of the fastener from the base to the required amount. You can install it on uneven surfaces, maintaining the vertical position of the chimney. There is no need, as in other options, to cut rods or guides to the required size.

Devices consisting only of cantilever guides, without fixing clamps and ring pads, are easy to install. It is also easy to adjust the installation distance of the chimney outlet to the wall. However, their fastening is less rigid than in ring clamps.

Composition of a set of external chimneys

The outdoor installation kit consists of several elements:

Straight element

Direct components to obtain height

Most of the structure consists of straight elements 1 meter long. The links are connected to each other by a single system. Each part has a clamp to ensure the safety of this connection.

Door component

Control element with service hatch

To facilitate annual cleaning by the chimney sweep, an additional maintenance item may be provided. It is a straight component with a removable waterproof door that can be opened for cleaning.

Lower part of the structure

Wall bracket

The chimney is attached to the facade of the building with two types of fastenings. First, use a wall bracket at the bottom of the structure to support the weight of the entire system. Then using wall collars, the number of which is adapted to the height of the pipeline.

Crimp clamp

Wall clamp

To attach the chimney to the front of the body, wall clamps are fixed every 3 meters, or use a telescopic wall bracket if the wall has an uneven surface.

Connecting tee

Connecting tee 90

To connect the external assembly to the heater, a 90 connector tee is used. It is used to combine with the internal connection of the wood stove and a single wall to double wall adapter is installed.

Connector

Double wall connection

The connection on the external wall is provided by a double-walled element. This allows you to properly connect the ductwork outside and the pipe from the wood stove.

Bottom Buffer

Bottom gasket

At the lower end of the connecting tee, a lower buffer is added to cover the lower hole.

Insulation protection

Output tip

An output tip is installed at the top to protect the insulation. It protects the walls, but does not protect the inside of the chimney from rain. It is recommended to install a cap over this outlet.

Water protection

rain hat

For complete protection of the outside, it is better to cover the chimney with stainless steel. The cap discharges gases horizontally and protects the air duct from water penetration and, therefore, from corrosion.

In special cases, when the pipe exceeds the last clamp by more than 3 meters, it is recommended to install additional fastening. That is, holding the top of the chimney on the roof using a guide collar system with 2 or 3 point fastening.

A well-built chimney creates a cozy atmosphere in the house

In addition to this rule, take all necessary safety precautions during installation, including safety equipment and the use of safety belts for all work at heights.

Tips for choosing

Products are selected based on their functionality. The kit should include a starting support and fasteners according to the number of chimney mounting points.

Support structures are used to install tees.

Also take into account:

- The diameter of the product, which is selected depending on the cross-section of the smoke channel.

- The length of the cantilever elements with which the device is attached to the wall.

- Material of manufacture of the fastener.

Homemade clamp

When there is no store nearby to buy a holder, there is a chance to make a fastening device on your own. Let's look at how to properly make a metal clamp.

Homemade clamp

The crimping part is easy to make from a strip of sheet steel. It is better to use galvanized sheet with a thickness of 1 mm. To align the edges you will need an M6 bolt

Required tools for making fasteners:

- metal scissors;

- pliers;

- calipers;

- hammer;

- wrench;

To drill holes, you will need an electric drill with a set of drills of a suitable diameter.

Using a caliper we measure the radius of the pipe that we are preparing to fix. If the size of the pipeline does not allow you to measure with a caliper, use a ruler and an angle, but the measurement may be inaccurate

We cut a strip of the required width from a piece of sheet metal. According to the rules, it is recommended to calculate the length of the strip as follows. The diameter of the pipe is multiplied by the number 3.14. We get the length of the product. However, in order to make ears for fastening, you need to add another 4-5 cm.

Cut out the blank of the required shape

Using metal scissors, cut out the workpiece of the required shape. Holes are drilled in the area where the ears are located.

The number of bolts directly depends on the width of the strip:

- width up to 6 cm requires 2 fasteners;

- width 6-8 cm, best option 3 bolts

You may have to increase the diameter of the holes if the bolt heads are large.

Ideally, it would be better to buy iron washers for fastening.

Having checked the alignment of the holes in the ears, all that remains is to thread the bolt and tighten the nut. With the bracket made, all that remains is to wrap the pipe and connect the ears with bolts.

The finished clamp is pulled onto the pipe and secured to the wall.

approximate price

The cost of brackets depends on the standard sizes of devices, materials of manufacture, metal content and surface finish of the products.

Prices for domestically produced wall fasteners made of ferrous metal start from 260, and for stainless steel products - from 360 rubles, and go up to 750 rubles for large-sized fasteners.

Telescopic devices are more expensive: from ferrous metal - from 450 rubles and above, from stainless steel - from 1000 rubles.

Imported models start from 750 rubles. Products finished with special polymer coatings will cost from 2.5 thousand to 4.5 thousand rubles.

Manufacturing materials

Fastenings are made mainly from the following materials:

- stainless steel;

- aluminum alloys;

- ferrous metal followed by galvanizing or painting.

Stainless steel has an aesthetic appearance and goes well with the material of sandwich chimney pipes. Such structures are strong, durable and not subject to corrosion. The disadvantages include high cost. Independent production of stainless steel brackets is difficult due to the complexity of the technology for welding stainless alloys.

Aluminum structures are lightweight and have a pleasant appearance. They have not yet received wide distribution in our country due to their high cost.

Regular structural steel is very inexpensive and can be welded in a home workshop using a regular welding inverter. This makes it an ideal material for making DIY brackets.

Rules for installing wall brackets

The installation of sandwich pipes and coaxial chimneys in terms of their fastening has certain rules.

Fastening devices must be installed along the height of the chimney every 1.5 - 2 meters, which ensures safe and reliable fixation of the entire chimney system.

The tee is secured with a support bracket on powerful cantilever guides.

Fastening devices cannot be installed at the junction points of the channel parts; the best place for them is in the middle of the pipe.

Technical characteristics of pipes

These are important parameters when choosing elements for specific installation conditions. Safety and service life depend on the correct identification of the required parts.

Diameter

Most manufacturers of boilers and other heating devices specify the optimal chimney diameter in their operating instructions. This parameter depends on both the height of the fastener and the traction force.

When it is necessary to make a transition from brickwork to sandwich modules in a room, the diameter is calculated as follows:

- In a fireplace, 1 kW of power produces 8 sq. cm sections.

- In wood stoves with a power of up to 3.5 kW 0.02 sq. m section is equal to 160 mm diameter.

- If the furnace power is higher than 5.2 kW, then the diameter increases to 190 mm.

- With a productivity of up to 7 kW per 0.038 sq. m is 220 mm in diameter.

Wall thickness

In gas devices it is determined by the diameter of the product:

- with a value of 130 – 450 mm, the wall thickness is 0.5 mm;

- with a diameter of 500 mm - 0.6 mm;

- with an indicator of more than 500 mm - 0.8 mm.

In solid fuel boilers, the main factor influencing the choice of wall thickness is the combustion temperature of the raw materials.

Thus:

- up to 450 degrees, a value of 0.6 mm is enough;

- more than 450 degrees need 0.8 mm.

It is important to note that such boilers must have an uninsulated part of the pipeline, which must be connected to the outlet pipe. It is made from a piece of heat-resistant stainless steel

Wall thickness – 0.8 – 1 mm.

From the outside, the chimney casing with a diameter of up to 450 mm is taken with a wall thickness of 0.5 mm, with a wall thickness of more than 500 mm - 0.6 mm.

Height

The height of the chimney relative to the ridge is determined based on three parameters:

- SNiP 41-01-2003;

- construction rules SP 7.13130.2009;

- manufacturer's instruction manual.

The recommendations are as follows:

- The height of the sandwich pipe is from 5 m.

- If the roof deck is made of flammable material, the pipe is made 1-1.5 m higher than the ridge.

- On a roof made of non-combustible material (corrugated sheeting) it can be placed at a height of 0.5 m from the ridge. The same applies to roofs with a flat structure.

- On pitched roofs, when the chimney is located at a distance of 1.5 m from the ridge, the height is 0.5 m or more.

Brick

The classic option is red fireproof. Withstands high temperatures up to 1000 degrees. Has good heat dissipation. The masonry technology is complex, so you won’t be able to create such a structure yourself without experience. This process is labor-intensive and lengthy. A foundation needs to be poured, which should be planned at the design stage. It is recommended to install a sleeve made of stainless steel sheet inside, otherwise the brick will become saturated with condensation and over time, the inside of the walls will begin to peel off, and stains will form on the outside. Construction will be expensive.

Ceramics

Chimneys are durable, resistant to changes and high temperatures.

Manufacturers can supply ceramics with the following assembly options:

- Ceramo-stainless. The shell is made of stainless steel with a thickness of 0.8 mm, so externally the pipe cannot be distinguished from metal.

- Ceramo-expanded clay. The edging of the product is made of expanded clay blocks. Reminds me of brickwork.

- Expanded clay-stainless steel. A combination of the two previous types.

The ceramic surface is smooth, so soot and ash settle on the walls minimally.

Stainless steel

Modular type. The optimal steel alloy is AISI 430 BA. Features: heat resistance, resistance to chemicals and environmental influences.

The chimney is:

- single wall;

- sandwich (double-walled).

Single-walled can be mounted inside the house.

A sandwich pipe is the best for outdoor conditions, as it has a layer of insulation that minimizes the accumulation of condensate inside the pipe, extending the service life of metal parts.