Pipelines made of ordinary and reinforced polypropylene, polyvinyl chloride, and metal-plastic are widely used in domestic communications for hot and cold water supply, heating and sewerage. A pipe clip has been developed especially for these types of polymer products and is widely used, produced by a wide range of manufacturers.

It is worth noting that despite the similarity of design, products from different companies have some operational differences that affect the effectiveness of their use. Therefore, when choosing and purchasing, you should know the advantages and disadvantages of a particular product from different manufacturers, its features.

Rice. 1 Examples of clip mounting

Types of fastenings for PVC pipes

Plastic pipe holders are designed for attaching pipelines to a wall, ceiling or floor. According to their configuration and method of fixation, channels are divided into the following types:

- Clamps in the form of plastic clips.

- Ring brackets in the form of fastening clamps.

All of them do not require the use of special tools for installation.

Metal clamps

Clamps, unlike clips, completely encircle the pipe, ensuring reliable fastening. Their purpose is to use them in pipeline bends with large diameters that transport heavy media that are prone to vibrations and fluctuations, and temperature changes. They are appropriate in critical turning areas where rigid fixation of the bend is necessary.

The design consists of a metal bracket, inside of which a rubber gasket can be inserted, designed to compensate for vibrational and temperature expansion of the wiring. The two parts of the clamp are tightened using bolts. A threaded fastener for a stud is welded onto the ring. The bracket can be attached to bases made of various materials (wood, brick, concrete) using a screw pin and dowel (pictured).

As a rule, clamps on PVC channels are not tightened too tightly, allowing the bends to move slightly under the influence of thermal expansion.

Plastic clips

This type of fastening is most popular when working with polypropylene and PVC pipes. In appearance, the clips are plastic clips with elastic sides, which allows you to quickly and conveniently insert bends into them. The clamps grip the pipes quite reliably and thus all the wiring is attached to all the walls of the room.

The bases of the clips have a hole through which they are mounted to the wall with a self-tapping screw using a built-in or separately purchased dowel.

The polystyrene from which the products are made is a durable and wear-resistant material, thanks to which the clips last a long time and are able to withstand the adverse effects of external factors for a long time.

If two branches are laid side by side parallel to each other, double structures are used, which have one stud with a dowel, which speeds up the installation of the system and makes the laying of pipes smooth and beautiful.

Holders of different diameters are produced, which are connected to each other with special clamps.

Clamps

This type of fastener is in many ways similar to clips. The difference lies, first of all, in the fact that the clamps completely enclose the elbow with their ring shape and a strong connection is obtained. Thanks to this function, they are used when attaching vertical bends.

Available in two types. In the first, the self-tapping screw simultaneously fixes the clamp ring and secures it to the wall.

In the second option, the screw serves only as a fastener, and the latch is made independently of it, which makes it possible to unfasten it during repairs without removing or damaging the fastener. This option seems more convenient if pipes are to be removed.

Staples

This type of fastening has been used for a long time and has many varieties:

- Single-jaw simple parts for fastening light channels.

- Double-leg brackets for more secure fastening.

P-shaped elements with an eye, through which they are convenient for attaching corrugated pipes, flexible hoses to a wall or ceiling, or using the products as brackets.

The brackets are often equipped with rubber gaskets for more durable fastening and to prevent vibration of the pipes.

The main thing when choosing them is not to make a mistake in the diameter of the product.

Anchor shackles and dowel hooks

The emergence of these types of fasteners was facilitated by the use of underfloor heating systems.

Anchor brackets are equipped with legs of a special figured shape, reminiscent of an anchor. Thanks to them, the product is easily inserted into the thermal insulation layer and securely fixed in it.

The dowel-hooks are mounted into the drilled hole with their spacer part and pressed to the floor (installation in the wall is also possible) two channels at once.

Installation of these fasteners does not require self-tapping screws.

Specifics of use

Most often, steel pipe brackets are used when installing large-diameter communications. High consumer characteristics make it possible to use them in the arrangement of workshops.

It should be remembered that brackets are not independent parts - they are used in conjunction with supports, clamps and hangers.

The pipe mounting bracket has the following advantages:

- Easy to install.

- Strength.

- Reliability.

- Durability.

- Corrosion resistance.

- Ability to withstand significant loads.

- Resistant to deformation.

No need for experience or special tools. Even an amateur can handle the installation of such fasteners.

When installing fasteners into a base made of brick or concrete, it is necessary to screw a special bolt to a depth of 25 mm or deeper. If the bracket needs to be installed on a metal surface, then use one of three methods:

- bolted;

- riveted;

- welding.

The parameters of the cantilever shelf depend on the type of pipe insulation and the distance at which the product is allowed to be fixed to the base.

Advantages and disadvantages of clips

The main advantages of clips include:

- High strength and resistance to temperature changes.

- Light weight and easy to install.

- Low cost of products.

- Wide range of standard sizes and configurations available.

This type of fastening also has disadvantages:

- The fragility of the latches closing the channels from above.

- Limitations in use for fastening pipelines with heavy working media.

- There are products with an excessively large distance from the wall.

Materials for polypropylene pipes

Before attaching polypropylene pipes to the wall, you need to select the material from which they will be made. To manufacture this type of pipe, several types of raw materials are used, the choice of which determines the characteristics of the finished products.

The production of polypropylene pipes is possible using the following materials:

- PPH. This material is quite fragile at low temperatures, but very strong in bending. Using various additives, such polypropylene can be added with resistance to open fire, transparency and antistatic properties.

- PPC. Being a product of copolymerization of ethylene and propylene, this type of raw material allows you to create pipes with higher mechanical strength and flexibility than in the previous case.

- PPB. This raw material is a block copolymer.

- PPR. This material is a static copolymer.

- P.P.R.C. This polypropylene copolymer allows you to create lightweight and durable pipes that do not deform even if the water in them is frozen. This material is capable of operating in a temperature range from -10 to +90 degrees. In addition, this copolymer has good resistance to various alkalis and acids.

- mPP. Metallocene polypropylene has quite unique characteristics that make it similar to rubber.

After choosing the appropriate option, all that remains is to purchase the required number of pipes and begin installing the pipeline.

Types and shapes of clips

Plastic holders are available in the form:

- Singles.

- Pair clamps.

- Connected together into one strip, which makes it possible to mount several pipeline branches located side by side.

There are clips on sale that resemble rings in shape, which, due to latches, close the pipes from above, thereby pressing them more tightly to the wall.

There are holders with a dowel directly in the clip body - this is convenient and speeds up the installation process.

Pipe clip - varieties

Despite the similarity in design and fasteners, the pipe clip is available in the following versions:

Various standard sizes. Based on this feature, fastenings are distinguished for cold and hot water supply pipelines, heating with a diameter of 16, 20, 25, 32, 40 mm, and sewerage with typical sizes of PVC pipes in a circle of 50 and 110 mm.

With different numbers of fragments. Pipe clips are produced by:

- Single - used for fixing single-pipe communications.

- Paired - used to hold two parallel-laid pipelines of the same size.

- Tape - assembled from any number of clips by joining their side walls into various types of locks. The tape can be assembled from parts of different diameters and from only one manufacturer.

Tips for choosing

The holders are selected so that the inner diameter of the clip matches the outer section of the outlet, and the fasteners fit tightly to its surface.

When choosing a joined tape of clips, pay attention to ensure that it does not fall apart at the slightest touch.

Often you come across products with latches that cannot withstand even two or three opening and closing operations.

approximate price

The cost of holders for plastic pipes starts from one and a half rubles and depends on the presence of such attributes on the clip or in its set as a latch and dowel, single or paired knot. In any case, your family budget will not suffer from their purchase.

Installation rules

When installing the most popular sizes of polypropylene (PP) pipelines with clips, it is important to know the following distances between the fastening points:

- In polypropylene pipelines with a diameter of 20 mm, with a temperature difference from 20 to 80 ° C, the established distance between fastening points is reduced from 600 to 500 mm.

- For polypropylene pipes with a diameter of 25 mm, transporting a working medium with temperatures from 20 to 80 ° C, the recommended distance between supports gradually decreases from 750 to 550 mm.

- For the 32nd PP pipe, when temperature thresholds change from 20 to 80 °C, the distance between the fastening points changes in the range from 900 to 650 mm.

- It is worth noting that there is a rail method for mounting holders, in which these distance standards can be adjusted depending on the specific operating conditions of pipelines.

Rice. 12 Table of distances between supports of polypropylene PP pipes depending on their temperature and diameter

Clip fasteners are the main method of fixing popular polypropylene pipelines on building structures, combining speed and ease of installation, reliability of fastening, and aesthetic appearance. It is produced by a wide range of domestic and foreign manufacturers with some design differences, allowing you to select products with different costs, fastening reliability, distances to the supporting surface and between adjacent pipelines.

How to fasten with clips

Fastening work with clips is simple. They can also be carried out by a person inexperienced in repair matters.

The work process begins by marking the wiring and placement points of the holders. To do this, use a level, a large ruler and a construction pencil.

At the marked points, holes are drilled with a hammer drill, using a drill with a diameter sized for the dowels used.

Next, the holders are attached with self-tapping screws through dowels inserted into the holes.

The pipes are snapped into plastic clips with little effort and a securely fastened structure is obtained.

Recommended mounting pitch

The distances between the fastening points, called the fastening pitch, should be approximately 100 cm when laying heating pipes, 110 cm when laying a plumbing system.

If plastic pipes have a diameter of 110 cm or more, the pitch will be 160 cm and 190 cm, respectively.

Installation work

The first step is to apply markings to the pipe locations where the fasteners (clamps) will be installed. For correct marking, use the necessary recommendations in accordance with the type of clamps being installed.

It is necessary to make technical holes at the marking sites; make sure that the holes coincide with the diameter of the pipes and clamps.

Dowels must be inserted into the prepared holes if the work is carried out on a concrete or other type of wooden surface.

The next step is to fasten the clamp to the surface with specialized bolts.

Next, you need to install the pipes in the clamps and secure them with a fastening element, which is provided by the design of the clamp.

Lanyard for rigging workCrab system for profile pipes: features of the selection and use of fastening systems and connecting elements

What is a rigging shackle? Size standards, modern types, rules and features of choice

If any step is not clear to you, then on the Internet you can find detailed instructions for each type of clamp so that the work is done as efficiently and reliably as possible.

Which mounts are best to use?

According to the rules, when choosing fasteners for pipelines, you should not stop only at clamps or only at clips. Experts advise combining two types of fastening. Not everyone is ready to do this: clamps are not as beautiful as polypropylene fasteners. This can become a problem if the rigid mounts do not fit into the interior at all. Since, oddly enough, many people are stopped from using clamps by the aesthetic side of the issue. However, you shouldn’t get lost here, follow these recommendations:

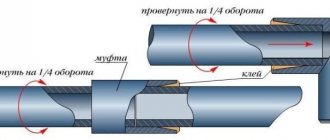

- Make the clip motionless. To do this, it is enough to install it between two fittings at a distance of the width of this support. You can use this knowledge as a theorem.

- Fixed fastening on a straight section of pipe can be done differently. True, you will need two pipes. Couplings are installed on each and an insert is made with a small segment in the middle.

- In fairly critical areas, clamps should still be installed. Of course, if the aesthetics of the room do not suffer from this.

It is worth noting that the first two points apply not only to single polypropylene fastenings, but also to groups of these fastenings, double clips.