When building a house or arranging a yard, developers begin to select pipe products for installing sewer and water supply systems. Recently, the installation of HDPE pipes has become especially popular. Such designs are gradually replacing metal analogues from the market, as they have a large number of advantages.

PND - decoding or what it is

The abbreviation HDPE stands for simply: low-density polyethylene (you can find HDPE - it means the same thing as HDPE). The material is highly dense and is the end product of the polymerization reaction of polyethylene at low pressures. It is gray-transparent, hard, and is used as a raw material for the production of pipes for various purposes. These properties are explained by the special structure of the substance, the intermolecular bonds of which provide a higher density in comparison with other polyethylene analogues. It is also called high-density polyethylene (HDPE).

The benefits of water supply from HDPE pipes

In contrast to other materials (cast iron, steel, asbestos), HDPE water supply is significantly superior to them in the following indicators:

- guaranteed service life is 50 years;

- products with a diameter of 20-110 mm, offered in 1000 meter coils, speed up the pipeline laying process and save money on consumables;

- the use of thermistors in connecting fittings speeds up work and simplifies the joining process;

- It is easier to learn to work with polyethylene than with metal products.

They can be disassembled and reassembled many times with minor losses. It is possible to extend the old pipeline inside the structure.

Physical and chemical properties

The use of polyethylene water supply is considered the right decision due to the positive consumer qualities of this material. These include:

- it is not susceptible to corrosion and is capable of transporting water and more aggressive liquids;

- has less weight than traditional materials, which simplifies the work of loading and transporting it;

- has the ability to expand up to 7.5%, thanks to this elasticity it can easily withstand earthquakes and minor ground movements;

- the smoothness of the inner surface enhances throughput;

- the low elasticity of the material significantly reduces the potential for possible water shock hazards and increases resistance to freezing.

The smaller diameter of the HDPE pipe for water supply is equivalent in throughput to the larger diameter of the product made from traditional material.

When are holders needed?

The created pipeline from HDPE products is attached to the wall using clamps. It is advisable to install them under each joint - this ensures maximum reliability. In areas where there are no joints, the distance between the clamps should be equal to 10 pipe diameters, and the distance from the walls will be 2-4 mm.

The most popular are rigid clamps with a rubber seal - they provide the highest noise absorption coefficient. However, some experts recommend not using a gasket, but leaving the pipeline loose in the fastener. Thanks to this, it will maintain mobility and durability.

Read our separate article about connecting HDPE pipes with fittings. This type of installation is widespread when using pipes of small diameter.

And here there is information about the use of polyethylene pipes as casing for wells.

We talked about organizing a blind area around the house here. Why is it needed and what types are there?

Step-by-step instructions for welding PP pipes

The installation of polypropylene pipes in an apartment is carried out in several stages. To prevent incorrect actions and make high-quality wiring, you need to follow a sequence of actions.

Step 1: pipe cutting

You need to cut the PPR for installing a water supply system in an apartment with your own hands using a pipe cutter. The tool has a wide base and can accurately maintain the specified angle during cutting. If a bevel occurs, it will reduce the passage of the fitting or create an overhang.

Step 2 pipe processing and chamfering

Having completed cutting the PPR for pipeline installation, you need to move on to the next stage - processing the pipe and forming a chamfer. Such procedures are performed using special calibrators or attachments for electric instruments. Two versions are equipped with cutting elements that create a chamfer with basic characteristics.

- To form a cut, it is necessary to put the pipe on a calibrating device and make several rotations around its axis.

- If the structure has a protective foil coating, you need to remove it with a shaver. The device is made in the shape of a cylinder and is intended for one diameter.

After completing the forming activities, all that remains is to clean the parts.

Step 3 preparing the soldering iron

The following work on laying a polypropylene pipeline involves preparing soldering equipment. PPR soldering for installation is carried out at a temperature of 260-280°C, however, novice installers are better off using non-adjustable models of soldering irons with an operating mode of 260°C. Before starting the tool, you should equip the iron with a mandrel and a sleeve - special attachments - and then place it on a special base.

The number of welded products over a period of time is determined by the power of the equipment. However, you can install communications at home using 800-watt devices.

If the soldering iron is heated to the desired temperature, a green indicator will appear on it.

Step 4 heating and joining parts

The rules for installing polypropylene structures provide for the use of personal protective equipment. They include rubber gloves that will protect your hands from damage when working with hot tools.

To heat the pipe, you need to use special nozzles. The soldering depth is adjusted using a marker - it makes a mark on the pipe, which will serve as a guide when installing products.

There is a table that displays the duration of heating and cooling of soldered structures, taking into account their thickness. You also need to take into account that the duration of the process will be increased by 1-2 seconds when working in a cold environment.

When the parts are heated, they need to be connected to each other, guided by the applied markings. The parts must not be allowed to rotate. Deviations from the norm are possible only for a short time. Further, all errors will begin to deteriorate the quality of soldering.

After completing the connection of the parts, you should wait a couple of minutes for the PP to completely cool down. The time of this period is indicated in the table.

You should also evaluate the properties of the internal seam and make sure that the influx does not interfere with the passage. If you miss this moment, you will have to re-solder the parts.

To prevent errors, you must have some installation skills and information.

Permanent connection methods

To join HDPE pipes, two permanent connection methods are used: by butt welding and by installing an electric welding coupling.

In any case, when implementing these methods, the following requirements are imposed on connections:

- The maximum displacement angle of the welded sections should be no more than 10% relative to the wall thickness of the pipes being joined.

- The joining seam should be made above the outer level of the surface of the adjacent sections.

- The height of the bead of a well-made seam should vary in the range of 2.5-5 mm.

The optimal value of the roller height depends on the thickness of the walls of the product being fused. On thin-walled pipes (up to 5 mm) it should be no more than 2.5 mm. If the thickness of the pipe walls varies between 6-20 mm, then the height of the roller should be no more than 5 mm.

By butt welding of pipes

The creation of a permanent connection is carried out by softening the material to the state of a viscous substance so that a diffuse unification of its parts occurs. It is used for pipes with a wall thickness of over 5 mm.

Butt joints using a welding machine are used when constructing pipelines through which liquid is to be transported under high pressure conditions.

The welding connection method is used on straight sections of water pipelines that are supposed to be operated under pressure. Only it allows you to obtain a tight connection with diameters over 200 mm, since it does not create a loss of pipe rigidity, leading to deformation.

Do-it-yourself durable welding of HDPE pipes is carried out using a special tool. The essence of the method is to heat the ends of the joined elements to a viscous state using a heating nozzle. The softened ends are simply connected to each other under pressure, after which the connection area is simply allowed to cool.

The main difficulty in working with equipment is the need to control not only the degree of heating of the elements, but also your own body movements in order not to spoil the seam or compromise the integrity of the pipes

When performing welding work, it is important to maintain the temperature conditions of the heating elements.

The parameters of the time delay and temperature of the heating elements are determined taking into account three factors:

- Pipeline wall thickness.

- Diameter of bends.

- Technical parameters of the soldering device.

Connecting pipes by welding is the most reliable and durable option. With its help, you can create a permanent mount that can withstand the pressure of both free-flow and pressure water supply systems.

The main advantage of welding fasteners is reliability, which cannot be achieved when using the cold pressing method. The only “disadvantages” of the welding method include the inability to disassemble the connection for carrying out preventive maintenance and cleaning the same pipe

Welding is performed in the following sequence:

- The communication is trimmed to the specified size. The parallelism of the plane of the ends is adjusted. The ends are cleaned with a piece of sandpaper.

- A chamfer 2-3 mm wide is removed from the ends. The welding site is thoroughly cleaned and treated with a degreasing compound.

- The soldering iron is set to the heating mark of 260°. While it is warming up, string the welding nozzles and wait until their degree of heating reaches the set temperature.

- Using a centering mechanism, the fitting and the end of the pipe are buried in the cavity of the nozzle. If the soldering iron does not have a centering mechanism, the alignment will have to be checked “by eye,” making the alignment as accurate as possible.

- The centered elements are pushed to the specified mark, connecting under pressure, and the time specified in the instructions is maintained for melting.

- After completion of work, the device is moved to the side and disconnected from the network. The welding area is fixed in a given position without displacement or rotation until the surface is completely cooled.

When welding, it is important not to overexert it. This can provoke the formation of an influx of polyethylene onto the inner diameter of the product.

A table that should be used to control the process in order to obtain the strongest possible connection, but not to overheat the plastic.

To obtain reliable fastening, the installation depth should be about 2 mm. By maintaining a given depth, the resulting weld will have an even, presentable appearance with the same indent height.

The following selection of photos will introduce you to the stages of butt welding of HDPE pipes:

Image gallery

Photo from

Stage 1: Installation of welded pipes into the centralizer

Stage 2: Preparation of pipe ends with a facing tool

Step 3: Installing the heating element

Stage 4: Waiting for the polyethylene to cool

Through electrofusion welding

When implementing this method of continuous connection, electrofusion welding or an electric welding fitting is used.

The disposable coupling used for this purpose is made of the same material as the pipes, but is additionally equipped with a built-in heating element

This method is effective when you have to work in cramped conditions. For example, when performing repair work in wells or when you need to make inserts into previously connected pipes.

There are no uniform standards for socket soldering in domestic regulatory documents. This technology is more often used in European countries and is regulated by DVS-220715 standards.

Image gallery

Photo from

Installation of electrodes for electrofusion welding

Prompt repair with clutch

Automation of the welding process of HDPE pipes

Scope of application of electrofusion welding

The technology for connecting HDPE pipes using couplings includes a number of main stages:

- Preparation of the communication area. The outer surface of the outlet is cleaned of grease and dust. For this purpose, soap and alcohol solutions are used, which are available in a wide range in hardware stores.

- Treatment of joints. The tightness of the fastening directly depends on how smoothly the cut is made. To obtain a perfectly smooth surface, the end of the pipe is rubbed with a piece of fine-grained sandpaper.

- Creating chamfers . The elbow joint is cut at 45°. The bevel will ensure the tightest possible fit of the elements and their fastening.

- Installation of the coupling. The coupling is connected to a power source. After it has heated to a given temperature, one side (mandrel) of the coupling is put on the pipe, and the other end (sleeve) is connected to the second pipe outlet.

The key condition for performing electrofusion welding is to ensure that the parts remain immobile during the heating and solidification of the elements. When deepening the branches of the segments into the cavity of the heated coupling, it is important to perform the work quickly, but as carefully as possible so as not to overheat the polyethylene.

The second section of the pipe is buried at the end of the coupling, marking the parts of the pipeline as tightly as possible so that a minimum gap is obtained

At the moment of deepening the segments into the cavity of the coupling, be prepared for the fact that liquid plastic will gradually begin to emerge from under it. After completing the work, all that remains is to remove the coupling and lay out the connected pipeline on a hard surface in order to fix it in the desired position.

After the melt has solidified, a crimp clamp tightly fitting to the pipe will be visible at the joint.

But when choosing this method, it is worth considering that plastic pipes are not very rigid. Therefore, with strong internal pressure, the created seam can simply separate. A coupling connection is not the best solution for arranging heating communications and creating outlets for a washbasin.

An article is devoted to assessing the strengths and weaknesses of various methods of welding HDPE pipes, the contents of which we recommend that you familiarize yourself with.

System planning

Due to the fact that PPR pipes do not bend, when developing a wiring diagram it is necessary to create as few detours and turns as possible. After all, they are all made using fittings, and they have a significant cost (compared to a pipe). Therefore, we try to optimize the wiring - make as few turns, detours and bends as possible.

Serial (Tee) connection

Installation of water supply from polypropylene pipes with serial connection of consumers (plumbing and household appliances) is used in small systems. Usually they have 5-6 connection points. With this arrangement of the water supply system, one pipe leaves the riser and it sequentially bypasses all connection points. In the case of PPR plumbing, all branches are made using tees, which is why this type is also called tee.

Installation of water supply from polypropylene pipes with serial connection of consumers

The advantage of this system is that a small number of pipes are needed, and the disadvantage is that the pressure on each branch drops. As a result, with one or two working disassembly points, the third, located further from the riser, may simply not have enough pressure.

Parallel (collector) wiring

A parallel connection circuit is also called a collector circuit. This is because after the outlet from the riser, a special device is installed - a collector. This is an element with one input and a number of outputs. Available in polypropylene and metal. For water supply, polypropylene manifolds are more suitable (and cheaper).

The connection diagram is such that a separate pipe runs from each branch to each consumer (sometimes to a small group of consumers).

Parallel scheme for installing a water supply system from PPR pipes

Plumbing and household appliances

In each method of installing a water supply system made of polypropylene pipes, a pipe is suitable for a specific consumer. There are two ways to connect to the system: flexible and rigid connection.

Rigid liner is more reliable: PPR pipes and fittings have high strength. Moreover, in this case there is only one thread - at the consumer connection point. But this type of eyeliner requires high precision: the error can be only a few millimeters. This is difficult to achieve when installing a polypropylene water supply with your own hands, so flexible hoses are often used. Just be careful, in some cases it is impossible to use it: connecting gas boilers or gas water heaters, supplying water to storage water heaters, water heated towel rails is recommended only using a rigid connection.

Rigid liner options

Soft eyeliner, on the contrary, does not require high precision - errors are leveled out by a flexible stainless steel braided hose or a hose that is used to connect a washing machine or dishwasher. The tubes are removed approximately in the area where the equipment is installed or the plumbing is connected. It ends with an adapter for metal, to which a flexible hose is connected (its other end is connected to the device).

Flexible hoses are connected to the adapters

This option is less reliable, since much depends on the quality of the flexible liner. Also not the most pleasant moment is the presence of two threaded connections, and this is a potential place for a leak to appear.

Electrofusion welding connection

Electrofusion pipe welding

This fastening method consists of using shaped elements with built-in electric spirals. The spirals heat up and melt the polyethylene, tightly soldering the pipes.

This method is used when installing sections with a cross-section of less than 160 mm or when access to the joining point is difficult. The diameters of the pipes being welded should not differ by more than 10%.

To make a connection, the edges must be cleaned of dirt and leveled. And also fix it for the duration of work. A positioner will help with this.

Both ends are inserted into the coupling and the welding machine is turned on. The duration and temperature of heating are usually indicated on the barcode of the part.

Accessories for polypropylene pipes

Various components are used to install water pipes from plastic pipes. Their assortment is very extensive and amounts to dozens of items in the price lists of manufacturers. The parts vary in shape, size and purpose. Let's look at the most common types of such elements.

A large number of components are produced for polypropylene pipes

When purchasing them, it is important to choose parts from the same manufacturer as the pipes. Couplings

The simplest connecting part. The shape resembles a small barrel, the inner diameter of the hole exactly matches the cross-section of the pipes being connected. The element is intended to connect two sections of pipe

Couplings. The simplest connecting part. The shape resembles a small barrel, the inner diameter of the hole exactly matches the cross-section of the pipes being connected. The element is intended to connect two sections of pipe.

Adapters. These parts are designed to connect pipes of different diameters. Outwardly, they are very similar to couplings, but their main difference is that the internal diameter at the two opposite ends of the element is different.

Adapters are selected according to the diameter of the pipes being connected and come in various sizes. Parts are produced with internal or external threads, designed for transition to threaded connections.

Corners. As you know, polypropylene pipes cannot be bent. Therefore, to perform the rotations necessary during installation, the manufacturer produces special connecting parts bent at an angle of 90° and 45°.

The corners can end with holes for pipes or have threads, both internal and external. For example, such parts are used to install a mixer. Moreover, they can be either double or single.

Some home craftsmen argue that there is no need to complicate things and use corners. After all, polypropylene is plastic and can be bent. They heat the pipe to softening temperature and bend it the way they want.

Indeed, it is very easy to bend a part, but you need to understand that unpleasant changes occur in it: the wall on the outside of the bend becomes thinner. This will significantly reduce the life of the pipe and lead to its breakthrough.

A shut-off ball valve made of polypropylene is installed in the water supply using soldering

Crosses and tees. These are the names of elements designed to connect three or four pipes at the same time, which is often required for installing a water supply system. They are produced in a wide variety of variations: with hole diameters of different sizes, with fittings for other types of pipes, for example, for metal-plastic or copper, with internal and external threads of various sizes.

Contours. This is the name given to specially formed bends that are used to guide the pipe around a small obstacle. In this case, it is desirable that the distance from the pipeline to the wall be minimal. The bypass is welded into the gap in the water supply section so that the sections of pipe lying before and after it are straight.

In addition to these components, other elements are also produced. Among them are plugs used to shut off unnecessary branches of the water supply system, and special ball valves for polypropylene pipelines.

To secure the pipes to the wall, special clips are used, which are selected to match the diameter of the part. Can be single or double. Experts advise choosing pipes and components from the same manufacturer. This way there will be fewer problems during installation, and the system will be of higher quality.

For PP pipes of all sizes, a wide range of connecting parts are produced, allowing you to quickly install the plastic circuit and, if necessary, connect it to metal branches

Butt welding - work technology

Butt welding of polyethylene pipes

The peculiarity of this method is that such welding is used to connect pipes whose cross-section is greater than 50 mm, and their thickness exceeds 5 mm. This method cannot be called simple, since it requires a special welding machine and some skill in working with it. How are pipes connected by welding? The order of work is as follows:

- To begin with, the master aligns the edges of the pipes, cuts them at right angles and carefully cleans them.

- Using a welding machine, the ends of the pipe are heated to the melting temperature and quickly connected.

- All that remains is to wait until the seam cools down and becomes secure.

- Finally, it is important to check the tightness of the connection by filling the pipe with water.

When carrying out such manipulations, it is very important to monitor the heating time of the product in order to make it ideal for joining and not to overmelt or not heat it enough. The pressure on the surfaces to be joined is also important, since to ensure maximum strength of the connection, it must be uniform along the length.

Butt welding machine

Note!

You should not try to weld products from different manufacturers together. Their characteristics may vary slightly, so during operation, water pressure may tear the seam made in this way.

Types of garden aqueduct

There are two ways to lay a pipeline at a dacha - summer and seasonal (major). Each of them has its own advantages and disadvantages.

Summer option

The method of ground installation of a water supply system in summer cottages is used to organize watering of vegetable beds, berry bushes, and fruit trees. Ground water supply is used for supply to a bathhouse, summer kitchen, and garden house.

The seasonal water supply system is a ground loop with pull-in fittings at the branch point. If the site is used exclusively during the warm season, it is reasonable to lay pipes on the surface. Such a system can be easily disassembled for the winter to prevent theft of materials during the off-season.

On a note! To avoid damage to communications by agricultural equipment, summer water supply is laid on special supports.

The main convenience of a seasonal polyethylene water supply is its mobility. If necessary, the configuration can be changed in 10-15 minutes. It is enough to add or remove a few meters of pipe or run it in a different direction.

Irrigation system

Scheme

Temporary summer water supply at the dacha from HDPE pipes is assembled and disassembled with your own hands according to the principle of a children's construction set.

Typical diagram of a country water supply system

The network diagram is drawn up in relation to the detailed site plan. The drawing marks the location of green spaces, water intake points, a house, a shower, and a washbasin.

Important! Pipes are laid with a slope towards the water intake point. A drain valve is installed at the lowest point of the system

Capital system

If the site is thoroughly developed and used all year round, it is reasonable to spend time and money on installing a capital water supply system. The principle of connecting elements in this case does not change. The difference lies in the additional installation of compressor equipment and the closed arrangement. To install a permanent water supply system, communications are laid in trenches below the freezing depth of the soil.

Inserting HDPE pipes into the house

Insulation

The depth of soil freezing in different regions of the Russian Federation differs significantly. To avoid rupture of communications during sudden temperature changes, it is recommended to insulate them.

To insulate the capital water supply system from HDPE at a summer cottage, the following materials are used:

- Basalt insulation in the form of ready-made cylindrical modules.

- Fiberglass sheet in rolls. You will need to purchase additional roofing material to protect the warm layer from getting wet.

- Expanded polystyrene. Reusable folding modules of two halves, which are used repeatedly, are assembled simply and quickly.

Insulation for pipes made of foamed polyethylene According to statistics, the depth of soil freezing in winter in Russia exceeds 1 meter. For clay and loam in Moscow and the region this is...

On a note! Water under high pressure does not freeze. If a receiver is installed in the system, there is no need for additional thermal insulation of the water supply system.

In capital construction, when laying a pipeline to a shallow depth, a heating cable is laid parallel to the system and connected to a grounded source of electricity.

Defrosting water supply and sewerage pipes Russia is located in a harsh climatic region, so in winter and early spring there is a risk...

How to choose?

Manufacturers offer several types of polyethylene pipes to choose from. First of all, products are distinguished by the type of transported medium.

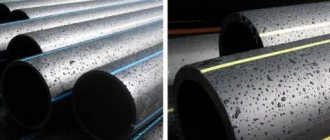

For the production of gas pipes, special additives are used that change the composition of water. Gas pipes with yellow markings are strictly prohibited for use in the plumbing system!

To assemble the pipeline underground, two types of polyethylene are used:

- HDPE PE 100, manufactured in accordance with GOST 18599-2001. The diameter of the products is 20 to 1200 mm. Such pipes are made black with a longitudinal blue stripe along the entire length.

- HDPE PE PROSAFE, produced in accordance with GOST 18599-2001, TU 2248-012-54432486-2013, PAS 1075. Such pipes have an additional mineral protective shell, 2 mm thick.

For the main line, blanks with a diameter of 40 mm are selected. For secondary - 20 mm or 25 mm.

This is interesting: Rimless toilets - pros and cons, reviews from owners

DIY installation

Installation should begin with drawing up a diagram, taking into account the location of the site in relation to the water intake, determining the number and location of water distribution points. Based on the existing sketch, the amount of consumables and reinforcement material is calculated.

The number of water consumption points depends on the location of the bathhouse, shower, garden beds, and pool on the site. A rational solution is to arrange from 5 to 10 pipe outlets, and connect rubber hoses to them so that there is convenient access of water to each zone.

Installation of a summer collapsible water supply system at the dacha

To install a water supply system in a summer cottage, you will need a standard set of tools and materials:

- HDPE pipes in quantities depending on the wiring diagram. For the main water supply, pipes of a larger diameter are taken, and for distribution to supply points, smaller diameters are used.

- Various fittings.

- Cutting tool: cone-shaped end knife, hacksaw for metal.

- Connecting elements for connecting HDPE pipes to taps, irrigation installations, and showers.

- Plastic water trays, covering grates.

The work is carried out using the following technology:

- Connect the country water supply to the source. Whether it is a common pipe or a column, a special adapter is used for this. The connection is made at an angle.

- Distribution is carried out throughout the site by laying pipes with a diameter of 20 or 25 mm to the water intake points.

- Connect the pipe sections using collet fittings, having first checked the correct assembly. Before this, the fitting is disassembled, the gasket and clamp are removed. The gasket is firmly inserted into place again, and a clamp with special fixing protrusions is placed behind it. Screw on the clamping nut, but only lightly.

- The ends of polyethylene pipes are prepared for installation. First, cut the end with a knife, then insert it into the fitting and tighten the clamping nut.

- Connect pipes to taps, irrigation systems, etc.

If a seasonal water supply is laid on the surface, it will become a hindrance for both equipment and people. It is better to make a trench using special plastic trays, and then cover it with the gratings included in the kit.

Main technical characteristics

Technical characteristics of low-density polyethylene:

- density – 0.94-0.95 g/cm³;

- tensile strength is 100-170 kgf/cm²;

- melting point of HDPE – 130-135°C;

- Brinell hardness – 1.4-2.5 kgf/mm².

Types of HDPE pipes: assortment

Purpose of HDPE pipes:

- for cold water pipelines. Blue or striped tubes are not used in residential premises, but HDPE products are simply ideal for laying networks underground and wiring in basements. Communications of small diameters are often installed with fittings, while large external diameters are often installed using welding with thermistor couplings. Smooth designs are used more often;

- for sewerage. For non-pressure sewerage, socketed products are used. Installation occurs by inserting an element into the socket of the previous one. Sealing occurs using rubber seals. For pressure sewerage, ordinary black pipes for technical purposes are used. They are connected using fittings or welding. When communications are located at great depths, a two-layer corrugation with sockets is used;

- For drainage systems, green perforated structures with a socket are used. Corrugation is often used;

- as casing pipes. HDPE structures are installed in a drilled well to strengthen the walls of the well. The depth of the aquifer can be up to 50 m. A pump is lowered into the well to draw water. The only limitation for the use of HDPE products is the danger of landslides and seismic hazard;

- for sewer systems and for wiring electrical cables, communication lines and the Internet in buildings, ordinary smooth or corrugated technical black or red pipes are used;

- For industrial technological networks, smooth and corrugated black pipes for technical purposes are used.

The following grades of HDPE are used for pipelines: PE-100, PE-80, PE-63. Permissible pressures are respectively 1.25 MPa, 1.6 MPa, 1.0 MPa.

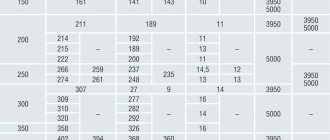

Standard sizes and diameters

Smooth products made of low-density polyethylene in accordance with GOST 18599-2001 are produced with outer diameters from 10 to 2000 mm.

Wall thickness varies from 2 mm to 95.5 mm. The exact characteristics of the most popular sizes are presented in the table: Table of HDPE pipe sizes

| ⌀, mm | SDR 21 | SDR 17.6 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | SDR 7.4 | |||||||

| PE-80 | PE-80 | PE-80 | PE-80 | PE-80 | PE-80 | PE-80 | ||||||||

| PE-100 | PE-100 | PE-100 | PE-100 | PE-100 | PE-100 | PE-100 | ||||||||

| Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | Thickness walls, mm | Weight, kg | |

| 16 | 2,0 | 0,09 | 2,3 | 0,102 | ||||||||||

| 20 | 2,0 | 0,116 | 2,3 | 0,132 | 3,0 | 0,162 | ||||||||

| 25 | 2,0 | 0,148 | 2,3 | 0,169 | 2,8 | 0,198 | 3,5 | 0,240 | ||||||

| 32 | 2,0 | 0,193 | 2,4 | 0,229 | 3,0 | 0,277 | 3,6 | 0,325 | 4,4 | 0,385 | ||||

| 40 | 2,0 | 0,244 | 2,3 | 0,281 | 2,4 | 0,292 | 3,0 | 0,353 | 3,7 | 0,427 | 4,5 | 0,507 | 5,5 | 0,600 |

| 50 | 2,4 | 0,369 | 2,9 | 0,436 | 3,0 | 0,449 | 3,7 | 0,545 | 4,6 | 0,663 | 5,6 | 0,786 | 6,9 | 0,935 |

| 63 | 3,0 | 0,573 | 3,6 | 0,682 | 3,8 | 0,715 | 4,7 | 0,869 | 5,8 | 1,05 | 7,1 | 1,25 | 8,6 | 1,47 |

| 75 | 3,6 | 0,821 | 4,3 | 0,97 | 4,5 | 1,01 | 5,6 | 1,23 | 6,8 | 1,46 | 8,4 | 1,76 | 10,3 | 2,09 |

| 90 | 4,3 | 1,18 | 5,1 | 1,4 | 5,4 | 1,45 | 6,7 | 1,76 | 8,2 | 2,12 | 10,1 | 2,54 | 12,3 | 3,00 |

| 110 | 5,3 | 1,77 | 6,3 | 2,07 | 6,6 | 2,16 | 8,1 | 2,61 | 10,0 | 3,14 | 12,3 | 3,78 | 15,1 | 4,49 |

| 125 | 6,0 | 2,26 | 7,1 | 2,66 | 7,4 | 2,75 | 9,2 | 3,37 | 11,4 | 4,08 | 14,0 | 4,87 | 17,1 | 5,78 |

| 140 | 6,7 | 2,83 | 8,0 | 3,35 | 8,3 | 3,46 | 10,3 | 4,22 | 12,7 | 5,08 | 15,7 | 6,12 | 19,2 | 7,27 |

| 160 | 7,7 | 3,71 | 9,1 | 4,35 | 9,5 | 4,51 | 11,8 | 5,5 | 14,6 | 6,67 | 17,9 | 7,97 | 21,9 | 9,46 |

Products with a diameter of up to 180 mm are supplied in coils and sections, more than 180 mm - only in straight sections 6 and 12 m long.

SDR coefficient of pipes

The SDR (Standard Dimension Ratio) coefficient of pipes according to GOST 18599-2001 is the standard dimensional ratio of the outer diameter to the wall thickness. SDR is a standard value, taken from tabular data. The thickness of the pipeline wall and its strength depend on SDR.

Features of creating detachable connections

To install polyethylene pipes with your own hands for water supply and sewerage systems in apartments with a diameter of up to 110 mm, you can use connections using fittings. These can be either compression fittings made of brass or plastic, or socket plugs with a flexible seal.

The pipeline is assembled according to the following algorithm:

- The pipes are cut to the required length and so that the ends are perpendicular to the body.

- The union nut of the fitting is turned several turns and the pipe is inserted into it completely - so that a force is felt when entering the rubber seal.

- The collet and elastic ring are put on, after which the nut is tightened.

Tip: Small connecting elements are screwed on by hand, but it is better to use a wrench. And do not forget to check the tightness of the connections after completing the work.

Specifications

Polyethylene pipes have earned their wide popularity due to their high performance and technical qualities. The technical characteristics of HDPE pipes are regulated by the provisions of GOST No. 18599 of 2001. One of the main factors influencing the choice of pipe is its required throughput: for example, a pipe with a diameter of 25 mm is capable of passing approx. 30 l/min., d=32 mm already 50 l/min.

Technical characteristics directly depend on the brand of polyethylene from which the pipe was made. So the model from PE-100 has the following data:

- Density 0.95 kg per 1 cubic meter. dm.

- Elasticity, which determines tensile elasticity, is 800 mPa.

- Linear expansion – 2 mm per meter of length.

- Tensile elongation modulus – up to 250% at room temperature.

- Thermal conductivity – 0.4 Watt per mK.

- The recommended operating temperature range is from -50° to +40°C.

- Working pressure can vary, depending on the type of pipe, up to 40 atmospheres.

- The average service life is about 50 years.

Pros and cons of HDPE pipes

Like any other material, HDPE has its advantages and disadvantages. Among the advantages of HDPE pipes are:

- Resistance to corrosion and chemical environments.

- Sufficient strength and durability in operation.

- Low price compared to metal counterparts.

- Smooth inner surface to avoid the formation of build-up and blockages.

- Wide range of operating temperatures.

- Sufficient elasticity allows the HDPE pipe not to burst when the water inside it freezes.

- The material is environmentally friendly and safe for the human body.

- Light weight, making it easy to transport and store.

- Easy to connect with each other, availability of a wide range of additional elements and fittings.

Disadvantages of HDPE pipes:

- Can only be used for cold water supply, with the exception of cross-linked HDPE models.

- Low resistance to mechanical shocks and excessive loads.

As you can see, HDPE pipes have much more positive qualities than negative ones. In this regard, a polyethylene pipe is one of the best options for laying a country water supply in terms of price and quality.

Helpful15Not Helpful

Price for work

The price for installing a water supply system varies depending on the type of pipes, installation technology, and scope of work. Average prices are summarized in the table:

| No. | Name | Unit | Quantity | Price, |

Rub.

In the future, polymer pipes will replace their metal counterparts. And which polymer to choose HDPE, LDPE or PVC depends on the purpose of the water supply and power.

An excellent solution for watering at the dacha is the construction of a local water supply system from polymer, preferably polyethylene pipes. The do-it-yourself scheme for installing a water supply system in a dacha using HDPE pipes is quite simple, and any home craftsman can cope with such a task. To do this, you do not need to have the skills of a plumber, but just the ability to use simple hand tools.