Ball valves are the most common type of shut-off valve, widely used in municipal and industrial areas and are the main one when used in households. One of a number of numerous brands of shut-off valves is the 11b27p1 ball valve, which has a standard design in relation to its analogues.

Before purchasing a ball valve from the 11b27p1 series, it is useful to study its structural design, manufacturing materials, and technical characteristics. When purchasing, pay attention to the manufacturer of the product and its cost, trying to get closer to the optimal price-quality ratio

Rice. 1 Ball valves in domestic pipelines

Ball valve, description and technical characteristics

Ball valve (KSh) is a general industrial pipeline shut-off valve whose design uses a ball valve made of high-quality steel.

Modern technologies for the production of sealing materials have given a sharp impetus to the improvement of valve designs, which also made it possible to use ball valves on high-pressure pipelines up to 16 MPa (160 kg/cm).

To accurately select this type of industrial equipment, it is recommended in most cases to fill out a questionnaire.

Regulations

What specific GOST standards for the 11b27p1 coupling ball valve are currently in effect?

- The material of the body, ball and rod complies with GOST 15527-2004 “Pressure-processed bronze-zinc alloys”.

- The handle material must comply with GOST 1583-93 “Aluminum casting alloys”.

- The climatic performance of the valve is assessed according to GOST 15150-69 UHL 4, and tightness - according to GOST R 54808.

- Finally, the product as a whole must comply with the requirements of the intergovernmental standard GOST 21345-2005 “Cylindrical, cone and ball valves”, adopted by 12 countries of the former USSR.

A caveat: the latest standard regulates the production of shut-off valves for operating pressures not exceeding 250 atmospheres. Very high pressures have their own requirements.

Let us mention several key requirements of GOST 21345-2005.

- The effective diameter (size of the through groove in the ball) of a valve up to DN 350 inclusive must be at least 95% of the diameter of the body inlet.

- Thread imperfections that take it beyond the average diameter should not have a non-specialized length of more than half a turn. Along with this, shortcomings should not interfere with the execution of the threaded pipe connection.

Ball valves

Ball valves with large bore diameters successfully compete with gate valves and butterfly valves, and have found application in the food, agricultural, gas and oil industries. It so happens that this type of shut-off valve is considered one of the most popular pipeline fittings for installers, as it has many advantages.

- Small building dimensions – compactness of the ball valve, which simplifies installation

- The relatively light weight of the valves reduces the load on the pipeline

- The speed of controlling the valve shutter, almost with one movement

- Choice of design options for almost any operating conditions from steel to stainless steel

- Reliable, virtually maintenance-free

The increased hydraulic resistance of the valve shutter is a little confusing. Steel valves win in this regard, but you must agree - convenient control, compactness, ease of operation, aesthetic appearance, all these factors make ball valves more and more popular among consumers

Installation

It is recommended to install taps with a smaller diameter in places with easy access. During installation you will need

- block the pipe line

- clean and degrease joints

- bring shut-off valves to a closed state

- eliminate deformation in pipes (bends, distortions)

The faucet can be installed in several ways

- The flange method involves placing a flange with holes on both sides of the valve, through which it is connected to the system flanges with bolts.

- The threaded version of the connection occurs using threaded nuts.

- The welding method is a conventional welding to a pipe.

Attention!!! The welded installation option is reliable, but greatly complicates maintenance. Dismantling for repairs will be difficult.

How to choose the right faucet

- determine the area of application (substance)

- pipe diameter

- case quality (no defects such as bulges, cracks)

- possibility of hydraulic shocks in the pipeline (if any, the ball system will quickly become unusable)

The taps may differ in some versions. This is a straight coupling ball valve, its feature is the same connections on both sides.

The faucet is equipped with a lever or butterfly lever.

The main difference is the connection options.

Ball valve designations

The diameter of ball valves is DN or Dn, this is the standard nominal bore designation generally accepted for shut-off valves. For example, the diameter can reach 1200 millimeters, abbreviated as KSh Du1200. Different countries apply different DN standards.

Standard diameters of the most popular ball valves in Russia in millimeters: 6, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 400 ... and up to 1200. The most used on pipelines KSh Du from 15 to 50 mm.

The nominal pressure of the flow media for the tap is standardly designated PN or Pn

for example Ru160 kg/cm or Pn16 MPa.

The type of valve may differ in connection to the pipeline and control of the valve; manufacturers usually designate short designations KSh with an additional letter, for example KShF - flanged ball valve. Well, the full designation looks something like this: KShF Du100 Ru16.

Usage

What specific sizes of taps are in demand when installing plumbing communications in a house or apartment? Where exactly should they be used? Let's give a couple of examples.

Ball valve 11b27p1 with a diameter of 15 mm is used:

- At the cold water and hot water supply inputs into the apartment.

- As a control valve for pressure and temperature measurements.

- On taps into the water supply system of individual plumbing fixtures (toilet cistern, washbasin, sink, etc.).

Ball coupling valve 11b27p1 with a diameter of 20 mm is used to cut off individual heating devices from the heating circuit. It can also be placed on a jumper in front of the radiator.

Captain Obvious reminds us: if you close both the jumper and the battery connections at the same moment, the circulation in the riser will stop completely. Soon your neighbors, led by a mechanic, will come to you and begin to utter angry, offensive words.

Ball valve 11b27p1 with a diameter of 25 mm is mounted on heating and water supply risers, on the discharges of the elevator unit and on the inlet pipes of the boiler.

Ball valve 11b27p1 with a diameter of 32 mm can be used on risers in multi-storey buildings and on heating bottlings to cut off individual sections of the circuit.

Ball valve 11b27p1 with a diameter of 40 mm is used in a gravity heating system (when the pump is inserted, it breaks the bypass). It, along with valves of larger diameter, can be installed in water meter units and on hot water taps in elevators.

Ball valve catalog

Catalog of ball valves - steel, cold-resistant, stainless steel valves Ru up to 160 kg/cm, by connection

- KShM coupling Steel coupling ball valves DN15 - DN600; Ru16 - Ru160

- KShP for welding Steel welded ball valves DN15 - DN800; Ru16 - Ru160

- KShF flanged Steel flanged ball valves DN15 - DN800; Ru16 - Ru160

- KSh with electric drive Ball valves with electric drive DN50 - DN800; Ru16 - Ru40

- KSh with gearbox Steel ball valves with gearbox DN65 - 800; Ru16 - Ru25

- KSh with extended stem Steel ball valves with increased stem length

- KShK combined Steel ball valves welding / flange Ru16 - Ru40

- Three-way KShT Steel distribution ball valves DN15 - DN80; Ru16 - Ru160

For uninterrupted control of flows on pipelines for different regions of our country, steel taps are manufactured in various climatic versions for installation outdoors, under canopies and indoors

The main versions are U, HL, UHL, the bulk are made by manufacturers from carbon steel St20 to U1, this applies to body parts

Cold-resistant taps are also manufactured - from 09G2S steel, which does not change its properties up to 60 degrees Celsius

Stainless steel taps are made of high-quality stainless steel 12X1810T, and less often, upon special order, they are made of acid-resistant steel.

All crane bodies are manufactured in a repairable and non-dismountable version.

Steel taps compare favorably in price with analogues made of brass, bronze and other expensive alloys, which has made them popular today for complex installation on designed new pipelines. In addition, by choosing steel taps, you save on your budget.

Of course, there is an unfavorable moment - corrosion, but if a steel tap is mounted on a new pipeline and the material is selected according to the materials of the pipeline, then in fact the tap will serve you until the pipeline line is dismantled and replaced.

The presented steel ball valves correspond to

Russian GOST standards for connecting parts

Purchasing recommendations

When choosing a locking device, you need to give preference to certified products, and also be sure to take into account the following basic indicators:

- the type and aggressiveness of the substance with which the device ball is expected to come into contact;

- pipe cross-section in the pipeline system;

- quality of the valve body;

- the presence of possible hydraulic shocks in the system.

A wide range of ball coupling fittings are produced not only by foreign, but also by domestic manufacturers (read about valves for heating radiators here).

Marking of taps 11b27p1 is used, according to GOST, in Russian and Ukrainian devices.

Foreign manufacturers, including:

- Valtec (through drain valve),

- STC-UNO

- Giacomini, ,

— standard metric designation is used, in accordance with the dimensions of the nominal pipe diameter.

Table DN to pipe diameter

| Du, (mm) | Nozzle diameter/pipe wall thickness (mm) | GOST |

| 15 | 21,3 / 2,8 | 3262 |

| 20 | 26,8 / 2,8 | 3262 |

| 25 | 33,5 / 3,2 | 3262 |

| 32 | 38 / 4 | 10705 |

| 40 | 48 / 3,5 | 10705 |

| 50 | 57 / 3,5 | 10705 |

| 65 | 76 /4 | 10705 |

| 80 | 89 / 4 | 10705 |

| 100 | 108 / 5 | 10705 |

| 125 | 133 / 5 | 10705/8731 |

| 150 | 159 / 6 | 10705/8731 |

| 200 | 219 / 6 | 10705/8731 |

| 250 | 273 / 8 | 10705/8731 |

| 300 | 325 / 8 | 10705/8731 |

Technical characteristics of ball valves

The characteristics of the valves depend on the materials used to manufacture the ball valve parts, compliance with production technologies and the use of modern equipment in production.

As a result, the characteristics of materials used are higher, there are more possibilities for operation in the environment and a variety of compositions of flow media.

Briefly about the main characteristics of the CS for operation in the environment under different climatic conditions, designations:

- U - temperate climate

- HL - moderate and cold

- UHL - moderate, cold and acid-resistant

Also, service life depends on the quality and characteristics of the sealing materials of the ball valve and the valve stem.

Methods for making brass products

The most difficult thing to manufacture is the housing - for the location of the control ball in it, precision assembly is required, and for strength and reliability - manufacturing the housing in the form of a single solid element.

We recommend that you read: The use of various types of shut-off and control valves in pipeline systems

The ball mechanism and rod are turned on a machine, and the body is cast into a mold, baked in a matrix or forged using a mechanical press:

- A die-cast brass body may have voids in the walls and uneven surfaces. Casting does not require serious time and financial costs, but the resulting workpiece is of low quality and requires additional mechanical processing.

- For baking in the matrix, brass powder is used, which, when exposed to heat, is welded into a single piece. This method produces a body with precise parameters that does not require additional processing, but due to the weak connection of the brass particles, the finished product is not very strong.

- The most reliable, but also expensive, is a forged faucet made by hot stamping. To make the case, a mechanical press with a die is used, in which hot brass is compressed to give the desired shape. The finished part has no cavities in the walls or irregularities on the surface and does not require any modification other than descaling.

Technical differences of ball valves:

- According to the steel materials from which the body and moving parts of the crane are made - brass, steel, stainless steel, cold-resistant. The main element of the faucet is the ball valve in most types of stainless steel faucets.

- According to maintainability - dismountable or non-dismountable (all-welded)

- By aisle - partial bore (reduced) and full bore

- For use in the environment - climatic version U, HL, UHL, T

- By interaction with working media - water and steam, gas mixtures, acid resistance

What you need to pay attention to when choosing, installing and operating

Although a brass ball valve has virtually no negative aspects, the process of selecting, installing and operating this type of device has its own specific points.

When choosing a faucet, you need to pay attention to the massiveness of the external or internal threads of the fittings, the presence of a molding on the body for a wrench or gas wrench. The fact is that the fittings are attached to the body using 5-6 turns of thread with a fine pitch. And although brass is a viscous metal, you should not use excessive force to clamp the body or fitting.

Aluminum alloys are often offered on the market under the guise of brass products. Such products can be distinguished by holding them in your hand and comparing the weight; brass ones seem more massive, even when steel balls are inserted into silumin cases. The service life of such devices is 3-4 times less.

Installation of the product is carried out on a form tape. The use of traditional tow and silicone sealant is not recommended. This can lead to over-tightening of the threads, which, when operating pressure is applied, can lead to increased metal stress and rupture of the housing. Well, during operation, overheating of the product above 150-185 degrees and water hammer should not be allowed.

Ball valve design

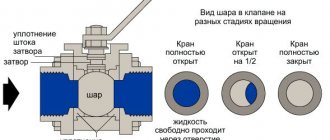

Ball valves, regardless of the type of body and connection to the pipeline, have one thing in common in their design and name - this is a valve in the form of a ball in a seat with sealing rings.

The design consists of four main parts.

- The fixed part of the ball valve is the body (collapsible or all-welded)

- The moving part, the valve shutter, is a ball with a passage hole and a control rod

- Sealing elements of the ball valve and stem - rings and gaskets made of fluoroplastic or other sealing material

- Control mechanism - handle or flywheel, gearbox, pneumatic drive or electric drive

Classmates

Along with ball valves, you can find plug and screw valves in plumbing stores. Let's compare the product we are studying with them.

A plug valve requires a lot of hardening to transform the position of the plug: the brass or cast iron surfaces of the contacting parts have a fairly large area. With a ball valve, the sliding of a nickel-plated ball with a perfect surface on a polymer seat with a very low coefficient of friction does not provide any noticeable resistance to pressing the lever.

The gland packing of a plug valve begins to leak the first time the plug is turned. Moreover, the oil seal inevitably wears out during downtime: any mechanic will confirm that to avoid leaks it has to be refilled every few years. The polymer seal of the ball valve does not require maintenance in principle.