Polymers are gradually taking over the market and replacing expensive materials. PVC ball valve is an excellent replacement for spool and valve structures. This is a vivid example of how effective the synthesis of the advantages of a manufacturing material and an adjustment mechanism is. The variety of types and design features allows them to be used for pipelines for various purposes.

Plastic ball valve

Ordering table for taps with bonded couplings, EPDM seals

| d, mm (must match the outer diameter of your PVC pipeline) | Du, mm (must match the inside diameter of your PVC pipe) | Opening time/ closing | Power supply drive | Order code | Price with VAT, rub. |

| 16 | 10 | 1 | 220/AC | 22PVCER1622001 | 28836 |

| 4 | 220/AC | 22PVCER1622004 | 32129 | ||

| 12 | 220/AC | 22PVCER1622012 | 25543 | ||

| 12 | 24/AC/DC | 22PVCER1624U12 | 28658 | ||

| 12 | 24/DC | 22PVCER1624D12 | 28747 | ||

| 20 | 15 | 1 | 220/AC | 22PVCER2022001 | 29014 |

| 4 | 220/AC | 22PVCER2022004 | 32307 | ||

| 12 | 220/AC | 22PVCER2022012 | 25810 | ||

| 12 | 24/AC/DC | 22PVCER2024U12 | 27590 | ||

| 12 | 24/DC | 22PVCER2024D12 | 27679 | ||

| 25 | 20 | 1 | 220/AC | 22PVCER2522001 | 29370 |

| 4 | 220/AC | 22PVCER2522004 | 32663 | ||

| 12 | 220/AC | 22PVCER2522012 | 26077 | ||

| 12 | 24/AC/DC | 22PVCER2524U12 | 28302 | ||

| 12 | 24/DC | 22PVCER2524D12 | 28391 | ||

| 32 | 25 | 1 | 220/AC | 22PVCER3222001 | 29993 |

| 4 | 220/AC | 22PVCER3222004 | 33286 | ||

| 12 | 220/AC | 22PVCER3222012 | 26700 | ||

| 12 | 24/AC/DC | 22PVCER3224U12 | 29014 | ||

| 12 | 24/DC | 22PVCER3224D12 | 29103 | ||

| 40 | 32 | 1 | 220/AC | 22PVCER4022001 | 31150 |

| 4 | 220/AC | 22PVCER4022004 | 34443 | ||

| 12 | 220/AC | 22PVCER4022012 | 27857 | ||

| 12 | 24/AC/DC | 22PVCER4024U12 | 30171 | ||

| 12 | 24/DC | 22PVCER4024D12 | 30260 | ||

| 50 | 40 | 4 | 220/AC | 22PVCER5022004 | 36401 |

| 12 | 220/AC | 22PVCER5022012 | 29726 | ||

| 12 | 24/AC/DC | 22PVCER5024U12 | 32040 | ||

| 12 | 24/DC | 22PVCER5024D12 | 32129 | ||

| 63 | 50 | 4 | 220/AC | 22PVCER6322004 | 37469 |

| 12 | 220/AC | 22PVCER6322012 | 30883 | ||

| 12 | 24/AC/DC | 22PVCER6324U12 | 33197 | ||

| 12 | 24/DC | 22PVCER6324D12 | 33286 | ||

| 75 | 65 | 12 | 220/AC | 22PVCER7522012 | 50374 |

| 16 | 24/AC/DC | 22PVCER7524U16 | 53133 | ||

| 16 | 24/DC | 22PVCER7524D16 | 51620 | ||

| 90 | 80 | 12 | 220/AC | 22PVCER9022012 | 54379 |

| 16 | 24/AC/DC | 22PVCER9024U16 | 57138 | ||

| 16 | 24/DC | 22PVCER9024D16 | 58028 |

Ordering table for valves with bonded couplings, FPM seals

| d, mm (must match the outside diameter of your PVC pipe) | Du, mm (must match the inside diameter of your PVC pipe) | Opening time/ closing | Power supply drive | Order code | Price with VAT, rub. |

| 16 | 10 | 1 | 220/AC | 22PVCFR1622001 | 29548 |

| 4 | 220/AC | 22PVCFR1622004 | 32841 | ||

| 12 | 220/AC | 22PVCF1622012 | 26344 | ||

| 12 | 24/AC/DC | 22PVCFR1624U12 | 29459 | ||

| 12 | 24/DC | 22PVCFR1624D12 | 29548 | ||

| 20 | 15 | 1 | 220/AC | 22PVCFR2022001 | 29993 |

| 4 | 220/AC | 22PVCFR2022004 | 33286 | ||

| 12 | 220/AC | 22PVCFR2022012 | 26789 | ||

| 12 | 24/AC/DC | 22PVCFR2024U12 | 28569 | ||

| 12 | 24/DC | 22PVCFR2024D12 | 28658 | ||

| 25 | 20 | 1 | 220/AC | 22PVCFR2522001 | 30349 |

| 4 | 220/AC | 22PVCFR2522004 | 33642 | ||

| 12 | 220/AC | 22PVCFR2522012 | 27056 | ||

| 12 | 24/AC/DC | 22PVCFR2524U12 | 29281 | ||

| 12 | 24/DC | 22PVCFR2524D12 | 29370 | ||

| 32 | 25 | 1 | 220/AC | 22PVCFR3222001 | 31239 |

| 4 | 220/AC | 22PVCFR3222004 | 34532 | ||

| 12 | 220/AC | 22PVCFR3222012 | 27679 | ||

| 12 | 24/AC/DC | 22PVCFR3224U12 | 30260 | ||

| 12 | 24/DC | 22PVCFR3224D12 | 30349 | ||

| 40 | 32 | 1 | 220/AC | 22PVCFR4022001 | 32574 |

| 4 | 220/AC | 22PVCFR4022004 | 35867 | ||

| 12 | 220/AC | 22PVCFR4022012 | 29281 | ||

| 12 | 24/AC/DC | 22PVCFR4024U12 | 31595 | ||

| 12 | 24/DC | 22PVCFR4024D12 | 31684 | ||

| 50 | 40 | 4 | 220/AC | 22PVCFR5022004 | 37914 |

| 12 | 220/AC | 22PVCFR5022012 | 31239 | ||

| 12 | 24/AC/DC | 22PVCFR5024U12 | 33553 | ||

| 12 | 24/DC | 22PVCFR5024D12 | 33642 | ||

| 63 | 50 | 4 | 220/AC | 22PVCFR6322004 | 40317 |

| 12 | 220/AC | 22PVCFR6322012 | 33731 | ||

| 12 | 24/AC/DC | 22PVCFR6324U12 | 36045 | ||

| 12 | 24/DC | 22PVCFR6324D12 | 36134 | ||

| 75 | 65 | 12 | 220/AC | 22PVCFR7522012 | 53934 |

| 16 | 24/AC/DC | 22PVCFR7524U16 | 56693 | ||

| 16 | 24/DC | 22PVCFR7524D16 | 55180 | ||

| 90 | 80 | 12 | 220/AC | 22PVCFR9022012 | 60342 |

| 16 | 24/AC/DC | 22PVCFR9024U16 | 63101 | ||

| 16 | 24/DC | 22PVCFR9024D16 | 63991 |

Advantages of plastic products

There are almost no disadvantages to plastic locking fittings:

- the ability to use the tap only to stop and resume the supply of the working medium, since when the product is used to regulate the flow, it quickly becomes unusable;

- instability to high temperatures and pressure;

- impossibility of repair in case of failure.

However, plastic taps have significantly more advantages:

- the cost of materials is low, and processing polymers is easier than working with metal, so plastic fittings are cheaper than metal ones;

- the chemical and biological inertness of polymers makes products made from them resistant to corrosion and the formation of deposits on the walls and environmentally friendly - no toxic substances enter the working environment, harmful microorganisms do not settle in the interior of the fittings;

- The service life of ball valves with proper operation is at least 50 years;

- polymer fittings are suitable both for connecting plastic pipes and for connecting pipeline elements made of different materials;

- due to the simplicity of the device, ball valves are easy to install and do not require further maintenance: the seals do not lose their sealing properties, the metal ball of the locking mechanism does not stick to the plastic body;

- the full bore ball element does not reduce the pipeline capacity;

- lightweight plastic does not require effort during transportation and installation, and does not put stress on the pipeline and fasteners.

We recommend that you read: Copper pipes and their use in air conditioners

Ordering table for valves with internal threads, EPDM seals

| Thread | Du, mm | Opening time/ closing | Power supply drive | Order code | Price with VAT, rub. |

| G3/8 | 10 | 1 | 220/AC | 22PVCEG3822001 | on request |

| 4 | 220/AC | 22PVCEG3822004 | on request | ||

| 12 | 220/AC | 22PVCEG3822012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG3824U12 | on request | ||

| 12 | 24/DC | 22PVCEG3824D12 | on request | ||

| G1/2 | 15 | 1 | 220/AC | 22PVCE G1222001 | on request |

| 4 | 220/AC | 22PVCEG1222004 | on request | ||

| 12 | 220/AC | 22PVCEG1222012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG1224U12 | on request | ||

| 12 | 24/DC | 22PVCEG1224D12 | on request | ||

| G3/4 | 20 | 1 | 220/AC | 22PVCEG3422001 | on request |

| 4 | 220/AC | 22PVCEG3422004 | on request | ||

| 12 | 220/AC | 22PVEG3422012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG3424U12 | on request | ||

| 12 | 24/DC | 22PVCEG3424D12 | on request | ||

| G1 | 25 | 1 | 220/AC | 22PVCEG122001 | on request |

| 4 | 220/AC | 22PVCEG122004 | on request | ||

| 12 | 220/AC | 22PVCEG122012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG124U12 | on request | ||

| 12 | 24/DC | 22PVCEG124D12 | on request | ||

| G11/4 | 32 | 1 | 220/AC | 22PVCEG11422001 | on request |

| 4 | 220/AC | 22PVCEG11422004 | on request | ||

| 12 | 220/AC | 22PVCEG11422012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG11424U12 | on request | ||

| 12 | 24/DC | 22PVCEG11424D12 | on request | ||

| G11/2 | 40 | 4 | 220/AC | 22PVCEG11222004 | on request |

| 12 | 220/AC | 22PVCEG11222012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG11224U12 | on request | ||

| 12 | 24/DC | 22PVCEG11224D12 | on request | ||

| G2 | 50 | 4 | 220/AC | 22PVCEG222004 | on request |

| 12 | 220/AC | 22PVCEG222012 | on request | ||

| 12 | 24/AC/DC | 22PVCEG224U12 | on request | ||

| 12 | 24/DC | 22PVCEG224D12 | on request | ||

| G21/2 | 65 | 12 | 220/AC | 22PVCEG21222012 | on request |

| 16 | 24/AC/DC | 22PVCEG21224U16 | on request | ||

| 16 | 24/DC | 22PVCEG21224D16 | on request | ||

| G3 | 80 | 12 | 220/AC | 22PVCEG322012 | on request |

| 16 | 24/AC/DC | 22PVCEG324U16 | on request | ||

| 16 | 24/DC | 22PVCEG324D16 | on request |

Ordering table for female valves, FPM seals

| Thread | Du, mm | Opening time/ closing | Power supply drive | Order code | Price with VAT, rub. |

| G3/8 | 10 | 1 | 220/AC | 22PVCFG3822001 | on request |

| 4 | 220/AC | 22PVCFG3822004 | on request | ||

| 12 | 220/AC | 22PVCFG3822012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG3824U12 | on request | ||

| 12 | 24/DC | 22PVCFG3824D12 | on request | ||

| G1/2 | 15 | 1 | 220/AC | 22PVCFG1222001 | on request |

| 4 | 220/AC | 22PVCFG1222004 | on request | ||

| 12 | 220/AC | 22PVCFG1222012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG1224U12 | on request | ||

| 12 | 24/DC | 22PVCFG1224D12 | on request | ||

| G3/4 | 20 | 1 | 220/AC | 22PVCFG3422001 | on request |

| 4 | 220/AC | 22PVCFG3422004 | on request | ||

| 12 | 220/AC | 22PVCFG3422012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG3424U12 | on request | ||

| 12 | 24/DC | 22PVCFG3424D12 | on request | ||

| G1 | 25 | 1 | 220/AC | 22PVCFG122001 | on request |

| 4 | 220/AC | 22PVCFG122004 | on request | ||

| 12 | 220/AC | 22PVCFG122012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG124U12 | on request | ||

| 12 | 24/DC | 22PVCFG124D12 | on request | ||

| G11/4 | 32 | 1 | 220/AC | 22PVCFG11422001 | on request |

| 4 | 220/AC | 22PVCFG11422004 | on request | ||

| 12 | 220/AC | 22PVCFG11422012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG11424U12 | on request | ||

| 12 | 24/DC | 22PVCFG11424D12 | on request | ||

| G11/2 | 40 | 4 | 220/AC | 22PVCFG11222004 | on request |

| 12 | 220/AC | 22PVCFG11222012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG11224U12 | on request | ||

| 12 | 24/DC | 22PVCFG11224D12 | on request | ||

| G2 | 50 | 4 | 220/AC | 22PVCFG222004 | on request |

| 12 | 220/AC | 22PVCFG222012 | on request | ||

| 12 | 24/AC/DC | 22PVCFG224U12 | on request | ||

| 12 | 24/DC | 22PVCFG224D12 | on request | ||

| G21/2 | 65 | 12 | 220/AC | 22PVCFG21222012 | on request |

| 16 | 24/AC/DC | 22PVCFG21224U16 | on request | ||

| 16 | 24/DC | 22PVCFG21224D16 | on request | ||

| G3 | 80 | 12 | 220/AC | 22PVCFG322012 | on request |

| 16 | 24/AC/DC | 22PVCGG324U16 | on request | ||

| 16 | 24/DC | 22PVCFG324D16 | on request |

Dimensions:

| Dimensions (mm) and weight (kg) | ||||||||||

| d | Du | H1 | H2 | H3 | N | W | L | L1 | L2 | Weight |

| 16 | 10 | 27 | 47 | 149 | 223 | 120 | 93 | 127 | 25 | 2,2 |

| 20 | 15 | 27 | 47 | 149 | 223 | 120 | 95 | 127 | 25 | 2,2 |

| 25 | 20 | 30 | 56 | 149 | 235 | 120 | 109 | 127 | 25 | 2,2 |

| 32 | 25 | 36 | 67 | 149 | 252 | 120 | 119 | 127 | 25 | 2,3 |

| 40 | 32 | 44 | 73 | 149 | 266 | 120 | 135 | 127 | 45 | 2,5 |

| 50 | 40 | 51 | 80 | 149 | 280 | 120 | 147 | 127 | 45 | 2,5 |

| 63 | 50 | 64 | 97 | 149 | 310 | 120 | 168 | 127 | 45 | 3,2 |

| 75 | 65 | 85 | 152 | 149 | 391 | 120 | 233 | 127 | 70 | 3,9 |

| 90 | 80 | 105 | 176 | 149 | 430 | 120 | 254 | 127 | 70 | 4,4 |

Electrical connection diagram for 220/AC drives

Electrical control circuit for an electric drive with a supply voltage of 220V AC with a frequency of 50 Hz with two limit microswitches (LS1, LS2) that turn off the electric motor in the extreme positions of the working body and two additional microswitches (LS3, LS4) that are responsible for feedback when the extreme positions are reached .

| Terminals: 1: positive wire 3: “Open” command 4: “Close” command 5: “Open” signal lamp 6: “Closed” signal lamp 7: not used 8: not used ↓: protective zero (“ground”) | Dry contacts: 3-NC: normally closed 3-NO: normally open 3-COM: common 4-NC: normally closed 4-NO: normally open 4-COM: common |

Legend: LS3: additional limit switch "Open" LS4: additional limit switch "Close" F1: fuse H: engine heater (optional) M: engine

Features of the structure of ball valves

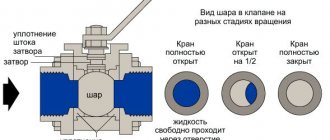

All types of shut-off and control valves have a similar structure and consist of a body, seals, regulating and control mechanisms. Ball valves differ from other shut-off devices by the type of mechanism, which is a ball or sphere with several through holes - two or more, depending on the purpose of the valve. Seat seals are located between the body and the locking ball to ensure tightness and reduce friction.

In the closed position, the ball is turned with its blind side towards the flow, and the through holes are turned towards the walls of the body; the seats ensure reliable tightness of the valve. In the open position, one or more passage holes turn towards the supply pipes, passing the working medium into the ball, and through the hole on the opposite side, liquid or gas flows further through the pipeline.

Based on the materials used for the manufacture of fittings, ball valves are divided into two types:

- metal (steel, cast iron, brass, bronze, aluminum),

- plastic (polyvinyl chloride, polyethylene, polypropylene).

However, this classification takes into account only the body material, since the ball mechanisms of all valves without exception are made of stainless steel. It is the ball that must withstand the pressure of the working medium in the closed position of the valve, so the strength of the material is a key property here.

Note! In metal valves, the ball mechanism can either perform only a shut-off function or regulate the flow.

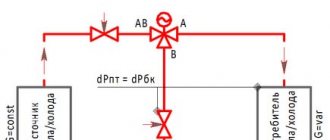

In ball fittings made of polymers, including polyvinyl chloride, there is no control function, and the valve can only be in two positions: open and closed.

We recommend that you read: Features and purpose of cast iron valves

In addition, unlike metal ones, plastic taps are made only full bore, that is, the holes in the ball mechanism have the same capacity as the pipes on which the fittings are installed.

Note! The simplified structure for polymer valves was not chosen by chance: with incomplete shutoff, the pressure of the working medium increases, and polymers, which are lighter than metal, lend themselves to the formation of cavities, the appearance of which quickly renders the valve inoperative.

The ball valve is controlled using a mechanism consisting of a rod that drives the control ball and a direct control unit - a butterfly valve or lever.

Fittings that have a passage hole with a diameter of up to 15 cm are controlled manually, larger ones are equipped with a pneumatic, electric or hydraulic drive, which allows you to open and close the tap without exerting much physical force.

Electrical connection diagram for 24/AC/DC drives

Electrical control circuit for an electric drive with a supply voltage of 24V AC with a frequency of 50 Hz and DC with two limit microswitches (LS1, LS2) that turn off the DC motor in the extreme positions of the working body and two additional microswitches (LS3, LS4) that are responsible for the reverse communication when reaching extreme positions.

| Terminals: 1: positive wire 3: “Open” command 4: “Close” command 5: “Open” signal lamp 6: “Closed” signal lamp 7: not used 8: not used ↓: protective zero (“ground”) | Dry contacts: 3-NC: normally closed 3-NO: normally open 3-COM: common 4-NC: normally closed 4-NO: normally open 4-COM: common |

Legend: LS3: additional limit switch "Open" LS4: additional limit switch "Close" F1: fuse H: engine heater (optional) M: engine

Applications of PVC taps

Plastic taps are installed in cold and hot water supply systems on pipeline branches to stop the water supply for the period of planned or emergency repairs of any of the sections.

Plastic fittings are used in low-temperature heating systems and for heated floors. Such a faucet helps to painlessly repair one or more points in the network, as well as turn off the heating. T

It is important to note some details of the use of ball valves made from plastic fittings:

- Polymer taps are installed only on pipes made of a similar material: this eliminates temperature differences and structural failure.

- Permanent connections are reliable, and detachable connections are easy to install. It is important to decide what exactly is needed for the pipeline. Cold heating pipes and connection points require crimping valves. There is no danger of depressurization in cold water and it is easy to replace the fittings. For hot water supply, it is better to use one-piece taps, which will reduce the likelihood of accidents.

- If you are going to install a pipeline or part of it, it is worth purchasing pipes and taps from the same manufacturer with the same parameters: this way there will be no problems with installation and operation.

- Taps and pipes have their own markings indicating their capacity and operating limits. This confirms in-house manufacturing and assists in selecting piping material that will perform in the appropriate environment.

- During installation, the connecting pipes are cleaned of debris and dust. It is imperative to wash and degrease the elements before starting the connection, otherwise the installation will undergo significant disruptions and the system will be ineffective.

- Although the design based on plastic PVC reinforcement is sufficiently reliable, its damage leads to the need for complete replacement.

Such crane elements have significant throughput and serve for a long time. Their simplicity of design allows them to be integrated into both hot and warm water supply systems. It is necessary to choose pipes and ball valves wisely, look at manufacturers and markings. Then it will be possible to avoid low-quality products and problems during installation and operation.

Electrical connection diagram for 24/DC drives

Electrical control circuit for an electric drive with a supply voltage of 24V DC with two limit microswitches (LS1, LS2) that turn off the DC motor in the extreme positions of the working element and two additional microswitches (LS3, LS4) that are responsible for feedback when the extreme positions are reached.

| Terminals: 1: positive wire 3: “Open” command 4: “Close” command 5: “Open” signal lamp 6: “Closed” signal lamp 7: not used 8: not used ↓: protective zero (“ground”) | Dry contacts: 3-NC: normally closed 3-NO: normally open 3-COM: common 4-NC: normally closed 4-NO: normally open 4-COM: common |

Legend: LS3: additional limit switch "Open" LS4: additional limit switch "Close" F1: fuse H: engine heater (optional) M: engine

Types of PVC ball valves

Shut-off valves made of polymers are manufactured in various variations. Differences may be in terms of materials, purpose, housing, connection pipes. Such elements are made from polyvinyl chloride, polypropylene or polyethylene, processed using low pressure.

PVC tap installation

Cranes that are made from the first two materials are significantly more stable and durable in terms of operating conditions compared to polyethylene. Reinforcement made from such polymers can withstand temperatures up to 95 degrees and 20 bar pressure . Polyethylene is suitable for use at temperatures up to 45 degrees at 15 bar pressure.

It is important to remember that a tap is placed on the pipeline made of the same plastic from which the pipe is made, this ensures a reliable connection and tightness during operation. As a result, exposure to the operating environment will affect compression and expansion equally.