Installation of heating equipment using any type of fuel (gas, solid fuel boiler, fireplace or stove) also implies the design of a pipe system that discharges combustion products. Even in the last century, there was no alternative to brick and then asbestos-cement chimneys. Such systems had a significant number of shortcomings, so now they are almost completely forced out of the market by chimney pipes made of stainless steel.

A stainless steel chimney is a reliable and durable design that can be installed with various types of boilers

Characteristics of stainless steel chimneys

Stainless steel pipes are not the only products produced for heating boilers. Chimneys come in aluminum, ceramic, and enameled steel. But it was stainless steel that gained maximum popularity. The reason for this was the wide range of advantages that this material has:

- versatility. Steel pipes can work with most types of equipment operating on any fuel and energy source. Stainless steel smoke hoses are used even in industrial systems;

- ease of maintenance. Preventative cleaning of steel chimneys can be performed at any time of the year, without waiting for the system to be completely turned off and cooled down;

- availability of repairs. If one of the chimney elements fails, there is no need to change the entire hose. It is enough to simply replace the failed element;

- fire safety. On the smooth walls of steel hoses, toxic soot and gas formation remain in much smaller quantities than on more porous and rough asbestos-cement or ceramic ones. If the system is completely sealed, the risk of the chimney burning out will be minimal.

Of course, stainless steel chimneys also have disadvantages. These include thermal conductivity, which provokes the formation of condensation on the walls of the system. Over time, this problem can lead to complete failure of the smoke duct.

Helpful advice! Breakage can be avoided if the pipe is insulated in a timely manner. If it is not possible to do the insulation yourself, it is worth purchasing a ready-made “sandwich” type structure.

The stainless steel chimney duct must be insulated to reduce the formation of condensation on its walls

The principle of the pipe insulation procedure will depend on the characteristics of a particular region. In northern latitudes, the insulating structure may consist of several layers.

Sealing and insulation

When connecting elements, you must ensure that the joints are assembled hermetically, otherwise there is a risk of moisture getting inside the structure. This may subsequently cause the sandwich to collapse due to defrosting. A good sealant specially designed for this purpose and resistant to high temperatures will help to avoid this. When the chimney is sealed efficiently, it will last for decades.

When installing the system, you must ensure that the joints of the sections do not coincide with the brackets for hanging the pipes. It would be more correct when the chimney is fastened approximately in the middle of the section. Also, do not forget the rule according to which chimneys connected to gas-using units are prohibited from being covered with umbrellas of any design. Only a small nozzle is allowed.

If you want to insulate a single-wall stainless steel pipe, then you will need mats made of basalt or kaolin wool and asbestos cord or steel wire. All components of the chimney are wrapped in insulation, which is secured with a cord or wire. To protect the heat-insulating layer from precipitation, a galvanized case is usually put on top, fastened at the joints with rivets or self-tapping screws.

What types of stainless steels are there for chimneys?

Steel itself, as you know, is not the best material for making pipes. Especially intended for such a serious operation as removing smoke from a heating system. Regular (or black) steel is a durable material, but highly susceptible to corrosion.

The problem of rust on steel products was solved when stainless steel began to be used in production. The resistance of this material to corrosion is due to the fact that chromium was added to the alloy of ordinary steel. When interacting with oxygen, a special film with anti-corrosion properties is formed on a surface containing chromium.

There is a classification of stainless steel used to create various products:

- Steel class AISI 430 (as well as AISI 409, AISI 410) will have a chromium content of 11%. This class is not suitable for the production of pipelines, since its use is only possible in low-aggressive environments. The use of steels of such classes is advisable in the manufacture of tableware and interior elements.

- Steel classes AISI 304 or AISI 321 have a chromium element content of about 17%. The alloy will also contain nickel, which provides ductility to the steel. The alloy is widely used in the production of pipes. Such products not only do not become covered with a layer of rust over time, but can also function perfectly at temperatures up to 450 degrees. The use of chimneys from the presented steel classes is possible only under temperature conditions not exceeding this limit.

- Steel class AISI 309. This type is considered a heat-resistant material, the alloy contains at least 25% chromium, and nickel - at least 20%. Chimneys made of such an alloy can be used in higher temperature conditions, as well as in fireplace systems, solid fuel boilers and gas turbine units.

- AISI 316 grade steel. In addition to chromium, stainless steel also contains titanium and molybdenum. Chimneys made from this class of material are optimal for use in any conditions. The maximum temperature for class AISI 316 is 800 degrees, which fully satisfies the requirements of modern heating systems.

- AISI 310S grade steel. The most expensive and heat-resistant material. It is distinguished from other types not only by its absolute resistance to chemical (acid) attack, but also by its ability to withstand temperatures reaching 1000 degrees.

Chimney systems are made only from those types of steel that are heat-resistant

The entire range of steels differs in quality, purpose and, accordingly, cost. Manufacturers offer mainly a chimney made of class 304 stainless steel, which is affordable to most consumers in both price and performance.

The main requirement for smoke exhaust hoses is their wall thickness. This is especially true for gas-fired boilers. The thickness of chimneys for such equipment should be more than 1 mm.

Design options for stainless chimneys

Chimneys can be sold with different configurations and delivery forms. There will be three variations in total:

1. Chimneys made of single-layer material. The simplest mono-structures, made by the factory method from a stainless steel sheet with a thickness of 0.6 mm to 2.0 mm. Normal operation is possible only indoors, but the use of mono-systems without insulation outdoors sharply reduces the performance of not only the channel itself, but also the heating device.

Helpful advice! A single-layer chimney can be an inexpensive solution for secondary heat sources: water heating tanks, external heat exchangers in areas.

2. Corrugated stainless steel structures. Can be used as an independent chimney duct or an auxiliary element for a smooth steel system. Corrugations significantly save the budget when designing chimneys with a large number of curved transitions. However, improperly installed corrugation can lead to depressurization of the hose and fire. Gas inspectors do not recommend using corrugated steel, especially if the duct is installed by a non-professional.

3. Sandwich pipes. They are considered the easiest to install and use. The purchase of elements of this type also solves the issue of thermal insulation of the system. Sandwich chimneys essentially consist of two pipes of different diameters. A product of smaller diameter is placed in a larger pipe, and the space between them is filled with heat-resistant material (usually basalt mineral wool). Chimneys from this category can be located indoors or outdoors.

The most practical chimney option is the sandwich system.

Cost of sandwich systems

The price of such structures depends on many factors, including the selected type of system model, the area for its placement and components.

Before purchasing a sandwich chimney, you should take the required measurements at the installation site and make appropriate markings. The cost of the purchased system depends on the accuracy of such work, so it is necessary to approach this process as responsibly as possible.

When choosing a chimney, the material from which it is made is not the main criterion for evaluating the product. It is important to take into account the technical characteristics of sandwich systems: a high-quality chimney means good draft, ease of use, safety, etc.

The average cost of one pipe ranges from 1,500 to 3,000 rubles. The specific price depends on the following parameters:

- internal section of the product;

- thickness and material of the thermal insulation layer;

- degree of strength of stainless steel pipes;

- presence or absence of coating on system elements;

- module length.

The sandwich system consists not only of straight modules, so you will need to select other components: tees, elbows, adapters and corners. Such elements have a high price, for example, the cost of one product can reach 4,000 rubles.

What parts are needed for a stainless steel chimney pipe?

The choice of components for the chimney duct will depend on the initial drawing. You can choose everything you need from the existing range:

- Straight sections of chimneys. The length of the straight sections, which are the basic part of any smoke duct, can range from 330 mm to 500 mm and 1000 mm. Straight sections of the system are fastened using a simple socket method; they do not require any connecting elements.

- Knees (abductors) with an angle of 45 degrees. Designed to change the angle of inclination of a straight pipe. The area of application of abductor elbows is vertical and inclined (horizontal) sections.

- Bends from 90 degree angles. Versatile part: due to the fact that the design of the right angle abductor elbow consists of four elements, the angle of inclination can be changed from 0 to 90 degrees. They are used mainly when connecting a short horizontal part extending from the boiler (pipe) with the main smoke hose.

- Tees. Available in various configurations: 87 and 45 degrees. They play an important role in chimney maintenance. Using tees, it is possible to clean the system and attach the main channel with a condensate collector. Also used as splitters when connecting two heating sources (the procedure requires the agreement of the relevant authorities).

- Revisions. Just like tees, they make it easier to clean the chimney from internal contaminants. Usually installed under the base of a vertically directed chimney duct under a tee.

- Condensate collectors. Necessary for releasing excess moisture from the vertical smoke shaft. Watering cans are also installed under the tee.

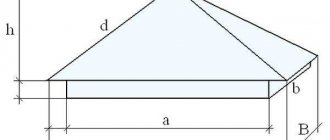

- Protective elements for the upper part. Fungi deflectors, weather vanes, and waterproofing skirts are used as protection against precipitation. Spark arrestors also protect non-heat-resistant roofing from fire.

- Other details. Also during installation, heat-resistant penetrations through the roof, penetrations for walls and interfloor ceilings are used.

Installing modular ducts and sandwich chimneys is a fairly unproblematic undertaking. It is possible to achieve efficient operation of the system even without having any special knowledge in this area. Selecting a chimney and components from a suitable steel grade and compliance with technical standards will make it possible to install a safe and sealed system.

Preparing for self-installation

Installing a chimney with your own hands is not difficult. The main thing here is to ensure the correct connections in the main nodes. During work, you should use a building level to clearly control the accuracy of the vertical position of the system. No less attention should be paid to the distance of channels from elements with flammable properties.

Sequence of work:

- The pipeline is connected to the stove (heating device) with special fittings.

- Pipe sections with fittings must be properly crimped using clamps.

- Attach them to the wall or ceiling surface, depending on the installation method.

- If the horizontal section is too long, then somewhere in the middle you need to install a pipe with an inspection. It is necessary to clean the canal.

- The slope should be maintained in the direction where the drainage device is located near the boiler, so that moisture cannot enter the stove.

- For each linear meter of the pipeline, a slope of 20-30 mm should be maintained.

- Near the junction with the vertical pipe and the chimney passage area, you need to install a tee equipped with a socket. It is needed for soldering to a vertical pipe and draining condensate.

- In passages through floor slabs, you must first install couplings made of fireproof materials. And only then, through them, pass the pipes.

How to pass through the roof