Scope of application

Corrugations have different purposes. Most often they are used to create a cable channel for laying insulated power or low-current wires.

The voltage in such electrical networks can be either alternating or constant. Its maximum value is 1000 V. The material is also used in the installation of telephone and computer networks. Both internal and external. Corrugated PVC pipes are used to create drainage systems. They are called drainage. Their diameter is larger than that of the previous version of the product. Otherwise they are just as comfortable and practical.

In this article we will focus on the pipe options required for installing various cables.

Types of corrugated pipes by material of manufacture

Today, corrugated pipes are available on the market in a variety of materials, each of which is suitable for a particular situation. There are pipes made of PVC, PPR, PPR and stainless steel. Let's look at each in more detail.

PVC (polyvinyl chloride)

Lightweight and flexible material that does not support combustion (but melts well). Products are made in gray or white. The PVC corrugation is intended exclusively for internal laying and protects the wire from mechanical influences. Polyvinyl chloride has self-extinguishing properties, that is, if there is a short circuit on the line or the contact burns out, the corrugation will not burn, but only melt. It can be used for laying in non-combustible places (brickwork or concrete). If you need to lay it over wood, you should additionally use a non-flammable underlay. Cannot be used outdoors, as the sun's rays quickly dry out the plastic and crack.

PPR (polypropylene)

Does not support combustion and is resistant to self-extinguishing. Unlike PVC, it is resistant to ultraviolet radiation and moisture, so it can be used for outdoor installation. Usually made in blue (although AliExpress has all the colors of the rainbow, but its quality is rather questionable).

HDPE (low density polyethylene)

The material is moisture and ultraviolet resistant. HDPE corrugation can be used for outdoor installation or in rooms with high humidity. However, under no circumstances should it be used for laying cables over wooden or other flammable structures, since HDPE burns well. It comes in two colors: black and orange. Unfortunately, some installers use such corrugations for their own convenience in routing power cables - it is convenient to do the routing in different colors. However, this is incorrect, and if the cable breaks down, the corrugation is easily flammable.

Stainless steel

The strongest and most durable material that can be used for installing wiring on flammable and non-flammable structures.

Moreover, if it is necessary to lay a wire on wood, then such an armored sleeve can be used without an additional non-flammable substrate. It perfectly protects against mechanical influences, for example, from rodents. If you need to install wiring under a suspended ceiling on brickwork or concrete, take PVC corrugation - it is inexpensive and easy to install. For wiring over flammable materials such as wood, it is better to take an armored sleeve made of stainless steel or PVC and PPR, but with an additional backing. For outdoor installation, we recommend using a corrugated HDPE tube in black or orange, or using polypropylene products.

Key Features

Flexible corrugated pipes made of self-extinguishing lightweight PVC plastic have outstanding performance characteristics. They have the following features:

- the resulting flame does not spread, it dies out immediately after the ignition source is eliminated;

- characterized by high moisture resistance;

- over time they do not age and do not lose their properties;

- mounted in the temperature range from -5 to +60 degrees;

- It is allowed to operate the products in temperatures ranging from -20 to +80 degrees.

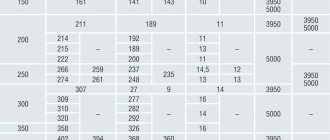

The characteristics of the pipes are good. The products have high resistance to compression. The value of this indicator in the light type exceeds 320N/5cm. Products of the heavy and super-heavy series are characterized by compression resistance at the level of 750N/5cm and 1250N/5cm.

Product color varies. The products are mainly produced in gray color. The level of protection corresponds to IP55. The products have high dielectric strength. This indicator is minimally equal to 2000 V at a current frequency of 50 Hz. The duration of exposure to electric current can be fifteen minutes. The products also have excellent insulation resistance.

Sometimes a rigid, smooth pipe made of self-extinguishing PVC plastic is used for laying electrical networks. It can be used in dry conditions. The product is also suitable for use in buildings with high humidity and outside structures. The product is used for laying straight cable ducts. In terms of flexibility, it is inferior to the corrugated version.

Self-extinguishing corrugated pipe

Did you like the video? Subscribe to our channel!

Despite the fact that self-extinguishing corrugated pipes have been on sale in hardware stores for quite some time, many builders continue to work the old fashioned way, using a metallized sleeve to lay telecommunications and network cables for protection from mechanical damage and as an additional insulating layer. By directly laying cables in hollow walls, the fire safety of construction sites is neglected.

When carrying out reconstruction or laying new cable systems, take advantage of new developments and technologies. One of these modern developments by manufacturers of insulating equipment is a self-extinguishing corrugated pipe.

Self-extinguishing corrugated pipe has a lot of advantages, and most importantly, it prevents fires resulting from cable damage and short circuits, as well as spontaneous combustion. The material used in these pipes has non-flammable properties and prevents the spread of flame.

Various types of corrugated pipes

At the moment, there are several types of corrugated pipes used for laying cable routes in them:

- Pipes made of self-extinguishing polyvinyl chloride (PVC) plastic. These pipes have a corrugated surface, are flexible, and are not subject to combustion. Can be used for laying cables indoors at industrial, administrative and residential facilities.

- Pipes made of low pressure polyethylene (HDPE). Most often they are used for drawing networks in them, both low-current and power, and for installation in a hidden way inside concrete floors or pouring into concrete during monolithic construction, as well as outside premises.

Having decided on the choice of pipe type, according to the purpose of its application, pay special attention to the outer and inner diameter of the pipes, which directly depends on the place of application of the product. For example, a corrugated self-extinguishing gray PVC pipe (RAL 7035) with an outer diameter of 25 millimeters has a permissible inner diameter of 20 millimeters.

Therefore, when choosing a cable laying system, it is necessary to calculate the number of cables, specify their outer diameter, and only then select a corrugated pipe (Fig. 1). In this case, it is necessary that the free space inside is at least 30%.

Corrugated self-extinguishing PVC pipe is supplied in cassettes (coils), with a technical passport, which indicates the marking, product name, length, diameter, GOST according to which the product is manufactured, and other characteristics (Fig. 2). Coil lengths can be 15, 20, 25, 50 and 100 meters, which depend on the outer diameter of the pipe itself.

Design features

The unique structure of the pipe allows it to withstand mechanical loads of up to 35 kg per 5 cm/p (light pipes) and up to 75 kg per 5 cm/p (heavy pipes). The inner surface of the pipe is a smooth plastic channel intended for laying cables. In addition, all types of pipes have a steel cable (pulling), which allows for quick installation and cable connections in the pipe system.

Its undeniable advantage is such properties as resistance to moisture, resistance to chemical and climatic oxidizers, allowing the pipe to be used in rooms with high humidity and for outdoor use. In addition, corrugated PVC pipes have the ability to maintain operating parameters regardless of temperature changes. For example, light pipes can be operated in the temperature range from minus 25°C to plus 60°C, and heavy ones - from minus 25°C to plus 50°C.

And, of course, the pipe has high tensile strength. For example, the strength of light fraction PVC is over 320 newtons per 5 5 cm. p., and the heavy one has a strength of 750 newtons per 5 cm. P.

From all of the above, we can conclude that flexibility, elasticity and simplicity of design make it easy to install corrugated hoses even in hard-to-reach places. Product quality, durability, high degree of protection of PVC and HDPE pipes will guarantee the safety of your apartment, office, and industrial premises.

Diameter selection

There are certain criteria according to which the diameter of the product is selected. To select products, use the following information:

- For cables supplying lighting devices, use products measuring sixteen millimeters.

- Wires to switches and sockets are carried out in pipes with a diameter of twenty millimeters.

- If you need to connect distribution boxes in several rooms, you need products measuring twenty-five millimeters or larger. For this purpose, it is advisable to use a reserve pipe.

- Electrical panels are connected to each other by wires located in the product measuring at least thirty-two millimeters. It is recommended to use an additional reserve pipe.

- To connect wiring between different floors of a building, it is necessary to lay the cable in a material measuring from forty to fifty millimeters.

- If the task is to lay a telephone or coaxial network, use products with a size of sixteen to twenty millimeters.

Features of operation

Laying corrugated pipes is easy. Even an inexperienced master can handle it. The key purpose of the products in question is hidden wiring. However, it is also possible to install products in an open way. For hidden installation, it is necessary to create grooves in the walls. The problem is solved exclusively using non-combustible materials.

The open installation option is mainly done inside buildings. Certain materials are used as the basis for corrugation. They must be non-flammable or, at a minimum, difficult to burn. PVC is sensitive to ultraviolet radiation. Please take this into account when installing products.

If strict requirements are imposed on the strength of the cable channel, use heavy and extra-heavy versions of the products. Use them if the wires are installed under a layer of concrete or mortar.

PVC products serve as additional insulation for electrical networks. The use of these products does not allow electric shock if the insulating layer of the wires is damaged. The corrugation also reliably protects the cable from physical influences. Laying wires in pipes will ensure continuity of their operation and safety.

Flexible corrugated pipes made of self-extinguishing PVC plastic compound

Any room containing electrical wires is classified as a fire hazard. A number of measures are being taken to reduce the risk of fire. Wire protector is one of them. For these purposes, a flexible corrugated pipe made of self-extinguishing PVC plastic is used. Excellent performance properties and compliance with fire safety requirements are the key properties of such a product.

PVC corrugated pipe made of self-extinguishing PVC is characterized not only by high combustion resistance, but also by practicality. It is easy to install and transport. The light weight of the coil ensures ease of manual loading. In addition, a corrugated pipe made of self-extinguishing PVC does not deform at high temperatures, continuing to perform its main function, is resistant to high humidity and has a long service life.

How do flexible light corrugated pipes made of self-extinguishing PVC get their properties? The thing is that polyvinyl chloride itself is poorly flammable. To improve these properties, at the production stage, special additives are added to the mixture, which modulate the properties of the finished product.

In addition, with the help of other additives, a corrugated pipe made of self-extinguishing PVC plastic compound is supplied with other properties. For example, the fragility of the material decreases, its resistance to ultraviolet radiation increases, etc. To improve the quality of the final product, such additives can be combined.

Flexible corrugated pipes made of self-extinguishing PVC: application

The type of pipe used completely depends on the network section, the features of the room and the fire safety requirements of a particular facility. Thus, a pipe made of self-extinguishing PVC plastic with a diameter of 16 mm is best suited for protecting the cable going to a switch or socket for hidden or open installation in a residential or administrative building.

In general, the entire variety of such products is used for hidden, outdoor installation indoors and outdoors. In addition, self-extinguishing corrugated pipe with thick walls is also used for constructing underground pipelines. However, what is most important in this type of product is the high degree of fire safety, ease of installation, low price of corrugated pipes and excellent insulating properties.

Self-extinguishing PVC pipe is a universal electrical installation material with excellent performance properties. The variety of configurations and types of such products provides a wide range of effective applications.

Installation rules

Laying wires in polyvinyl chloride products has its own characteristics. When performing installation, consider:

- Installation involves pulling the cable. To do this, a steel cable is placed inside the pipes.

- For installation with broaching, the corrugation is mounted in the walls.

- To stretch the wire, a cable is attached to one of its ends. Then he is pulled. Along with it, a wire is pulled into the cable channel.

- Corrugation is cut using various cutting tools. PVC scissors are best suited for this purpose.

Using the pulling method reduces the cost of installing wires by three times. Corrugation is sold in coils. The length of products in one package ranges from twenty-five to one hundred meters. There are no special rules for transporting products.

When purchasing products, pay attention to compliance with GOSTs. The price of high-quality corrugation is higher. We do not recommend purchasing products from dubious manufacturers. Its performance characteristics may be much lower than stated. Since the use of corrugation in laying electrical networks ensures safety, you should not purchase cheap, low-quality options. Such savings can be fatal.

Watch the video: