CPVC pipes began to be produced about 50 years ago. In those years it was used in the aerospace industry. Not so long ago, products for the production of which chlorinated polyvinyl chloride is used have become in demand for laying water pipelines. It is important to note that they are suitable for cold and hot water supply. In Russia, similar products from polyvinyl chloride began to be manufactured only in 2008. What types are there and where they are used - in this article.

Products made from chlorinated polyvinyl chloride.

Distinctive features of CPVC pipes

Common PVC pipes are allowed to be used in systems with temperatures no higher than 55 ℃, and CPVC pipes for heating can function properly in temperature conditions up to 95 ℃.

In addition, CPVC pipes have a considerable list of additional advantages, which are discussed below.

Initially, such pipes were created for self-installation, since it would be easy for any craftsman to learn how to properly connect all the elements of such a system within five minutes.

To install CPVC pipes, you do not need to use any welding equipment or other special tools. A simple water supply system can be built in as little as 3 hours, but a complex system can take up to two days, so sometimes it may be better to seek professional help. If installed correctly, the system will look very aesthetically pleasing, so it will not need to be painted.

It is worth noting that all parts of the system are connected using cold welding. The solvent in this case is glue, after application of which, and after joining the elements, a single structure is obtained.

Features of installation of CPVC pipeline

*

Manufacturers initially, even in the advertising video, presented that such communications could be assembled independently. If we consider the practical side, the work looks like this.

Angles - necessary elements of the pipeline

Pre-assembly

First you need to stock up on the CPVC products themselves and the corresponding fittings. Pipes are selected according to footage, and fittings are selected depending on the number of joints and corner joints.

The next stage is marking the supporting surfaces for the future pipeline. Every 25 - 50 cm it is necessary to make fasteners.

Next, the pipes are cut to the required sizes. If necessary, various fittings are purchased: angles, tees and other branching and shut-off valves.

The products themselves are cut with a special pipe cutter or a regular hacksaw for metal.

Assembling joints

The assembly procedure is carried out using special CPVC glue. To do this, the inside of the fitting and the outside of the pipe are lubricated with glue. There is no need to wait, the product is immediately inserted into the fitting, after which it needs to be turned along the axis. This is required to distribute the adhesive composition over the entire surface of the pipe.

After 20 seconds, the procedure is repeated, only now with the other side of the fitting. During this time, the glue seam has time to dry. As you can see, even a housewife can do the job.

The only thing that may be difficult is that you need to choose the right glue that is suitable for a specific pipe. It is better if all products belong to one brand. In fact, the glue is the same CPVC, only melted in a solvent.

Note! Before you start gluing, the products need to be freed from debris and burrs, for which the end is processed with a file. If you neglect this issue, then any burr can cause depressurization of the joint.

Finishing work

The laying and assembly of communications is considered complete after the final quality check. For this purpose, the system is connected to the valve and water is turned on. If it works properly, leaks will not occur.

CPVC products in fire extinguishing system

Conclusion

Modern construction is dominated by monolithic housing construction, prefabricated and affordable housing, built using simple but reliable technologies. These must be accessible systems that at the same time comply with modern safety requirements. One such solution was discussed in the article - communications made of chlorinated polyvinyl chloride. On the Russian market, among the entire list of plastics, this material is distinguished by its ease of installation, design and high strength. Meanwhile, fire safety authorities continue to increase the requirements for the materials used and CPVC fully complies with them.

What are they made from?

The material from which CPVC pipes are made is not susceptible to exposure to aggressive chemicals. Through such pipes it is possible to transmit not only ordinary water, but also sulfuric, phosphoric, nitric and hydrochloric acids, as well as oils, soap, petroleum, mercury, and fats. In factories they can be used to transport milk, beer and wine. It is also important to note that the pipes do not affect the color, taste and smell of the substance transmitted through them.

If pipes are laid underground, then during operation they will not be affected by microelements present in the soil.

PVC chloride prevents the growth of bacteria. Often, water is supplied to an apartment that has a bad smell, taste, and sediment. This happens because water is supplied to your home through a dirty pipeline. Microorganisms may be present in such pipelines, and if, in addition, the system is very old, then it simply stagnates there. In PVC and CPVC pipes, such problems are almost one hundred percent absent.

The material is difficult to ignite - pipes and fittings made from it ignite only when the temperature reaches 433 ℃. In this case, fire is possible only with a direct source of fire, but if the pipes are removed from the fire, they immediately go out.

Polyvinyl chloride has low thermal expansion rates. However, it is a good idea to allow for some possibility of expansion when designing and installing a finished piping system.

It is worth considering that to prevent the occurrence of internal stresses, it is recommended to use movable or fixed holders.

PVC and CPVC pipes are not afraid of ultraviolet radiation, unlike any other plastic types of pipes. This makes it possible to use them in open and closed pipeline systems.

The highest technical characteristics of CPVC pipes give them high quality and long service life.

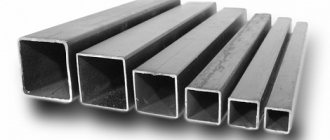

Types of pipes made of chlorinated polyvinyl chloride

Today there are three classes of these products for pressure resistance:

- PN10;

- PN16;

- PN25.

In addition, products made from chlorinated polyvinyl chloride are divided into two main groups.

You can understand what class the pipe belongs to and what its technical parameters are by the markings on the outside

The first group includes devices that are used when laying various communications in unfavorable conditions (at low temperatures). The main operational areas of products belonging to the first group:

- in refrigerators;

- in communications that provide air conditioning of premises.

The maximum operating temperature for the first group reaches +95 °C, however, experts do not recommend using such products at temperatures above +80 °C.

The second group includes parts whose maximum operating temperature reaches 100 °C. Such products are considered universal and are used for installation of internal as well as external pipeline structures.

Helpful information! The second group of pipes made of chlorinated polyvinyl chloride is highly resistant to mechanical stress, which significantly expands its operational range.

Rules for the use of CPVC pipes

Pipe installation is carried out using the gluing method. The method is based on the effect of chemical diffusion, in which the molecules of two surfaces mix with each other, thereby forming a common structure and, as a result, a homogeneous monolithic compound.

This method has several features:

- ease of installation - work is possible even in the most inaccessible places;

- low financial and time costs;

- low labor costs;

- There is no need for electricity costs, since there is no need to use welding equipment.

System reliability is achieved thanks to:

- precise alignment;

- absence of sagging, which is typical for welded joints, and which can reduce the hydraulics of the finished system.

How to install CPVC pipes

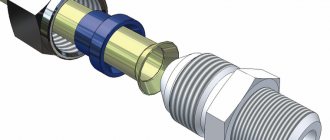

All parts of the CPVC line are connected in three ways:

- Using the cold welding method, which is based on the effect of diffusion of atoms, the process of their mutual penetration. The glue, in this case, acts as a solvent. When it is applied, the surface atoms of the two elements are mixed, forming a monolithic, homogeneous structure. In this case, no sagging is formed, which often occurs when using hot welding, and does not create obstacles to the movement of the working medium.

- By threaded connection method using couplings with threads and a seal.

- Using flanges.

During installation, you do not need to use additional tools, which is extremely popular with home craftsmen, since it does not require physical or economic costs.

Fire safety features

When handling plastic materials that will be used in engineering systems, a certain list of fire safety rules must be observed.

Many currently existing plastics are highly flammable. This may produce hot droplets, which further increase their fire hazard.

CPVC material has fire-fighting characteristics, since it is based on no more than 30% hydrocarbons, with 70% allocated to an inorganic compound - table salt.

This ratio gives the material such useful properties as:

- the material turns out to be self-extinguishing (thanks to the oxygen index of 60 units);

- minimal smoke formation;

- low toxicity during combustion.

Specifications

| Properties | Meaning | Standard |

| Density | 1.5 g/cm³ | EN ISO 1183-1 |

| Yield strength at 23 °C | 53 N/mm² | EN ISO 527-1 |

| Modulus of flexibility at 23°C | 2550 N/mm² | EN ISO 527-1 |

| Charpy impact strength at 23 °C | 6 kJ/m² | EN ISO 179-1/1 eA |

| Ball indentation hardness (358N) | 110 MPa | EN ISO 2039-1 |

| Thermal deformation temperature HDTA1.80 MPa | 102 °C | EN ISO 75-2 |

| Thermal expansion coefficient | 0.06…0.07 mm/m K | DIN 53752 |

| Thermal conductivity at 23 °C | 0.15 W/m K | EN 12664 |

| Water absorption at 23°C/24h | 0,1% | EN ISO 62 |

| Color | RAL 7038 agate gray | |

| Limiting Oxygen Index (LOI) | 60% | ISO 4589-1 |

Some examples of using CPVC pipes

Such pipes are widely used throughout the world. Heating and water supply systems are installed in the USA, Africa, Asia, the Republic of India, as well as in the Middle East.

More than half of the CPVC water supply pipe market is in the United States. This popularity is justified due to the fact that the material has excellent fire-fighting properties. Pipes are used not only in standard and mass construction.

CPVC has been used to create special unique objects such as:

- Disneyland in Hong Kong;

- Beijing Airport;

- Madame Tussauds and the Royal Opera House in Covent Garden (London);

- A large list of objects of the 2008 Olympics and many others.

In this material we learned what it is - a CPVC pipe. In conclusion, it is worth saying that this is a unique and inexpensive material that is ideal for creating heating and plumbing systems, not only due to its quality and durability, but also due to its ease of installation, aesthetics and excellent fire-fighting properties.

Application

Pipes made from this material are widely used throughout the world today. They are often used for the construction of heating and water supply systems. CPVC structures are used not only in standard mass construction, but also in the construction of unique objects according to individual drawings.

These pipes are also highly resistant to the negative effects of chemicals. They can transport not only water, but also some acids. For example, such as sulfuric, nitrogenous, phosphoric and hydrochloric. Transportation of oil, soap, mercury, petroleum, fat, milk, beer, wine is allowed. The most important thing for food products is that when moving through such pipes, they do not change taste, color or smell. At the same time, if you lay CPVC structures underground, they will not be exposed to harmful microelements that may be in the soil.

Installation of CPVC pipes can be carried out without additional protection from sunlight. The fact is that this material contains titanium dioxide, which is an additive widely used specifically for ultraviolet protection. Thanks to this, the service life of CPVC structures does not decrease when installed in open sunlight. This distinguishes them very favorably from other types of polymer pipes.