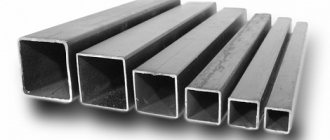

A stainless steel square pipe is a product that is actively used not only in various fields of industry, but also in everyday life. Such pipes, which belong to the profile category, can be produced using different methods and, therefore, meet the requirements of various regulatory documents (GOSTs).

Durability, lightness and easy installation - properties of stainless steel that do not need advertising

Areas of application

Where is profiled stainless steel used:

- Mechanical engineering and shipbuilding - mufflers for vehicles, hydraulic cylinders, outlet pipes of gas turbines and motors, parts of various shafts and valves, accessories for automobiles

- Furniture production - legs, stands and frames of furniture.

- Construction - supports, posts, truss columns, chimneys, stairs and stair railings, frames for cornices and awnings.

- Food industry - processing plants (especially for chocolate, mayonnaise), grills, oven heat exchangers.

- Production of commercial equipment - shelving, equipment for bars, restaurants.

- Chemical and oil refining industries - installations for the production of alkalis, acids, ring collectors.

- Department of Housing and Utilities.

- Medicine - manufacturing of equipment, various implants.

Technical characteristics and properties

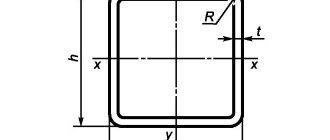

Parameters of stainless steel profile pipe:

- Type of rolled pipe profile.

- Geometric dimensions of width, height and length of a segment.

- Wall thickness.

- Weight of 1 linear meter.

- Steel grade and its characteristics.

For the production of profile stainless steel products, the grade of austenitic steel AISI 304 (Russian analogue 08Х18ХН10) is mainly used. This is an acid-resistant material, not subject to corrosion, and can withstand short-term temperatures up to +900 °C. The metal density is 7.9–7.93 g/cm2, the elastic modulus is 193–200 GPa, and the shear modulus is 86 GPa.

Life time

Stainless steel profile metal can be used for at least 50 years without losing its original properties.

Design Features

The main design feature of a stainless steel profile pipe is the shape of the profile. A number of technical characteristics of profiled pipe products depend on the cross-section configuration.

Available Sizes

10x10x0.810x10x0.910x10x110x10x1.210x10x1.415x15x0.815x15x0.915x15x115x15x1.215x15x1.415x15x1.520x20x0.820x20x0.920x20x120x 20x1.220x20x1.420x20x1.520x20x225x25x0.825x25x0.925x25x125x25x1.225x25x1.425x25x1.525x25x225x25x2.525x25x330x30x0.830x30x0.93 0x30x130x30x1.230x30x1.330x30x1. 430x30x1.530x30x230x30x2.530x30x330x30x3.530x30x432x32x435x35x0.835x35x0.935x35x1.435x35x1.535x35x235x35x2.535x35x335x35x3. 535x35x435x35x536x36x440x40x1.440x40x1.540x40x240x40x2.540x40x340x40x3.540x40x440x40x540x40x642x42x342x42x3.542x42x442x42x542 x42x645x45x245x45x345x45x3.545x45x445x45x545x45x645x45x745x45x850x50x250x50x2.550x50x350x50x3.550x50x450x50x4.550x50x550x50x6 50x50x750x50x855x55x360x60x260x60x2.560x60x360x60x3.560x60x460x60x560x60x660x60x760x60x865x65x670x70x370x70x3.570x70x470x70x5 70x70x670x70x770x70x880x80x380x80x3.580x80x480x80x580x80x680x80x780x80x880x80x980x80x1080x80x1190x90x390x90x490x90x590x90x690 x90x790x90x8100x100x3100x100x4100x100x5100x100x6100x100x7100x100x8100x100x9110x110x6110x110x7110x110x8110x110x9120x120x6120x1 20x7120x120x8120x120x9140x140x6140x140x7140x140x8140x140x9150x150x7150x150x8150x150x9150x150x10180x180x8180x180x9180x180x1018 0x180x12180x180x14

How are they produced?

Profile pipes are made from stainless steel using two technologies:

The finished product is formed from a blank in the form of a metal strip (strip). A round pipe is profiled.

Strip manufacturing technology

The method makes it possible to obtain a profile pipe made of stainless steel with a seam. Welding of sheet steel strips is carried out using high-frequency electric welding, laser or plasma welding in a conventional environment, as well as tungsten electrodes in inert gas (TIG welding). The production process itself is as follows:

- The strip is cut from stainless steel sheets on special rolling mills and fed into a sheet bending mill.

- The metal strip is formed on the rollers of a sheet bending mill into a round blank with open edges.

- The edges are welded using one of the selected types of welding. Excess metal (grant) is removed with cutters.

- The workpiece is calibrated on rollers to a given profile shape.

- The finished product is cut into pieces of the required length.

To relieve internal stress, the stainless steel profile pipe is subjected to heat treatment (annealing). The workpiece is heated to +550…650 °C for 60–90 minutes, followed by gradual cooling (tempering). As a result, it becomes stronger and more durable.

Main types

Profile pipes for which stainless steel is used, as indicated by GOST, can be produced using different technologies. Depending on this, they are divided into the following types:

- welded, obtained from rolled sheets;

- made from round pipes using hot-rolled technology;

- made using cold rolled technology.

GOST strictly stipulates the maximum deviations of the geometric parameters of profiled stainless steel pipes, which, in particular, include:

- right angles forming the profile (the deviation in this parameter cannot exceed 1.5° in any direction);

- curvature measured on a surface segment of 1 meter (no more than 2 mm).

In the assortment of stainless steel profile pipes you can find a product of a suitable shape and size

The modern market offers a wide variety of types of profile pipes made of stainless steel. It is worth dwelling in more detail on the characteristics of the most popular and sought-after types of such products.

Profiling

This technology for the production of profile stainless pipes involves the use of seamless cold- and heat-deformed pipes of round cross-section as initial blanks. They acquire the desired profile shape when passing through calibrating rollers in a cold or heated state.

Next, the cold-deformed profile pipe is subjected to heat treatment. At the last stage, the rolled metal is cut into pieces and undergoes surface quality control, tensile tests, and geometric dimensions testing.

Regulations

Technical production conditions, chemical composition of raw materials, geometric parameters for each cross-sectional shape of profile stainless steel pipes are regulated by several regulatory documents (GOSTs).

Standards and GOSTs

Russian manufacturers producing profile pipe products made of corrosion-resistant steel, depending on the technology used, use the following standards:

- GOST 11068-81 - for electric-welded pipe products.

- GOST 9940-81 - for seamless pipes manufactured using the profiling method.

- The range and standard sizes of profiled stainless steel pipes are established by the following regulatory documents:

- GOST 8639-82 - for square profile.

- GOST 8645-68, GOST 8645-78, GOST 8645-86 - rectangular section.

- GOST 8642-68 - for oval pipes.

GOST standards and types of rolled metal products

The production method in this case depends on the requirements of GOST. For example:

- GOST 9941 81 defines the production method that results in stainless steel electric-welded pipes.

A narrow ribbon is created from the raw material, and it is wound onto a drum shaft. In it, the future pipe blank is bent into a cylinder. Its extreme parts are welded using one of the welding methods.

This can be an electric arc, an electron beam, the use of high-frequency points, plasma or laser. The “bundles” option in the manufacture of electric-welded stainless pipes is not used very often, as it is quite expensive, because all technical processes are performed in a vacuum.

Electric-welded metal products are used for the manufacture of pipelines and various structures.

The length of electric-welded pipes is as follows: measured length - from 5 to 9 meters; unmeasured length - from 1.5 to 9 m. The limit deviation in the length of types of short and measured lengths cannot exceed +15 mm.

The specified regulatory document applies to types of electric-welded pipe assortment with wall dimensions from 0.7 to 5 mm.

- Seamless stainless steel pipes are also produced in accordance with GOST.

The raw material base for a seamless product is round blanks obtained by casting or pressing. Production according to the standards includes a couple of stages of “running” through rollers. In them, the pipe receives the required dimensions and volume. Next, the seamless products are calibrated and cut into pieces of the required size.

The following types are determined by temperature conditions: cold-deformed; heat deformed; hot-deformed. The first two types of seamless pipe materials are standardized by document - 9941 81.

These are options with an external volume from 0.6 to 27.4 cm, and wall dimensions from 0.3 to 21 mm. For the last type of seamless options, other standards are used, these are 9940 81. Such standards provide for volumes from 58 to 326 mm and wall thicknesses from 3.6 to 31 mm.

IMPORTANT! In practice, the production of stainless steel pipe products is not always limited by standards. By agreement with the client, products can be manufactured with other volume and wall dimensions.

Types, assortment: sizes and sections

There are different types of stainless steel profile pipes depending on the cross-sectional shape. She may be:

- Oval.

- Rectangular.

- Square.

- Flat oval.

- Drop-shaped.

- With hollow ribs.

Stainless steel pipes and other profile configurations are also produced: in the form of a trapezoid, rhombus, parallelogram, triangle, hexagon, etc. But they are mainly produced by foreign companies according to European or American standards.

The classification of profile pipes by type of surface treatment is as follows:

- Polished.

- Matte.

- Polished to a mirror finish.

Square

Square profiles are highly durable and reliable. Their advantage is the presence of four stiffening ribs, which increase resistance to bending loads. The production of pipes with a square profile and their assortment is regulated by GOST 8639-92, according to which the external dimensions of the edges range from 10 × 10 mm to 180 × 180 mm. The minimum wall thickness is 0.8 mm, the maximum is 14 mm. The length of the products can be:

- Unmeasured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed and electric-welded - from 1.5 to 11 m.

- Measured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed - 4.5–11 m, electric welded - from 5 to 9 m.

- Multiple measured. With an allowance for each cut of 5 mm.

Rectangular

Stainless steel pipes with rectangular profiles can withstand high loads, the same in magnitude as solid products. In addition, it is convenient for installation, transportation and storage. It is used in the construction industry and mechanical engineering for the manufacture of frame metal structures and support posts.

Regulatory documents provide for the possibility of producing stainless rectangular pipes with non-standard dimensions, for example, an extended range of wall thickness from 0.8 to 20 mm and edge sizes from 28 × 25 mm to 230 × 100 mm.

The length of the segments according to GOST 11068-81 is:

- Measured (5–9 m).

- Unmeasured (1.5–9 m).

- Multiple measurements (no more than 9 m with an allowance of 5 mm for each cut).

Matte

Profile pipes with a matte outer surface are used as structural elements, the decorative appearance of which does not require high requirements. For example, for installation:

- Production shelving.

- Work sites.

- Support structures, etc.

Sanded

Polished stainless steel profile pipes combine aesthetic appearance with high strength, wear resistance and durability. They have no planar or structural flaws; they are in demand in areas where impeccable smoothness of surfaces is required.

To process stainless steel profiles, 2 technologies are used:

- Electrochemical. The workpiece is immersed in a solution of concentrated acid. If the outer surface is polished, then the product is then surrounded by round electrodes. To treat the internal surface, the electrode is inserted into the cavity of the pipe. Electric current is then applied to them.

- Abrasive. For primary processing, coarse abrasives with a grain size of 180–320 microns are used; a polished surface is obtained by using abrasive materials with a finer grain size. For final polishing, felt sanding belts are used.

Stainless steel pipes with a polished surface are endowed with decorative qualities, therefore they are used for interior decoration, the manufacture of cabinet furniture elements, fences, and railings.

Differences between square profile pipes

A stainless steel profile pipe with a square cross-section combines the characteristics of temperature and chemical resistance, resistance to torsion and bending, and durability without significant corrosion. The products are easy to process and install, and their cost compares favorably with conventional round products.

Matte stainless steel pipe Mirror stainless steel pipe Polished stainless steel pipe

Download price: Square pipes

| Name | Price RUR/m |

| Stainless steel pipes ESV ESV square 10×1 imp polished AISI 201 | 47 |

| Stainless steel pipes ESV ESV square 10×1.5 imp polished AISI 201 | 72 |

| Stainless steel pipes ESV ESV square 10×1.5 imp polished AISI 304 (08Х18Н10) | 108 |

| Stainless steel pipes ESV ESV square 15×1 imp polished AISI 304 | 130 |

| Stainless steel pipes ESV ESV square 15×1 imp polished AISI 304 (08Х18Н10) | 147 |

| Stainless steel pipes ESV ESV square 15×1.5 imp polished AISI 304 (08Х18Н10) | 174 |

| Stainless steel pipes ESV ESV square 20×1 imp polished AISI 201 | 102 |

| Stainless steel pipes ESV ESV square 20×1 imp polished AISI 304 (08Х18Н10) | 128 |

| Stainless steel pipes ESV ESV square 20×1 imp polished AISI 430 | 111 |

| Stainless steel pipes ESV ESV square 20×1.2 ground AISI 304 (08Х18Н10) | 187 |

| Stainless steel pipes ESV ESV square 20×1.2 imp polished AISI 201 | 117 |

| Stainless steel pipes ESV ESV square 20×1.2 imp polished AISI 304 (08Х18Н10) | 176 |

| Stainless steel pipes ESV ESV square 20×1.2 imp polished AISI 430 | 133 |

| Stainless steel pipes ESV ESV square 20×1.2 imp. grind (240) AISI 430 | 133 |

| Stainless steel pipes ESV ESV square 20×1.5 imp mirror AISI 201 | 157 |

| Stainless steel pipes ESV ESV square 20×1.5 imp mirror AISI 304 (08Х18Н10) | 230 |

| Stainless steel pipes ESV ESV square 20×1.5 imp mat AISI 304 (08Х18Н10) | 227 |

| Stainless steel pipes ESV ESV square 20×1.5 imp polished AISI 201 | 156 |

| Stainless steel pipes ESV ESV square 20×1.5 imp polished AISI 304 (08Х18Н10) | 240 |

| Stainless steel pipes ESV ESV square 20×1.5 imp polished AISI 430 | 162 |

| Stainless steel pipes ESV ESV square 20×1.5 imp grind (240) AISI 201 | 156 |

| Stainless steel pipes ESV ESV square 20×2 imp polished AISI 201 | 210 |

| Stainless steel pipes ESV ESV square 20×2 imp polished AISI 304 (08Х18Н10) | 306 |

| Stainless steel pipes ESV ESV square 25×1 matte AISI 304 (08Х18Н10) | 153 |

| Stainless steel pipes ESV ESV square 25×1 imp polished AISI 201 | 147 |

| Stainless steel pipes ESV ESV square 25×1 imp polished AISI 304 (08Х18Н10) | 204 |

| Stainless steel pipes ESV ESV square 25×1 imp polished AISI 430 | 163 |

| Stainless steel pipes ESV ESV square 25×1.2 imp polished AISI 201 | 169 |

| Stainless steel pipes ESV ESV square 25×1.2 imp polished AISI 304 (08Х18Н10) | 226 |

| Stainless steel pipes ESV ESV square 25×1.2 imp polished AISI 430 | 188 |

| Stainless steel pipes ESV ESV square 25×1.5 ground AISI 201 | 179 |

| Stainless steel pipes ESV ESV square 25×1.5 imp mirror AISI 304 (08Х18Н10) | 275 |

| Stainless steel pipes ESV ESV square 25×1.5 imp mirror AISI 201 | 179 |

| Stainless steel pipes ESV ESV square 25×1.5 imp matte AISI 304 (08Х18Н10) | 282 |

| Stainless steel pipes ESV ESV square 25×1.5 imp polished AISI 201 | 179 |

| Stainless steel pipes ESV ESV square 25×1.5 imp polished AISI 304 (08Х18Н10) | 298 |

| Stainless steel pipes ESV ESV square 25×1.5 imp polished AISI 430 | 220 |

| Stainless steel pipes ESV ESV square 25×1.5 imp grind (240) AISI 201 | 179 |

| Stainless steel pipes ESV ESV square 25×1.5 imp. grind (240) AISI 304 (08Х18Н10) | 275 |

| Stainless steel pipes ESV ESV square 25×2 matte AISI 304 (08Х18Н10) | 393 |

| Stainless steel pipes ESV ESV square 25×2 imp mirror AISI 304 (08Х18Н10) | 398 |

| Stainless steel pipes ESV ESV square 25×2 imp mirror AISI 201 | 237 |

| Stainless steel pipes ESV ESV square 25×2 imp matte AISI 304 (08Х18Н10) | 362 |

| Stainless steel pipes ESV ESV square 25×2 imp polished AISI 304 (08Х18Н10) | 360 |

| Stainless steel pipes ESV ESV square 25×2 imp. grind (240) AISI 304 (08Х18Н10) | 360 |

| Stainless steel pipes ESV ESV square 25×2 imp. AISI 201 | 237 |

| Stainless steel pipes ESV ESV square 30×1 section AISI 304 (08Х18Н10) | 193 |

| Stainless steel pipes ESV ESV square 30×1 imp mirror AISI 201 | 167 |

| Stainless steel pipes ESV ESV square 30×1 imp polished AISI 201 | 167 |

| Stainless steel pipes ESV ESV square 30×1 imp polished AISI 304 (08Х18Н10) | 224 |

| Stainless steel pipes ESV ESV square 30×1 imp polished AISI 430 | 162 |

| Stainless steel pipes ESV ESV square 30×1 imp. grind (240) AISI 201 | 167 |

| Stainless steel pipes ESV ESV square 30×1.2 matte AISI 304 (08Х18Н10) | 308 |

| Stainless steel pipes ESV ESV square 30×1.2 ground AISI 201 | 197 |

| Stainless steel pipes ESV ESV square 30×1.2 imp mirror AISI 304 (08Х18Н10) | 270 |

| Stainless steel pipes ESV ESV square 30×1.2 imp mat AISI 304 (08Х18Н10) | 267 |

| Stainless steel pipes ESV ESV square 30×1.2 imp polished AISI 201 | 195 |

| Stainless steel pipes ESV ESV square 30×1.2 imp polished AISI 304 (08Х18Н10) | 267 |

| Stainless steel pipes ESV ESV square 30×1.2 imp polished AISI 430 | 200 |

| Stainless steel pipes ESV ESV square 30×1.5 matteAISI 304 (08Х18Н10) | 356 |

| Stainless steel pipes ESV ESV square 30×1.5 imp mirror AISI 304 (08Х18Н10) | 341 |

| Stainless steel pipes ESV ESV square 30×1.5 imp mirror AISI 201 | 211 |

| Stainless steel pipes ESV ESV square 30×1.5 imp matte AISI 304 (08Х18Н10) | 341 |

| Stainless steel pipes ESV ESV square 30×1.5 imp polished AISI 201 | 217 |

| Stainless steel pipes ESV ESV square 30×1.5 imp polished AISI 304 (08Х18Н10) | 341 |

| Stainless steel pipes ESV ESV square 30×1.5 imp polished AISI 430 | 237 |

| Stainless steel pipes ESV ESV square 30×1.5 imp. grind (240) AISI 201 | 217 |

| Stainless steel pipes ESV ESV square 30×2 matte AISI 304 (08Х18Н10) | 556 |

| Stainless steel pipes ESV ESV square 30×2 imp polished AISI 304 (08Х18Н10) | 437 |

| Stainless steel pipes ESV ESV square 40×1 section AISI 304 (08Х18Н10) | 331 |

| Stainless steel pipes ESV ESV square 40×1 imp polished AISI 201 | 223 |

| Stainless steel pipes ESV ESV square 40×1 imp polished AISI 304 (08Х18Н10) | 292 |

| Stainless steel pipes ESV ESV square 40×1 imp polished AISI 430 | 226 |

| Stainless steel pipes ESV ESV square 40×1.2 imp mirror AISI 304 (08Х18Н10) | 365 |

| Stainless steel pipes ESV ESV square 40×1.2 imp polished AISI 201 | 250 |

| Stainless steel pipes ESV ESV square 40×1.2 imp polished AISI 304 (08Х18Н10) | 361 |

| Stainless steel pipes ESV ESV square 40×1.2 imp polished AISI 430 | 283 |

| Stainless steel pipes ESV ESV square 40×1.5 matteAISI 304 (08Х18Н10) | 488 |

| Stainless steel pipes ESV ESV square 40×1.5 ground AISI 304 (08Х18Н10) | 421 |

| Stainless steel pipes ESV ESV square 40×1.5 imp mirror AISI 201 | 300 |

| Stainless steel pipes ESV ESV square 40×1.5 imp mirror AISI 304 (08Х18Н10) | 448 |

| Stainless steel pipes ESV ESV square 40×1.5 imp matte AISI 304 (08Х18Н10) | 495 |

| Stainless steel pipes ESV ESV square 40×1.5 imp polished AISI 201 | 304 |

| Stainless steel pipes ESV ESV square 40×1.5 imp polished AISI 304 (08Х18Н10) | 448 |

| Stainless steel pipes ESV ESV square 40×1.5 imp polished AISI 430 | 329 |

| Stainless steel pipes ESV ESV square 40×1.5 imp. grind (240) AISI 201 | 300 |

| Stainless steel pipes ESV ESV square 40×2 AISI 304 (08Х18Н10) | 650 |

| Stainless steel pipes ESV ESV square 40×2 mat AISI 201 | 391 |

| Stainless steel pipes ESV ESV square 40×2 matte AISI 201 | 391 |

| Stainless steel pipes ESV ESV square 40×2 matte AISI 304 (08Х18Н10) | 596 |

| Stainless steel pipes ESV ESV square 40×2 ground AISI 201 | 391 |

| Stainless steel pipes ESV ESV square 40×2 ground AISI 304 (08Х18Н10) | 636 |

| Stainless steel pipes ESV ESV square 40×2 imp mirror AISI 304 (08Х18Н10) | 590 |

| Stainless steel pipes ESV ESV square 40×2.5 matte AISI 304 (08Х18Н10) | 911 |

| Stainless steel pipes ESV ESV square 40×2.5 imp polished AISI 304 (08Х18Н10) | 762 |

| Stainless steel pipes ESV ESV square 40×3 imp polished AISI 304 (08Х18Н10) | 919 |

| Stainless steel pipes ESV ESV square 50×1.5 mat. AISI 304 (08Х18Н10) | 663 |

| Stainless steel pipes ESV ESV square 50×1.5 matte AISI 304 (08Х18Н10) | 608 |

| Stainless steel pipes ESV ESV square 50×1.5 imp mirror AISI 304 (08Х18Н10) | 636 |

| Stainless steel pipes ESV ESV square 50×1.5 imp polished AISI 304 (08Х18Н10) | 636 |

| Stainless steel pipes ESV ESV square 50×1.5 imp polished AISI 430 | 437 |

| Stainless steel pipes ESV ESV square 50×2 matte AISI 304 (08Х18Н10) | 845 |

| Stainless steel pipes ESV ESV square 50×2 ground AISI 304 (08Х18Н10) | 901 |

| Stainless steel pipes ESV ESV square 50×2 imp mirror AISI 304 (08Х18Н10) | 947 |

| Stainless steel pipes ESV ESV square 50×2 imp polished AISI 304 (08Х18Н10) | 942 |

| Stainless steel pipes ESV ESV square 50×3 matte AISI 304 (08Х18Н10) | 1307 |

| Stainless steel pipes ESV ESV square 50×3 imp polished AISI 304 (08Х18Н10) | 1368 |

| Stainless steel pipes ESV ESV square 60×1.5 imp polished AISI 304 (08Х18Н10) | 683 |

| Stainless steel pipes ESV ESV square 60×2 matte AISI 304 (08Х18Н10) | 1044 |

| Stainless steel pipes ESV ESV square 60×2 imp mat AISI 304 (08Х18Н10) | 1021 |

| Stainless steel pipes ESV ESV square 60×2 imp polished AISI 304 (08Х18Н10) | 965 |

| Stainless steel pipes ESV ESV square 60×3 imp matte AISI 304 (08Х18Н10) | 968 |

| Stainless steel pipes ESV ESV square 60×3 imp polished AISI 304 (08Х18Н10) | 1675 |

| Stainless steel pipes ESV ESV square 80×1.5 imp polished AISI 304 (08Х18Н10) | 890 |

| Stainless steel pipes ESV ESV square 80×2 matte AISI 304 (08Х18Н10) | 1570 |

| Stainless steel pipes ESV ESV square 80×2 imp matte AISI 304 (08Х18Н10) | 1319 |

| Stainless steel pipes ESV ESV square 80×2 imp polished AISI 304 (08Х18Н10) | 1153 |

| Stainless steel pipes ESV ESV square 80×3 matte AISI 304 (08Х18Н10) | 2269 |

| Stainless steel pipes ESV ESV square 80×3 imp polished AISI 304 (08Х18Н10) | 2162 |

| Stainless steel pipes ESV ESV square 100×2 imp polished AISI 304 (08Х18Н10) | 1623 |

| Stainless steel pipes ESV ESV square 100×3 imp matte AISI 304 (08Х18Н10) | 2499 |

| Stainless steel pipes ESV ESV square 100×3 imp polished AISI 304 (08Х18Н10) | 2499 |

| Stainless steel pipes ESV ESV square 100×4 imp matte AISI 304 (08Х18Н10) | 3575 |

| Stainless steel pipes ESV ESV square 100×4 imp polished AISI 304 (08Х18Н10) | 3575 |

| Stainless steel pipes ESV ESV square 120×3 imp polished AISI 304 (08Х18Н10) | 2883 |

| Stainless steel pipes ESV ESV square 120×4 imp polished AISI 304 (08Х18Н10) | 4010 |

Standard sizes and markings

Marking of profile stainless steel products is applied to their outer side at the factory after manufacturing. It consists of information about the standard size of the product, as well as the steel grade and the manufacturer’s trademark.

For example, let’s decipher the marking 100×100x5 09G2S:

- The first two positions indicate the size of the ribs in mm. In this case, 100 mm and 100 mm, since the pipe has a square profile.

- The third is the thickness of the walls.

- The fourth is the steel grade (set if necessary).

Production stages

Manufacturing technology affects the characteristics of the final product, but regardless of the methods chosen, the production process consists of the following stages:

- Unwinding and cutting the strip into narrow strips of the required length.

- Welding strips to create a continuous strip to speed up production.

- The forming machine rolls the round blank without bending the edges.

- The seam is welded using the selected technology.

- The resulting protruding burr is cleaned.

- The required profile is given to form the finished product on sizing rollers.

- Non-destructive testing of the seam using eddy current is carried out.

- After receiving the product, the required dimensions of the stainless steel are set, and it is cut under visual control.

Advantages and disadvantages

Stainless steel profile pipes have the following qualities and advantages:

- High strength characteristics with low weight.

- Due to the flat edges, they are more convenient to install than round profile pipes.

- Resistant to temperature changes.

- The ability to withstand any type of load (transverse, tensile and torsional), since they are distributed to the walls at right angles.

- High corrosion resistance, long service life.

- Heat resistance.

- Good weldability.

- Aesthetic appearance.

- Wear resistance.

- Frost resistance.

- Completely inert to chemical influences.

The disadvantages of profile products include:

- Relatively high cost.

- Inability to use for water supply pipelines and heating system wiring.

Tips on how to choose

Stainless steel profile pipes should be selected taking into account operating conditions, based on the following indicators:

- Maximum load.

- Duration and intensity of mechanical, thermal and chemical influences.

Depending on these parameters, the technical characteristics of the products are selected:

- Steel grade.

- Profile shape and dimensions.

- Wall thickness.

- Production technology.

The quality of purchased stainless steel products must be confirmed by factory certificates.

Classification

Stainless steel pipes vary in geometric characteristics depending on the diameter and cross-sectional shape of the pipe, as well as the type of surface treatment. The cross-sectional shape of the pipes can be round, square and rectangular. According to the type of processing, they are divided into:

- Matte

- Sanded

- Polished

The thickness of the pipe wall allows stainless steel pipes to be divided into thick-walled with great strength and thin-walled. Thin-walled pipes are characterized by high flexibility, so they are necessary for the manufacture of complex structures.

How to bend stainless pipes

When bending such products, it is important to prevent changes in the original cross-sectional configuration and the formation of creases on their inner surface. Deformation will weaken the load-bearing capacity of such a part, reduce its throughput, and increase the likelihood of corrosion.

In industrial conditions, bending of stainless steel pipes is carried out in the following ways:

- Run-in.

- Winding.

- Rolling.

- Drawing.

- Hydrostatic.

- By pushing.

- Using two supports.

Such pipe bending technologies allow you to obtain high-quality results, but require special equipment.

At home, you can bend a stainless steel profile using a manual pipe bender. In this case, to support the walls from the inside, the following is used:

- Clean dry sand and two plugs. First, one of the plugs is installed. Then the pipe at the future bend is filled with sand through the free end, carefully compacted and clogged with another plug. Next, the pipe is bent around a blank of the required size.

- A bundle of wire. The pipe cavity is filled to capacity with pieces of thick wire. After bending, the wire is removed one by one.

- A spring of the appropriate shape. It should be wound from wire 2–4 mm thick in such a shape that it fits freely into the cavity of the pipe at the bend. At the end of bending, the spring is removed using a wire previously left outside.

To bend a profile with a significant bending radius, the walls are preheated with a blowtorch or gas torch. Heated metal bends more easily.

Installation Tips

When assembling metal structures from stainless steel profile pipes, the parts are connected by welding or fastening with clamps. The elements can be fixed using electric arc, gas or resistance welding.

When arc welding, it is important to choose the right electrode. The quality of the weld depends on its diameter. If it is too thin, the welding process will be interrupted; if the electrode cross-section is too large, a thin-walled pipe can be burned.

Electric arc welding should not be performed in open areas. Such work is carried out in special premises. In this case, the ends of the parts to be welded must first be cleaned and degreased.

The contact type of welding forms a welding seam of increased reliability. There are no restrictions on ambient temperature and other weather conditions for its use.

General recommendations for carrying out any type of welding are as follows:

- When choosing a welding temperature, you should proceed from the thickness of the metal, since profile products are more susceptible to deformation than round ones.

- To maintain the internal clearance of the profile, it is necessary to prevent molten metal from entering the stainless steel profile pipe.

- When performing welding, it is necessary to carefully check the geometric coincidence of the ends of the parts being welded so that distortions do not occur in the metal structure.

Alternative to profile pipes

The use of profile stainless pipes is not always technically and economically feasible. It's not cheap. In addition, it cannot be used for laying pipelines transporting liquid and gaseous media under high pressure. This is especially true for electric-welded products with a seam: due to the presence of different angles inside such pipelines, blockages can quickly form at the bends. For the installation of such communications, only round pipes are used. And it doesn't have to be stainless steel.

Modern pipe products made of reinforced polypropylene are not inferior in a number of technical characteristics to stainless steel, but are much cheaper. Profiles made of plastic are more often used as ventilation ducts. They are available in white, so they fit more harmoniously into the interior of kitchens and bathrooms.

An alternative option for constructing a chimney could be a galvanized sandwich pipe. Galvanized steel is just as fire-resistant and fireproof as stainless steel, but is less resistant to corrosion from condensation. But the price of galvanized sandwich chimneys is much lower, as is the cost of installation. And in order to slow down the corrosive destruction of the metal, the surfaces of the chimney are coated with a special heat-resistant paint for galvanizing.

Aluminum pipes are also of good quality. They are lightweight, corrosion-resistant, and are a good option for making indoor decorative elements, furniture parts and other lightly loaded structures.

Features of operation

Structures made from profile stainless steel pipes do not lose their load-bearing capacity and presentable appearance over time. They do not need painting and can be easily washed with household chemicals that do not contain chlorine. Dried stains cannot be scraped off or removed with a wire brush: use only a soft cloth or foam sponges.

Possible problems

In some cases, rolled stainless steel may be subject to corrosion. Foci of rust appear on the walls of products after prolonged contact with a concentrated chlorine solution. To eliminate the cause of corrosion, it is necessary to thoroughly rinse off the chlorine-rich liquid. The rusting process of stainless steel parts will slow down, and they will retain their anti-corrosion properties.

Packaging, transportation and storage

For ease of transportation, profiled stainless steel pipes are bundled or tightly placed in wooden containers lined with waterproof paper. The packages are tied with wire or metal tape in three or four places depending on the weight. For strapping during loading and unloading operations, bags and containers are equipped with special clamps.

They can be transported by any type of transport. The packages are placed on the floor of the car or in the body of the car in stacks, separating the rows with spacers.

Profile stainless steel products are stored on racks in closed warehouses or under a canopy, where they will be protected from atmospheric moisture.

Specifics of product operation

Like other types of profile pipes, rectangular products can be manufactured in a full cycle, starting with unpacking the strips and forming a round pipe along the profile. Production can be carried out using the electric welding or seamless method, however, with the seamless option, the final cost increases noticeably and the main advantage of the product is lost. Therefore, profile products are not used for distilling liquids, but are used in almost all other cases.

Often, rectangular stainless steel pipes are produced by rolling the finished product into a round shape, achieving a number of advantages. This is a reduction in costs when increasing the cross-section, ease of manufacture and lower costs for the manufacturer, which allows buyers to purchase cheap stainless steel of good quality.

Matte stainless steel pipe Mirror stainless steel pipe Polished stainless steel pipe

Download price Rectangular pipes

| Name | Price RUR/m |

| Stainless steel pipes ESV ESV rectangular 20x10x1.5 ground AISI 201 | 122 |

| Stainless steel pipes ESV ESV rectangular 20x10x1.5 ground AISI 304 | 177 |

| Stainless steel pipes ESV ESV rectangular 30x15x1.5 ground AISI 201 | 162 |

| Stainless steel pipes ESV ESV rectangular 30x15x1.5 ground section AISI 304 (08Х18Н10) | 254 |

| Stainless steel pipes ESV ESV rectangular 40x20x1 mirror AISI 304 (08Х18Н10) | 226 |

| Stainless steel pipes ESV ESV rectangular 40x20x1 section AISI 304 (08Х18Н10) | 226 |

| Stainless steel pipes ESV ESV rectangular 40x20x1 section AISI 430 | 169 |

| Stainless steel pipes ESV ESV rectangular 40x20x1 grind (240) AISI 304 (08Х18Н10) | 226 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.2 ground section AISI 304 (08Х18Н10) | 254 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.2 ground AISI 430 | 200 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 mirror AISI 201 | 220 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 mirror AISI 304 (08Х18Н10) | 336 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 matte AISI 304 (08Х18Н10) | 436 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 ground AISI 201 | 220 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 ground section AISI 304 (08Х18Н10) | 336 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 ground AISI 430 | 238 |

| Stainless steel pipes ESV ESV rectangular 40x20x1.5 ground (240) AISI 304 (08Х18Н10) | 365 |

| Stainless steel pipes ESV ESV rectangular 40x20x2 matte AISI 304 (08Х18Н10) | 462 |

| Stainless steel pipes ESV ESV rectangular 40x20x2 grinding. AISI 304 (08Х18Н10) | 485 |

| Stainless steel pipes ESV ESV rectangular 40x30x1.5 mirror AISI 304 (08Х18Н10) | 393 |

| Stainless steel pipes ESV ESV rectangular 40x30x1.5 ground AISI 304 (08Х18Н10) | 391 |

| Stainless steel pipes ESV ESV rectangular 50x20x2 ground section AISI 304 (08Х18Н10) | 474 |

| Stainless steel pipes ESV ESV rectangular 50x25x1.5 matte AISI 304 (08Х18Н10) | 503 |

| Stainless steel pipes ESV ESV rectangular 50x25x1.5 ground section AISI 304 (08Х18Н10) | 421 |

| Stainless steel pipes ESV ESV rectangular 50x25x1.5 ground AISI 430 | 312 |

| Stainless steel pipes ESV ESV rectangular 50x25x1.5 ground (240) AISI 430 | 312 |

| Stainless steel pipes ESV ESV rectangular 50x25x2 matte AISI 304 (08Х18Н10) | 660 |

| Stainless steel pipes ESV ESV rectangular 50x25x2 ground section AISI 304 (08Х18Н10) | 552 |

| Stainless steel pipes ESV ESV rectangular 50x30x1.5 polished AISI 304 (08Х18Н10) | 428 |

| Stainless steel pipes ESV ESV rectangular 50x30x1.5 polished AISI 430 | 332 |

| Stainless steel pipes ESV ESV rectangular 60x30x1.5 matte AISI 304 (08Х18Н10) | 626 |

| Stainless steel pipes ESV ESV rectangular 60x30x1.5 ground AISI 304 (08Х18Н10) | 476 |

| Stainless steel pipes ESV ESV rectangular 60x30x1.5 polished AISI 201 | 336 |

| Stainless steel pipes ESV ESV rectangular 60x30x1.5 polished AISI 430 | 382 |

| Stainless steel pipes ESV ESV rectangular 60x30x2 mirror AISI 304 (08Х18Н10) | 692 |

| Stainless steel pipes ESV ESV rectangular 60x30x2 matte AISI 304 (08Х18Н10) | 794 |

| Stainless steel pipes ESV ESV rectangular 60x30x2 ground section AISI 304 (08Х18Н10) | 688 |

| Stainless steel pipes ESV ESV rectangular 60x40x1.5 mirror AISI 304 (08Х18Н10) | 573 |

| Stainless steel pipes ESV ESV rectangular 60x40x1.5 matte AISI 304 (08Х18Н10) | 648 |

| Stainless steel pipes ESV ESV rectangular 60x40x1.5 ground AISI 201 | 375 |

| Stainless steel pipes ESV ESV rectangular 60x40x1.5 ground section AISI 304 (08Х18Н10) | 573 |

| Stainless steel pipes ESV ESV rectangular 60x40x1.5 ground AISI 430 | 382 |

| Stainless steel pipes ESV ESV rectangular 60x40x2 matte AISI 304 (08Х18Н10) | 832 |

| Stainless steel pipes ESV ESV rectangular 60x40x2 ground section AISI 304 (08Х18Н10 | 745 |

| Stainless steel pipes ESV ESV rectangular 60x40x2 ground section AISI 430 | 543 |

| Stainless steel pipes ESV ESV rectangular 60x40x2 ground (240) AISI 304 (08Х18Н10) | 745 |

| Stainless steel pipes ESV ESV rectangular 80x40x1.5 matte AISI 304 (08Х18Н10) | 812 |

| Stainless steel pipes ESV ESV rectangular 80x40x1.5 ground section AISI 304 (08Х18Н10) | 682 |

| Stainless steel pipes ESV ESV rectangular 80x40x2 ground section AISI 304 (08Х18Н10) | 901 |

| Stainless steel pipes ESV ESV rectangular 80x40x3 matte AISI 304 (08Х18Н10) | 1470 |

| Stainless steel pipes ESV ESV rectangular 80x40x3 ground section AISI 304 (08Х18Н10) | 1461 |

| Stainless steel pipes ESV ESV rectangular 100x50x2 matte AISI 304 (08Х18Н10) | 1392 |

| Stainless steel pipes ESV ESV rectangular 100x50x3 matte AISI 304 (08Х18Н10) | 1766 |

| Stainless steel pipes ESV ESV rectangular 100x50x3 ground section AISI 304 (08Х18Н10) | 1825 |

| Stainless steel pipes ESV ESV rectangular 100x60x3 matte AISI 304 (08Х18Н10) | 2104 |

| Stainless steel pipes ESV ESV rectangular 120x60x3 matte AISI 304 (08Х18Н10) | 1917 |

| Stainless steel pipes ESV ESV rectangular 120x60x3 ground section AISI 304 (08Х18Н10) | 2056 |