At first glance, the question of what type of structure your chimney should have does not raise significant questions or problems, but digging deeper, it becomes clear that there are a lot of related factors. They directly influence the type and character of the future chimney, so we will further understand what the correct channel means. In addition, take into account the dimensions of the structure, because they not least affect the quality of smoke emission.

Types of chimneys

The type of chimney depends on the material used in its construction. The traditional option is brick construction. For this, only solid brick can be used, since silicate or concrete are not resistant to high temperatures and acids. The chimney masonry must be smooth (especially inside - no drips), and the seams must be completely aligned. It is better to choose a clay solution for the chimney. However, due to its fragility, its use is only feasible in single-story construction.

A brick chimney ends up being quite heavy. When using it, the brick absorbs some of the heat and does not cool down for a long time after that. This type of chimney is quite expensive. In addition, the structure needs a solid foundation in order to erect such structures. In addition, soot, soot, etc. accumulate on its walls.

The classic version of the chimney is modules. They are based on ceramic pipes. In this case, the chimney remains double: the inner pipe is made of ceramic, and the outer one is protective, usually made of expanded clay concrete. Basalt insulation is used between the two pipes. Modular bends made of metal are also used. Chimney pipes are made of stainless steel, resistant to both high temperatures and corrosion and acids. The wall thickness is usually taken to be 2 mm. They can be single or double, sometimes they are insulated as necessary. They are installed both inside the building and outside.

When building a house, you need to take into account the overall structure, the materials used for the walls, as well as the architectural component. Experts usually advise considering the option of sandwich pipes. They come in both ferrous metal and stainless steel. Their advantages include durability, as well as a smooth surface, which ensures excellent traction and minimal soot deposits in them.

Traction force

It is known that the intensity of the removal and discharge of heated smoke and gas into the external environment is directly influenced by draft

. This is a key characteristic of the chimney system, demonstrating its efficiency. The traction force is affected by the cross-section of the chimney, diameter and height:

- the narrower the upper part, the sooner the gas and smoke mass comes out;

- Minimizing inclined or horizontal parts and branches helps to speed up draft, that is, creating as vertical a chimney as possible.

Determination of effectiveness

The reason for the low efficiency is incorrect assembly of the system, poor connection of components. In most cases, these errors are noticeable at the time of assembly, so they can be easily eliminated. Otherwise, to eliminate the shortcomings, you have to dismantle and reassemble the chimney.

A sign of high efficiency is a noticeable hum in the pipes that accompanies the operation of the boiler. The rate of smoke removal is regulated using a damper that partially blocks the chimney.

Installation rules

The chimney is built according to strict requirements. This is necessary so that the draft in the fireplace or stove is stable. To do this, you should adhere to the following construction rules:

- The height of the chimney must be at least five meters and it must be located vertically (the draft depends on the height of the pipe);

- You can use separate sections of the chimney with a slope of forty-five degrees;

- If the horizontal sections of the supply pipe to the chimney are more than two meters, then they must be able to be cleaned (an inspection tee must be installed);

- The location of the stove should be chosen closest to the chimney, since horizontal sections significantly worsen the draft;

- The cross-sectional size of the chimney is strictly regulated for each stove or appliance; you cannot make it less than the recommended values;

- No more than three turns of the chimney are allowed;

- If several devices are used, then their pipes can be combined into one vertical riser;

- A one and a half meter pipe should extend from the boiler or fireplace and only then enter the main chimney.

Multi-level floor

To zone the space, craftsmen install floors at different levels.

They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something. It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free. However, such a design should not be made if there are small children in the family, since the podium can become an obstacle for him. In addition, various floor coverings can be used. They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

What to consider during installation

It is allowed to connect chimneys located on different floors. In this case, the total cross-section should be the sum of the chimneys included in it. Typically, this method is used when reconstructing a building when other options are not possible.

When designing a room, it is necessary to place the chimney closer to the ridge. This will avoid forming a long pipe and will increase draft in the system. If the chimney pipe is located in the same riser as the ventilation, then it must be placed above the hood - above the ventilation, so that smoke does not return to the room.

Building regulations suggest that the end of the chimney should remain open, tapering slightly towards the very top. However, a regular cap is often used to protect the pipe from precipitation. The distance from the edge of the chimney to the cap must be at least 20 centimeters. To ensure optimal draft in it, a constant flow of air masses into the room is needed, since operating stoves and boilers are powerful hoods.

Typically, draft is provided by ventilation. It can be either natural or artificial. The best option is to supply street air directly to the heated device (for example, closer to the boiler firebox). Thanks to this, the housing microclimate will not be affected at all, there will be enough oxygen, and the firewood will burn much better.

Full range of design and installation services

carries out a full range of work on the design, installation and commissioning of smoke removal routes of any level of complexity, length and design. The company’s installation department specialists will prepare a detailed technical work plan, taking into account all the nuances of the structure, its design and layout, as well as taking into account the personal needs and wishes of the customer. Drawing up a plan is possible both at the initial stages of construction and in finished buildings.

The project plan is drawn up with an accurate calculation of the cost of both all work and the required chimney elements, which is undoubtedly convenient for the customer. After approval of the project, a team of specialists arrives at the client’s site and promptly carries out high-quality installation of the smoke exhaust system, followed by commissioning. A big advantage is testing and a full check of the functionality of the heating and smoke exhaust system upon completion of the work. The client receives long-term guarantees of the quality of the constructed smoke removal system, installed in accordance with all fire and operational safety rules and regulations.

What is a chimney needed for?

The question, although it seems simple, is nevertheless very important. A good chimney, such as here, is vital for removing the combustion products that form after the combustion of fuel, so that they do not accumulate indoors. It creates natural draft in the combustion chamber, which not only promotes the removal of combustion products, but also the supply of oxygen necessary for combustion.

The efficiency and safety of the heating system will depend on the correct manufacture of the chimney and the materials used for this. According to statistics, the main causes of fires in our country are:

- Choosing low-quality material for the chimney;

- Errors in calculating pipe parameters;

- Failure to comply with fire safety regulations.

Do not forget that the chimney must be cleaned regularly and take into account the natural wear and tear of the material from which it is made.

Chimney

Principle of operation

Despite the complexity of the design of the unit, the principle of its operation is quite simple. The equipment is based on a simple law of physics: heated and warm air always rises, and cold air descends due to its weight. Carbon dioxide enters the device system, and due to the difference in temperature inside the unit and in the fresh air, a draft appears, with which it goes outside. This principle ensures that carbon monoxide goes directly to the street - no harmful substances remain in the room.

principle of operation of the chimney of different gas boilers

Chimney requirements

In ancient times, ordinary holes in the roof served as chimneys. A little later, special channels were used for this, which were laid in the walls, as well as separate smoke exhaust pipes made of brick. For many years, brick was almost the only material from which chimneys were made. However, over time, the requirements for heating devices increased, as did the chimneys themselves and the conditions for their operation.

Modern chimneys must be durable and strong, withstand high temperatures, meet fire safety requirements and resist the effects of aggressive acids.

Metal chimney

External and internal chimney: do it yourself or with the help of professionals?

On the Internet you can find numerous diagrams for connecting external and internal pipes, their designs and fastening methods. But installing a chimney with your own hands is always a big risk. Since it concerns fire safety, property safety, life and health of the residents of the house, it is recommended to use the services of trusted specialists.

Carrying out installation work by professionals has the following advantages:

- preparation of a work plan taking into account all technical features of the structure

- guarantee for work performed

- guarantee of high quality assembly and installation

- guarantee of compliance with all required standards, including those established by law

- taking into account all the nuances and features of the smoke exhaust system

- high efficiency of work

- fire safety guarantee

A worthy alternative

Today, metal pipes that are made of stainless steel, resistant to high temperatures and acidic environments, are increasingly being used as chimney pipes. Such smoke exhaust ducts are lighter in weight compared to brick, do not require an additional foundation, are easy to install, are resistant to corrosion, have a long service life and are suitable for most modern models of furnaces and boilers.

In addition, they have an optimal cross-section, which is best suited for removing smoke and generated gases. Soot is not deposited on their walls, and there are no natural turbulences that interfere with the normal removal of gases.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

Do you dream of your own country house, where, sitting by the fireplace on cold winter evenings, you will enjoy the silence and the quiet howling of the wind in the chimney. You have already decided what kind of house you will build and where you will place the fireplace. The normal functioning of the fireplace requires the installation of a chimney yourself. In this article we will highlight the main issues of the correct and safe design of such systems, and we will tell you how to make a chimney yourself. If you follow all the recommendations carefully, you will succeed.

- Chimneys for stoves

Purpose of the chimney

A chimney is a vertical pipe of round or square cross-section, which serves to remove fuel combustion products from the heating unit into the atmosphere. The product is designed for natural draft, due to which air for combustion products enters the firebox, and flue gas is removed from it. The main parameters of a good chimney are: ideal draft, high-quality combustion of fuel, rapid heating of the walls and overcoming the condensation threshold.

A properly installed combustion product exhaust system in a modern home can protect owners from unnecessary troubles. Its advantages also lie in the fact that it distributes heating air flows in the most optimal way. Incorrect arrangement of the chimney provokes unwanted smoke, backdraft, or even the threat of a fire. Impassive statistics show that heating problems have always been the main cause of fires in suburban homes.

Types of chimneys

The chimney is one of the main elements of the boiler room, because neither a heating boiler, nor a gas water heater, nor a fireplace can do without it. To create a vacuum in the heating unit, which ensures the combustion process, different types of chimneys are used.

Typical classifications of chimneys

According to their location, the channels that are used to remove smoke can be wall, that is, located inside the main walls, root, which are isolated in the form of a separate riser, and external, which are located on the facade of the building. For rooms with brick walls, the first option is the most economical and convenient, since it does not require additional materials; they make the chimney with their own hands simultaneously with the walls during the construction of the building.

Heating devices are divided into two groups according to the method of gas removal: with natural and forced draft. In the first case, gases are removed due to a built-in fan in the boiler, in the second - with the help of draft that is created in the chimney. For a forced draft heating system, it is better to install a compact coaxial chimney.

A single-wall chimney is a stainless steel pipe that has a thickness of 0.6 - 1.0 millimeters. Such pipes are usually used for placement inside the house, or inside brick ducts, because due to their heat transfer the room can be additionally heated. Double-walled pipes have two layers of stainless steel, between which there is a layer of insulation - non-flammable basalt wool. Also, stainless steel is often placed in a zinc casing. Most often, double-walled pipes are used to install chimneys outside the house or inside wooden buildings.

Classification of chimneys by material

The main advantages of a brick chimney exhaust are long service life and fire resistance, but the disadvantage is the uneven internal surface, which causes soot to settle. The pipe “overgrows” gradually and the draft decreases. Brick chimneys are usually installed during the construction of a house.

Brick channels for smoke removal are characterized by good fire resistance, as well as resistance to condensation and external influences. It is possible to install such a chimney on the facade or inside the building. The main disadvantage of the design is the complexity of installation work, as well as its significant weight. This is due to the metal rods that run inside the product.

Welded chimneys made from steel pipes are subject to corrosion. If a certain amount of sulfur oxides is present in the emissions, then these substances combine with condensate and ultimately form sulfuric acid, which destroys pipes. Installation of such chimneys is a long and very labor-intensive process.

Stainless steel chimneys have all the properties of a “good chimney”: they are durable and easy to install, lighter than brick ones, and do not corrode. Chimneys made of stainless steel can be laid through wooden ceilings. Do-it-yourself pipe modeling and chimney repairs are possible on site.

Chimney characteristics

The optimal shape of the channel for removing smoke is a cylinder, based on the fact that the more obstacles that are caused by angularity, the more difficult it is for it to pass and the more soot is deposited on the walls. The dimensions of the chimney are determined by the height and diameter of the structure.

The diameter is calculated taking into account the power, the width of its outlet, the nature and number of obstacles in the path of the combustion gases. The height of the chimney is calculated in accordance with building codes, taking into account the height of the building, the type of roof and the dimensions of neighboring buildings. It is important to comply with the requirements for horizontal sections of the chimney when designing. Their length should not be more than 1 meter, because warm air moves vertically.

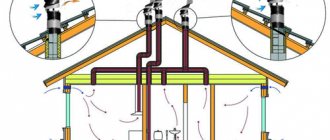

The figure below shows you the distances that are recommended to be observed:

- when installing a chimney on a flat roof, the pipe should protrude to a height of no less than 500 millimeters;

- when placing the pipe at a distance from the ridge of less than 1.5 meters, the height of the pipe must be at least 500 millimeters in relation to the ridge;

- when the chimney is located at a distance of 1.5 - 3 meters from the ridge, it must be no lower than the ridge;

- when placing the chimney at a distance of 3 meters or more from the ridge, it must be no lower than the line drawn from the ridge down to the horizon at an angle of 10º.

Connecting a fireplace insert or boiler to a chimney is often associated with problems of diameter mismatch. In this case, it is customary to use a reduction adapter. The area where the chimney connects to the equipment must be treated with a special sealant. Further assembly of the chimney is carried out with expansion upward along the condensate flow, so that the condensate does not escape onto the outer wall of the pipe.

Construction of a chimney: basic rules

Mistakes made in the chimney business are fraught with serious consequences. Remember that when building a chimney with your own hands, it is important to comply with all construction requirements and standards. Some consequences of illiterate design cause expensive modifications to the chimney, while others provoke poisoning by combustion products or fires.

Experts do not recommend using materials that are not intended for this purpose, for example, aluminum and asbestos. Changing the pipe diameter during useful operation without the involvement of specialists at a minimum reduces the efficiency of the heating system. The load on the base of the chimney should not exceed this value, which could lead to the destruction of the building.

Several installations can be combined into one chimney network only if there are supporting calculations made by a specialized specialist. Among the most dangerous mistakes are the following: insufficient thermal insulation of the pipe, which leads to charring of adjacent materials and their fire; use of ventilation ducts to remove smoke; unauthorized repairs and modifications without preliminary calculations.

Chimneys for stoves

The construction of chimneys for stoves is strictly regulated by building codes. Thus, it is recommended to build one stove for heating no more than 3 rooms, which are located on the same floor. In two-story houses, it is allowed to build two-tier stoves with separate fireboxes and chimneys for each floor.

The smoke ducts of the furnace can be located in external walls made of non-combustible material. In the absence of walls where a chimney can be placed, it is customary to use root and mounted chimneys to remove smoke. As a rule, a separate pipe or a separate channel is made for each furnace. Two stoves can be connected to one pipe, located on the same floor. When connecting two channels, it is necessary to provide cuts that have a thickness of 0.12 meters and a height of at least 1 meter from the bottom of the pipe connection.

Chimneys are designed vertically without ledges. Permissible deviations of the chimney from the vertical are 30 degrees, with a slope of no more than 1 meter. Sloping areas should be made smooth. Chimneys on houses with roofs made of flammable material should be equipped with spark arresters made of metal mesh with holes no larger than 5 by 5 millimeters in size.

Structures made of difficult-to-combustible or combustible materials that are adjacent to furnaces, ventilation ducts and chimneys should be protected from fire by cutting from non-combustible materials, and the resulting gaps between walls, partitions, ceilings and cuttings are recommended to be filled with non-combustible material. The distance from concrete or brick chimneys to difficult-to-combustible and combustible roof elements must be at least 130 millimeters, from a ceramic pipe without insulation - 250 millimeters.

Chimneys for fireplaces

The requirements for chimneys for a fireplace overlap with the conditions that apply to stoves. The fuel is the same, the operating principle of the heating systems is similar. For example, fireplaces are often used for heating. But if we are not talking about large-scale heating, then you can get by with a radiator pipe, which is a special device made of plates that increase the heat transfer area.

As with other chimney designs, smoke from fireplaces must be removed in a simple way. It is better if you build a straight vertical chimney that is more than 6 meters high. It is possible to make a more complex design, in which there are bends with an acute angle of less than 45°. If necessary, you need to use an elbow and install a tee, which facilitates access during subsequent cleaning.

An appropriate level of thermal insulation is also important. Smoke heats the pipe, which means it is necessary to protect floors and wall materials from fire. If a sandwich chimney runs near wood or plastic, it is usually insulated with basalt-based material. The location where the chimney passes should also be protected from the cold. For example, it is not allowed to place a single-wall pipe made of stainless steel on the street. Protect the chimney with an installed weather vane or fungus.

Chimney for solid fuel and gas boilers

Heating boilers that operate on solid fuel are similar to fireplaces and stoves, as well as gas boilers. They are united with the first group by wood as a common type of fuel and the frequent need to clean the device from ash, with the second group by the similarity in the distribution of energy for heating. The chimney construction scheme for solid fuel boilers is generally similar.

The chimney for gas boilers must have a channel in its design - two devices can be connected to one channel, which are located at a distance of at least 750 millimeters. It is imperative to build a sealed chimney to prevent carbon monoxide leakage, and a condensate-resistant structure. Modern high-performance gas boilers produce 1-3 thousand liters of condensate per year, and due to the low temperature of the outlet gas, the condensate cannot evaporate, but flows down the walls of the chimney, penetrating and destroying the brick.

The chimney draft for a gas boiler must not be impaired. The ideal cross-section for the exhaust duct is round. An uneven or rough inner surface of the pipe impairs traction. The cross-section of the smoke exhaust channel should not be less than the diameter of the gas exhaust pipe on the connected devices. For example, if the diameter of the outlet on gas boilers is 150 millimeters, then the diameter of the exhaust duct should not be less than 150 millimeters. Such a chimney should go into the sky, without coverings or canopies.

Chimney for sauna and bathhouse

The firebox and chimney of a Russian bath or Finnish sauna require thermal insulation. It is customary to insulate the ceilings by analogy with the chimneys described above, and the wall material next to the firebox must be covered with metal sheets. The excess heat generated by the chimney can be used for business.

A popular option for increasing efficiency is the use of a metal mesh, into which stones are poured, which can envelop a hot chimney and become heated. Another addition is a combustion intensity regulator. The chimney draft must maintain combustion at the required level, without releasing all the heat to the street and creating a room temperature of close to 70-80 degrees Celsius. It is clear that there can be no talk of smoke getting into the steam room.

Thus, you have become familiar with the intricacies of constructing a functional and technically correct chimney and watched a video of installing a chimney with your own hands. Each option has its own installation subtleties and requires consultation with a specialist. Follow the basic details of installing a smoke exhaust duct, and the heating system in your home will operate with high efficiency.