Washing machine Hotpoint-Ariston VMSL 501 B, white

15699 ₽ More details

Washing machine Candy CS34 1052DB1/2-07, white

16099 ₽ More details

Washing machines under the sink

For every room where gas or thermal electric appliances are used for cooking, a hood is required. This device is connected to the air duct and provides removal of steam, burning and unpleasant odors. Hoods are necessary both in residential premises and in professional kitchens. Even if a small family lives in the house and the cooking process does not take much time, without an exhaust hood the microclimate in the home will not be favorable for living. The exhaust device cannot be replaced by conventional ventilation, since the ventilation system has a completely different principle of operation and provides air exchange in a confined space, but does not remove combustion products and steam. Exhaust devices are connected by an air duct to the ventilation shaft. The duct diameter and length are calculated according to certain rules.

The most popular and practical are round air ducts.

Why is an exhaust device necessary?

A range hood is an important piece of equipment in any kitchen. Its main function is to remove polluted air. Smoke with combustion products, kitchen fumes, odors that have a bad effect on well-being, all this is removed from the room by this equipment. This device, by purifying the air, takes care of people directly in the kitchen or in neighboring rooms.

The hood provides comfortable conditions in industrial kitchens for working personnel and favorable living conditions if it is installed in a kitchen in a residential area.

Diagram of the device and operating principle of the air duct.

The exhaust device solves the following problems:

- removing odors generated in the kitchen;

- removal of combustion products;

- air cooling;

- decrease in humidity.

The hood prevents the appearance of mold and the proliferation of bacteria, for which a warm and humid environment is optimal. With an exhaust device, dirt, grease, and soot do not settle on the finishes and interior items.

The varied design of modern hoods allows you to choose this equipment in accordance with the style of your kitchen. Nowadays there are different types of such devices on sale: decorative, domed, modern and with ethnic motifs. You can also buy a built-in hood, which will be almost invisible in the kitchen interior.

What filters are used and how often should they be changed?

An important element of the hood, which works on the principle of recirculation, is filters. They come in two types: grease-catching and coal.

The first type, which is also called a coarse filter, is designed to process the intake air from evaporated fat, soot particles and soot. The main purpose of such a filter is to protect the motor and hood blades from contamination and, accordingly, extend their service life. Such a filter is available in any type of hood.

In turn, they are a coarse filter that can be either metal or paper-based. Most hoods use a metal filter: in the form of a perforated sheet or in the form of a fine mesh. In this case, it is reusable; approximately once every 3-6 months it must be washed with water and powder, soap or dishwashing detergent, and then can be installed back. Paper filters are disposable and must be changed when dirty. On average, the replacement period is also about 6 months. Here it is important to determine what is more important - the possibility of periodically cleaning the filter and its further use (saving money) or the ease of replacing the filter to the detriment of the home budget.

A carbon, or fine filter, is a container with activated carbon, to which disinfection elements can be added: silver, cation exchange resins, ion exchange resins. The carbon filter effectively eliminates odors and perfectly retains the smallest particles. Carbon filters cannot be maintained or washed in any way - only replaced. Typically, the period for replacing a carbon filter in a hood is 3-6 months. If the carbon filter is not changed for a long time, then over time it becomes increasingly clogged, and the performance of the hood drops by up to 50%.

How to choose an air duct pipe?

Air duct system diagram.

The correct choice of the diameter of the air duct pipe is of great importance for the efficient operation of the exhaust device. For the system to work effectively, without failures and noise, the diameter of the air duct must be the same or larger than the diameter of the hood outlet. When using an exhaust duct of a smaller diameter, the efficiency of operation decreases as a result of increased air resistance and the exhaust power decreases. However, not only the diameter of the air duct is important for the good operation of the exhaust device; you should also pay attention to the configuration of the air duct, how it is located along the wall and what its length is. When laying the air duct, you need to ensure that there are no sharp or right bend angles. When a pipe is bent by 90°, 10% of the performance of the exhaust device is lost.

The duct pipe should have only obtuse bend angles.

To avoid reverse air movement, it is necessary to equip the air duct with a non-return valve.

Depth of dome and recessed model

The depth of the hood is as important as its width, because as already noted, the larger the area of the working suction surface, the more effective the cleaning of the kitchen air. Standard depth parameters correspond to standard width options, these are: 30, 45, 50, 60, 80, 90, 100, 120 cm. The depth of the exhaust work surface must be equal to or greater than the depth of the stove or built-in hob. The dome can be greater than the depth of the hanging modules, but not greater than the depth of the table top.

But the depth of the built-in hood is adjustable, but its body, of course, must correspond to the depth of the kitchen wall cabinets, as shown in the photo below.

How to position a kitchen hood?

Using an air duct in kitchen ventilation.

Exhaust devices should be located above the heating equipment, mounted on the ceiling, or on the side, mounted on the wall. The kitchen stove should not be located at a great distance from the ventilation shaft where the air duct will be discharged, since the air duct pipe should not exceed 3 m. Exceeding this length will lead to a decrease in the efficiency of the equipment. The stove should not be installed against the wall opposite the exit of the ventilation shaft, otherwise, when laying the air duct, you will have to make a lot of bends, which will also negatively affect the operation of the exhaust system.

Pipe for hoods: nuances of selection and installation features

One of the prerequisites for comfort and coziness in the kitchen is its cleanliness. In order to minimize the accumulation of unpleasant odors and contaminants both on furniture and in the air, it is necessary to purchase special equipment. The main assistant is a ventilation hood. It is very important to choose and install it correctly. The exhaust system also affects the efficiency of operation, so it is necessary to choose the right exhaust pipes .

When installing a flow-through hood, you cannot do without ventilation pipes.

Which air ducts are better – plastic or corrugated?

Now two types of air duct pipes are used: plastic and aluminum corrugated. The cross-section of plastic products can be round or rectangular. Round plastic air ducts have less air resistance than those with a rectangular cross-section, so they work more efficiently. But rectangular air ducts in the interior look more natural; they blend in with furniture and other kitchen equipment.

Diagram of the air duct fire protection system.

When installing air duct pipe elements, great attention should be paid to the quality of the connections. Therefore, it is better to buy all components for the system together with plastic pipes, so that there are no problems when joining the elements. Corrugated pipes do not require connecting elements; they are easily bent at any angle, as well as stretched and compressed. Their installation boils down to fixing one edge of the pipe to the opening of the ventilation duct, and the opposite to the outlet of the exhaust device. In addition to ease of installation, another advantage of corrugated pipes over plastic ones is their light weight. Disadvantages include noise during operation of the exhaust system, accumulation of fat and soot on the inner walls of the pipe. Plastic air ducts have many advantages:

- quiet operation;

- low air resistance due to smooth internal walls;

- are not clogged with dirt, all waste is discharged into the ventilation shaft.

The disadvantages of plastic pipes include more complex installation and the need for connecting components, as well as a higher cost compared to corrugated pipes.

What else to consider during installation?

Before installation, you should consider the specifics of connecting the device to the network.

Any hood is connected to the electrical network. Therefore, the socket should be installed at a height of 2 -2.5 meters from the floor and 15-25 cm above the wall cabinets.

Such an outlet must be grounded so that the hood does not burn out due to power surges. Never install an outlet in line with an air duct. Aim for about 15-20 cm from it.

Also, when taking measurements, it is worth considering the distances to the side cabinets. Aim for 5-10 cm in both directions.

We have provided diagrams of the location of sockets in the kitchen and the details of their installation with our own hands in the following material.

When making calculations, it is very important to take into account all pieces of furniture and wiring in the kitchen and draw a diagram of the location of each item

For example, let's look at a specific situation. The dome hood must be installed above a 5-burner gas stove in a 31-cu.m. kitchen. m, ceiling height 2.8 m. Cooking is done on the stove every day, the kitchen is closed with a door.

First, let's find out the approximate power. Let’s take the coefficient 20 due to the number of burners and the frequency of use of the stove: 31 * 2,8 * 20 = 1736.

Thus, this kitchen requires a hood with a capacity of at least 1800 cubic meters. m/hour.

The stove will be used by a person with a height of 170 cm, the height of the stove is 75 cm, and the height of the hood is 60 cm. Therefore, we compare all the data and get an approximate range of 77-80 cm for the height of the hood.

It is important to carry out such calculations to avoid errors during installation. But it’s best if you have the opportunity to check the conventional arrangement of equipment in the kitchen and the ease of its use.

Tips for installing a fume hood

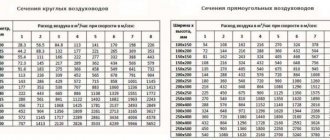

Table for calculating the diameter of air ducts.

When installing an exhaust system, you must correctly calculate the height and location of the hood relative to the working surface of the slab. If it is placed too high above the stove, the hood will not work effectively; steam and unpleasant odors will remain in the room. And if you install it low above the stove, it will interfere with work. The optimal distance from the exhaust device to the stove is 75 cm.

When connecting the air duct to the ventilation duct, care should be taken to ensure that the access of fresh air to the kitchen is not completely blocked. To do this, you need to install a special grille with a mount for the air duct pipe and a special valve. When the exhaust device is operating, the valve closes, and when the equipment is not in use, the check valve opens and allows air to circulate.

When installing corrugated air ducts, grids with fittings and clamps are used. It is recommended to stretch the corrugated pipe so that there are no folds left on it, otherwise dirt will accumulate in them, and the operation of the exhaust device will be accompanied by noise.

Plastic air duct systems are installed using adapters for connection to the hood and ventilation duct.

Schemes for attaching the air duct to the wall.

In order for the exhaust system to work efficiently and with minimal noise, the diameter of the air duct must be larger than the outlet of the device. Failure to comply with this condition will increase the load on the device’s engine, reduce its operating efficiency and cause noise.

When choosing the location of the exhaust device, you need to consider its type. Flat appliances are mounted to the wall, island hoods are mounted to the ceiling. Devices with a corner mounting strip are installed inside hanging furniture. For the air duct, a hole of suitable diameter is made in the furniture. Decorative dome hoods are mounted on the wall. To disguise the air duct, install a decorative box.

What about the noise level of such devices?

High performance also has its downside: when the device is operating, a very noticeable noise is heard. The lower its level at the hood, the less tired the person who has to cook will be. Fans of modern hoods have a very complex blade configuration, aimed at ensuring minimal noise while maintaining maximum performance of the device.

This indicator is measured in dB (decibels). In modern hoods it ranges from 36 to 60 dB. The smaller it is, the better, of course - the optimal value would be 40-50 dB.

It is better to choose a hood with a plastic ventilation unit, since, unlike metal cases, the use of sound-absorbing and flexible plastic is more effective in absorbing noise from vibration and turbulence of moving air.

Types of exhaust devices

Today it is easy to choose a kitchen hood based on price, technical parameters, and design. Taking into account the operating characteristics, the size of the room, and the interior design, you can choose the appropriate type of equipment. Compact and inexpensive flat-panel appliances are the best option for small kitchens. They have low power, but if food is not often prepared in the kitchen, such equipment copes with its functions perfectly.

Telescopic built-in devices are more powerful than flat devices. They are equipped with a retractable carriage, which increases the air suction area and improves efficiency. Built-in devices are suitable for any interior, but they are more expensive than flat devices. Dome and decorative devices are the most powerful. They have many additional useful options, including a timer, automatic shut-off, intensive mode, perimetric suction, etc. They can be equipped with a display, touch or button controls, halogen lighting, sound-absorbing blocks and other latest improvements. This type of equipment is suitable for large kitchens where people often cook. Other advantages of dome and decorative hoods include low noise levels, varied designs, and a wide price range.