A septic tank is the final design of an autonomous sewer network. The choice of its location is carried out in careful compliance with all current norms and regulations.

When determining the distance from the house to the septic tank, a whole list of factors is taken into account, including:

- site boundaries

- location of a residential building and non-residential buildings;

- finding water sources;

- arrangement of vegetation.

All these elements can affect the size of the external sewer system, and therefore are reflected in regulatory sources.

How to choose a slope angle - several possible options

There are several positions that guide home craftsmen:

- Make the angle as sharp as possible;

- Make the slope minimal or skip this point altogether when installing sewer drains;

- Create a slope in accordance with SNiPs, GOSTs or specialized reference books.

At first glance, an excessively sharp slope of the sewer pipe will help the water that requires treatment to reach its destination faster. But on the other hand, the pipe is exposed to the harmful effects of wastewater. Because water moves through the drain too quickly, sewage solids, food debris and other debris that is often flushed down the toilet remain in the pipe. Therefore, the maximum pipe slope is strictly regulated. Looking ahead, I will say that it is equal to 15 cm per 1 linear meter.

Silting of the pipe will also be a problem. Over time, the sewer will become clogged and you will have to work to repair it. The service life of such a system is much shorter than the standard one and is less than a year.

A minimal slope or its absence is a serious mistake when installing a sewer pipeline. In this case, the pipe not only silts up, but is practically not cleaned naturally.

Why is a slope needed when building a sewer system in a private house?

The slope is needed to prevent excess water and dirt from accumulating in the pipe. If the pipe is located on a slope, then the water in it will flow by gravity, therefore, there will be practically no blockages.

If there is no way to make a slope, then you will have to resort to using a special pump, which will “push” the wastewater through the pipe. But even in this case, blockages may occur. What to do in such a situation? You will have to call specialists if it is no longer possible to handle it yourself. In rare cases, if special equipment cannot cope with the blockage, the pipes have to be dug up.

The outer pipe must not be allowed to rotate, because it is not always possible to clean it quickly without the help of specialists!

If you cannot do without turning, then experts recommend making an additional (small) sewer well in its place. If necessary, it will always be possible to penetrate it without any problems. Using this trick, it will be possible to lay a sewer system even in the most “built-up” area.

Why do you need a pipe slope at all?

Using the angle of inclination of the sewer pipe must be used in order to deprive yourself of the following problems:

- When the pipe becomes silted, the air siphons are broken, which serve as protection against unpleasant odors in the room;

- Siltation of the main pipe threatens to completely disrupt the basic functions of the sewer outlets, which, in essence, is the cessation of the system’s operation;

- Protecting the basement of a residential building from leaks and breakthroughs depends on the correct slope.

Video on the topic:

Sewage slopes and their setting methods:

How to choose the correct sewer slope:

Also, if there are no problems with corrosion during unsloped installation of plastic, then holes may appear in the cast iron pipe. It will begin to leak water and sewage into the basement.

Previously, in multi-storey buildings, sewers were not installed with a slope, which is why there were so many cases of flooding in an apartment on the first floor or a breakthrough of the entire sewer system.

Sewer pipe laying depth

At what depth should the sewer be laid? This question was asked by everyone who dealt with sewer systems. The depth of the pipe depends directly on the depth of the sewer system (septic tank or cesspool). The depth of a standard size septic tank is approximately one and a half meters. A concrete or cement “cushion” is usually poured into the pit, or rather at its bottom, so that the septic tank does not harm the groundwater and does not crack under the weight of the earth’s surface.

Dependence of pipe depth on terrain

The depth of the sewer pipe directly depends on the area in which you live. In the warm climate in the southern part of the Russian Federation, pipes are usually not buried at a great distance from the surface. 50 centimeters will be enough. In the middle latitudes of Russia, the pipeline will need to be buried to 70-90 centimeters. This norm should be especially taken into account if trenches (pipes) lie under roads, that is, in places where snow will be constantly cleared. The ground in such places freezes deeper than in places with snow. In northern Russia, the minimum depth of sewerage should be 2-3.5 meters.

The main rule is that you cannot use bends in pipes, otherwise blockages will constantly occur.

How to choose a slope

To determine what the minimum pipe slope should be that will be optimal for you, you need to know the length of the entire sewer system. In reference books, data is used immediately in ready-made form, they are depicted in hundredths of an integer. Some employees find it difficult to navigate such information without explanation. For example, information in directories is presented in the following form as in the figures below:

Table: required slopes and diameters of pipes for drainage Table: slopes of drain pipes in the apartment

Minimum and maximum sewerage slope per 1 linear meter according to SNiP

Below is a picture that shows the minimum slopes depending on the diameter of 1 meter of pipe. For example, we see that for a pipe with a diameter of 110 the slope angle is 20 mm, and for a diameter of 160 mm it is already 8 mm and so on. Remember the rule: the larger the diameter of the pipe, the smaller the slope angle.

Examples of minimum sewerage slopes of 1 meter according to SNiP, depending on the diameter of the pipe

For example, a slope for a pipe with a diameter of up to 50 mm and a length of 1 meter needs 0.03 m. How was this determined? 0.03 is the ratio of the height of the slope to the length of the pipe.

Sewage pipe slope 110 mm for external sewerage

Suppose you need to calculate the optimal slope for a common 110 mm pipe, which is used mainly in external sewage systems. According to GOST, the slope for a pipe with a diameter of 110 mm is 0.02 m per 1 linear meter .

Autonomous sewage systems

There are three main types of autonomous sewerage systems:

- Cesspool - all waste goes directly into the ground;

- Storage tank - sewage is accumulated in a special container and then pumped out by a sewer truck;

- Septic tank - the wastewater, before entering the ground, goes through a purification stage, as a result of which the wastewater is purified by 80-90%.

Let's consider all the pros and cons of the above-mentioned autonomous sewage systems.

Using calculated and optimal occupancy levels

Also, the fill level of a plastic, asbestos-cement or cast iron sewer pipe must be calculated. This concept determines what the flow rate in the pipe should be so that it does not become clogged. Naturally, the slope also depends on the fullness. You can calculate the estimated fullness using the formula:

- H – water level in the pipe;

- D is its diameter.

The minimum permissible SNiP 2.04.01-85 filling level, according to SNiP, is Y = 0.3, and the maximum Y = 1, but in this case the sewer pipe is full, and, therefore, there is no slope, which means you need to choose 50-60%. In practice, the estimated occupancy is in the range: 0.3

Hydraulic calculation for filling capacity and slope angle

Your goal is to calculate the maximum allowable speed for the sewer drain installation. According to SNiP, the speed of liquid movement must be at least 0.7 m/s, which will allow waste to quickly pass past the walls without sticking.

Let's take H=60 mm, pipe diameter D=110 mm, material – plastic.

Therefore, the correct calculation looks like this:

60 / 110 = 0.55 = Y is the level of calculated fullness;

Next we use the formula:

K ≤ V√ y , where:

- K - optimal filling level (0.5 for plastic and glass pipes or 0.6 for cast iron, asbestos-cement or ceramic pipes);

- V is the speed of fluid movement (we take a minimum of 0.7 m/s);

- √Y is the square root of the calculated pipe fillability.

0.5 ≤ 0.7√ 0.55 = 0.5 ≤ 0.52 – the calculation is correct.

The last formula is a test one. The first number is the coefficient of optimal filling, the second after the equal sign is the speed of movement of the wastewater, the third is the square of the filling level. The formula showed us that we chose the speed correctly, that is, the minimum possible. At the same time, we cannot increase the speed, since inequality will be violated.

The angle can also be expressed in degrees, but then it will be more difficult for you to switch to geometric values when installing an outer or inner pipe. This measurement provides higher accuracy.

Slope of sewer pipes schematically

In the same way, it is easy to determine the slope of the external underground pipe. In most cases, external communications have large diameters.

Therefore, a larger slope will be used per meter. At the same time, there is also a certain hydraulic level of deviation, which allows you to make the slope slightly less than optimal.

To summarize, we will say that according to SNiP 2.04.01-85 clause 18.2 (standard for installing water drainage systems), when installing a corner of sewer pipes in a private house, you must adhere to the following rules:

- For one linear meter of a pipe with a diameter of up to 50 mm, you need to allocate 3 cm of slope, but for pipelines with a diameter of 110 mm you will need 2 cm;

- The maximum permissible value for both internal and external pressure sewerage is the total slope of the pipeline from the base to the end of 15 cm;

- SNiP standards require mandatory consideration of the level of soil freezing for the installation of an external sewer system;

- To determine the correctness of the selected angles, it is necessary to consult with specialists, and also check the selected data using the formulas above;

- When installing a sewer system in a bathroom, you can make the filling coefficient, and therefore the slope of the pipe, as minimal as possible. The fact is that water comes out of this room predominantly without abrasive particles;

- Before starting work, you must make a plan.

Expert advice:

Do not confuse the method of installing sewer pipes in an apartment and a house. In the first case, vertical installation is often used. This is when a vertical pipe is installed from the toilet or shower stall, and it then goes into the main pipe, made at a certain slope.

This method can be used if, for example, the shower or washbasin is located in the attic of the house. In turn, installation of the external system begins immediately from the rings of the toilet, septic tank or washbasin.

In order to maintain the required angle during installation, it is recommended to dig a trench on a slope in advance and stretch the string along it. The same can be done for the floor.

Storage capacity

Container for sewage

The storage tank is a completely sealed container in which the sewage does not go anywhere, and when the container is filled, it is pumped out by a sewer truck.

The sewage that enters the tank is divided into three layers:

- The first layer , the lowest, represents solid organic waste, which, as a result of the activity of anaerobic bacteria (bacteria that multiply in an oxygen-free environment), turns into sludge;

- The second layer is clarified water, which is formed after all solid particles have settled;

- The third layer is fat, which is an accumulation of fatty waste and other particles lighter than water. The fat layer forms an airtight crust, creating a favorable environment for anaerobic bacteria to reproduce.

As in the case of a cesspool, the walls of the storage tank can be made of brick, monolithic reinforced concrete, reinforced concrete rings or a solid plastic container. Particular attention should be paid to sealing the walls and bottom , because the container can be placed below the groundwater level. And for polluting groundwater and poisoning the environment, a person may incur criminal liability.

Sewage well made of bricks (round section) Sewage well (square section)

A brick storage container is sealed as follows: the internal and external surfaces of the brickwork are plastered with cement-sand mortar in a ratio of 1:1 or 1:2. In this case, the grade of cement must be at least M400, and the sand must be sifted. In some cases, to increase waterproofing properties, liquid glass, ferric chloride, sodium aluminate or ceresite solution are added to the cement-sand mortar.

Waterproofing a sewer well made of reinforced concrete rings

Sealing a storage tank made of reinforced concrete rings is carried out as follows: the joints are expanded with a hammer drill and covered with cement-sand mortar with the addition of liquid glass, as described above. The joints need to be processed both outside and inside the rings. Then the outer surface of the rings is waterproofed with roofing felt on bitumen mastic. This will prevent the tank from flooding during heavy rainfall, when the groundwater level reaches its peak level. You should also waterproof the inner surface of the rings with bitumen or waterproofing compounds that penetrate deep into the concrete structure.

Sealing a storage tank made of monolithic reinforced concrete is carried out in the same way as sealing a tank made of reinforced concrete rings: roofing material with bitumen mastic is glued to the outer surface of the monolithic reinforced concrete, and the inside walls and bottom are coated with bitumen or special waterproofing compounds.

Plastic container for collecting sewage

A one-piece plastic container made of fiberglass or polyethylene does not require additional sealing. The walls of such a container are absolutely sealed and are not subject to corrosion or rotting. As a rule, plastic containers are used to collect sewage with subsequent pumping by a sewer truck, or as a treatment facility (septic tank), connecting two containers with an overflow pipe.

Many online resources advise performing external waterproofing of storage tanks using clay ( clay castles ). But this method of sealing will only aggravate the situation, because... In winter, clay saturated with water will expand significantly in volume, which will create excess pressure on the walls of the container, which will lead to the formation of cracks on the walls. In the spring, when the clay melts and decreases in volume, the reverse process occurs, a free space will form between the clay and the walls of the container, into which rainwater will flow, and this will further aggravate the situation in winter.

The bottom of the storage tank , if the walls are made of monolithic reinforced concrete or brick, is made of monolithic reinforced concrete. The ratio of ingredients should be as follows: 1 part cement, 2 parts sand, 1 part crushed stone or gravel. Such a foundation gains the necessary strength in about 7 days. And so that the concrete does not dry out and crack within 7 days after pouring, it is watered with water and covered with plastic film.

If the walls of the storage tank are made of reinforced concrete rings, then it is more expedient to immediately order a reinforced concrete bottom of the appropriate diameter from the factory.

Official standards

There are official standards for the required slope of pipes, prescribed in SNiP 2.04.01-85, paragraph 18.2. This paragraph contains information regarding the arrangement of the sewer system inside the house and to wells, which are located no more than 12 meters from the house. According to these data, the slope of sewer pipes does not exceed 2 cm per linear meter if the pipe diameter reaches 100 mm, and 3 cm per meter with a diameter of about 50 mm. However, in small areas the angle of inclination does not matter, therefore, in the area of a kitchen, for example, or a bathtub from one structure to another, it is quite possible to do without inclination in principle.

For the street network of sewer systems, the standards indicate the required 2 cm of slope, which is standard. However, for a domestic or industrial sewer network within a block or production area, a slope of 1.5 cm is acceptable. Reducing this parameter is possible depending on the minimum speed of movement of wastewater that is permissible in the selected area. They are usually used for wider pipes because it makes sense there.

The optimal length of the sewer system from the house to the septic tank

Good evening! I have the following problem: I bought a septic tank (concrete) from a company that assured me that its installation would be successful. When we installed it, we saw that we had 34 m from the house to the septic tank and the height difference between the outlet of the sewer drain pipe and the entrance to the septic tank was 232 cm. Those. observing the standard slope of 2 cm per 1 m, we come to 164 cm above the entrance hole to the septic tank. The company’s employees did not agree among themselves on how to resolve the issue, and we parted ways with me. From what I have learned, such options are being looked at, taking into account that 2 inspection wells are needed. 1) 3 steps to descend, 55 cm each - 45 degree bend - pipe 45 cm long - 45 degree bend. and between them 12 m with a slope of 2 cm. 2) One long section of 15m with a slope of 8cm and then 19m with a slope of 2cm. 3) Lower the vertical sewer pipe of the house another 1 m, bring it significantly below the foundation and, in two steps of 30 cm each, reach the level of the septic tank. 4) I would really not like to deepen the septic tank with a groundwater level of 0.9.

I would earnestly ask for advice on choosing a sewerage scheme between the house and the septic tank. Kuzmin Vladislav

The situation is indeed a little confusing, and it is not surprising that “the company’s employees did not agree among themselves.” But in fact, everything is not so complicated and we do not see any serious problem. You just need to figure it out:

- First, let's try to understand what kind of sewer we are talking about. The pipe from the house to the septic tank is located outside the building. Someone will definitely tell you that you need to be guided by SP 32.13330.2012 “Sewerage. External networks and structures." However, you should look at what is written at the very beginning of the joint venture:

Is the pipe from a residential building to a septic tank part of the city sewer system? More likely no than yes

Is the pipe from a residential building to a septic tank part of the city sewer system? More likely no than yes. Let us ask ourselves what types of external sewage systems are considered by the mentioned joint venture:

As you can see, street, intra-block, domestic and industrial sewage systems are considered.

Does the effect of the mentioned joint ventures apply to the pipe section from the house to the septic tank? Rather yes than no. But even a specialist will not give you a definite answer to this question. Moreover, according to the rules, the minimum diameter of pipes for external networks is 150 mm. Based on domestic standards, 110 mm pipes cannot be used outdoors. Nevertheless, such pipes are produced and networks assembled from them are successfully operated. We are, of course, not talking about general village highways, but about local sections of pipelines. Since the rules for the construction of external sewer networks do not contain clear instructions regarding the installation of a pipeline from a residential building to a local treatment plant, we suggest focusing on both the standards and common sense. You write: “...observing the slope norm of 2 cm per 1 m...” But such a “slope norm” is not included in the rules. Let us turn to SP 32.13330.2012 already known to us:

As you can see, the joint venture clearly stipulates only the minimum slope of the external sewerage system. Moreover, for a pipe with a diameter of 110 mm (most likely, this is what you will use) this value is not set at all

The joint venture does not say anything at all about the maximum slope for external gravity networks, and the optimal slope is proposed to be determined by calculation using a rather complex formula. We do not know the parameters of your sewer network necessary to determine the exact figure. And we don’t consider the calculation strictly necessary, because 34 meters is not such a long distance, and the volume of wastewater will not be large and constant. In most cases, the optimal calculated value of the slopes of urban domestic sewer networks is a value of 0.02-0.03 (2-3 cm per meter). However, the slope can be significantly greater without compromising the functioning of the pipeline. How to determine the maximum slope for external sewerage if there is not a word about this in the corresponding joint venture? We suggest turning to the good old SNiP 2.04.01-85 “Internal water supply and sewerage”. We will assume that the hydraulics of flowing sewage are similar both inside and outside the house. SNiP specifies the maximum permissible slope - 15% for all pipe diameters. True, this clause disappeared from its updated version SP 30.13330.2012, leaving only restrictions on minimum values and a calculation formula for determining the optimal slope

Minimum slopes for internal networks depending on the diameter of the pipes. Less is not possible, more is possible. But in moderation

So, 15% is a slope that cannot be exceeded, otherwise insoluble sediments will not be washed away and the pipe will certainly become clogged. Let's see what you get: with a length of 34 m, the difference is 232 cm. 232: 34 = 6.82 cm per meter of length. More than the optimal value, of course, but significantly less than the critical value. In our opinion, nothing bad will happen if you lay a pipe from the house to the septic tank at a slope of 0.07 (7 cm per meter). About wells. You write: “2 inspection wells are needed.” Let's look at the norms:

These are the requirements for external networks. As you can see, for a pipe with a diameter of 150 mm and a length of 34 m, there is no need for a well

Rules for internal networks. For pipelines with a diameter of 110 mm, one revision is required per 20 m

Total: if you use a pipe with a diameter of 110 mm and there are no sharp turns on the way to the septic tank, you only need one revision closer to the middle of the route. Moreover, it is an inspection for washing/cleaning. It is not necessary to build a full-fledged concrete well with a hatch. If you still decide to lay pipes with a recommended slope of 0.02, the height difference can be made in a single inspection well. As for the use for turning fittings at 45º - here you are absolutely right, you cannot use 87º turns. When laying pipes at a slight slope, close attention should be paid to its strict adherence. It is not allowed to reduce the slope below the minimum permissible values. The soil or bedding on which the pipes are laid must be thoroughly compacted. Otherwise, if it subsides, areas with a reverse or zero slope may form. Even a small puddle in the pipe will quickly turn into a permanent blockage. By the way, it is more difficult to reliably lay a sewer system at a slope of 0.02 than at a slope of 0.07.

When laying a sewer system from the house to the septic tank, you should carefully monitor the uniformity of the accepted slope. Deflections should not be allowed where the slope would be less than required

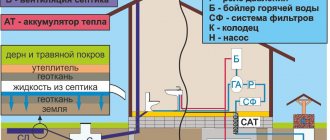

Many people in their summer cottages and country houses use a septic tank as a treatment facility, but not everyone knows what kind of design they need and how the system generally works.

So what is an autonomous septic tank in a private house and how does it work?

A septic tank is a special treatment facility (sewage system for a country house), which operates without the consumption of electricity, where wastewater is processed in a sump, and an underground filtration system produces decomposition without access to oxygen.

The treatment plant can be located up to 20 meters from the building; dirty water flows through outlets into a common tank. Elements that cannot dissolve remain at the bottom, and with the help of anaerobic bacteria, the water part begins to ferment. During the life of bacteria, methane is released; to remove it, a pipe installed 1-2 meters above the roof of the building is used.

From 50 to 75 is the percentage of water purification, after which the incompletely purified liquid flows into the ground for final purification. The insoluble sediment that accumulates at the bottom of the septic tank is cleaned out by the pump of a sewage disposal machine. Depending on the intensity of use, the structure must be cleaned at least once a month.

To improve the quality of wastewater, a specialized biofilter is installed in the system, the most common option is made of expanded clay.

Here, wastewater can also be purified aerobically, that is, using oxygen. Before the water enters the biofilter, it is clarified. Afterwards, anaerobic bacteria break down the impurities, turning them into sludge; the resulting sediment on the filter must be removed after a certain period of time.

The percentage of water purification in this design is much higher and is about 90%. Once the water is purified, it goes into the well to process the remaining impurities with the help of aerobic bacteria and oxygen. In this interaction, all elements are finally decomposed. To completely clean the liquid, the next stage is to drain the water into the soil.

The most common and effective method of wastewater treatment is underground filtration. To install the system on the ground, layers of filter sand will be required.

The structure is made of pipes with small holes, lined with crushed stone around the perimeter. This cleaning system has a small throughput and is suitable for use by families of 2-3 people.

To increase volumes, additional filter layers of gravel and sand are used, with the use of additional cleaning trenches.

Cleaning systems are divided according to their operating principle:

- with soil filtration;

- with biological treatment;

- cumulative.

Septic tanks are divided according to the material used for the manufacture of structures:

- plastic;

- brick;

- reinforced concrete rings;

- metal.

Designs differ in installation method and shape:

Treatment facilities can be installed both on the surface of the earth and underground.

Which pump is optimal for supplying water from a well?

A wall-hung toilet is a new solution for the toilet.

The choice of a particular type of design depends on the intensity of use, and calculations of daily throughput will be required.

The septic tank is cleaned using the pump of a sewer truck.

A storage septic tank is presented in the form of a container where wastewater coming from the building is collected. The operating principle of the device is simple: the entire incoming mass is divided into heavy fractions, which settle at the bottom and light impurities that float to the top.

In modern cleaning devices, the liquid is stored in a container until the cleaning stage. Containers are cleaned as they are filled using a special equipment pump. The main advantage of the design is its ease of use, but the disadvantage is the need for constant cleaning during operation.

Storage-type devices are recommended for use in buildings not intended for year-round living, for example, in summer cottages. When choosing a septic tank, for uninterrupted operation it is necessary to take into account the following factors:

- It is better to choose a large-volume container, which will subsequently reduce costs for the services of a sewage disposal team;

- The design of the container must be made of high-strength material so that the container is not damaged during operation under soil pressure.

If you plan to live permanently in a country house, then it is better to choose an overflow septic tank design; here, not only does the liquid drain, but also cleans it . Using such a device, you will have to call a sewer truck a maximum of 3 times a year.

To increase the period between container cleanings, bacteria for septic tanks are also used; with their help, you can significantly reduce the mass of undecomposed particles.

Advantages of the cleaning system:

- the septic tank is easy to maintain and use;

- Cleaning of drains;

- saving money on the services of sewage disposal equipment

The installation of the cleaning structure cannot be carried out on clay terrain . The disadvantage of this type of septic tank is that it will not be possible to produce a functional filtration field if groundwater is located close to the surface, and it also cannot be installed on clay soil.

The construction of a septic tank with your own hands occurs in several stages.

To dig a pit with the correct parameters, you need to accurately calculate the daily volume of wastewater discharge, and increase the data obtained by 3 times with a 20% margin. The volume of the first chamber of the septic tank is equal to the volume of the drain. 30% of the volume of the first chamber is the second. The approximate depth of the pit is 2.5 meters; here it is necessary to take into account the composition of the soil where the treatment facility is installed.

The lower edge of the drain pipe should be located 80 cm from the bottom of the 1st chamber.

Here we will consider the construction of a concrete septic tank; you can also use plastic containers, reinforced concrete containers and other materials.

The construction of the formwork takes place according to the parameters of the future septic tank, that is, the filling takes place in two parts. A 10 cm tee is used as a partition. The upper edge is installed 2-5 cm below the drain pipe.

The filling is done in several layers, everything is compacted and strengthened with stone. After pouring the next layer, time is given for complete drying. You need to remember about the hole for the drain pipe. The partition is poured at the same time as the walls. As a result, a solid structure is formed. Any metal is used for reinforcement, and fine crushed stone or gravel is used to dilute cement.

After building the walls, the septic tank structure is left to dry completely for 3-4 days so that the concrete gains its maximum strength. The septic tank is covered with a wooden deck.

Metal reinforcement is installed on top; if necessary, it can be nailed in some places.

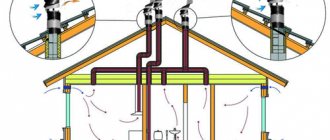

One board wide formwork is installed around the perimeter of the cleaning device. A 5-10 cm ventilation pipe is installed in the ceiling of the 2nd chamber, it should be 2-3 meters above ground level, in the ceiling of the 1st chamber it is necessary to leave a connector for the hatch.

The lid is filled with concrete in a 15 cm layer, the filler is crushed stone. After the concrete has completely dried, the surface of the lid is completely covered with earth, and the resulting area is used for its own needs.

If the design of the septic tank in the 1st chamber is made with a solid bottom, and a layer of crushed stone is laid in the 2nd chamber, then additional soil treatment will not be needed, the main thing here is to correctly calculate the required volume.

The process of installing a sewer-septic tank in a private house with your own hands is shown in the video:

As you can see, there is nothing complicated in the construction of an autonomous sewer system , but this matter requires a special approach and responsibility. The entire processing process is carried out by bacteria, and we create all the conditions for their life.

The construction market offers many septic tank designs that can be used in almost all conditions, even in cases of clay soil or groundwater flowing close to the surface. There are treatment facilities where wastewater is filtered up to 100%, and therefore liquid can be discharged into rivers, lakes or onto the ground.

How to arrange a route on a slope

The most important point in arranging sewer systems is the issue of laying a route in areas that have a natural slope. After all, on a flat area there is no problem making a slope at the desired angle, but on the slopes there are a number of difficulties! If you lay a pipe simply parallel to a piece of land that has a slope, then it is impossible to maintain the required correct slope, and this leads to the formation of blockages in the pipe section.

In this case, it is necessary to carefully consider a detailed plan for the arrangement of the sewer network in order to comply with the slope required by the regulations. Sometimes this requires very serious excavation work, since structures have to be buried to a more impressive depth. This is the only way in some cases it is possible to maintain the correct angle of inclination so that various kinds of problems do not arise as a result.

What to do if the distance is not enough?

Not every owner of a country house or dacha can boast of a large plot of land. Therefore, when creating a sewer system, for the outer part of which clearly visible, bright red pipes are used, a situation often arises when it is impossible to measure the distance required by the standards.

But even in this case, disregarding the rules is unacceptable. The problem can be solved by searching for another option for arranging a sewer disposal system.

For example, you can choose to install a storage septic tank - equipment in the form of a monolithic tank that requires periodic cleaning of sludge deposits. Or spend money on installing a VOC, which carries out a full cycle of water treatment, making the use of an individual drainage system simple.

How to make the right slope

It is possible to lay a pipe without violating the requirements of SNiP using a building level with a length of 1 meter. By placing the level above the pipe so that one end rests against the pipe, and the other has a gap of 2 cm with the pipe (if we are talking about a pipe with a diameter of 110 cm), you can quite accurately meet all the necessary requirements.

Under the pressure of the gravity of the soil, the pipe may well change position, and in order to prevent this from happening, you need to thoroughly sprinkle the pipe with sand and compact it (to do this, just pour water on the sand around the pipe). This ultimately avoids the risk that the pipe will change its angle of inclination when the soil moves. It is important to remember that soil settlement in a dug trench is inevitable, which means there will definitely be movement!

Network ventilation system

To prevent an unpleasant odor from the sewer system, a ventilation system should be installed. It is mounted together with risers. To avoid mistakes, study building codes. The ventilation pipe must rise above the roof so that the roof and gusts of wind do not interfere with the removal of air. There should be a special umbrella at the end of the pipe.

The sewerage system should be equipped taking into account building codes and regulations. Otherwise, if the requirements of SNiP are not met, the surrounding area and nearby water bodies will be polluted due to the improper functioning of the autonomous treatment plant. In addition, living in the house will become uncomfortable.

;

Sewerage

Did you find this article helpful? Share it with your friends:

What types of pipes should be used for laying in the ground?

When laying sewer pipes in the ground, it is worth knowing that the same pipes that were originally intended to create a network indoors are not suitable here. Heavy layers of soil are gradually capable of causing serious deformation to the walls of the pipes, flattening them, which can even lead to complete blocking of the route. One of the most unpleasant consequences will be that you will have to completely redo all the work, which is especially inappropriate in already landscaped areas near the house, when excavation work is simply no longer possible or undesirable. In addition, the situation threatens to become critical, and work will be required as urgently as possible, since it will be impossible to use the sewer system in order to avoid other problems.

For external work, pipes with a wall thickness of at least 3.2 mm are used so that they can withstand the appropriate load. They are usually red in color, but sometimes they are gray or deep black. It is these pipes that should be laid in underground structures so that they can withstand the weight of the earth poured on top of the pipes.

Septic tank and water pipes

Another criterion that will help determine at what distance from the house to build a septic tank. It is very important to prevent even a small leak into drinking water. Therefore, the autonomous sewage system should be located as far as possible from conventional water pipes. In the event of a leak, immediately stop using water for washing dishes, cooking and personal hygiene. In order to avoid premature problems and mistakes, it is better to perform everything according to the stated standards. General recommendations state that it is better to conduct an autonomous sewerage pipeline separately. The distance should be more than 10 meters. This method will help protect yourself from unnecessary diseases.

Layout of water and sewer pipes Layout of water and sewer pipes Source dobrostroy54.ru

Obviously, a septic tank is a rather dangerous structure that needs to be taken seriously. If you neglect the basic rules for operation, you can easily lose money, free time, and most importantly, health. It is necessary to accurately plan the construction and carry out the appropriate calculations. It is better if the distance from the septic tank to the house is calculated in a special bureau. Even if the installation is planned to be done manually. However, proper installation and purchase require certain skills.

To install a septic tank, it is better to use the services of specialists Source vi.decorexpro.com

Carrying out road cleaning

In a situation where autonomous sewer systems are located at a distance of more than 15 meters from the house, then, according to SNiP, the equipment of various inspection wells or cleanings is required. Such special inspection wells should be installed every 15 meters of the pipe, or even every 10 meters if we are talking about straight, level sections.

Special inspection wells for an entire network of sewer pipes with a diameter of 100 mm or more are usually installed in sections of the pipeline where there are turns in the circuit or changes in slopes, as well as connections of branches or pipes of different diameters. This will increase the level of reliability of the entire system, as well as simplify monitoring the operation of the system and the use of sewerage.

When arranging communications, various questions arise, for example, how to choose the diameter of a sewer pipe in a private house. It is this parameter that determines how the entire wastewater disposal system will function.

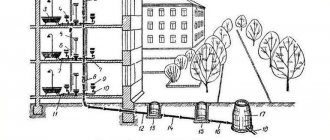

Elements of external sewerage

Installing an external sewer system is quite difficult, since it consists of many turns, inspection hatches, slopes, and tanks. Such a system should be equipped taking into account sewerage building codes, adhering to safety precautions.

The highway includes the following components:

1. Pipes of different lengths and sections.

2. Well: one or several. Wells can be:

- auditing;

- drainage;

- differential;

- rotary.

3. Outlets and receivers so that wastewater can enter the storage tank.

4. VOC (local treatment plant): septic tank or aeration plant. How many there should be is specified in the sewerage building codes. After filtration, wastewater seeps into the soil or ends up in rivers and lakes. They can also be used for technical purposes, to water garden plants.

Important! An autonomous sewer system cannot function without a septic tank or aeration unit.

5. Pumping station. They are installed in some cases if it is necessary to supply wastewater for filtration in parts.

How to choose a septic tank for a country house:

6. Parts that help the sewer system function properly, such as installation equipment.

Types and uses

The sewer system removes large amounts of liquid, which may contain large particles. Therefore, tubular products with a cross-section from 50 to 110 mm are recommended for use here.

A smaller cross-section pipeline is suitable for creating an internal network. This includes outlets from household appliances and plumbing fixtures.

Pipelines for the general sewerage outlet are assembled from large-sized elements. Most often, installation is carried out through the toilet. This is due to several reasons:

- A large amount of water is drained from the toilet cistern at the same time.

- Large waste passes through the toilet, which can cause blockage in a narrow pipeline.

Materials for external sewerage

In order for external sewerage to work without interruption, it is important to choose the right materials for the pipeline and other elements of the system. Wastewater contains household chemicals, so pipe materials must be resistant to aggressive environments.

Note! In most cases, when installing an external pipeline, polymer pipes are used.

Choose modern materials, for example:

- polyvinyl chloride;

- polypropylene;

- polyethylene;

- cast iron;

- steel.

Experts recommend installing an external autonomous sewer system made of polymer materials, such as plastic. Installing metal pipes will be problematic.

However, when the pipeline is laid in an open way, polyethylene products cannot be used, since this material changes its characteristics under the influence of ultraviolet radiation and deteriorates. If it is not possible to purchase pipes from another material, it is necessary to install a protective casing. It can be played by old steel pipes.

The most durable pipes are made of polyvinyl chloride. This material is budget-friendly and is not afraid of exposure to sunlight. Installing such a pipeline is relatively easy, especially when compared with steel pipes. PVC pipes are available in different ratios of diameter, length and wall thickness. Product characteristics are contained in a special table. A pipeline made of this material is suitable for both pressure and non-pressure sewerage.

Important! A non-pressure pipeline is installed in gravity mains.

If the sewage system is non-pressure, you can install PVC pipes for the external main (at an angle). However, the flow speed of wastewater should be no more than 8 m/sec.

When sewage is removed by pump operation, pressure pipes made of polyvinyl chloride will be required. Their operating pressure is 10 atmospheres or more.

Corrugated PVC products are used for laying complex routes. During installation there is no need to use special machinery and equipment. Such pipes are suitable for creating both pressure and non-pressure lines. To determine what the cross-section and wall thickness of the product should be, you should use the table.

In rare cases, it is possible to make a pipeline from reinforced concrete or asbestos cement. Such pipes are suitable if the sewer system is large and products with a large diameter are required. Due to the fact that the material is fragile, it is suitable for creating non-pressure networks.

Main settings

When arranging a sewer system, you have to master a lot of information. You need to know the diameter of sewer pipes for a private house, as well as the main parameters of products for this system:

- The symbol “D” indicates the internal diameter; it is taken as a basis when choosing elements for the drainage system of a private house.

- The letters “DU” usually indicate the size of the nominal diameter. This parameter is necessary when determining the nominal value of the internal section of the pipe.

- When designating the nominal cross-section, the letters “DN” are used.

Norms, standards and requirements for organizing a sewer system

Since wastewater moves from the house to the septic tank by gravity, it is important to lay the pipes at a certain angle to avoid stagnation. Typically the slope is from 2 to 3 cm per meter of pipeline, but not less than 1.5 cm.

It is also important to choose the correct diameter, which depends on the type of pipe and the number of devices connected to the cleaning system.

Recommendations for choosing the diameter:

- To connect a washbasin or bidet – Ø32-40 mm,

- To connect a sink or bath – Ø from 50 mm and more,

- For a riser or when connecting several elements of sanitary equipment at once - from 70-85 mm in diameter,

- For connecting a toilet or for installation as a drain pipe, riser – Ø100 mm or more.

Important! In an unheated room or outside, installing a sewerage system yourself necessarily involves protecting pipes from overheating and freezing. In order to maintain a constant temperature in the range of +5-+45C, the pipes are usually covered with mineral wool or other types of thermal insulation.

As for the angle of inclination, the angle of change in the direction of laying the pipeline should be more than 90°, but those pipes with which various plumbing fixtures are connected to the riser are fixed at an angle of 45° or less.

Calculation rules

When deciding how to calculate the diameter of a sewer pipe in a private house, a special regulatory document is taken as a basis. Here we take into account:

- Pipeline slope.

- The size of the angles of connection of horizontal sections with the riser and much more.

The drainage system requires precise calculations, but the solution to the problem in private housing construction should be simpler.

The diameter of sewer pipes for a private house is calculated as follows:

- Houses with a small number of plumbing equipment and household appliances can be equipped with 10 cm sewer elements.

- The removal of water waste with small particles is carried out with products measuring 50 mm.

- Metal and cast iron pipelines have a rough inner surface. This is most often the cause of silting or clogging of pipe sections. The cross-section of cast iron products for sewerage should be larger than that of their plastic counterparts.

- The sewer riser of a multi-storey building should have a cross-section of 10-15 cm.

- When installing several sewer risers, their connection is made with 200 mm pipe sections. This ensures the efficient operation of the entire sewer system.

Features of the operation of plastic pipelines

PVC sewer pipes 50 mm do not require the creation of greenhouse conditions for transportation, storage and operation.

When working with these products, you must adhere to several rules:

- Do not use them for the construction of fire water pipelines.

- Sawing workpieces only with hand tools. The grinder can greatly melt their edges. After cutting, the edges of the cut are thoroughly cleaned of burrs.

- To avoid bending, products should be stored horizontally.

- It will be easier to join the fragments if the rubber gaskets are lubricated with Vaseline or silicone.

Assembling a sewer system is a fairly simple task, which is accessible even to a beginner.

How to choose

The selection of sewer components requires preliminary drawing up of a pipeline diagram. It should indicate areas with maximum and minimum load. The diameter of the sewer pipe in a private house is selected taking into account several nuances:

- Blockages always form in narrowing areas, so sewer outlets must have the same diameter along their entire length. Horizontal sections of the system connected to a common riser should have less internal clearance.

- Sewer outlets 16-25 mm can be used for liquids without contamination. In particular we are talking about air conditioners, dehumidifiers or ventilation units.

- When draining contaminated liquid from a washing machine or dishwasher, use a 2.5 cm pipe.

- The kitchen sink is connected to the general network with 4 or 5 cm drains. This is explained by the size of the outlet pipes and holes. In addition, the cost of large-sized products is several orders of magnitude higher; they take up more space.

- A bidet and a bathroom sink allow a large amount of water to pass through at the same time, so it is better to choose 40-50 mm connections.

- A bathtub or shower can be connected to a common drain with elements of 3.2-5 centimeters. In the case of a bathtub, this is explained by the presence of a special grate in the drain hole. It slows down the flow rate of outgoing water. As for the shower stall, the contaminated liquid flows out of it gradually.

- Toilet drains may contain large particles, so the discharge pipeline must be assembled from elements with a cross-section of at least 11 cm. The same size is recommended to be used when installing a sewer riser and a waste pipe.

- Pipeline sections outside the house should have a cross-section of 160-260 mm.

The correct solution to the question of what pipe diameter to choose for sewerage in a private house ensures the effective removal of waste liquid from the sewer.

Application area

Application of plastic pipelines

Due to their many advantages and varied sizes, 50 mm plastic sewer pipes have a fairly wide range of applications.

According to the method of use, they are divided into the following categories:

- For the construction of an internal sewer system.

- For the installation of external sewage systems.

- To create a rainwater drainage system.

- For the installation of water pressure systems.

Based on their purpose, the walls of the products have different thicknesses and materials of manufacture. The most durable are those produced for pressure systems. 50 mm plastic pipes for internal lines have the least strength, as they do not experience strong impact. They are used to drain wastewater from kitchen sinks, washbasins and bathtubs. But even they have sufficient strength to withstand a strong impact or bending.

On a note

: For ease of use, the fragments for arranging the external drain are painted bright orange. This draws attention to them, which helps prevent destruction of the drain system.

Internal systems can be assembled from white, black and gray material. The most practical is gray plastic. Dust and scratches are practically invisible on its surface.

For ease of use, the following elements are used when assembling sewer systems:

- tees for creating a branched highway;

- adapters for inserting 50 mm plastic pipes into 110 mm risers;

- couplings for connecting identical fragments;

- angles for making highway turns;

- stubs.

Fittings are more durable than pipeline products. To ensure insulation, special glue and sealant can be used. Considering that rubber gaskets quickly fail, you can purchase a set of spare gaskets.

Helpful operating tips

In order for the autonomous drainage and water purification system to become clogged as little as possible and to function for a long time and efficiently, it is enough to adhere to a few simple operating rules:

- Periodically, it is recommended to carry out preventive flushing of all systems with large volumes of hot water,

- If possible, avoid washing fats of animal origin into the sewer - they harden when cooled and accumulate on the walls of pipes,

- Clean the septic tank in a timely manner - for a MAPLE septic tank, cleaning should be done at least once every 2 years,

- Be sure to use protective debris catchers in bathtubs and sinks to prevent hair, dirt and other waste from ending up in the drain.

Now you know everything and even more about DIY sewer installation. Good luck!

Fines for violations

For any violations of the construction or operation of a cesspool, the legislation of the Russian Federation provides for a fine.

However, its size will depend on the severity of the violation, as well as on the number of previously recorded cases of ignoring regulatory documents.

Diagram of daily waste volume

For example, the standards stipulate that a pit with a filter bottom can only be equipped if the daily volume of wastewater does not exceed 1 m3.

Otherwise, the owner of the land plot faces a fine.

Its size will be determined by the court, because it is in court that the issue of choosing a punishment will be decided.

But it should be understood that this is a serious violation of environmental standards, so the fine can reach several thousand rubles.

Well with filter bottom

If a complaint is received from neighbors and a single violation of the rules for operating a cesspool is discovered, then the owner will first be issued a warning with a strong recommendation to eliminate the problem.

If sanitary standards for the operation of a cesspool continue to be violated, there is a risk of receiving a fine. The maximum fine for a cesspool without a bottom is 500 rubles. (according to the Code of Administrative Offenses of the Russian Federation, Article 6.3. Violation of legislation in the field of ensuring the sanitary and epidemiological well-being of the population).

At the same time, its size may increase, especially in cases where the owner of a private plot ignores warnings and penalties more than once.

It is necessary to monitor the condition of the cesspool

In addition to a fine, which can reach 500 rubles, the court may order the drain to be remodeled, moved, or completely eliminated.

This is relevant in cases where the distance of the cesspool from its neighbors according to SNiP is violated.

In view of this, it is better to initially carry out construction taking into account all norms and distances.

Cesspool location, diagram