Plumbing siphons are a device for draining waste liquid into the sewer system. Any types of these devices are connected to the sewer through pipes and hoses. The most popular corrugated connections. Siphons and their connecting elements are made of various materials and are functionally designed both directly for drainage and for protection against the penetration of unpleasant sewer odors into the home.

Peculiarities

The widespread use of corrugated connecting structures is due to the fact that they are much stronger than pipes with a smooth surface and are convenient to use. Due to the ability to stretch and compress, it is not necessary to use additional fasteners. Corrugation is a flexible ribbed pipe that is available in single-layer and multi-layer types. It can be ribbed on the outside and smooth on the inside.

According to their intended purpose, they perform connecting functions for transporting waste liquids to the sewer system. When used in sewer drains, they actually play the role of water seals, which, based on physical laws, ensure, along with drainage, the creation of an air gap in a pipe curved in the shape of the letters U or S and, accordingly, protect the room from unpleasant odors.

Features of connecting the drain of washing machines

Connecting the drain of washing machines is a different matter. These hoses are subject to higher strength requirements, since due to the smaller diameter the pressure, especially when draining the washing machine, is increased. For these purposes, thick-walled bends are often used from the most durable and elastic materials, resistant to the effects of fracture and designed for increased pressure.

In such cases, polypropylene or reinforced plastic corrugated connections with a diameter of 20 mm are used.

Connecting the drain of washing machines is done in the following ways.

- Direct connection to sewer. A special insert into the sewer system is provided, but a water seal is used based on a standard hose included in the equipment set (a standard holder is used, which gives the drain hose a U-shape).

- Connection to the sewerage system using an autonomous siphon for the car. A special connection is also made into the common drain, where a siphon is installed, to which, in turn, the drain hose of the washing machine is connected.

- To connect the washing machine drain hose to the sewer inlet, the most acceptable solution is to attach the drain to a siphon under the sink. To do this, a bottle-type device must be installed with an additional connecting fitting of the appropriate diameter, the so-called universal siphon of a combined configuration.

Such devices are the most functional and save time and money. They are designed to simultaneously discharge used water from washing machines and sinks. Currently, similar devices are produced with several fittings, which are equipped with check valves. This provides double protection and allows you to synchronously connect such powerful units as a washing machine and dishwasher.

You can learn how to repair the corrugation and siphon from the following video.

In the drainage system, sink siphons connect it to the central sewer system or to an autonomous one in the case of country houses. There are different types of structures, but the most common of them is corrugated. It combines the necessary practicality and affordability.

Advantages and disadvantages of different types of corrugated siphons

Corrugation. This is a flexible folded pipe made of plastic, less often metal, with connecting elements and a hole for draining water from a sink or other plumbing fixtures. A water seal in such a siphon is formed because the pipe is bent during installation (that is, it forms an “elbow”) and secured with plastic clamps.

The advantages of this design include:

- low price;

- mobility - if the sink is moved, the corrugated drainage device can be easily moved due to its ability to shrink and stretch;

- compactness;

- versatility - the corrugation is suitable for almost any plumbing fixture (sink, bath, shower, bidet), in addition, there are models with several outlets for connecting to household appliances);

- ease of installation - assembling and installing a corrugated siphon can be done easily without the help of a specialist.

But this device also has its drawbacks. These include the low strength of the pipe (it is easy to damage mechanically), as well as the ability to accumulate fat and small waste in folds. Therefore, the corrugated siphon needs periodic cleaning, which consists not only of using special chemical compounds, but also of washing it with running water when dismantled.

Do not forget that you cannot crush the pipe or use sharp objects on it, as this will lead to the appearance of cracks and, accordingly, leaks.

The corrugated metal siphon looks stylish and aesthetically pleasing; due to its rigidity, it does not need to be fixed with clamps, which is why it is used for open washbasins.

Corrugation is also used in bottle siphons, where it replaces a standard rigid pipe and makes it easier to connect the device to the sewer. This corrugation has the advantages of both types of siphons. In addition, if there is a flask, the device is easy to clean, due to which its corrugated part will not need frequent washing.

Dimensions

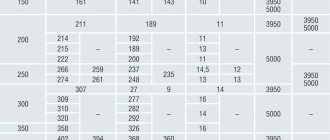

Standard sizes of corrugated connections:

- diameter – 32 and 40 mm;

- The length of the pipe varies from 365 to 1500 mm.

For showers, bathtubs and sinks, overflow holes are used to protect against overfilling of the tanks. These devices use conventional corrugated thin-walled plastic pipes, usually with a diameter of 20 mm. They are not subject to high loads, so this solution is quite acceptable.

It is not advisable to lay corrugated pipes horizontally, since under the weight of water they sag, forming stagnation of liquid.

How to choose a corrugated siphon for a sink

When choosing a corrugated siphon, you need to pay attention to the following characteristics:

- Device dimensions. The product should fit easily into the space under or behind the sink or in a cabinet. Its length is often specified as a range of values (for example, 32–65 cm), since the pipe can shrink or stretch. If there is only one value, this means the maximum length of the corrugation.

- Diameter of inlet and outlet pipes. They must match the diameters of the sewer pipe and sink drain. If you use plumbing fixtures of non-standard sizes, it is better to consult with specialists at a plumbing store or purchase a custom-made siphon.

- Complete set. It is advisable to make sure that the kit includes all the parts necessary for installation: outlet, pipes, gaskets, fasteners and clamps. If these items are not available, you will have to purchase them separately.

- Number of taps. If you plan to connect not only a sink, but also another device to the siphon, you need to select a product with additional outlets. For a double sink in the kitchen you will need a siphon with two pipes.

If there is a hole in the sink that prevents it from being overfilled with water, then you need to choose a siphon with a so-called overflow (an additional hose for drainage). This function will protect the room from flooding if you forget to turn off the tap.

Manufacturer. It’s not always worth paying attention to expensive foreign models right away. Products from Russian companies are cheaper, but at the same time they have decent quality.

It is important to ensure that there are no cracks, scratches, creases or other defects on the surface of the product parts (especially the corrugation). All this can lead to improper operation of the device and leakage.

Once the choice is made and the siphon is purchased, you can begin installing it.

Installation of plumbing corrugated pipes

Over time, almost any plumbing fixture fails. As a rule, the reason for this is the occurrence of one or another emergency, or they fail because they have already exhausted their service life.

When moving, many people have a need to replace plumbing fixtures. In some cases, they are replaced completely, and in others, components are changed, such as, for example, certain pipes or, for example, siphons. The reasons for replacing these elements vary. Some people simply trust advanced manufacturers, another part is not satisfied with the quality of work and installation of existing devices, and the third part simply wants to redo everything themselves.

Corrugated pipe, or as it is also called corrugation, is one of the most popular types of plumbing fittings. They are used to provide a connection between a toilet or sink and a sewer pipe. They are quite elastic, they can bend easily, which is very important, since this circumstance allows you to connect a plumbing fixture to the sewer without taking into account the location of the sewer pipe, and without taking into account the required bending angles of the pipe. Also, a very important positive feature of corrugation is its ability to not become clogged and to prevent the penetration of unpleasant odors into the room. Most often, these corrugated pipes are used when it is necessary to install a toilet or sink.

Installation and replacement of corrugated pipe

Do you need to understand which corrugation should be replaced? In particular, there are several types and sizes of such products. For toilets, sanitary corrugations are used, which have a diameter of 10 centimeters, and for sinks, a diameter of 5 centimeters is used. At the first stage of corrugation installation, you need to make sure that the plumber has sufficient experience to perform this type of work. It is also necessary to remember that during installation we will need silicone. Silicone is necessary to ensure sealing of joints. To do this, the joints in the places where the corrugation is attached to the toilet on one side and to the sewer pipe on the other side must be coated with silicone. This action is very important, because if this is not done, after a short time the corrugation will have to be replaced again.

Among other things, before purchasing corrugated pipes on the market or in a specialized store, you need to make sure of the quality of the purchased products. Corrugations of high quality are produced by renowned manufacturers, such as Malpine. Also, a quality product must be dense and must have any visible external damage on the surface. A good corrugated pipe should have high elasticity properties, and at the same time it should have fairly hard rubber. This corrugation will last longer, and you won’t have to change it more often than you would like. If you install low quality products, they will eventually harden and crack, after which they will need to be replaced.

Positive qualities of corrugation when used under a sink

Traditionally, a sink is connected to the sewer network using two methods. With the first method, the connection is made through plastic pipes, and with the second, the sink is connected to a siphon, and the siphon is connected to the sewer network using corrugated products.

The use of a ribbed product when installing a sink has some positive qualities. In particular:

- Using corrugation under the sink is an excellent solution, as it can stretch quite easily, and this will eliminate the problem of choosing the length of the pipe. It is important to remember that even though the corrugation stretches, it should not be stretched with great force, because its walls are made of rubber materials, and accordingly they are not very strong. Therefore, if the corrugation is stretched too much, its strength can be seriously damaged, and thus its shelf life can be reduced.

- Sink and drain installation is greatly simplified. When using plastic pipes, you will be faced with the need to form various kinds of turns and bends. In the case of corrugation, this problem disappears, since you can directly connect the pipe coming from the outlet of the siphon to the sewer network pipe.

- The use of corrugated pipes is also more effective when working in cramped conditions. If you install plastic in such conditions, you will encounter certain difficulties.

- Cheap and accessible. A siphon with corrugated pipes can be purchased at almost any plumbing supply store. Its average price ranges from 200 to 600 rubles.

In addition to the positive qualities, there are also some negative qualities, and some of them are quite significant. In particular:

- Corrugated pipes have a ribbed surface. Such a design is not always beneficial, especially for ensuring the removal of waste, especially in the kitchen area. When using corrugation under the sink in the bathroom, there will not be any big problems, since water will flow through it, but in the kitchen it can get clogged quite quickly. The folds will do a good job of holding down food residues.

- Corrugation has a rather low resistance to various types of mechanical stress. The walls of the corrugated pipe are quite thin and can therefore be damaged very easily.

- If a corrugation is installed under the sink, then using a plunger to clear the blockage is prohibited. Since certain pressure differences will be created, which in turn can lead to pipe rupture. Also, it is forbidden to clear the blockage using other tools, such as a plumbing snake (cable).

Corrugation, when used under the toilet

Corrugated pipe is very popular today when installing a toilet. They have a lot of positive qualities.

- Installing the corrugation is quite simple. Almost anyone can do this kind of work.

- If you need to move the toilet, then the corrugated pipe is simply an irreplaceable element.

- The corrugation is also indispensable if the toilet is installed for a certain period of time, for example, in a bathroom still under construction or being renovated.

- Corrugation will also help solve the problem that arises when the diameter of the pipe on the toilet and the entrance to the sewer pipe do not converge.

In addition to the many advantages of using corrugation, there are also certain disadvantages. In particular:

- Corrugated pipes have a low level of strength, so they can be damaged quite easily. This circumstance must be kept in mind when carrying out installation or repair work. It is also important to remember this during operation.

- Corrugations are usually used exclusively in areas that are open. They are not allowed to be installed on the wall.

- Pipes of this kind, when used for a long time, tend to sag in some places, which can become a point of contamination and, accordingly, clogging, especially if a large angle is formed.

In addition to the above disadvantages, there is one more. It is not related to the qualities and properties of the pipe, but is related to the fact that there is simply a huge amount of counterfeit products on the market today. For this reason, you should buy corrugation only from trusted outlets.

Features of installing a corrugated pipe on a toilet

Usually the work is carried out by a plumber, but if you decide to do everything yourself, then installing the corrugation on the toilet is done in the following order. First, the end of the corrugation is lubricated with silicone and inserted into the sewer pipe until it stops, and the other side is inserted into the toilet drain pipe. Both the toilet flush and the sewer pipe should be cleaned before installation. The corrugation must correspond to the diameter of the connected pipes and not have any cracks or damage.

The use of a rubber seal on both sides will be a significant plus, coupled with the above, since this will significantly reduce the risk of leakage. And if a plastic pipe is inserted into a cast iron pipe, then you cannot do without it.

Features of installing corrugations under the sink

When ensuring the installation of corrugations under the sink, some requirements apply to the siphon fastenings, as well as the corrugations. At the first stage, a siphon is installed. It is important to do everything correctly, because if you make mistakes or do not secure the siphon well, when using the sink, unpleasant odors will escape into the room. Leaks may also occur. Installing corrugations under the sink is a fairly easy process. It is necessary to secure the corrugation to the sink outlet pipe, on the one hand, and to the sewer pipe, on the other. This is done through membranes, which should be included in the kit. The performance of such work should be entrusted to an experienced person. If you do it yourself, check the dryness of the joints over the course of several days.

vseprotruby.ru

Selecting the right model suitable model

The choice of a corrugated siphon for a sink is determined by several main factors:

- the place where the siphon will be installed;

- the size of the sink and the diameter of the drain hole;

- the material from which it is made.

If the kitchen sink is located in a place where there is very little space under it, definitely just install a corrugated pipe and bend it. If space allows, you can also use a glass siphon with a corrugated outlet. The choice of material and the money for which the buyer is willing to buy the product are interconnected. If strength and durability are more important, it is better to choose metal corrugation. If the budget is limited, the plastic corrugation for the siphon will cope with its functions, but it will have to be used more carefully.

Types of designs

Plastic product

According to the type of material, the corrugated siphon can be plastic or metal. The first option is much more common and is in great demand, as it is cheaper. The second one looks more aesthetically pleasing and solid, but costs more. Plastic corrugations are less strong and therefore less durable.

By design, there are two main types of such siphons:

- consisting only of a corrugated pipe, bent and secured with clamps;

- glass (bottle) type siphon with corrugated outlet.

The first design is the simplest. The pipe can be bent and stretched to fit any space. The clamps used are plastic. The product is installed very simply: it is inserted from above and screwed to the drain hole in the sink, and from below it is connected to a pipe that leads to the sewer. A metal corrugation for a washbasin or sink for such a design does not require clamps that hold the bend of the pipe, since it is made of a more rigid material than plastic, but installation is carried out according to the same principle.

The second design is more complex. The drain pipe is attached to a glass, to which a small smooth pipe leads directly from the sink opening. The glass itself consists of several elements; it can be disassembled: all parts are attached with threads and can be easily unscrewed. The corrugated glass is connected to the sewer pipe.

More complex designs are equipped with additional outlets (for example, for a washing machine) or two drains, which are removed from two sinks, combined into one pipe and connected to the sewer.

Installing a combined drainage system under a sink or sink

- We put a large flat gasket on the top part of the flask-shaped assembly. Screw on the screw cap and tighten tightly. The siphon is ready.

- Take a corrugated pipe. At one end we install a union nut and a cone gasket. We insert it into the side hole of the siphon and tighten the nut.

- We install the union nut, then the cone gasket on the pipe that will be attached to the sink. We insert the pipe into the upper hole of the siphon and secure it with a nut.

- We put a gasket on the other end of the same pipe and screw on the plastic drain in which the nut is installed. We bring the assembled structure from the bottom of the sink to the drain hole.

- Holding it with one hand, press the upper part of the pipe against the sink. With the other hand, install a metal drain with a gasket into the sink drain hole. Insert a screw into the middle of the metal drain and tighten it.

- We insert the corrugated pipe into the sewer system.

- We check for leaks.

Recommendations for installation

Siphon installation

Installation of a siphon on any plumbing object is fundamentally the same. The only differences are in the shape of the siphon, depending on where it is placed. The bend of the corrugation for the kitchen sink and washbasin is made lower than for the bathtub.

The installation diagram for the corrugated siphon is as follows:

- A rubber gasket is placed on top of the drain hole of the sink (washbasin, shower cabin or bathtub). It is better to fix it with waterproof sealant.

- A neck is inserted into the drain hole from above and covered with a grid (mesh), which is connected to the neck with a screw.

- The corrugation is connected to the neck and tightened with a nut.

- After this, the corrugation is bent into pieces of the required (or possible) length and fixed with clamps.

- The second, free end of the corrugation is attached to the sewer pipe.

After installation, the tightness of the connections must be checked - the tap is opened to full pressure, and a container is placed under the siphon. If the product does not leak anywhere, it is installed correctly and is ready for use.

Installation of drainage fittings with overflow under the bathtub

- We put a gasket on the siphon thread.

Place a nut in the plastic drain. We install the drain on a siphon. Bath siphon with overflow - On the pipe connecting the siphon and the corrugation, we put a union nut and a conical gasket with the blunt side forward. We connect the pipe with the siphon and tighten the parts with a union nut.

- We connect the assembled structure with the corrugation. To do this, we put a union nut and a cone gasket on the corrugated pipe. We pull the parts together.

- We close the cleaning hole with a solid nut, first placing a gasket in it.

- We put a union nut and a cone gasket on the additional corrugation. We insert the corrugated pipe into the siphon and secure it with a nut.

- We connect the other end of the additional corrugation to the plastic overflow drain.

- We insert a rubber gasket with double sides into the drain hole of the bathtub. We press the assembled structure of the drainage fittings under the bathtub close to the gasket. In the bathtub, install a metal drain on top of the drain hole and tighten it with a bolt to the nut placed in the plastic drain.

- We put a gasket on top of the plastic overflow drain and install a nut on the bottom. Press it against the overflow hole on the back side of the bathtub. We press the metal drain on the inside of the bathtub. Insert the bolt and tighten it, tightening the overflow parts.

- To connect the bathtub siphon to the sewer, insert the edge of the corrugated pipe into the sewer system.

- We check for leaks.

Toilet siphon

Comments

March 11, 2021

Posted by Ralphkah

I bought here Construction » Plumbing » Baths and accessories » Siphons tovaromania.rf/index.php?cat=167587 delivered free of charge

Answer

March 11, 2021

Author: Georgedrere

I bought here Construction » Plumbing » Engineering plumbing, water supply, drainage » Siphons and corrugations » Siphons for kitchen sinks tovaromania.rf/index.php?cat=191441 delivered free of charge

Answer

March 11, 2021

Author: Williamcreno

I bought here Construction » Plumbing » Engineering plumbing, water supply, sanitation » Siphons and corrugations » Siphons for sinks tovaromania.rf/index.php?cat=191442 delivered free of charge

Answer

March 11, 2021

Author: Raymondnoupt

I bought here Construction » Plumbing » Engineering plumbing, water supply, sanitation » Siphons and corrugations tovaromania.rf/index.php?cat=191436 delivered free of charge

Answer

May 04, 2021

Author: Fidelcon

I bought here Sewing goods » Ribbons » Satin ribbons » With a pattern tovaromania.rf/index.php?cat=150168 delivered free of charge

Answer

Connecting the toilet to the sewer system

The toilet outlet in relation to the floor can be located horizontally, vertically or at an angle of 45˚. The method of connection to the sewer system will depend on this. If the toilet outlet is located vertically, then a rubber cuff is used for connection. One end of the cuff is put on the toilet outlet, and the other end is inserted into the socket of the sewer hole. Using a toilet with this type of connection allows you to completely hide the sewage system in the floor. As a result, the appearance of the sanitary room becomes aesthetically pleasing.

If the toilet outlet is horizontal and the drain outlet is close to the sewer pipe opening, you can use plastic pipes. This method is the most economical. Fan pipes are also suitable, but they are made of earthenware, porcelain or semi-porcelain. These materials are very fragile, which makes installation difficult. Let's consider the case when the toilet flush outlet is located at an angle. To connect the toilet siphon to the sewer, use a corrugation. At one end it is attached by means of an internal membrane to the outlet pipe of the toilet, and at the other - in the technical opening of the sewer pipe. Here fixation occurs due to the outer membrane.

It is convenient to use such a corrugated pipe. You can easily change the angle of the plumbing connection or give the pipe the required size depending on the distance to the wall. Corrugated cuffs are flexible and of high quality. Experts recommend using reinforced cuffs with a stainless steel coating. Their service life is much longer.

An alternative to corrugated pipes are eccentric sleeves. They are two pipes with offset centers, connected to each other. By rotating the eccentrics, you can achieve the required connection angle.

How to install corrugation on a toilet with your own hands

You should start with measurements. The length is taken with a margin of several centimeters to avoid tension. It is accepted taking into account bends. It is necessary to measure the diameter of the inlets and outlets - they may not be standard. It is possible that a rigid corner adapter will be required.

Tools and consumables

- Sledgehammer.

- Hammer.

- Chisel.

- Roulette.

- Building level.

- Set of wrenches.

- Liquid Nails.

- Tow or sealing tape.

- Silicone sealant.

- Hose - you will need it to drain the water from the bowl.

Dismantling work

As a rule, communications are changed when equipment is replaced. If the cause is a leak or planned repair, it is more convenient to install the channel with the bowl removed.

How to hide?

You can’t do without a siphon, but in some places, for example, on a bathroom sink, it doesn’t always look pretty. Sometimes its appearance can ruin the entire interior. Avoiding this is completely easy. Many people don’t even try to hide modern siphons, making them part of the interior of the kitchen or bathroom. Of course, if you purchase a stainless steel siphon, it can become a decoration in itself.

However, most models still need to be covered with something decorative. The simplest option is a special sink leg, which can be purchased separately. You can match it to the existing plumbing fixtures or, conversely, take something that stands out. With such a leg it is very easy to hide both the siphon and partially the pipe leading to the sewer. Another fairly simple and effective way to keep all the unsightly things behind and under the sink is with a cabinet. It can be easily installed under the sink. Its simple design will reliably hide everything unnecessary. Such modifications can be purchased ready-made in the store or made independently. For such a cabinet you will need drywall, profiles, some tools and some free time.

If you want, you can cover the pipes and siphon with a plasterboard frame, and then decorate it with tiles. This will allow you not to leave any unnecessary gaps and all unattractive moments will be reliably hidden from view. Of course, for a bath, where the humidity is often very high, you can choose materials that are more resistant to moisture (glass magnesite).

The most important thing is that when covering the place where the siphon is installed, you need to make sure that air flows there, so it is better to leave small gaps on the sides or bottom.

Advantages of using corrugation

Connecting the sink to the sewer can be done in 2 ways. You can use ordinary plastic pipes, or you can simply connect the outlet of the siphon to the entrance to the sewer pipe with a corrugated pipe.

This solution has several advantages:

- Due to the corrugated side wall, the corrugation under the sink stretches without problems, so you don’t have to worry about guessing the length of the pipe;

Note! It is still not recommended to stretch it too much. It must be remembered that the wall is made of rubber and is not particularly durable; if it is stretched excessively, its service life will be shortened.

- simplifies the installation process. If when using conventional pipes you cannot do without turns, then the corrugation allows you to immediately connect the entrance to the sewer with the exit from the siphon;

- in cramped conditions, the use of conventional pipes can be very difficult; the corrugated analogue is very convenient in this case;

Plumbing corrugation is indispensable when there is a shortage of free space

- low price and availability are also advantages - you can purchase a bottle siphon with corrugation for connection for approximately 200-300 rubles at any plumbing store.

There are also a number of disadvantages, some quite significant:

- a ribbed surface is not the best option for draining waste, especially in the kitchen. In the bathroom this does not play a special role, because only water is discharged into the sewer, but in the kitchen the corrugation can quickly become clogged. This is due to the fact that in addition to water, fat and other substances that you have to deal with in the kitchen pass through it; the folds become clogged very quickly;

- less resistance to mechanical stress - the thin rubber wall is very easy to damage;

- the impossibility of using a plunger to clear a clogged drain; the pressure drops created in this case can lead to a rupture of the wall . Other methods of clearing clogs, such as using a plumbing cable, are also prohibited.

Advice from professionals

Installing a siphon yourself is not at all difficult, especially if you look at a number of tips from professionals in advance. For example, when assembling siphons at home without the help of specialists, you need to carefully control the force with which the clamp is made. Otherwise, the device will be damaged otherwise. Particular care should be taken when fixing the gaskets when installing the lower plug and at other joints. A sealant is best for this. It should be remembered that the siphon parts must be tightened until they stop, but do not press hard.

When assembling the exhaust pipe, it is important to tighten the fastening screw well and also remove excess sealant. The installation height of the siphon can be adjusted precisely due to this part.

Experts advise that when purchasing a siphon, immediately check the presence of all parts in the kit. After all, sometimes by printing out the packaging at home, you may end up missing the necessary parts from the device. Also, when purchasing a device, you need to make sure that the thread is intact. It should be free of the slightest chips, burrs, and various protrusions that lead to disruption of the integrity of the gasket. When the siphon is assembled, all its parts must be cleaned and dried. Under no circumstances should there be sand or dirt on the seals. In the future they will lead to leaks.

For better drainage of liquid when installing the device, its outlet should be at a greater height from the floor than the inlet into the sewer. When choosing a siphon related to bottle models, it is worth considering that dirt may accumulate in the place where the water passes. In addition, they are not very durable. The best in terms of durability and corrosion resistance are bronze and brass siphons with galvanic coating. And stainless steel devices are very expensive, so they are not very popular.

When installing, do not overtighten the connections where there are threads, as they may need further adjustment. Too much force when fastening threaded connections often leads to failure. The force must be such that the rubber seal is pressed tightly to the landing site. This will make the joint fairly airtight.

What are the benefits of guava?

Guava is a delicacy and a medicine. Its therapeutic effect is recognized by official medicine, prescribed to patients by healers in the East, and used by cosmetologists.

Health

Guava improves the functioning of the body physically and emotionally:

- Vitamin C in large quantities is a powerful immunostimulant.

- Bones, swallowed whole, eliminate constipation and improve digestion. Tea made from the roots of the plant stops diarrhea.

- The seedless pulp is used to treat dysentery and food poisoning.

- Juice of unripe fruits or a decoction of leaves is used to gargle for sore throat and other infections of the oral cavity; Warm drinks are given for coughs as an antipyretic.

- Exot is endowed with anti-inflammatory properties. It is prescribed for pneumonia.

- The heart rhythm is adjusted, the pressure is normalized.

- Fruits in the diet prevent or inhibit cancer. The effect on the cells of the prostate, mammary glands, and oral cavity is especially effective.

- Vitamin A slows down the degradation of vision, prevents cataracts, and improves the general condition of the eyes.

- The high copper content helps produce collagen and normalizes the production of blood cells. Regulates the functioning of the thyroid gland.

- Cholesterol is reduced, blood clots are prevented, and blood pressure is reduced.

- Fruits help overcome stress, survive difficulties, and overstrain at work.

- Crushed leaves of this tree are applied to fresh wounds, abscesses, and chewed for toothache.

beauty

A tropical apple improves the condition of the skin and hair, making it beautiful and healthy:

- Masks made from pulp remove oily shine, tighten pores, and refresh the face.

- You can wash your face with a decoction of leaves, peel or pulp of unripe fruits.

- Rinse your hair with freshly squeezed juice.

Tips and tricks for use

In order for the product to last longer, you must follow some rules before installation:

- It is not recommended to stretch the corrugation too much, as this reduces its strength and wear resistance;

- It is also undesirable to pull out the reinforcement, since in the future this will lead to sagging of the product and the formation of blockages;

- Before shortening a reinforced drain, it is recommended to measure the distance to the pipe, and it is better to cut it with a small margin of length;

- when installing, it is better that the corrugated pipe channel be slightly curved - this will help water drain freely, without forming blockages or blockages;

- You should not press or put pressure on the drain or place anything on it, as the product is fragile and not designed for high loads;

- no additional elements in the bathroom should press the device, otherwise it will quickly lose its properties and fail.

These rules will help prevent premature failure of reinforced drains.

Why is the toilet bowl dripping?

Sometimes situations arise when all the work was carried out at a high level, but problems with leakage are still present. The reasons why the toilet bowl drips may be as follows:

- The product is of questionable quality and does not adhere well to the pipe, forming unwanted folds.

- The skirt at the cuff is not straight, but cone-shaped. This is a problem that can only be corrected by replacing the corrugation.

The toilet bowl is leaking - what to do?

When plumbing malfunctions, it becomes the source of a large number of problems. To prevent the smell of sewage that leaks from being absorbed into the floor surface, you need to know what to do if the toilet bowl leaks. Before starting repairs, an inspection is carried out to identify the problem and only then a decision is made on how to correct the situation. The causes of leakage may be the following situations:

- pipe rupture;

- poor sealing of joints.

The corrugation for the toilet bowl is repaired according to the following scheme:

- The crack is dried and covered with a rubber patch. To do this, use only waterproof glue.

- You can soak a bandage in a cement mixture and wrap it around the pipe.

- The loose fabric is treated with sanitary silicone and placed on the toilet outlet.

How to seal a toilet bowl?

To get rid of voids, a silicone compound is used. This is done at the installation stage, the sealant is distributed in a thin strip over the seam, and then smeared over the surface. Installing the corrugation on the toilet with your own hands allows you to use the plumbing after just a few hours. When using quality products during the installation phase, reapplying sealant is more of a precaution than a mandatory process.

Sealant for toilet bowl corrugation

Among the range offered on the market, the following types are used for installing corrugations on a toilet:

- Silicone

. The most popular option, which has high resistance to humidity and temperature changes. It can be used for both external and internal application. For example, Ravak Professional and Ceresit Sanitary CS 15. - Polyurethane

. Elastic adhesive composition, characterized by strength, durability and wear resistance. Due to toxicity, it is recommended for outdoor use only. For example, Molder PU and PU 39 Bostik.

When figuring out how to lubricate the corrugation between the toilet and the pipe, we note that professionals recommend using silicone sealant. Popularity was achieved due to the following advantages of the composition:

- resistance to UV rays;

- suitability for working with all materials;

- resistance to temperature changes;

- creating protection against the appearance of fungus;

- high strength;

- resistance to household chemicals;

- environmental cleanliness.

Subtleties of installation and assembly

The process of connecting the corrugation to the hood and ventilation system will be within the capabilities of a home craftsman.

To complete this job, you will need to take:

- flexible pipe;

- clamps;

- aluminum tape;

- grille with check valve;

- silicone sealant;

- adapters from round to square.

The last point is useful when the hood has a square or rectangular pipe, and the corrugation is round.

Adapters for smaller and larger diameters are available for sale. They should be used only when necessary, so as not to reduce the performance of the exhaust equipment.

It is good to buy all the necessary parts together with the corrugated pipe.

This will prevent you from making a mistake with the number of spare parts needed.

All components for future installation of the air duct should be selected by first taking measurements at the site of the upcoming installation

If you need to connect 2 or more flexible pipes together, you can use aluminum tape.

It connects the material of metal air ducts well, provided that it is carefully glued to the surface.

Aluminum tape can not only connect 2 corrugations together, but also seal an accidentally torn hole

The corrugated pipe will have to be stretched to its full length. In this state, one end must be attached to the outlet pipe of the hood.

For fastening you will need to use a metal pipe and sealant.

The sealant should only be applied to a dry and clean surface. Otherwise, he will not be able to reliably close the joints

Then, every 1.0 meter vertically or 1.5 meters horizontally when laying the corrugation, you need to install additional clamps. These devices will ensure proper fastening of the air duct.

If the ventilation hole is only 0.5-0.8 meters away, then there is no need to install any additional clamps.

If the ventilation duct is long, you should not make sharp corners - each of them will reduce the performance of the hood by 10%.

If the ventilation entrance is more than 3 meters away, then you need to choose a more powerful hood model or run a corrugated pipe in a straight line under the ceiling to shorten the path. After all, the longer the channel, the more powerful the equipment should be.

Having installed additional clamps, all that remains is to connect the corrugation to the ventilation hole by inserting its second end into the corresponding hole in the wall grille.

Wall-mounted ventilation grilles are available with or without a built-in check valve

The joints between the grate and the pipe should also be thoroughly treated using sealant. Now we need to check the quality of the installation. To do this, you need to turn on the hood and attach a sheet of paper - if it is attracted, then everything is mounted perfectly. So you can start decorating.

The decorative casing of the hood itself can be used as decoration.

Sometimes this is clearly not enough. Then the owners use their imagination, choosing the most optimal option, for example, hiding the pipe in wall cabinets. This is especially true for built-in type hoods.

Sometimes the ventilation duct is hidden in a plastic box. If you also install lighting in it, then no one will guess about the metal corrugation inside.

Depending on the style of the kitchen interior, the corrugated pipe can be hidden under the suspended ceiling. If the furniture in the room is in high-tech style, then the metal corrugation will organically fit into the overall picture.

It happens that the air duct fits perfectly into the interior of the kitchen, being a logical continuation and not getting out of the overall composition.