Published 01/26/2016

When choosing cast iron pipes, special attention should be paid to their diameter, length and weight. The specific application of the products depends on these criteria. There are several standards that define the operational features of water supply and sewerage pipelines made of cast iron. GOSTs contain tables where the weight of pipes is compared with their outer diameter: a pipe that suits you can be found without any problems if you use these data. You can also calculate the mass using the formula. But, regardless of size, cast iron products are characterized by high performance properties, in particular, they can last up to 100 years.

Types of cast iron pipes

According to their purpose, they are divided into several groups:

- pressure - VShChG ;

- non-pressure - CHK ;

- socketless - SML ;

- pressure socket type - ChNR .

To lay the sewer and choose the right pipe, let's take a closer look at these types.

Pressure

VShCHG are widely used in many industries. These cast iron pipes contain nodular graphite. It gives the product increased elasticity and makes the material more viscous.

VShChG pipes can work instead of similar ones made of gray cast iron. Their properties are comparable to forged and cast steel. The mechanical characteristics of these pipes compete with steel products due to their high corrosion resistance coefficient.

The service life is almost 8 times longer than their analogues. Pressure products can be installed to work with aggressive substances. They feel great in the cold season. They are not afraid of any frost. High strength allows sewer pipelines to be laid under highways, and the depth of the trench is always very large.

The pressure pipe set includes:

- Bells.

- Rubber seals.

Gravity

Since the material contains flake graphite, these products do not have such great strength. Gray cast iron is used for their manufacture. ChK pipes are installed only in those sewers where high loads are excluded. They are freely mounted together with those made of plastic.

To create a reliable connection, rubber cuffs are installed. The main advantage of such products is the ability to use them a second time after dismantling.

Socketless

The material of such a cast iron pipe includes graphite. To create greater strength, the inner surface of the pipe is covered with epoxy resin. This makes it possible to get rid of siltation and the formation of various layers.

Epoxy resin performs well in any aggressive environment and saves the surface from destruction and corrosion.

SML products do not need to create additional noise protection. They meet fire safety requirements, are highly durable, and can also withstand extreme heat.

Special clamps are used to connect pipes. This is due to the lack of bells at the ends.

Socketless pipelines first became known in the early 60s of the last century. In those days, construction engineers worked to create the latest materials and technologies. Today, socketless structures remain a reliable and very high-quality method of manufacturing a plumbing system, which combines the following advantages:

- Due to the absence of sockets, butt joints are characterized by high sealing without the use of special sealing materials.

- Since the internal coating of such products is made very smooth, they differ from their analogues in their increased throughput.

- High wear resistance is ensured by the absence of corrosion.

- SML products can operate at any temperature. They are resistant to large changes.

- Cast iron pipe is very easy to process. Thanks to graphite in the form of a rosette, the strength of the material increases several times. The thickness of the walls of the product does not change along its entire length.

To eliminate brittleness, the pipe is subjected to heat treatment.

Bell-shaped

These CHP pipes remain in demand today. They are used in a wide variety of industries. Their main advantage is considered to be an increased service life when compared with a steel counterpart. After all, steel begins to quickly rust over time. The disadvantage is the fragility of such cast iron. The labor intensity of sewer installation is much more complex compared to other pipes.

To prevent products from corroding, they are coated with bitumen on the outside and inside.

Application

Cast iron channels are used for:

Products for sewerage

- heat supply lines;

- sewer systems, the price of which is fully offset by quality;

- pipelines transporting petroleum products;

- fire-fighting water supply systems;

- ensuring the functioning of pipelines used in the chemical, oil refining, and mining industries.

If you take a cast iron pipe with a diameter of 100 millimeters, then it can and should be used in those places where the created load is significantly greater than the household load.

Such objects include:

- food industry and catering enterprises;

- meat processing plants;

- farms and other places for keeping animals;

- healthcare facilities;

- sanatoriums, educational institutions;

- non-industrial laboratories, etc.

Dimensions

Factories manufacture such products according to the dimensions established by GOST. No deviations are allowed.

There are also cast iron products with non-standard parameters. They are used for laying sewer lines with your own hands on a summer cottage or installing an autonomous sewer system in your own cottage.

To correctly select such a pipe, 3 main parameters must be taken into account:

- wall thickness;

- diameter;

- weight.

Diameter

The following indicators have been developed for cast iron products:

- Nominal diameter. Based on this dimension, a cast iron sewer pipe is selected for future installation. In the drawings it is designated “Dn”.

- The size of the conditional passage. Determines the internal diameter of the pipe, shown in millimeters - “Dy”.

- Outside diameter. According to this size, any sewer system is calculated - “G”.

The choice of CT diameter is influenced by the volume of wastewater passing through the system. The size is taken from the range 50–150 mm. When carrying out internal sewerage, it is enough to install a CT with a diameter of 50 to 100 mm. The installation of the external system is carried out with pipes whose diameter is in the range of 100–150 mm.

When installing an internal sewer system, additional plumbing products and risers are also used. When the volume of wastewater increases, the diameter of the pipes is taken from the range of 500–1200 mm.

Weight and wall size

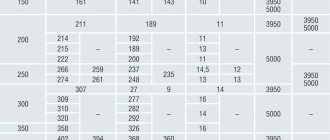

One of the disadvantages of cast iron is its weight. This is very inconvenient and causes a lot of problems during sewer installation. However, due to its heavy weight, the structure has very high strength and becomes monolithic. As a result, it works for many years without repair. According to GOST 6942-98, the ratio of 2 meters of pipe and its nominal diameter should have the following weight:

- 50 mm – 11 kg;

- 100 mm – 25 kg;

- 150 mm – 40 kg.

The weight of cast iron products also depends on the wall thickness. Let's consider several options.

- The outer diameter is 80 mm . Wall thickness 8 mm. The mass of one meter of pipe will be 13 kg. Therefore, 75 mm of such a pipeline is 1 ton.

- Product diameter 170 mm . Total length 1 m. Product wall – 10 mm. According to the table, the weight will be 36 kg. 27 meters of such a pipe will weigh 1 ton.

- With an outer diameter of more than 1000 mm and a wall thickness of 27 mm, the mass of the product will reach 620 kg.

The thickness of the pipe wall affects the strength of the entire sewer system of any type. Its reliability and service life depend on this value. This is due to the fact that the pressure on the pipe walls and various loads can be easily withstood by a product that has certain parameters. Therefore, cast iron pipes were divided into several classes:

- A;

- B;

- LA.

Such sewer pipes can safely operate at a pressure of 0.1 MPa, even without an anti-corrosion bitumen coating. Such types are installed only in very critical sections of the sewer network.

After treatment with bitumen, they can withstand higher pressures. They have the largest wall thickness. The strength indicator is always higher than any analogue. The service life is designed for long-term operation.

The installation of such products is carried out during the installation of a sewer system inside a building, under special operating conditions. Cast iron pipes "LA" are installed when installing sewerage in an individual house. They are able to withstand hydraulic pressure that does not exceed 25 kgf/cm². They can work quietly in systems where there are no heavy loads.

Saddle: what is it?

If the elements are connected correctly, there should be no problems with the operation of any pipeline. If you need to make a branch correctly, for example in a sewer system, then it is best to use a nurse on a cast iron collector 150.

Saddle

What is such a component of pipelines? A saddle is a part that can be attached to a pipe in the place from which it is necessary to make the correct branch.

The importance of using a saddle lies in the fact that it can be used to make a branch at any point in the water supply system, heating network, or sewer system, without dismantling them. How it's done? First you need to make a hole in the riser on which to install this part.

After this, the hole must be surrounded with a tight-fitting rubber gasket to prevent water from leaking in this area. That's it, now you need to secure the part, tighten the bolts and connect pipes and shut-off devices with a high tightness class (GOST 9583-75). The branch is ready for use.

Saddles are produced in the form of clamps and overlays. In the first version of the part, the riser is clamped using two parts of the clamp. One half of the saddle is equipped with a threaded outlet, which is used to install the part added to the new cutting-in pipeline.

The saddle-overlay is used for making bends on polyethylene pipes.

Positive and negative qualities

Today, cast iron pipes are installed in most sewer systems. The properties of these products allow them to be installed in any type of soil. The main advantages are:

- very high strength;

- not afraid of temperature changes;

- long service life;

- does not burn;

- meets modern environmental requirements, does not emit toxic substances;

- has excellent soundproofing properties;

- does not react with aggressive substances;

- not afraid of corrosion.

Unfortunately, in addition to such a large number of positive properties, cast iron products also have a number of characteristic disadvantages. Some factors greatly influence the labor intensity when installing a sewer system:

- large mass;

- increased fragility;

- installation requires special equipment and additional materials;

- very high cost;

- repair work requires large financial investments.

Advantages of cast iron pipe products

- designed for 80-100 years of operation without losing quality;

- resistance to the formation of a corrosive layer;

- resistance to mechanical damage;

- ability to withstand frost down to -60°C;

- plastic;

- low operating costs (repairs are rarely required);

- easy disposal and recycling;

- environmental Safety;

- wide range of operating temperatures;

- the ability to bury to a depth of 10 meters;

- During installation, you can use welding, socket connections and fittings.

Disadvantages include heavy weight, roughness of the internal surface and the need for special materials for installing sealed connections.

More information about cast iron pipes

Gray cast iron is used by manufacturers to make domestic sewerage pipes. The surfaces of such products are coated with anti-corrosion bitumen both inside and outside. It becomes soft when the heating temperature exceeds 60 degrees.

The presence of cracks and the appearance of air bubbles on such a coating is prohibited. It has a smooth and very durable surface. Moreover, the solid surface of the bitumen should not stick to the pipe wall. It is strictly forbidden to have traces left from transportation devices.

The presence of dents and drips is not allowed. The quality of the product is checked on special technological stands directly at the production site that produces cast iron pipes.

The tightness test is carried out by visual inspection of the pipeline section after it is filled with water under a pressure of about 0.1 MPa. The joints should not have leaks. External surfaces must be free of fogging.

If there are no such defects, the product is considered sealed. Overall dimensions are checked with special reference instruments. Deviations from the nominal value must be within acceptable values. To determine the mass of the pipe, it must be weighed. When purchasing such a product, the consumer can check it for compliance with any verified indicator.

The pipes have markings that are located directly on the socket. It is applied with indelible paint. Sometimes it is cast together with the pipe. The marking must have:

- product icon;

- GOST numbers;

- release article.

Finished products can have very different packaging:

- containers;

- cassette;

- packages;

- bundles secured with wire.

The sockets are laid in different directions. According to regulatory requirements, manufacturers are required to produce products:

- with a guaranteed shelf life of 3 years;

- with a service life of 2 years.

Why do you need to determine the weight of the pipeline?

The weight of 1 meter of cast iron pipe products needs to be known when you plan to purchase them in bulk. Then the pipes are sold in tons. In this case, the mass of one product does not matter, since the footage is calculated the other way around, based on data on the number of meters per ton. For retail purchases, the weight of the pipe is not taken into account. The dimensions of cast iron pipes are of key importance in this case. It is also necessary to look for the weight of products in order to:

- determine the carrying capacity of the vehicle for transportation;

- find out the cost of transportation;

- calculate labor costs for each shift;

- Determine the lifting capacity of a crane or loader.

Important! Incorrect calculations can lead to accidents when transporting cast iron pipe products or during work with them. For example, beams will bend, hangers will break, crane slings will break.

Without preliminary calculations, it is impossible to be sure that the work will be 100% successful.

External sewerage

The external sewer system runs underground on the street and carries wastewater to the septic tank. Pipes for external sewerage can withstand static and dynamic loads:

- soil pressure,

- movement of people

- traffic,

- groundwater movement,

- temperature changes,

- humid environment,

- aggressive environments.

Dynamic loads. These are all variable loads: movement of cars and people, movement of groundwater. Pipes with high ring stiffness can withstand dynamic loads well.

Static loads. These are loads that constantly put pressure on the pipeline: soil pressure. Products with high ring rigidity also resist pressure well. Static loads also include others; we will consider them separately.

Temperature changes. The most dangerous are cold snaps, since many pipes can withstand 30-degree heat, but cannot cope with 30-degree frost.

Wet environments. High humidity in spring and autumn destroys ferrous metals without anti-corrosion coating and some other materials. Groundwater movement can dislodge the pipeline if it is not installed correctly.

Aggressive environments. These are acids, salts and alkalis that are found in soil and wastewater. Therefore, pipes inside and outside must be resistant to various substances.