The issue of water supply will probably always be relevant, especially in rural areas. And often the problem of water supply is solved by erecting a well that performs a direct function (in other words, providing the area with water), but at the same time it must be reliable and durable. To prevent it from freezing in winter, it should be properly insulated even before the onset of cold weather. There are many different insulating materials suitable for this purpose. You just need to know how to properly insulate a well for the winter.

- 1 In what cases is insulation required?

- 2 Method one. Cover insulation

- 3 Method two. We thermally insulate the upper ring of the structure 3.1 We use polystyrene foam for the “under the fur coat” ring

- 3.2 We use polyurethane foam for the ring “under a fur coat”

- 4.1 Video – House installation

- 7.1 Video - Insulating a well

What to do if the water in the well is frozen?

If the winter turned out to be really very cold, but you did not have time to insulate your source, you will have to familiarize yourself with the features of its “defrosting”. What will it take?

- Assess the degree of freezing of water at the source;

- If the layer of ice is not too thick, break it with a crowbar;

- After this, remove large pieces of ice from the water;

- Cover the source with an insulated lid;

- Wrap the base of the structure with polystyrene foam.

In essence, thermal insulation of a well is a way to extend the “life” of the entire structure. When water freezes, the walls of the source begin to quickly collapse, making it no longer possible to operate it. To insulate a structure, you can use materials such as penoplex, expanded polystyrene, izolon and others. They will protect the well from water freezing, and the structure itself from deformation and complete destruction.

Why is it necessary to insulate?

The main reason for insulating a well is the need to ensure uninterrupted water supply in winter.

In addition, freezing of water in a well and the formation of an ice lens in it can damage the walls and dislodge the rings. This movement can damage the pipes leading into the house.

Equipment installed in the well may also be damaged:

- pump;

- intake pipe;

- filter.

It no longer makes much sense to insulate the well walls and head in the winter, after it has frozen. It is necessary to take care of insulation in advance. It is best to do this when building a well.

How to insulate a well

Water supply in a summer cottage is an integral part for comfortable living. And many people install wells on their property to organize an uninterrupted water supply. Correctly drilling a well and laying communications is one of the main tasks, but the second equally important problem that you will need to solve is to think about how to insulate the well so that it works smoothly even in winter frosts.

Why do you need to insulate a well?

Note! Before insulating a well, consider the possible options for available methods, which vary in the complexity of their implementation.

Methods for insulating wells

If you do not live in a country house in winter, then you will not need insulation; it will be enough to pump out the water before the winter season, close the lid, fill the well with sawdust or leaves, cover it all with polyethylene and secure the structure. For those who spend the winter in country houses. There are several options for how to insulate a well.

Caissons

These are structures (made of concrete, iron or plastic) that are installed at the top of a well or borehole. They come in square or round shapes and are often installed as the last link of a well, instead of a reinforced concrete ring section.

Better insulation of the well will be achieved by installing caissons followed by laying insulation, which is expanded clay or fine gravel screenings.

Note! If your well is powered by an automatic pump. then in the caissons it is possible to install additional filters and other automation, which are usually located in the house

Insulation of well rings

Insulation of rings

You can insulate a well using expanded clay. You need to dig a trench around the well rings to a depth of two meters and a width of 70-80 cm, and then fill it with expanded clay or fine-grained gravel. You can also use mineral wool, but this will only require the construction of wooden formwork, which must be laid with roofing felt. so that the insulation does not rot. The insulation is also covered not with earth, but with expanded clay with the top layer being concreted.

Decorative house

You can build a small hut made of logs or bricks above the location of the well. To do this, you will need to prepare a shallow foundation and build a structure. This structure will protect water well from freezing and play an additional decorative role. A more spacious house, which can be used as a storage room for summer cottage equipment, will be of great benefit.

Hanging cover in a well

Hanging cover

This is a fairly simple, but no less effective way to insulate a well. An insulating cover will provide protection from frost, which helps to accumulate the temperature of the water in the well. It needs to be mounted at a depth at which it will not reach the water, and will be slightly above the freezing level or at the same level with it.

Insulation of a country well from concrete rings

Insulating the topmost ring of a well is actually not that difficult.

The technique of this procedure is quite clear and primitive. To explain briefly and concisely, the top concrete ring needs to be covered with the familiar polystyrene foam. Let us consider in detail the progress of the work to be performed

- The wall ring needs to be dug out twenty centimeters - to the depth of ground freezing. In total you will have to go deeper by about 1.2 meters. Since this is not very comfortable to do, you will have to dig a fairly large pit. If you count the rings from above, then it is enough to get by with a depth of 20 cm below the junction of the first two rings.

- We take layers of foamed polymer and cut it into strips 20 cm wide. High-density material is more suitable, and the best option would be to purchase extruded or ordinary foam.

- We clean the wall rings from dust and dirt, moisten them with water, and glue the parts of the prepared foam polymer with special glue.

- When the surface of the ring is fully covered, the gaps between the individual strips of foamed polymer are filled with foam for installation. Its remains are cut off after complete drying, the soil around the well is added, and the well itself is put in order.

So that the foam for installation work does not fade in the sun and the foamed polymer does not deteriorate, the structure is reinforced with a mesh and then covered with a layer of plaster. This option is very effective, but it doesn’t really help in all cases: the cold can penetrate through the top.

Thanks to this, it will be better, without delay, to move on to the next insulation method with your own hands.

Making a warm shutter

What is a warm shutter?

It must be stated that this is a specialized cork with small holes made in it. One of them serves for ventilation and prevents water spoilage. The second is for the intake hose. This option will be optimal for a summer cottage, which is supplied with well water using a pump.

How to make such a shutter lid?

- It is necessary to make two similar rings from moisture-resistant plywood, corresponding in size to the inner diameter of the concrete ring of the well.

- One of the rings is covered with 5-centimeter polystyrene foam. All remnants are carefully cut off: the foam circle should exactly repeat the shape of the plywood one.

- The second plywood circle is glued on top of the foamed polymer.

- Final stage. We drill two 6-centimeter holes (for ventilation and for the hose), make a handle to which we attach a thick rope or chain, so that in the spring you can easily remove this plug.

There is nothing difficult in all these events, but there is also no special beauty here.

It should be noted that the considered methods of thermal insulation with polystyrene foam are suitable only if the water supply is carried out using a pump.

If water is taken from the well with a bucket and a collar, then it is unlikely that the stopper will help. In this case, there is another, third method of insulating a well with your own hands.

Insulation of water wells

This is an excellent option for every occasion. There is an optimal way to thermally insulate a well, which solves several problems at the same time: the appearance of the site outside the city will not be affected at all, and the insulation will be done really well. This primitive and good method is the construction of a special closed well house.

Closed well house

This design solves the following problems:

- Prevents water from clogging with leaves and other small debris. A thoughtful and airtight house with a tight lid will not allow anything unnecessary to get into the source.

- The well will not freeze in winter. In the only case such a house will not save you from freezing if the water level in the well is higher than the ground freezing level. If this is the case, then it will be necessary to implement additional insulation of the upper wall ring with polystyrene foam.

If insulating a well yourself seems too difficult to you, you can make the task easier for yourself. At a minimum, you won't have to do most of the work yourself. Foam half-rings, a warm seal and good sealed houses themselves can be purchased at hardware stores.

All you need to do is install such products, and this, of course, is several times easier. Well, factory-made products, in most cases, will look much more beautiful than homemade ones. This is especially true for a well house. Still, only homemade interior items will give the site an original and distinctive look.

Methods of pumping water

The ideal option for draining liquid from the reservoir is to connect to a centralized liquid drainage system. However, on personal plots this method of pumping is impossible. It is necessary to construct a waste pipeline through which the water flows by gravity beyond the boundaries of the summer cottage.

It is important to decide on the location of the discharge, be it a ravine or some kind of reservoir, and coordinate it with local authorities. If drainage does not occur naturally, as the well shaft fills, then they resort to forced pumping of water

This requires an electric pump that can be immersed in a container.

If drainage does not occur naturally as the well shaft fills, then forced pumping of water is resorted to. This requires an electric pump that can be immersed in a container.

Pump for pumping water with a float from storage drainage wells

A float sensor is attached to the pump on a small cable, which reacts to the fill level of the tank and sets the pump in motion. The efficiency of pumping equipment depends on the power of the unit and the degree of contamination of the pumped liquid.

Large debris can accumulate in stormwater wells. This must be taken into account when purchasing a pump. If groundwater is pumped out of the storage tank, then you will need a simpler unit that can cope with solid particles less than one centimeter.

Experts advise completely pumping out well water every month in order to rinse its base with a stream of clean water under strong pressure.

It is important not only to install the drainage system correctly, but also to regularly care for it. Then your home, garden and vegetable garden will be completely safe

Preparing a well for winter

Ideally, insulation of a well should be carried out at the stage of its construction, but with a competent approach, the desired result can be achieved even when the structure is already in operation.

Pumping water from a well.

If living near a well is seasonal and temporary, complete drainage of the water supply system can protect you from freezing, which will prevent subsequent defrosting of the system and costly repairs.

A complex approach

Insulating a well from which water is drawn even in winter is a little more difficult and requires an integrated approach to prevent freezing of the entire system. Since the top ring is the most vulnerable, it is insulated in several ways. For example, a plastic cover or a decorative wooden frame together with a well house will help your water source not freeze at significant low temperatures.

Thermal insulating structures

Various thermal insulation structures inside the structure will also be very effective. This can be an insulating cover using combined materials or reinforced concrete “eternal” insulation with a plastic hatch.

Hydrant protection

Insulation of the water intake column, namely its upper part, with various materials is also very effective in comprehensively solving this issue. In addition to the well wooden frame and the house around the upper ring, additional insulation can be expanded clay, mineral wool or other insulation installed between the ring and the frame.

It is also possible to create an electrical heating system for the upper parts of the well, water pipes and mains.

Installation stages

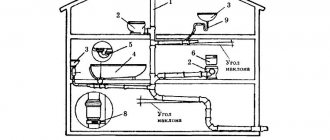

You need to start arranging a water supply by designing the system and drawing up drawings. The diagram should clearly show the paths that water will take from the water intake point to the distribution points in the house.

Branching pipes indoors can be done in several ways:

- Collector - a separate pipe is connected to each water intake point.

- Sequential - the entire pipeline is installed along the entire building and several branches extend from it to water intake points.

It is recommended to resort to the latter method if the volumes of water consumed are small and no more than three people live in the house.

If the building has a washing machine and dishwasher, there are watering hoses and more than three people live in it, it is better to install a collector water supply system that can create optimal pressure in the water column and provide good pressure from the tap.

Stages of winter water supply installation:

- System design. Selection and acquisition of equipment and materials.

- Preparation of trenches for pipes. A layer of sand and gravel is compacted at the bottom of the recess.

- Installation of pumping equipment, hydraulic accumulator.

- Connection of a pumping station, hydraulic accumulator with a pipe.

- Inserting an intake pipeline into a well shaft.

- Installation of insulated pipes from the well to the dacha.

- Wiring of an autonomous water supply system indoors.

The installation of the pipeline is carried out using special pipes - these are special short pipes with threads on both sides. Pressed against pipes using fitting adapters or flanges.

To prevent leaks, the joint between the parts must be carefully treated with sealant. Polyethylene pipes are connected using fittings or soldering. Additionally, adhesive joints are treated with silicone sealant. It is strictly forbidden to use bitumen and mastic.

The cost of laying a winter water supply system for a summer residence depends on the area and model of pumping equipment. The average price ranges from 15,000 – 20,000 rubles.

Warm cover

The essence of the structure:

An insulated cover is placed inside the well at ground level.

There are two options for water supply at home - manual (you have to carry water in buckets) and automatic (water enters the house through water pipes using a pump).

Let's consider a modern and technological case.

To make an insulating cover you will need the following materials:

- Sheet of moisture-resistant plywood;

- Insulation material – polystyrene foam with a thickness of 50 mm;

- Plastic ventilation pipe;

- Wood glue;

- Polyurethane foam;

- Wire.

Cover for insulating a well (moisture-resistant three-layer insulating sandwich panel)

Two circles are cut out of moisture-resistant plywood. The diameter should be close to the inner diameter of the well rings.

In the resulting blanks it is necessary to cut a hole for the ventilation pipe and water hose.

If you make a small hole just for the hose, the water in the well will smell unpleasant and taste bad. The hole should not be too large

so that a minimum amount of cold air enters through it.

For convenience, it is worth drilling a hole closer to the edge of the round workpiece, the diameter is about 50-60 mm.

Along the contour of the lower plywood circle, you need to drill 4 small holes for the wire.

It is needed to hang the lid from the upper edges of the well rings.

Now you need to cut a similar circle from polystyrene foam and make a hole in it for the ventilation pipe

.

The foam circle is glued to the plywood with wood glue, and a second sheet of plywood is glued on top of it. A ventilation pipe is inserted into the hole. To seal the connection and secure the pipe, you can use the same wood glue or polyurethane foam

.

Now all that remains is to make a wire ring.

To do this, you need to wrap it around the top ring of the well and fix the round shape.

The four ends of a wire attached to the bottom sheet of plywood are screwed to it. A water hose is passed into the hole in the ventilation pipe, the warm lid is lowered into the well and held on a wire. The water in the well does not freeze and is ventilated.

Water supply to a private house from a well - options

To organize an autonomous water supply from a well, you will need electric pumping equipment for water intake. It is neither practical nor very reasonable to use mechanisms in the form of hand pumps and other devices due to the fact that the simplest vibration pump can be purchased on the market for only 20 USD.

Other equipment is also relatively inexpensive, for example, the initial cost of a pumping station with a hydraulic accumulator, relay and pressure gauge starts from 100 USD.

Also, the owner will have to lay external and internal water supply from various types of pipes; if polymers are used, their cost is also relatively low.

Systems with storage capacity

Given the relatively low flow rate of the well, the possibilities of continuously pumping water out of it are limited. Therefore, the use of storage tanks, where injection occurs periodically in small volumes, is best suited for shallow wells with low pressure.

The storage water supply system for a private house from a well includes an electric pump and a tank with a volume of about 200 liters on the top floor or attic, connected to each other by a pipeline. An in-house water supply system departs from the reservoir, directing water to the distribution points.

The system with a storage tank works according to the following principle. An electric pump immersed in a water supply well (usually an inexpensive vibration pump) when turned on begins to supply water to a container in the attic. A float switch is installed in the tank, connected in series to the pump power cable. As soon as the tank is filled with water, the float rises, the contacts of the pump's power circuit open, and it stops pumping.

Rice. 4 Water supply to a private house from a well with a tank and a pressure-boosting station

When water is consumed, the reserves collected in the tank are consumed, the water level drops and the float switch lowers. The contacts inside it close the power supply circuit of the pump, it turns on and starts pumping water again.

If the design of the house does not allow installing a storage tank at the top of the attic, you can lower the tank down or bury it underground. In this case, to supply water to the internal water supply, you will need an additional surface electric pump or station.

There is an option to install a storage tank below, in which you can do without an additional electric pump. However, in this case, you will have to purchase an expensive large-volume hydraulic accumulator and pump water into it with a pump through a pressure switch, which will turn off the water supply when a given pressure threshold is reached.

A system with a storage tank can only provide a pressure of about 1 bar when the height of the tank is 10 m above the level of water intake points. However, there is a way out of the current situation, and it consists of installing an additional booster electric pump into the water main.

Another disadvantage of a storage tank in the attic, in addition to taking up useful space, is the likelihood of the house flooding if the internal float switch malfunctions. A solution to the problem is to use a drain hose at the top of the container that goes outside.

Rice. 5 Water supply to a private house from a well with a hydraulic tank

Water supply with hydraulic accumulator

An autonomous water supply system from a well without a storage tank is designed for continuous replenishment of water reserves during water consumption and is suitable for well sources with high flow rates. It includes a deep or surface pump, a pressure relay, a pressure gauge and a battery tank.

The functioning of an autonomous hydraulic accumulator system occurs according to the following principle. The switched-on electric pump forces water into the pipeline and into the hydraulic accumulator, which is a metal tank with an elastic membrane. After filling the hydraulic tank with water, it presses on the membrane of the pressure switch connected to it, inside it the contacts open and the power supply circuit of the pump is interrupted. Typically, the upper relay shutdown threshold in private homes is set at 2.5 bar.

When water is consumed, the pressure in the main drops, and when it reaches the relay switching threshold (approximately 1.5 bar), power is supplied to the electric pump again and water is pumped. The process is repeated periodically, the time interval between cycles is determined by the volume of the hydraulic tank.

Thanks to a hydraulic tank with an elastic membrane, the pipeline is not subject to strong water hammer, and the water volume collected in the tank guarantees some reserve during a power outage.

Rice. 6 Typical vibration pump and its installation diagram

On a note

Experts advise preserving all wells that are not used in winter for the cold period. To do this, disinfection is carried out, and then water is pumped out of the mine. An insulated lid is lowered onto the top ring. On top it is covered with plastic film and generously filled with any insulation of natural origin - fallen leaves, straw, sawdust. It is believed that the water in the well will arrive only in the spring. Although in fact this can happen much earlier if a well shaft is placed on a powerful water vein.

Wells that have wooden walls instead of concrete rings are not insulated with anything additional, except for the lid.

Expanded polystyrene is rightfully considered the best insulation for rings. It is resistant to moisture and fungus, does not deform and can be easily dismantled if necessary. The only disadvantage of the material is the fear of ultraviolet radiation.

Reports of completed work

- Insulation of the shaft and cover. Village Goluboe September 28, 2016

- Mine insulation. Bolshoye Snopovo August 23, 2016

- Mine insulation. SNT Meteor October 20, 2015

Perhaps the material will be useful to your friends. Share the article on social networks.

Rate this article

Why does the water in the well freeze in winter?

- Firstly, the material from which the well was built matters. If this is a tree, then you can calm down: the bucket in it will never hit the ice. If in doubt, remember what they were made from several centuries ago. But now they use reinforced concrete, which, if certain factors coincide, can leave its owners without life-giving moisture.

Wooden wells made it possible to collect water for the household at any time of the year, even in the harshest winters

Secondly, the water level in the well. If the area is swampy and the water is only 1.5-2 meters away, then, of course, the risk of seeing an ice shell is very high. Well, if the well is deep and the water is 8-10 meters from ground level, then there is nothing to worry about.

Thirdly, the depth of soil freezing. In the middle zone and southern regions, where the ground freezes to a meter and a half, a well will not freeze, even a reinforced concrete one. The water is usually below this mark. But if the soil can freeze two to four meters, it is imperative to insulate the well. So the well, and the nerves, and the money will be intact.

Why is insulation necessary?

By insulating the well, it will be possible to maintain a satisfactory temperature inside it, allowing water to remain in liquid form even in high frosts, without forming ice on the surface.

The appearance of an ice layer not only makes it difficult to collect fluid, but can also lead to cracks in concrete circles, or damage wires or pipes located in the well.

The circles begin to break down and age ahead of schedule. As a result, their service life is significantly reduced. If pipes freeze or cables are damaged, repairs will be necessary, which will not be cheap and will require labor-intensive processes.

Basic methods of effective insulation of wells

Unfortunately, polystyrene foam is not suitable for insulating a well - it very quickly begins to crumble and crumble

It is worth especially noting that when insulating a well, one of the main tasks is to maintain an environmentally friendly environment in order to ensure the purity of the water itself. Therefore, you should be strict in the choice of materials used.

There are a lot of insulation materials on offer on the modern market, but which ones are suitable specifically for a well, and which ones can only cause harm, let’s figure it out.

For example, it is unlikely that anyone would think of using expanded clay, polystyrene foam or polystyrene, as well as mineral wool or glass wool for these purposes, since materials that crumble or crumble should never be used, especially for insulating a well from the inside! In addition, during installation, each of the above-mentioned insulation forms many seams, which cannot be sealed hermetically.

Why freezing wells is dangerous

A well in a country house, which is used only in the summer, must be insulated in the same way as one that is used in any season. If you do not take measures to protect the internal space from frost, then the following problems will arise with the further use of the hydraulic structure:

- Ice jam formation. Ice forms both in an open well, from which water is drawn with a bucket, and in a closed well, equipped with a pump for water supply to the house. This will not allow the system to be operated until the plug thaws (approximately mid to late May).

- Destruction of concrete. Concrete soaked in water is easily destroyed when it freezes and expands in the pores of the material. When a plug forms, increased pressure from the outside also acts on the walls, from the expanding ice in the neck. The result is chipping of part of the concrete from the walls, leading to the destruction of the cladding and the appearance of cracks in it. Through them, turbidity and bacteria enter the well, reducing the quality of water.

- Ring displacement. Sometimes the ice pressure on the walls becomes so great that the joints of adjacent rings lose their tightness. The result of this is the penetration of particles of surrounding soil, melt and rain water, microbes, etc. into the well.

- The need for frequent repairs. Walls that collapse due to freezing require annual repair work and the cost of purchasing material.

The need for thermal insulation

This is by no means the main problem. The main thing is that the water does not freeze!

Where the well is planned to be used throughout the year, the structure is usually insulated during the construction stage. But country wells are sometimes made uninsulated. The result is not long in coming - already in the first fairly cold winter, serious problems begin.

It is necessary to protect a well from freezing for a number of reasons:

- The first, and most obvious, is the freezing of water and its transformation into ice. This process occurs quite slowly, because ice usually forms when the outside temperature reaches -15 ... -250C. However, even until this moment it will be inconvenient to use the source, since each time you will have to break through a thin ice crust with a bucket.

A layer of ice blocks access to water and leads to structural failure

- An ice plug that forms on the surface of the water can damage the walls of the well. This is due to the fact that when ice forms, its volume increases, and the edges of the plug begin to put pressure on the surrounding surfaces. If pressure is applied to the joint of reinforced concrete rings, then there is a possibility that they will separate, and if it is applied to a continuous area, then cracks may appear.

A small beginning of a big disaster

Concrete track joints have to be repaired more often

- The formation of ice also harms well equipment: pumps can completely fail, hoses can crack and lose their tightness. That is why it is not worth leaving any equipment in an uninsulated well for the winter.

- The same will be true for a caisson with installed external pumping equipment, and for a sewer well. Any structures with pumping or water-measuring equipment must be equipped with thermal insulation, otherwise the service life of the equipment will be greatly reduced.

The caisson, insulated inside with polystyrene foam, can be used in winter

- Another minus is the ice plugs themselves. During the thaw, they partially thaw and fall into the water under their own weight. The result may be damage to the pump or even broken cables.

Either way, freezing can lead to serious problems. Moreover, the higher the water level in the source, the more noticeable the negative impact of low temperatures will be. That is why shallow wells need to be insulated more carefully.

Insulation with polystyrene foam

The most profitable option is polystyrene foam insulation. Penoplex made in Russia is identical in quality and properties to imported ones, but has a lower price. Available in the form of tiles. A diameter of at least 30 cm is required to evenly place the shell for the rings. For insulation, you can use waterproof clay.

Insulation of a well with polystyrene foam is similar to insulation with polystyrene foam:

- Prepare the walls - clean them of dirt and degrease.

- Install the shell for the concrete rings using construction adhesive.

- If necessary, secure the penoplex with dowel nails.

- Do waterproofing.

- Cover the seams between the plates with foam.

Additionally, you can wrap the rings with water-repellent material. Secure the penoplex on the outside with special metal brackets.

How to insulate a pipe in a well if it is not possible to place it below the freezing level of the ground? The best option is the same penoplex. The width of the sheets should be sufficient for the entire length of the water pipe, covering it on the sides. But is an insulated pipe necessary if it is laid deep? The deeper the pipe is, the less insulation is required. The thickness of the outside insulation for a pipe at a depth of 1 meter is 50 mm. If the pipeline goes to the surface, then more than 100 mm will be needed.

Internal insulation is also important. The best protection against freezing is a wooden or three-layer lid made by yourself

The insulation of the well cover occurs as follows: foam plastic is placed between two plywood and fixed there. The wood is then treated with a waterproof compound to prevent swelling. Holes are drilled inside: one for ventilation (a plastic pipe is inserted into it), two for fastening with wire. The finished structure is lowered inside to ground level.

How to build a house over a well

A house built over a mine is a costly but effective way to protect a water source. For construction you will need logs, cement, expanded clay, mineral wool, and tiles. In order to build a house, you need:

- Build blind areas from cement. Can be covered with tiles or expanded clay.

- Make a log house on the blind area.

- Insulate the gaps between the house and the ring with cotton wool.

- Install a gable roof.

- Treat with moisture-resistant impregnation, then close the hatch.

Wells need to be insulated. The cost of the work will pay off in the near future, because you will not need to spend money on repairs and ordering water while the restoration is underway. The range of insulation materials is wide, so among them it is easy to find one that is suitable for you in terms of composition, installation method and price.

Freezing of a well is a very unpleasant event for residents of country houses who use well water for water supply all year round. It’s quite simple to avoid this - insulate the well yourself. And for a positive result, you need to know the specifics of performing thermal insulation and understand the materials. Do you agree?

We will tell you how to choose the right insulation for thermal insulation of a well shaft. Here you will learn everything about the methods and nuances of carrying out work. Taking into account our recommendations, you can ideally protect your water source from low temperatures.

Will the well freeze in winter? This can be predicted with a high degree of probability.

Firstly, if natural wood was used to construct the well, then it will not freeze even with prolonged exposure to sub-zero temperatures. Our ancestors took advantage of this property by constructing wells from wood.

Modern wells are built using reinforced concrete rings, and given that this material has high thermal conductivity, the well will freeze in the same way as the surrounding soil.

Secondly, you need to pay attention to the water level: if it does not exceed 1.1-2.2 m, then the risk of freezing is very high. If the well is deep and the water in it is below the freezing level of the soil, then the water does not freeze

The third factor that must be taken into account is the depth of soil freezing in the region. In the southern regions, the freezing depth rarely exceeds 0.5 m, in temperate regions - 1-1.5 m, in the northern regions - below 1.5 m.

Thus, the question of how to properly insulate a well for the winter faces owners of reinforced concrete wells located in temperate and northern climates. For residents of the southern regions it is less relevant. There are enough minimal measures - the construction of an insulated cover, and the well itself does not need thermal insulation.

Freezing of a well made of reinforced concrete rings can be prevented by making high-quality insulation, allowing uninterrupted use of water from it all year round

Method three. Construction of a wooden house

If your site is located in an area where the temperature in winter is not too low, you can build a protective wooden frame over the shaft. To do this, prepare:

- wire;

- nails;

- waterproof film;

- logs;

- plywood sheets;

- expanded polystyrene.

Step one. First of all, cover the inside of the top ring with a pre-prepared film. Next, take the foam and cut out six rectangles from it. Make the dimensions of the latter such that as a result of lining the ring, an even hexagon is formed. This little trick will significantly increase the adhesion density of the foam.

Step two. Then you need to secure the foam. To do this, wrap it with ordinary wire in at least three rings. It is advisable to use aluminum wire for this, since it does not rust and is quite soft. As a result, it will be easy to manipulate, and there will be no corrosion on the surface of the insulating layer.

Step three. After this, build a log house from small-sized logs. The height of the log house must be level with the well itself, and its shape must be hexagonal. Place a cover consisting of several layers on top of the finished house (as described in the first insulation method). Then you can paint the structure so that it is not only functional, but also aesthetic.

Video - House installation

For a more detailed introduction to the technology, we recommend watching the thematic video material.

How to insulate a concrete well with foam plastic with your own hands

If you do not want to pay extra money and contact specialists, then you can insulate a water supply well using polystyrene foam on your own. To do this, you need to stock up on polystyrene, which is sold in the form of a semicircular shape (“shell” made of polystyrene foam). The range of insulation is presented in different diameters and thicknesses, from which you can easily select the desired option.

Insulation with foam plastic or penoplex

Polystyrene is resistant to moisture, the appearance of fungi and mold, and mechanical soil pressure. It does not rot, does not absorb water, does not emit harmful substances, and mice do not live in it. That is why polystyrene foam can be easily used even after a possible well repair for the second time.

Before insulating a concrete well with polystyrene foam, you need to dig a trench 1.5 meters deep along its perimeter or to the freezing depth of the soil in your region. Then, we select a polystyrene “shell” to match the diameter of the concrete rings and install insulation around the source. After this, the trench is buried. Semicircular polystyrene has a convenient tongue-and-groove fastening, so they are often used when insulating water pipes in the basement.

Thermal insulation of structural elements of a well

- insulation of the outlet pipe, which should preferably be installed below the freezing level of the soil, and the installation site should be sealed. But, if this requirement is not met, then you need to take care of insulation.

Polymer shell-insert for a wellThermal insulation can be done using reliably protected mineral wool, PPU shell or a special, hard plastic shell (pictured).

Laying pipes from a well in polystyrene foam. It is permissible to use rigid insulation. Then the pipe is placed in it, like in a sandwich.

- insulation of the pipe entry point into the house. The incoming node is rarely made below the freezing level, so the place where the pipe enters the house should also be insulated. For this purpose, any thermal insulation material, properly installed, is used;

- insulation of water pipes. Thermal insulation of the water pipe is carried out regardless of the installation level. It is advisable to use a polyurethane foam shell of a suitable diameter or lay a heating cable along the pipe.

Since we are talking about wells, we cannot ignore its varieties:

- Insulation of the well along the entire length is not carried out, because The water in it is located quite low. If water intake is not planned, the well is preserved for the winter by draining water from the pipes. If the well is used year-round, it is necessary to insulate the caisson in which the pumping unit is located. The Abyssinian well is insulated in the same way;

- Insulation of a sewer well is a mandatory process that is carried out even at the time of installation of the caisson. Typically, sprayed polystyrene foam is used as insulation;

- There is no need to insulate the drainage well. But, only if the work on its installation is carried out correctly: the angle of water flow is ensured, the diameter of the pipes is correctly selected, and they are correctly laid below the freezing level of the soil. Otherwise, insulation is carried out in the same way as insulating a well.

Preventing the well from freezing

To prevent the well structure from freezing with the onset of winter, thermal insulation should be taken care of during its construction. If the suburban area will be visited occasionally (for example, only on weekends), then, in principle, there is no need to insulate the well. In such cases, it is only necessary to clean it and treat it with some kind of disinfectant (such as chloramine) before leaving.

After this, pump out the water completely and close the structure with a lid. Lay a polyethylene film over the lid and cover it all with leaves. Now you can go to the city with a clear conscience, because with the onset of warmth, the well will again provide clean water.

But if the well is used regularly, then the measures should be more serious. For example, pipes to the house must be located below the soil freezing line, the structure itself must be protected by the house described above, or by other available means.

Required tools and materials

Ideally, the owners of a well should think about this during its construction, then the amount of work with the soil will be much less. If a built and actively used well needs insulation, you will need to dig a shaft to install insulating materials. The insulation layer is laid 0.5–1 m below the soil freezing level.

To carry out the work, it is necessary to select a thermal insulation material. Experts recommend using one of the following options:

- Polystyrene foam or polystyrene foam. Rigid material with high thermal insulation, long service life and low price. Currently, the industry produces special round-shaped foam sheets, which are most convenient for installation on reinforced concrete rings.

- Penofol. Foil material of small thickness. It is rarely used for insulating wells.

- Polyurethane foam. Allows you to create a seamless coating based on any configuration. The disadvantages of polyurethane foam are the high price and the need to use special equipment for spraying.

- Shell made of polyurethane foam. Analogue of sprayed polyurethane foam coating. It consists of two halves that are attached to concrete rings. The industry provides the consumer with a wide selection of polyurethane foam shells of various diameters, so you can choose the required option for the installed well rings.

To attach the insulation you will need wire, tape or rope. If PPU shell or polystyrene foam is chosen as insulation, polyurethane foam is needed to seal the cracks. The insulation will need to be protected from moisture, so additionally prepare a vapor barrier material.

Insulation options

Well insulation

Modern industry offers several types of materials for insulating wells for the winter. Among them, the most popular are:

- Penofol. This is a sheet of foamed plastic, covered on one side with foil or metallized polymer. Has excellent thermal insulation properties. Unfortunately, it is soft and cannot withstand heavy loads associated with soil pressure, so it is rarely used.

- Styrofoam. Foamed polystyrene is an inexpensive and very popular material. It is easy to install with your own hands and is quite rigid. It is produced in large sheets; for installation, you will have to cut them into narrow strips so that they fit better into the round concrete rings.

- Polyurethane foam. The liquid composition is sprayed onto a concrete or brick surface, foams and hardens in a continuous layer. The consistency is similar to polyurethane foam. The best solution for thermal insulation of a reinforced concrete ring. It is distinguished by the high cost of equipment. Molded modules made of polyurethane foam. The so-called “shell” for insulating well rings consists of two halves - half-cylinders; they are easy to install and secure. The joints are sealed with construction foam.

- Many homeowners still use traditional insulation methods - filling with expanded clay, sawdust, etc. Given the relative cheapness of materials, these methods are significantly less effective. Mineral wool is not suitable for insulating wells due to its hygroscopicity.

Reasons for freezing wells

In the old days, when constructing a log house from wood, well builders simultaneously provided thermal insulation for the internal space of the well. In the northern regions, the neck was additionally closed, installing hatches and houses on the head of the structure. Wood has a fairly low thermal conductivity and reliably retains heat without the use of additional means.

Types of insulation of concrete wells.

Now the most common option for lining a well shaft is concrete rings. Even a thick concrete wall can freeze severely when the temperature drops below -10°C. The rings, apart from the ability to quickly transfer heat to the surrounding frozen soil, are not very thick.

The walls of the well lining are about 10 cm thick and almost do not protect the shaft from frost above the ground and at the depth of soil freezing (1-1.5 m or more).

Because of this, an ice plug may form in a well that is not prepared for winter, and if the water supply is laid shallowly (for example, in a summer cottage), the pipes may also freeze.

A completely reasonable question arises: What material is then optimally suitable for insulating a well?

Insulating a well by spraying polyurethane foam is the most ideal option of all available: quickly and reliably!

The most effective today is considered to be the use of polyurethane foam, which does not rot, is resistant to moisture and is completely harmless to human health, since it does not emit hazardous substances.

Such thermal insulation of a well as polyurethane foam has two, if you can call them that, disadvantages, which are most logical to call features.

- The first point is the ambient temperature when spraying this material. It should be at least +20 degrees Celsius, since when working with polyurethane foam at lower temperatures, the mixture will foam worse, which entails an increase in costs for the amount of material.

- The second point is that it is difficult to carry out the work of spraying polyurethane foam on your own, without the skills and necessary equipment.

Otherwise, insulating a well with polyurethane foam is the most ideal option of all available!

How to insulate a well for the winter with your own hands

Types of insulation:

- internal insulation of the well

. Since only technological wells can be insulated from the inside, in the case of a water supply system you should limit yourself to only installing a hatch; - external ground insulation

. It involves insulating all parts of the well located above the soil surface; - external underground insulation

. Provides for installation of heat-insulating material outside the well pipe.

Let us consider these methods in more detail with a brief description of the technology in the form of step-by-step instructions.

Internal insulation of a well (well cover)

Making an insulated cover (hatch) will prevent a drop in water temperature and the formation of an ice crust.

How to insulate a well cover

prepare materials: plywood (boards), wire, a piece of plastic pipe (diameter 30-50 mm), insulation, mounting foam. Note. Only hard and high-density insulation is used to avoid it crumbling and getting into water.

cut two panels from plywood or make panels from tightly fitted boards. The diameter of the shield is equal to the diameter of the well pipe minus 20-30 mm;

wrap one of the panels with film for waterproofing. This will prevent the wood from rotting. It is not recommended to use primers, because... We are talking about drinking water. Glue polystyrene foam on the back side of the plywood;

cover the structure with a second shield;

drill a hole in the manufactured structure and pass a pipe through it for ventilation;

fix the wire (will be used to lower and raise the lid);

install two hooks on the head of the well so that you can hook the wire and avoid the lid touching the water.

Note. An insulated well cover is installed below the ground freezing level.

As an option, you can make two separate shields and install them one by one. Thus, an air gap is formed, which will serve as additional insulation.

External ground insulation of a well

Insulation from the outside (upper ring, cap) can be implemented in two ways:

installation of heat-insulating material on the walls of the well located above ground level. The work procedure will be similar to the underground insulation described below. The difference is that there is no need to dig a trench to free the underground part of the well pipe, and the installed thermal insulation material needs protection in the form of decorative finishing of the head with bricks or timber. It is worth noting that this type of work has the least efficiency, but can be performed in conjunction with other types of insulation;

construction of a wooden house over the well head. The house will compensate for temperature differences and protect the water from debris.

External underground insulation of a well

A labor-intensive method, but it allows you to forget about problems with freezing forever. Let's look at it in more detail.

Insulation of the well pipe begins 1-1.5 m lower than the soil freezing level. This approach will eliminate the possibility of freezing even at extremely low temperatures for the region.

How to insulate a well made of concrete rings

prepare materials: insulation, polyethylene film (for greenhouses), assembly adhesive for insulation, foam, wire, protective sleeve, primer or waterproofing, finishing materials;

determine the depth of soil freezing. The insulation is laid at least 0.5 m deeper;

dig a trench around the well;

clean the surface of the concrete rings from dirt;

apply a primer to the concrete, or even better, waterproof it. As a last resort, wrap the pipe with film;

cut out insulation blanks. Craftsmen recommend making a bevel along the length of the sheet at an angle. This technique will allow you to fit the workpieces more tightly;

- pour the excavated soil back into the trench;

- form a blind area 0.5 m wide. If you plan to build a house around the well, you can make a small foundation.

Method two. We thermally insulate the upper ring of the structure

Every specialist will tell you that in order to prevent freezing of a well, you need to reduce the thermal conductivity of its upper ring. This method of thermal insulation is performed in two ways:

- by means of polystyrene foam;

- using polyurethane foam.

Let's look at the first method first.

We use polystyrene foam for the ring “under a fur coat”

Here you should prepare the following consumables for work:

- polyurethane foam;

- paint;

- plaster;

- insulating blocks made of polystyrene foam, which are connected using a tongue-and-groove system.

On a note! According to this technology, the first ring on top will be completely insulated, while the second only partially. Now to work!

Step one. Work should begin with preparatory activities. Dig a pit 20 centimeters wide and approximately 0.5 meters deep around the ring. Then thoroughly clean the surfaces from dirt and install the first “fur coat” ball. At this time, make sure that the density of all connections is maximum! Blow out the joints with foam to seal them. Having finished with the first level, proceed to assembling the second and gluing it to the ring. Blow out the gaps that have formed between the layers with foam.

Step two. Next, begin plastering the surface of the rings. This will protect the foam from the negative effects of the sun's rays, which, as we know, worsen the thermal insulation properties of this material. After the plaster has completely dried, apply paint to it - this will prevent the finish from getting wet.

Step three. All that remains is to fill the pit and thoroughly compact the earth.

Penoplex, we insulate the foundation reliably and correctly

We recommend that you read our article on insulating the foundation yourself. You can find out more here

We use polyurethane foam for the ring “under a fur coat”

If you chose polyurethane foam as insulation, then follow these steps. First, dig a similar pit (as in the previous method of insulating a well for the winter), and then build a wooden frame around the first ring. But this is in general terms; let’s analyze the procedure in more detail. Prepare the following materials for work:

- paint;

- dowels;

- polyurethane foam sprayer;

- collapsible metal formwork;

- plaster;

- a piece of plastic film;

- wooden bars.

Step one. Traditionally, start by digging a pit, but narrower (maximum 10 centimeters). After this, install bars around the first ring in increments of approximately 40 centimeters. Cover the edges of the trench with formwork made of thin sheet steel, which will exactly follow all the contours. Cover the formwork with the prepared film. For what? This is explained by the fact that the adhesion of foam plastic is very significant, and therefore dismantling the formwork is impossible.

Step two. Having finished building the formwork, you will notice that a void has formed between it and the ring - this is what needs to be filled with insulation. Upon completion of pouring, the polyurethane foam will increase in volume, and the trench will therefore be filled as densely as possible.

After this, you need to wait until the material is completely dry. As soon as this happens, dismantle the formwork. Plaster the finished surface and apply a layer of paint to it. Fill the void left after formwork with earth and compact it thoroughly.

On a note! It is also advisable to cover the well with a lid, which was described in one of the previous paragraphs of the article.

In what cases is insulation required?

If the well was built according to ancient traditions (read: made of wood), then, of course, it does not need any thermal insulation. There are exceptions - for example, a well cover needs insulation. In this case, it is necessary to make an additional cover from wood and fix it inside the structure itself. This cover will protect the country well from:

- snowfall;

- temperature changes;

- ingress of dry leaves and other debris.

Note that almost all modern wells are constructed using reinforced concrete rings. Such wells have numerous advantages, including:

- strength;

- reliability;

- durability;

- ease of installation and further maintenance.

Despite this, they have one significant drawback: they need to be insulated for the winter.

On a note! If the water in the structure is located below the soil freezing level, then the structure itself will not freeze. But if it’s higher, then installation of insulating material is required!

There are three thermal insulation technologies:

- insulation of the structure cover;

- thermal insulation of the upper ring;

- construction of a decorative house.

Let's take a closer look at each of the possible methods.

Lightweight, airy polyurethane foam is the most cost-effective option for well insulation!

This material has many advantages. Here are just a few of the main ones:

- Not only does it not rot, but it is also not subject to deformation under soil pressure if the well is insulated from the outside.

Ecotermix 300 is the best material for external insulation of wells!

- In addition to the fact that this material is resistant to moisture, it is not susceptible to infection by fungi or mold.

- It does not attract rodents, which is important when it comes to insulation for a well with drinking water.

- Does not require fastenings, preliminary preparation of the surface of the rings and their treatment with various primers.

- It is very light in weight and does not increase the load on the structure of the well, but rather strengthens all its elements.

- Ideally fills all wall defects and cracks at the joints of the rings, thereby extending the life of the well.

- It is easy and quick to apply, and if necessary (for example, for the purpose of cleaning or repairing a well), polyurethane foam can also be easily dismantled.

- It belongs to the group of materials that are difficult to burn because it does not support spontaneous combustion.

- This wear-resistant coating excellently retains its original thermal insulation properties for 50 years.

The procedure for performing insulation work

To obtain the desired result, it is necessary to perform a number of works, namely:

- insulate the lid;

- insulate the head;

- install a decorative house.

After completing this work, frost is no longer scary.

We insulate the lid

The process of making a warm lid is not difficult. Neither does it require material costs. Two identical circles are cut out of plywood to the size of the reinforced concrete ring. Another similar circle is cut out of foam plastic (or other insulation). Then all three circles are glued together so that the insulation is in the middle. Any glue can be used, but it must be frost-resistant.

After the entire structure has dried, it is necessary to drill four holes in it for the fastening wire and a small cutout of the edge for the hose and wire if a pump is installed in the well. All that remains is to drill a ventilation hole with a diameter of 40-60 mm and the lid is almost ready. When gluing, the insulation may crumble and gaps may form at the drilling sites and the cutout for the hose. We carefully foam them with polyurethane foam.

The lid is ready. All that remains is to install it in place. How to attach it - everyone will choose according to their own taste. The holes for the wire are drilled.

Lid lowered into place

The only thing that needs to be taken into account is the depth to which the lid will go down. It should be no less than the ground level around the head.