For laying, installation and repair of communication systems made of metal-plastic material, a special tool is used - press pliers for metal-plastic pipes. This device allows you to carefully process the parts and ensure a reliable, tight and strong connection of all the fragments with each other.

The system assembled using press jaws is characterized by durable operation, guarantees mechanical strength in the joint areas and does not require subsequent labor-intensive maintenance. We will tell you how to choose a tool and how to use it correctly in practice. The care tips we provide will help extend its working life.

Features of Hand Crimping Tool

In addition to their direct functions, certain models of manual press pliers have some additional functions that facilitate the installation process and promote compliance with basic safety rules during operation:

- OPS is an expansion option aimed at increasing muscle strength using a progressive four-stage clamp.

- APC is a unique system that monitors the correct execution of the connection (does not allow the pliers to be removed from the pipe until the clamp is completely completed).

- APS is a progressive device for the correct distribution of applied force depending on the dimensions of the press fitting.

When planning to purchase a manual press tong for metal-plastic, first determine the diameter of the pipes used, and then, based on this data, find out whether the store has a tool of the same diameter and fittings intended for crimping used to make connections.

If you need to crimp pipes of different sizes, take the maximum cross-section of the part as a basis. A large-diameter tool can also cope with smaller pipes, since the kit always includes additional inserts that allow this operation to be carried out.

The entire process of creating a connection using press jaws includes several standard steps:

Image gallery

Photo from

Stage 1: Calibration of the metal-plastic pipe

Stage 2: Installing the fitting on the prepared pipe

Step 3: Crimping the pipes to be connected

Step 4: Checking the strength and tightness of the assembly

How to choose a tool: professional or for home

Before you start purchasing press jaws for metal-plastic pipes, the volume and complexity of the planned repairs are established. In addition, you need to take into account the diameter of the product; this information can be found in the instrument’s passport.

If metal-plastic pipe materials with a diameter of 26 or 32 mm are being installed, it is better that the tool handles be extended.

For the home, a household pipe crimping tool is suitable, with a very affordable price. Manual models are ideal when working with internal systems, which often have a pipe material diameter of no more than 20 mm.

The main mites sold in the Russian Federation are:

- REMS - with liners from 16, 20, 26;

- VALTEC - 16, 20, 26, 32;

- FORApress - 16, 20, 26, 32;

- STC 500 - 16, 20, 26.

Press jaws with a hydraulic or electric drive are expensive, and buying them for home purposes to perform a one-time assembly is not justified. For professionals who perform large volumes, it is recommended to opt for them.

It is important to have options such as optimization and control over work:

- OPS is a design that has stepped clamps, which leads to optimization and increased pressure;

- APS is an improved model, in which the load is evenly distributed over the sleeve;

- APC is a feature of these pliers; the crimping process will not stop until crimping is complete.

This equipment is produced by Belgian and German companies and is expensive. However, according to user reviews, you can buy a device of equal quality and reasonable price from Turkish or Italian manufacturers.

There are uniform recommendations for everyone who plans to purchase an instrument:

- the purchase must be made in a store that specializes in this product or from a dealer;

- for large-scale volumes of crimping fittings, it is recommended to rent the device, so you will understand the feasibility of purchasing in detail;

- When choosing a press, you should pay attention to European manufacturers.

How are metal-plastic pipes connected?

In the process of laying metal-plastic pipes, special connecting parts - fittings - are used. They are fastening elements or nodal branches - crosses, tees, adapters, plugs, etc.

There are two types of these parts - compression and press. To install the former, you need a regular wrench, and for the latter, crimping pliers. Our recommended article will introduce you to the range of fittings used for assembling metal-plastic pipelines.

Press fittings fixed to metal-plastic pipes using a crimping tool allow for correct wiring in a system of any complexity

The press fitting is considered the most reliable and does not weaken during operation, minimizing the possibility of leaks in systems. This method of connection makes it possible to fill communications with concrete and, if necessary, carry out hidden laying of metal-plastic pipes in walls, floors and ceilings.

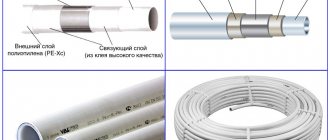

A press fitting is a modern element for reliable connection of metal-plastic pipes into a single system. Consists of a housing in which there is a fitting and seals that insulate the crimp sleeve and ring

The connection area demonstrates excellent performance, easily withstands pressure several times higher than the maximum permissible pressure in the pipes themselves, exhibits high mechanical strength and reliably serves for many years, without requiring unnecessary attention and labor-intensive maintenance activities.

When installing metal-plastic pipes to organize a heated floor, it is important to use press fittings. They provide maximum connection reliability and are suitable for subsequent pouring with concrete screed

To install fittings in metal-plastic pipes, crimping pliers of any type are used. With their help, crimping occurs quickly and efficiently, and the result is a clear, permanent connection, almost completely eliminating a breakthrough on the communication line.

When using press fittings, the system turns into a solid, non-separable complex. Errors made during the installation process cannot be corrected or repaired. To eliminate them, you will have to cut out the fragment and install a new communication node.

Another disadvantage is the rather high price of press parts. That is why they are not used very widely in everyday life.

Differences from compression analogues

Due to inexperience and ignorance of all the nuances of installing metal-plastic pipes, press fittings can be confused with compression fittings. They also have a fitting and a sleeve. Only the latter is crimped not with a tool, but using the union nut included in the design.

The main difference between these parts is the different type of connection resulting from installation. The compression version can be disassembled if necessary, but this cannot be done with a pressed version. The press fitting can only be cut off from the pipe to be replaced with a new one.

If a leak develops at the connection point, the nut of the compression fitting can be tightened, but the maintenance-free press fitting will have to be completely removed

However, the likelihood of a leak in the press connection is practically zero. It is not for nothing that this installation method is recommended for use when installing “warm floors” under a screed and when embedding pipelines into the wall. Cases when such fittings begin to leak in concrete occur extremely rarely in the practice of plumbers. This is more of an exception to the rule.

On the other hand, installation of both types of press fittings requires specialized tools. And to tighten the nuts of compression products, you only need a pair of wrenches. As a result, on one side of the scale there is “expensive instrumentation + higher reliability of the joint”, and on the other “no extra expenses + a slightly higher risk of leaks”. The choice here is only up to the master and the owner of the house where the pipeline is being laid.

Preparing pipes for processing with press jaws

Immediately before assembling metal-plastic systems, i.e. Before using press jaws and carrying out crimping activities, the pipe material is prepared accordingly.

When marking metal-plastic pipe material, it is necessary to add a small overlap (2-3 cm) to both ends of the part. Otherwise, after inserting the fitting, the fragment will be shorter than required according to the estimate. The position of an incorrectly installed press fitting cannot be corrected. You will have to cut out the entire fragment and install a new one in its place.

The sequence of actions is relevant for any type of tool and requires mandatory compliance:

- Using a tape measure, measure out the required amount of pipe material from the coil and make a mark with a marker where the intended cut will be.

- Using scissors for cutting metal-plastic, cut off a part of the required length, making sure that the resulting edge is as smooth as possible and makes a clear right angle with the conditional central axis of the product.

- When using a guillotine tool for work, its lower edge is held strictly parallel to the surface of the pipe, only slightly pressing the cutting part into the pliable material.

- When the trimming is done, the resulting end edges are processed with a calibrator. He corrects and aligns the shape of the cut and carefully removes the internal chamfer.

- Remove the ferrule from the fitting and place it on the edge of the pipe. The fitting is inserted directly into the cut.

- The end parts of the connection elements are pressed tightly, and the joint area is isolated with a sealing gasket. It protects the material from corrosion and ensures the tightness of the entire system as a whole.

- The placement of the pipe in the sleeve is controlled through a round cutout in the edge zone.

When the appropriate preliminary preparation is completed, proceed to the use of press pliers and carry out the crimping operation.

Methods for crimping metal-plastic

The hydraulic method involves filling metal-plastic pipes with water and then increasing the pressure to set values. Tests may affect the entire installed highway or only individual sections of it.

The pneumatic method uses compressed air instead of water. This crimping method is considered less effective and more dangerous compared to the hydraulic option. And it doesn’t matter whether metal or metal-plastic pipes are tested.

Image gallery

Photo from

Construction of a metal-plastic pipeline

Pressure testing of a gas pipeline

Metal-plastic pipes in the installation of heated floors

Metal-plastic pipes in high-rise buildings

Option #1: hydraulic

The process is no different from the standard version, which is used on steel water mains. The only caveat is that the operating pressures for plastic pipes are lower than those accepted for metal products.

Accordingly, the test pressure is calculated taking into account standard operating pressure settings for plastic according to the formula:

Ri = Ррп * 1.5,

In it, Ri is the test pressure; Ррп – working pressure of a plastic pipe.

The water temperature inside the pipeline is allowed within positive values of 5 – 40ºС.

Progress of the procedure:

- Prepare the test area (install taps, plugs).

- Install 2 pressure gauges at different points in the line.

- Install an air vent at the upper level of the pipeline.

- Connect the water pump at the lower level of the line.

- Fill the line with water supply from the lower level to the upper level.

- Open the air vent to bleed air from the system.

Inside the pipeline made of metal-plastic pipes, the pressure should be increased slowly, excluding sudden jumps. Such pressure pumping conditions are provided by a manual hydraulic press.

A hydraulic pump is used to test an assembled or repaired system that requires perfect tightness of connections. The connections themselves are not formed using the pump.

Until the pressure value approaches the operating level, it is recommended to periodically visually monitor areas of possible leaks.

These areas are usually:

- pipe-in-pipe connections;

- contact between pipe and fitting;

- installation points for taps and plugs.

Increasing the pressure inside metal-plastic pipes to a value exceeding the operating parameter by 1.5 times is allowed only in the absence of people near the tested line.

The established test pressure inside the pipeline must be maintained for a certain time. For water supply systems made of metal-plastic pipes designed for use in domestic conditions, a five-minute minimum holding period is adopted.

During the accepted minimum test time, a pressure drop at the installation points of control pressure gauges is not allowed. When negative changes are observed on control instruments, this condition indicates incomplete tightness of the system.

The pressure should be reduced to the operating value and carefully checked for possible leaks throughout the entire section of metal-plastic pipes. Eliminate detected defects and repeat the test procedure.

At the final stage of crimping metal-plastic pipes, the pump is disconnected from the system. Also remove control pressure gauges, previously installed plugs and shut-off valves

Leak tests are passed when they satisfy the following conditions:

- no leaks were visually detected;

- no pipe wall ruptures were visually detected;

- for five minutes there were no changes in pressure on the control pressure gauges;

- there are no visible deformations of the pipelines.

Meanwhile, it is necessary to clarify: if the time delay exceeds a five-minute interval, a slight drop in test pressure is allowed due to a natural change in the temperature of the water inside the metal-plastic pipes.

Option #2: pneumatic

If it is impossible to carry out hydraulic pressure testing for some reason, an alternative is allowed - pneumatic testing.

The pneumatic test method differs in a slightly different way of checking for leaks, but in general it practically repeats the hydraulic method. This technology is not used so often on pipes, but it is widely used for crimping individual devices, such as expansion tanks, boilers, heat exchangers, etc.

A convenient, small-sized and lightweight automobile air pump is quite suitable for performing pneumatic tests of a home plumbing system on metal-plastic pipes

To detect leaks under pneumatic pressure testing, a soap solution is usually used. The assembled line is filled with air under pressure Pu = Ppp * 1.15 and areas of potential leaks are irrigated with a soap solution. The release of air is determined by the swelling of bubbles.

This testing technique allows you to visually detect even minor leaks. But it is quite difficult for the inspector to monitor the presence of leaks in places that are difficult to reach for visual observation.

The pneumatic test method is quite suitable for testing the tightness of connections between metal-plastic pipes using fittings or using the “pipe-in-pipe” scheme. But when you need to test the strength of a pipeline system, this method is clearly not the best. Here it is necessary to resort to hydraulic testing.

How is crimping done with a handheld device?

The process of crimping a metal-plastic pipe with manual press pliers is not complicated, but it requires attention and accuracy. To work, you need an empty, flat surface that allows you to place a piece of pipe, connecting fittings and the tool itself.

To work correctly with press jaws, appropriate conditions are required, namely a spacious, flat surface and good lighting. In a conveniently equipped place, even a beginner who does not have much repair and installation experience can crimp and install the fitting correctly.

When everything necessary is prepared, the press tongs are placed on the table and the handles are moved apart 180 degrees.

The upper element of the holder is disconnected from the unit and the upper part of the press insert corresponding to the cross-sectional size of the pipe that is currently being processed is inserted into it. The lower half is placed in the lower part of the holder, which remains empty, and the tool is snapped into place.

You can crimp a fitting with press pliers only once. The second processing is categorically unacceptable, so each action should be taken responsibly

A joint assembly is made from a pipe and a fitting and the structure is placed into press jaws, carefully ensuring that the fitting sleeve is inside the press insert.

For high-quality crimping, it is very important to use nozzles that clearly correspond to the cross-sectional diameter of the pipe. Otherwise, the device will deform the fitting and the part will have to be replaced with a new one.

After the set of pipe and fitting is correctly placed in the device, the handles are brought together until they stop and crimped.

After the operation, two identical arcuate bends and two clearly visible annular stripes should form on the metal. And the result will be a clearly and firmly installed and secured fitting, which will be almost impossible to remove with a working tool.

Installation of the fitting must be carried out very carefully, carefully and without haste. Under no circumstances should bias be allowed to occur. Even 5 millimeters will become critical for the pipeline system and in the future will lead to a violation of integrity

You can tell if the work was done incorrectly by a loose, poorly secured nut, by the presence of an opening more than 1 millimeter wide visible between the metal-plastic pipe and the nut, and by the looseness of the nut. If such errors are found, the fitting will have to be cut out of the pipe and a new one reinstalled in its place.

Features of installation and selection of fittings

Metal-plastic pipes made of cross-linked polyethylene are not initially intended for welding and gluing. The welds on them will still crack and come apart after a couple of months. And glue is not used due to the resistance of this plastic to solvents and its low adhesion. It remains to use only specialized fittings for installation.

All cuts of metal-plastic pipes must be made exclusively at an angle of 90 degrees; even minor deviations can have a detrimental effect on the quality of the connection

When choosing a press fitting, the main attention should be paid to the crimp ring. It must be made of durable metal. And no seams on this metal surface, just seamless stamping. Any seam is a point for destruction. It is better to immediately reduce or completely eliminate the likelihood of a pipeline rupture resulting in flooding of the house. There's no point in chasing cheap prices here.

The standard sizes of the press fitting are indicated in the markings both on the ring and on its body. Similar information is contained on the pipe. Everything must match. Once again, you should not purchase fittings and pipes made of metal-plastic from different manufacturers. In most cases, such inconsistency leads to problems both at the installation stage and then during operation.

After crimping the fitting, the pipe must not be bent near the latter. This may place unnecessary stress on the connection. It is also unacceptable to apply any lateral force to the press fitting. It itself will not be damaged, but the plastic nearby may collapse.

Features of using press jaws

Despite the practicality and functionality of press pliers, there are places where using such a tool is very inconvenient. Repair and installation professionals say that when working with grooves laid in a false wall or under a suspended ceiling, it is wiser to take a press gun rather than pliers. It completely eliminates injury and makes it possible to control the process with one hand.

A pressing gun is a modern, convenient tool that allows you to crimp pipe material in the most inconvenient places and in limited spaces. However, it is not cheap and it is not advisable to buy it for one-time household work.

In addition, the tool can be rotated around the joint axis of the pipes, thus performing accurate, even and reliable crimping.

Practical tips for crimping metal-plastic pipes, tested in practice by plumbers, are given in the following article, the contents of which we recommend that you familiarize yourself with.

What kind of instrument is this

Press pliers are a special device for connecting press fittings to metal-plastic (and plastic) pipelines. Press fittings are pressed onto the pipe using pliers and form a reliable sealed connection. The press connection does not require further regular inspections, tightening or tightening. If the fitting is installed correctly, the system will not leak for many years. For pouring into grooves and screeds, only press fittings are allowed.

There are varieties for crimping cable ends into lugs, securing terminals and connectors to wires.

Safety precautions when working with the tool

To use press tongs at home, you do not need specific knowledge or extensive work experience. You just need to carefully study the operating instructions and strictly follow everything that is written there.

Do not use the tool in rooms with high humidity. Dampness has a bad effect on metal and leads to jamming and incorrect operation of tools.

It is advisable to carry out the pressing process in comfortable, practical clothes, and protect your hands with thick construction gloves. To avoid injury and damage, do not allow parts of clothing or limbs to get into the working mechanism. Following these simple rules will help you perform crimping carefully, without damaging either yourself or the tool.

Device and purpose

The shape resembles ordinary pliers, but functionally they do not bite parts, but clamp (press in). This is where the name came from. The device has a crimping head made of durable steel and comfortable long handles. The head is usually equipped with a set of crimping attachments of several sizes.

When using which fittings are press pliers required?

The device is required when crimping press fittings. The fittings are firmly pressed with press pliers at the end of the blanks (in this case, the upper coupling of the fitting is deformed and pressed into the thickness of the plastic) and form a reliable sealed connection.

How to care for press tongs?

In order for a tool to serve reliably for a long time, it needs to be looked after. After use, it is necessary to clean the metal head with a special product, and then treat the screw and the clamping parts of the nozzle with lubricant.

It is recommended to store the device in a dry place, pre-packing it in a case or a special box, usually sold with the instrument.

Regular, complete, high-quality care and proper storage will extend the “life” of the instrument for a long time and ensure its impeccable performance

Electric and hydraulic units are somewhat more difficult to maintain and require professional maintenance. How to keep them in order can be found in the data sheet included with the equipment.

In addition to press pliers, assembling a metal-plastic pipeline will definitely require a pipe cutter, the specifics of the selection and application of which are given here. We recommend that you read this very useful information.

Types of equipment and principle of operation

There are hydraulic and mechanical manual press pliers for crimping. The former require less physical effort from the operator and allow for greater developed force, and therefore are ideal for frequent use in various production conditions. For rare use, it is more advisable to purchase mechanical press pliers - they are cheaper.

Hydraulic equipment is divided into several types. Non-autonomous models require connection to a pump; autonomous models are more convenient, as they can be used without additional equipment. Hand press pliers with a remote pump are great for working in hard-to-reach places.

There are special press pliers for fittings - equipment designed for crimping the connecting parts of various pipelines.

Preparatory work before crimping

The actions that must be performed before starting control pressure testing of a gas pipe are carried out in accordance with labor protection instructions developed according to standard safety regulations when performing gas hazardous work.

Preparation includes:

Gas pipeline diagram

- reconciliation of the actual underground communication with the routing indicated on the diagrams in the project documentation;

- places for connecting the necessary plugs, instrumentation and regulators are selected;

- The connection point of the compressor unit is determined.

All those involved in this event, engineers and workers, must be re-instructed on labor protection and familiarized with the procedure for performing work.

What is flushing and pressure testing?

Flushing and pressure testing of heating systems is carried out in cases where the layer of deposits in the pipes becomes too large for them to continue to function. As a preventive measure, such events are rarely carried out, since this pleasure is quite labor-intensive and expensive. For hydropneumatic flushing, acid solutions are used that remove plaque from the walls of the pipeline to the outside. Metal particles cling to the inner walls of the pipes, thereby reducing their diameter. It leads to:

- increased pressure;

- increasing the coolant speed;

- decrease in efficiency;

- increased costs.

What is pressure testing of a heating system - this is an ordinary test, based on the results of which we can say whether it is safe to use such equipment or not, and whether it can withstand the required loads. After all, no one wants to become a victim of circuit depressurization and end up as a patient in the burn department. Pressure testing of the heating system is carried out in accordance with SNiPs. It is a mandatory procedure. After it, a document is issued confirming the technical serviceability of the circuit. Here are the main cases when pressure testing of a heating system is carried out:

- when assembling a new circuit and putting it into operation;

- after repair work has been carried out;

- preventative checks;

- after cleaning pipes with acid solutions.

Pressure testing of the heating system is carried out in accordance with SNiP No. 41–01-2003 and No. 3.05.01–85, as well as the rules for the technical operation of thermal power plants.

From these rules it is known that such an action as pressure testing of the heating system is carried out either with air or with liquid. The second method is called hydraulic, and the first is manometric, also known as pneumatic, or bubble. The rules for pressure testing a heating system state that water tests can only be carried out if the room temperature is above five degrees. Otherwise, there is a risk that the water in the pipes will freeze. Air pressure testing of the heating system eliminates this problem; it is carried out during the cold season. In practice, hydraulic pressure testing of the heating system is used more often, since everyone is trying to complete the necessary scheduled work before the onset of the heating season. In winter, only the elimination of accidents, if any, is carried out.

You can start pressure testing the heating system only when the boiler and expansion tank are cut off from the circuit, otherwise they will fail. How to pressurize a heating system:

- all liquid from the circuit is drained;

- then cold water is poured into it;

- as it fills, excess air is released from the circuit;

- after water has accumulated, a pressure blower is connected to the circuit;

- How pressure testing of a heating system occurs - the number of atmospheres gradually increases. In this case, the maximum test pressure should not be higher than the tensile strength of different circuit elements;

- High pressure is left for some time and all connections are inspected. You need to look not only at the threaded connections, but also at the places where parts of the circuit are soldered.

Pressure testing of a heating system with air is even easier. Just drain all the coolant, close all the outlets in the circuit and force air into it. But this way it is more difficult to determine the malfunction. For example, if there is liquid in the pipes, then at high pressure it will ooze through a possible gap. It is easy to determine visually. But if there is no liquid in the tubes, then there is nothing to come out except air. In this case, a whistle may be heard.

And if it is not audible, and the pressure gauge needle indicates a leak, then all connections are coated with a soap solution. To make it easier, you can check not the entire system, but by dividing it into segments. In this case, it is easier to carry out pressure testing of heating pipes and determine possible places of depressurization.

Classification of fittings

Types of compression fittings.

- corners and bends (used when connecting turns from 45 degrees);

- crosses (help to branch on two sides);

- tees (used for one-way branches);

- plugs (used for fastening at the end of a pipe);

- couplings (with the help of them pipes of the same diameter and direction are connected);

- fittings (if necessary, connection to a hose).

Fittings that are used to connect pipes of the same diameter are called straight, and those intended for fastening pipes of different diameters are called transitional.

There is a wide range of cast iron, steel, brass or copper connecting elements on the construction market.

As for cast iron, they are distinguished by such qualities as strength and durability. Cast iron fittings have a significant advantage over other connecting products, such as a steel coupling. Other positive qualities of cast iron elements include high resistance to negative environmental influences and versatility.

Modern industry today cannot do without steel fittings. More recently, it was possible to bypass obstacles in the pipeline path by bending the pipe. There's no need for that today

A pipeline using steel products is easy to assemble and disassemble, which is also important

Mini pliers

A mini press designed for metal-plastic pipes is a small-sized device that provides manual crimping of the coupling. These mini pliers are used for highways with a volume of 16 to 20 mm. These mechanisms are complemented by sets of nozzles with a TN profile.

Mini pliers are not equipped with telescopic handles, so you will have to put in more effort when working. The compression force in such devices is 10.5 kN.

Without attachments, the mini device weighs no more than two and a half kilograms. The handles on these pliers are often covered with PVC material, and the axial eccentrics on mini pliers make it possible to make adjustments when excessive play occurs.

Professional craftsmen highlight the quality of small-sized devices from VALTEC. These manufacturers offer not only high-quality mini crimping pliers, but also threading tools, scissors, and other tools for installation work.

Instrumentation with electrohydraulics

Watch the video

The battery press, used for metal-plastic pipes, is one of the electro-hydraulic tools. This also includes networked and universal machines.

As a rule, a device with a battery is a small-sized mechanism that is light in weight. But, if you compare a battery-powered device and devices that do not run on electricity, the first one is distinguished by high performance and ease of use. A battery-powered device is used to process highways with a diameter of no more than 110 mm.

Any rechargeable model operates on a battery. These mechanisms use only universal pressing heads that are suitable for specific sizes of metal-plastic pipes.

IMPORTANT! The battery pack can perform approximately fifty to one hundred compressions per charge cycle.

Technical parameters of the instrumentation

Before purchasing a press for installing metal-plastic pipes, it is necessary to study in detail the main parameters and characteristics of the equipment. These include:

Range of crimping diameters. Types of shaped elements for installation.

Some tools can only crimp certain manufacturers' fittings. The type of circuit that performs the crimping. The purpose of the model is indicated by a specific letter when marking. By looking at the profile view, you can determine the purpose of the model for installation. Handle length.

Any novice craftsman will be interested to know that this factor affects the cost of the device. The thing is that when crimping fittings with pliers with small handles, you need to put in more physical effort. Resource capabilities of pliers. This includes the amount of fitting crimp that the press can produce.

The ease of operation depends on this indicator. Equipped with a rotating mechanism into which replaceable attachments for pliers are attached. This addition to the tool makes it possible to crimp fittings on a vertical pipeline. Manufacturer. This factor largely affects cost and quality.

Watch the video

In order for the fittings to be crimped efficiently, you need to perform the following steps.

Place a removable ring at the connection point, which is intended for crimping fittings for a specific type and volume of pipe. Calibrate the line while simultaneously chamfering.

At this stage of installation, a calibrator will be needed. Then the end part of the pipe and the fitting are combined. Often, special holes are provided on the fittings; they allow you to control the position of the pipe part. Using press pliers, the fittings are crimped, which requires some effort. The quality of crimping is checked by the grooves formed; their appearance indicates the strength of the connection. The joint is checked for strength level.

IMPORTANT! Pressure testing of fittings can be done once. When this work is repeated, the connecting parts become unusable and cannot be repaired.