Auxiliary elements of pipelines ↑

Experts rightly call bends one of the most important elements of heating mains. These elements come in different configurations, being designed to solve the problem of pipelines bent to the desired shape .

Bends in polyurethane foam insulation are standard-sized steel pipes with a specific angle of rotation. The main functional task of bends is to change the direction of the pipeline, if necessary, to go around certain obstacles in sections of the pipeline

Steel bends in polyurethane foam insulation are, in fact, part of the pipeline designed to connect the main elements directly at the bending points of the route - from this alone one can judge the importance and necessary strength parameters of these pipeline elements. Due to the fact that bends for polyurethane foam are produced in a number of modifications (including different standard sizes, bending angles, arm lengths, thickness of pipe thermal insulation), these parts belong to the small category of universal elements of various types of pipeline systems.

What is included with a steel PPU PE outlet?

1) Steel pipes PPU 2) Steel tees PPU 3) Steel tees with ball valve PPU vent 4) Parallel steel tees PPU 5) Tee branches steel PPU 6) Tee branches steel with transition PPU 7) Sliding supports Fixed supports 9) End elements of pipelines PPU PE with conductor loop 10) PPU transitions 11) PPU ball valves 12) U-shaped PPU elements 13) Z-shaped PPU elements 14) PPU bellows compensators 15) PPU ball valves with vent 16) PPU joint insulation kits

9) End elements of pipelines PPU PE with conductor loop 10) PPU transitions 11) PPU ball valves 12) U-shaped PPU elements 13) Z-shaped PPU elements 14) PPU bellows compensators 15) PPU ball valves with vent 16) PPU joint insulation kits

An urgent need ↑

It is the use of bends that makes it possible to lay very complex pipeline systems with a fairly branched structure. Connecting base elements (pipes) with polyurethane foam bends is required for changes if it is necessary to direct the pipeline at the desired angle, and this applies to both vertical and horizontal planes.

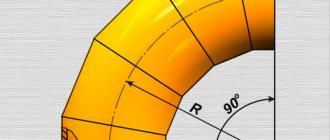

Bends in polyurethane foam insulation. Standard PPU bend angles: 90 g, 60 g, 45 g, 30 g

In addition, PPU bends of a certain configuration are, to a certain extent, devices designed to automatically compensate pipeline systems - this means that in a certain section of the pipeline, thanks to the bends, more or less natural spontaneous compensation (self-compensation) occurs. This opportunity allows you to reduce the number of so-called bellows expansion joints, and therefore reduce the costs required for the installation of a specific pipeline. Both in pipes and in shaped parts with polyurethane foam insulation, the bends have special SODK indicator wires (by special agreement with customers, SODK are not built in; they allow individual reduction in the length of the arms). If the outlet has not been previously insulated, pipe shells of suitable diameter are often used to insulate it.

This type of connecting elements in the field of industrial thermal insulation is often used in cases of ductless underground or, conversely, above-ground installation of heating networks.

Bends, as well as overhead pipes, are equipped with waterproofing, usually made of galvanized steel. In underground pipe laying, polyethylene waterproofing elements are usually used.

Bends with a standard arm length are most often used when laying heating networks; in a number of areas, at the same time, it is considered advisable to use connecting elements with a shortened arm length.

Such bends made of steel in polyurethane foam thermal insulation, having a protective shell of either polyethylene (PE) or galvanized steel (GS), are produced in accordance with GOST 30732-2006. Such bends with a shortened arm length are intended for laying thermal routes, heating heating networks, as well as for hot and cold water supply pipelines and process pipelines transporting products such as oil, gas, etc. Connecting elements of this type can also be used on pipelines with a number of design characteristics:

- working pressure not higher than 1.6 MPa;

- the temperature is preferably no higher than 140 degrees. C (temperature increases up to 150 degrees C are considered acceptable).

Structurally, bends with shortened arm lengths and polyurethane foam thermal insulation are a steel welded structure consisting of a curved bend with insulation and a pair of pipes welded directly to the bend. In order to ensure good waterproofing, a polyethylene or galvanized shell is put on the steel base and then all products are assembled using centralizers.

After assembly, polyurethane foam insulation is poured.

Nuances of bend production ↑

Production of polyurethane foam pipes

A specific copper wire (signal) is placed in the polyurethane foam insulation of the branches in order to connect the UEC system.

As a result, it turns out that the general physical and technical characteristics of the bends used are practically no different from the parameters of the main pipes.

The shaped elements are not a multiple of the dimensions of insulated polyurethane foam (standard) pipes. So the pipes to which these elements are welded are pre-cut (according to size), and at the ends of the pipe in the places where the cuts are made, the polyurethane insulation is removed, as a rule, by about 30-40 cm.

Many of today's specialists rightly considered this approach to be very wasteful due to the loss of expensive insulating material (extra consumption of about 0.3-0.6 linear meters for each cut). In addition, this leads to additional losses not only of money, but also of time - for cutting pipes in almost field conditions. The solution to this problem is facilitated by the use of bends with shortened arm lengths in PPU insulation.

For tightness, the junction of a pair of elements is insulated with heat-shrinkable tape, regardless of the type of laying of the pre-insulated pipeline and the waterproofing materials of the heat-insulating polymer material

The lengths of the section of shortened bends insulated with polyurethane foam, in contrast to the standards of industrially insulated pipes with a length of 8-12 m, are determined by the individual requirements of customers and can start from 0.3 m, the diameter of the elements is usually the same as that of the main pipes. The use of shortened elements makes it possible to reduce the construction time of heating mains and costs. Moreover, this reduction is noticeable: terms - up to 2.5-3 times, and capital costs - up to 1.2 times.

The design and installation of shortened shaped products (including the bends themselves) means avoiding joining them together, because When these joints are insulated, the ability to displace the heat-shrinkable sleeve, which is sometimes necessary during welding work, disappears. If it is necessary to use two or three or more bends in a row, use standard shaped products or specially made to order pipes of individual length. Or they simply do not allow joining of shaped products.

Price ↑

Alas, these “little things”, which actually turn out to be important components of the process, are often forgotten when creating estimates. But in fact, any pipeline includes not only straight sections with standard pipes, but also many different turns, and their proper installation requires these important “little things” - shaped elements called bends. So, when determining the costs of using thermal insulation options, it is necessary to take into account not only the cost of direct insulation of straight sections of the heating main, but also the mandatory costs for insulating branches.

At the same time, pre-insulated industrial shaped elements (including the notorious bends) actually cost four times (at least) more than standard pipes of the same length laid on straight sections of the route.

Expert advice: The use of pipes and bends in polyurethane foam insulation with a thermal insulation layer of the same polyurethane foam and waterproof polyethylene insulation when laying underground heating networks or with a galvanized steel shell when laying external heating mains can actually reduce costs by 1.2 times.

Angles ↑

Note that when laying heating networks, in addition to bends with standard arm lengths, they often resort to bends bent at an angle of 90 degrees, 120 degrees, 135 degrees. and 150 deg. This type of pre-insulated industrial PPU bends is a structure bent at the desired angle, which consists of sections of steel pipes welded together, covered on top with polyurethane foam thermal insulation with special pipes (welded sections of steel pipe. A signal wire from copper for installation of the UEC system. The design also includes centralizers and a waterproofing system made of polyethylene for laying underground heating mains using the ductless method or of galvanized steel for above-ground pipelines. Thus, the physical and technical characteristics of bends with these angles are entirely consistent with similar indicators for the pre-standard insulated pipes.

Depending on the physical and technical requirements of the project, pre-insulated bends with the mentioned angles of any diameters can be used when the thickness of the thermal insulation walls changes.

In terms of diameter, the standards for steel pipes are: 57, 76, 89, 108, 159, 219, 273, 325, 426, 530, 630, 720, 820, 920, 1020 mm. It is also acceptable to use polyurethane foam shells that have a waterproof coating made of fiberglass, as well as foil or other materials.

Manufacturing of pre-insulated steel bends bent at angles of 90 degrees, 120 degrees, 135 degrees. and 150 deg. made from solid pieces of pipe in accordance with GOST 30732-2001 “Seamless welded steel pipeline parts. The bends are steeply curved.”

When laying heating mains, bends bent at an angle of 90 degrees, 120 degrees, 135 degrees are also used. and 150 degrees, which are welded by each of the individual sectors in accordance with the decree “Products and parts of pipelines for heating networks”. Before applying a layer of thermal insulation to bends bent at angles of 90 degrees, 120 degrees, 135 degrees. and 150 deg. special extension pipes are welded. Welding joints in the factory must undergo separate visual and flaw detection inspections in order to fully comply with quality standards. Norms and rules for the production of bends provide guarantees of the service life of this type of pipeline. This is about 25-35 years compared to the 7-10 year service life of traditional heating networks.

Explanation of the symbol for bent exhaust outlets

Exhaust exhaust 45°-426(14K52) -16.0-0.75-5DN-1500/1500-UHL

Hot-bent bend with a rotation angle of 45°, outer diameter 426 mm, for connection to a pipe with a wall thickness of 14.0 mm, steel strength class K52, straight sections (or construction lengths) L1=1500, L2=1500, for operating pressure 16.0 MPa , operating conditions coefficient 0.75, turning radius 5DN in cold-resistant design with a minimum wall temperature during operation of minus 20°C.

Similar: Bent exhaust exhaust 15°-426(14K52) -16.0-0.75-5DN-1500/1500-UHL, Exhaust exhaust 60°-325(8K48) -16.0-0.75-5DN-1500 /1500-UHL, Exhaust outlet 9°-426(14K50) -16.0-0.75-5DN-1500/1500-UHL, Exhaust outlet 60 gr-426(14K52) -16.0-0.75-20DN -3000/3000-UHL, Exhaust outlet 5°-426(14K52) -6.3-0.75-5DN-1150/1150-UHL, Exhaust outlet 7°-426(14K52) -16.0-0.75 -5DN-1500/1500-UHL, Exhaust outlet 45°-530(10K55) -16.0-0.75-5DN-1500/1500-UHL, Exhaust outlet 21°-426(14K52) -16.0-0 ,75-5DN-1500/1500-UHL, Exhaust outlet 27°-426(14K52) -16.0-0.75-5DN-650/650-UHL, Exhaust outlet 35°-426(14K52) -16.0 -0.75-5DN-850/850-UHL, Exhaust outlet 57°-426(14K52) -16.0-0.75-5DN-750/750-UHL, etc.

Table of standard type of bends ↑

| Dн, mm | Retraction angle | |||||||||||||

| Type-1 | Type-2 | 90° | 60° | 45° | 30° | |||||||||

| L, mm | Weight, kg | L, mm | Weight, kg | L, mm | Weight, kg | L, mm | Weight, kg | |||||||

| Type-1 | Type-2 | Type-1 | Type-2 | Type-1 | Type-2 | Type-1 | Type-2 | |||||||

| 57 | 125 | 140 | 1000 | 100 | 12,86 | 1000 | 12,1 | 12,95 | 1000 | 12,14 | 13 | 1000 | 12,13 | 12,99 |

| 76 | 140 | 16 | 1000 | 15,79 | 16,43 | 1000 | 15,99 | 16,63 | 1000 | 16,05 | 16,7 | 1000 | 16,06 | 16,71 |

| 89 | 160 | 0,8 | 1000 | 18,39 | 19,35 | 1000 | 18,68 | 19,64 | 1000 | 18,76 | 19,73 | 1000 | 18,8 | 19,77 |

| 108 | 180 | 200 | 1000 | 24,52 | 25,64 | 1000 | 24,99 | 25,1 | 1000 | 25,13 | 26,27 | 1000 | 25,17 | 26,3 |

| 133 | 225 | 250 | 1000 | 34,02 | 35,99 | 1000 | 34,87 | 36,85 | 1000 | 35,12 | 37,13 | 1000 | 35,21 | 37,23 |

| 159 | 250 | 280 | 1000 | 40,56 | 43,24 | 1000 | 41,79 | 42,27 | 1000 | 42,15 | 44,87 | 1000 | 42,27 | 44,99 |

| 219 | 315 | 355 | 1000 | 70,5 | 74,88 | 1000 | 73,87 | 78,4 | 1000 | 74,64 | 79,25 | 1000 | 74,91 | 79,53 |

| 273 | 400 | 450 | 1000 | 101,64 | 107,59 | 1000 | 107,82 | 107,82 | 1000 | 109,38 | 115,85 | 1000 | 109,94 | 116,42 |

| 325 | 450 | 500 | 1050 | 126,84 | 134,01 | 8610 | 109,44 | 115,2 | 786 | 60 109 | 106,65 | 720 | 93,04 | 97,72 |

| 426 | 560 | 630 | 1100 | 184,89 | 197,9 | 889 | 164,5 | 175,28 | 807 | 144,54 | 154,03 | 734 | 130,67 | 139,06 |

| 530 | 710 | 710 | 1200 | 299,96 | 299,96 | 946 | 244,89 | 244,89 | 848 | 221,15 | 221,15 | 761 | 197,18 | 197,18 |

| 630 | 800 | 800 | 1200 | 354,34 | 354,34 | 945 | 291,97 | 291,97 | 848 | 264,65 | 264,65 | 761 | 235,96 | 235,96 |

| 720 | 900 | 900 | 1370 | 473,34 | 473,34 | 1066 | 385 | 385 | 948 | 348,46 | 348,46 | 843 | 306,22 | 306,22 |

| 820 | 1000 | 1100 | 1470 | 612,65 | 663,42 | 1073 | 471,28 | 507 | 990 | 367,5 | 481,53 | 820 | 367,58 | 394,21 |

| 920 | 1100 | 1200 | 1570 | 806,34 | 866,87 | 1132 | 594,57 | 594,576 | 1032 | 6476,96 | 587,39 | 446 | 476,96 | 476,96 |

| 1020 | 1200 | 1200 | 1620 | 944,72 | 944,72 | 1189 | 738,32 | 738,32 | 1022 | 645,43 | 645,43 | 874 | 552,74 | 552,74 |

An example of a symbol in an order specification for an outlet with a diameter of 159 mm, with a wall thickness of 4.5 mm, 90°, with Type 1 polyurethane foam insulation: Elbow St 159x4.5-90о-1(250)-PPU-PE GOST 30732-2001

Prices for bends in polyurethane foam insulation

| Pipe/sheath outer diameter | Cost of outlet in thermal insulation, rubles | ||

| Steel pipe/wall, mm | Shell, mm. | PE (polyethylene) shell | OC (metal) shell |

| 32x3.0 | 125 | 2 039 | 2 008 |

| 38x3.0 | 125 | 2 080 | 2 049 |

| 45x3.0 | 125 | 2 090 | 2 060 |

| 57x3.5 | 125 | 2 217 | 2 208 |

| 57x3.5 | 140 | 2 355 | 2 465 |

| 76x3.5 | 140 | 2 606 | 2 701 |

| 76x3.5 | 160 | 2 779 | 2 879 |

| 89x4.0 | 160 | 3 251 | 3 068 |

| 89x4.0 | 180 | 3 386 | 3 418 |

| 108x4.0 | 180 | 3 678 | 3 773 |

| 108x4.0 | 200 | 3 842 | 3 971 |

| 133x4.0 | 225 | 4 423 | 4 469 |

| 133x4.0 | 250 | 4 749 | 4 809 |

| 159x4.5 | 250 | 5 604 | 5 777 |

| 159x4.5 | 280 | 5 899 | 6 266 |

| 219x6.0 | 315 | 8 507 | 9 455 |

| 219x6.0 | 355 | 9 183 | 10 208 |

| 273x6.0 | 400 | 13 812 | 13 094 |

| 273x6.0 | 450 | 15 202 | 14 300 |

| 325x6.0 | 450 | 19 728 | 19 863 |

| 325x6.0 | 500 | 21 261 | 21 300 |

| 377x7.0 | 500 | 24 860 | 25 030 |

| 377x7.0 | 560 | 25 044 | 25 729 |

| 426x7.0 | 560 | 27 050 | 27 323 |

| 426x7.0 | 630 | 29 781 | 29 996 |

| 530x7.0 | 710 | 55 133 | 52 899 |

| 630x8.0 | 800 | 74 539 | 73 243 |

| 720x9.0 | 900 | 96 255 | 95 776 |

| 820x9.0 | 1000 | 134 116 | 136 835 |

We also produce shortened PU foam bends in thermal insulation (L=500 mm) in a PE or OC shell. Check prices with our managers.

Table of shortened type of bends ↑

| n, mm | Dн, mm | Retraction angle | ||||||||||||

| Type-1 | Type-2 | 90° | 60° | 45° | 30° | |||||||||

| L, mm | Weight, kg | L, mm | Weight, kg | L, mm | Weight, kg | L, mm | Weight, kg | |||||||

| Type-1 | Type-2 | Type-1 | Type-2 | Type-1 | Type-2 | Type-1 | Type-2 | |||||||

| 35,5 | 110 | — | 390 | 2,5 | — | — | — | — | — | — | — | — | — | — |

| 42,3 | 110 | — | 400 | 3,01 | — | — | — | — | — | — | — | — | — | — |

| 48 | 125 | — | 475 | 4,56 | — | — | — | — | — | — | — | — | — | — |

| 57 | 125 | 140 | 430 | 4,8 | 5,09 | 390 | 4 | 3,67 3 | 340 | 3,81 | 4 | 330 | 3,67 | 3,85 |

| 76 | 140 | 160 | 440 | 6,44 | 6,65 | 40 160 | 5,98 | 6,16 | 350 | 5,2 | 5,35 | 330 | 4,88 | 5,02 |

| 89 | 160 | 180 | 460 | 7,85 | 8,19 | 410 | 7,17 | 7,45 | 350 | 6,07 | 6,3 | 330 | 5,72 | 5,92 |

| 108 | 180 | 200 | 470 | 10,75 | 11,17 | 420 | 9,92 | 10,27 | 350 | 8,24 | 8,51 | 340 | 8,02 | 8,27 |

| 133 | 225 | 250 | 510 | 16,18 | 16,98 | 450 | 14,84 | 15,52 | 360 | 11,81 | 12,3 | 340 | 11,17 | 11,62 |

| 159 | 250 | 280 | 5,3 | 20,01 | 21,19 | 450 | 17,75 | 18,66 | 370 | 14,61 | 15,3 | 350 | 13,85 | 14,49 |

| 219 | 315 | 355 | 640 | 42,74 | 45,17 | 470 | 33,01 | 34,65 | 380 | 26,84 | 28,07 | 360 | 25,57 | 26,71 |

| 273 | 400 | 450 | 780 | 76,32 | 80,47 | 570 | 2 80,47 5 | 61,11 | 460 | 47,25 | 49,27 | 440 | 45,5 | 47,38 |

| 325 | 450 | 500 | 800 | 92,4 | 97,27 | 590 | 72,26 | 75,53 | 470 | 57,86 | 60,21 | 440 | 54,47 | 56,58 |

| 426 | 560 | 630 | 870 | 142,06 | 151,36 | 630 | 116,26 | 122,88 | 500 | 87,36 | 91,92 | 450 | 77,77 | 81,6 |

| 530 | 710 | 710 | 920 | 223,27 | 223,27 | 650 | 163,81 | 163,81 | 520 | 131,3 | 131,3 | 470 | 117,48 | 117,48 |

| 630 | 800 | 800 | 1000 | 288,9 | 288,9 | 700 | 211,81 | 211,81 | 540 | 163,87 | 163,87 | 480 | 144,01 | 144,01 |

| 720 | 900 | 900 | 1080 | 362,21 | 362,21 | 740 | 260,35 | 260,35 | 560 | 200,1 | 200,1 | 490 | 171,25 | 171,25 |

| 820 | 1000 | 1100 | 1200 | 482,53 | 521,48 | 800 10 | 339,72 | 363,54 | 600 | 259,61 | 276,5 | 520 | 223,01 | 236,49 |

| 920 | 1100 | 1200 | 1250 | 630,04 | 675,16 | 830 | 428,18 | 455,63 | 620 | 322,47 | 340,56 | 530 | 287,64 | 287,64 |

| 1020 | 1200 | 1200 | 1250 | 696,26 | 696,26 | 830 | 497,25 | 497,25 | 620 | 375,49 | 375,49 | 530 | 321,73 | 321,73 |

| 1220 | 1400 | 1400 | 1350 | 1009,96 | 1009,96 | 900 | 741,3 | 741,3 | 660 | 549,83 | 549,83 | 550 | 468,74 | 468,74 |

An example of a designation in an order specification for a shortened type of bend with a diameter of, for example, 159 mm, with a wall thickness of 4.5 mm, 90 and type 2 thermal insulation made of polyurethane foam, would be the following entry: Bend Standard. 159 x 4.5-90о-2(280)-PPU-PE to TU 5768-006-41852784-05

Manufacturing of bent elbows according to regulatory documents

- GOST 22793-83, .

- OST 36-42-81, OST 34-10-750-97, OST 34.10.420-90, OST 108.321.11.82, OST 108.321.12.82.

- TU 51-515-91, TU 102-488-95, TU 1460-001-88189979-2011, TU 1462-010-88189979-2015, TU 1469-004-88189979-2015, TU 1469-005-8818997 9-2015, TU 1469-001-05777029-2009, TU 1468-040-20872280-2010, TU 102-488-95, TU 14-1-5598-2011, TU 1469-003-88189979-2015, TU 24.20.40-01 3- 88189979-2017, TU 1469-001-48733781-2001, TU 1469-014-01395041-2003, TU 1469-001-34929762-2004, TU 102-488.1-05, GazTU 102-488/2-0 5, TU 1468- 284-20872280-2005, TU 1468-002-74238272-2007, Gas TU 1469-014-01395041-2007, TU 1469-015-74238272-2008, TU 1469-012-04834179-2008, TU 1469-014-04834179- 2008, TU 1469-003-34929762-2008, TU 1468-036-20872280-2008, TU 1469-016-01395041-2008, TU 1469-014-74238272-2009, TU 1469-014-45 657335-2009, TU 1469- T U 1469-012-01395041-2010 , TU 1469-001-90284633-2011, TU 14-1-5598-2011, TU 1469-015-04834179-2011, TU 1460-001-88189979-2011, TU 1468-038-20872280-2011, TU 1469-002 -90284633-2012, TU 1469-032-04834179-2012, TU 1469-034-04834179-2012, TU 1469-003-67983609-2012, TU 1469-013-04834179-2014, TU 14 69-004-90284633-2016, TU 1469-005-90284633-2016.

- STO TsKTI 10.003-2007, STO TsKTI 321.02-2009, analogue according to drawings

- Production of bent bends according to the Customer’s drawings or TEKKOS drawings.