At the first signs of depressurization of the pipeline, it is necessary to quickly find the damaged area and eliminate the identified defect. When performing emergency emergency work, you can use homemade clamps to stop the flow in the pipeline for a while. Ready-made clamps for fastening pipes, made in the factory from stainless steel or fire-resistant plastic, are used when performing installation work on the installation of heating, sewerage, water supply, and gas supply systems. These fasteners allow you to reliably fix the position of pipes running along horizontal and vertical surfaces (ceilings, walls), as well as those installed on special racks.

In this video, an experienced craftsman shows how to make a wire clamp:

Design features and application

Any performance of an element includes the following mandatory elements.

- Frame.

- Non-metallic lining.

- Fasteners

- Internal diameter adjustment mechanism (optional).

- Installation bracket (optional).

The use depends on the design, as well as which element of the pipeline - flexible or rigid - needs to be fixed.

Metal hose clamps

The designs of these parts are regulated by the technical requirements of GOST 28191-89.

The products are designed for a maximum operating medium pressure of up to 7 MPa, with a range of external operating temperatures of -60...+1200C. They can have a worm or bolt fastening, and the width of the tape (or wire diameter) is determined by the series of the product - light or heavy. There are two versions available, which differ in connection configuration.

Accounting for product dimensions

GOST establishes the following standard dimensions of these parts (smallest/largest), mm: 8/12; 10/16; 12/20; 16/25; 20/32; 25/40; 32/50; 40/60; 50/70; 76/100; 90/110 and further any diameter multiple of 10, with a difference in diameters of 20 mm.

The range of external diameters (for the most common versions of adjustable options) is, mm: 31-38; 32-35; 59-63; 83-92;108-116.

Diameters of steel pipes: internal and external dimensions, wall thickness, table in inches and millimeters Products for household pipelines and technological schemes have a number of characteristics. The most important of these are pipe diameters. This parameter is regulated by state standards, highlighted...

Types and designs for different piping systems

The design of pipe clamps affects the reliability and durability of the system. Before installation, it is necessary to study installation diagrams, maintenance and dismantling features. Finished products must comply with current standards.

Types depending on operational requirements:

- Clamp designs for high loads. They are taken into account by the increased thickness of the strip/tape, which is used as an initial blank during stamping, as well as by the use of structural high-carbon steel grades in accordance with GOST 14969-89.

- Designs of clamps for large diameter pipes. Such products are distinguished by an increased length of the guide part, as well as the presence of additional attachment points. If there is sufficient space for installation, double versions are used.

- Designs of clamps for PVC pipes. Most designs are characterized by the presence of elastic gaskets that absorb part of the clamping force, which eliminates cracking and deformation of the polyvinyl chloride. The noise from pumping the working medium is also reduced.

- Non-assembly connections using plumbing clamps. They are sold using KTr type products, which include a plumbing screw and a plastic dowel.

- Clamps with seals and long screw. Abroad, such designs are called BISMAT Flash. In addition to the gasket, they are equipped with an axisymmetrically located screw or self-tapping screw, with the help of which the product is pre-tensioned. Particularly useful when patching long sections of pipe.

- Ventilation clamps without sealing. Used for installation of air ducts. Since the connection of such sections is coaxial, there is no need for sealing elements.

Tip: Recently, Walraven star Quick plastic clamps with a ratcheting actuator, which speeds up the installation process, have become increasingly common.

Repair coupling for 300

Repair pipe clamp 300 is used for repairs on large diameter pipelines. This device copes excellently with problems such as:

- Formation of cracks running longitudinally (with a possible deviation of 5 degrees).

- The appearance of a dimensional fistula on a steel and cast iron main.

Using repair tools for 300, you can connect steel and cast iron lines with polyethylene ones. The 300 part allows you to eliminate the leak without cutting off the entire system.

These couplings use gaskets made of certified food grade rubber. And the use of random materials on devices is completely excluded. Therefore, such products are characterized by a high level of environmental friendliness.

The 300 device is a reliable and high-quality device because it is made from high-quality raw materials. To all these advantages should be added its affordable cost.

Self-production

If you can’t buy plastic clamps, you can try making them yourself from metal. To create you will need:

- hammer, pliers;

- set of wrenches, drill;

- bolts with nuts;

- metal sheet 1 mm thick, scissors for cutting metal.

Manufacturing:

- Cut a metal strip 4–8 cm wide. The length depends on the diameter of the tubes.

- At the ends of the strip, mark holes for the mounting bolts. Bend the ears using pliers.

- You need to secure a rubber gasket between the holes, clamp the pipes with a bolt or nut.

The number of bolts varies depending on the width of the metal strip. From 4 to 6 cm - 2, from 6 to 8 cm - 3. The pitch between the dowels is calculated depending on the material from which the tubes are made and their diameter. Additionally, you can consider a metal platform for securing the dowels. Metal clamps should not squeeze plastic pipes so that the plastic does not collapse when expanding.

When it is not possible to hide the pipeline in the walls, it is necessary to consider a system for securing the pipes on vertical or horizontal surfaces. Most often, plastic clamps are used for this. They are distinguished by high strength and low price. Anyone can install tubes onto clips without any training.

It is important not to forget that the pipes are first pushed into the clamps and then connected together

Watch a video about fixing a heating pipe to a wall using a clamp and a support plate:

Purpose

A repair clamp for water supply pipes is necessary to quickly and reliably eliminate leaks in the following types of pipes:

- steel;

- cast iron;

- copper;

- metal-polymer;

- polypropylene.

Of course, the repair clamp protects against leakage only for a short time. It is advisable to use this material in cases where it is not possible to quickly replace a section of pipe or use a welding machine to repair a crack.

Installation of clamps

Material selection

Clamps come in various sizes and designs, but all types have a spherical shape that follows the bend of the pipe. The design of the product necessarily contains clamping bolts, which make it possible to tighten the clamp as tightly as possible around the pipe being repaired/installed. According to the scope of application, these products are divided into fastening and repair items.

Mounting clamp: photo

The clamp fastener consists of a metal shell and a corrugated rubber gasket, which prevents noise from vibration and excessive compression when tightening. A prerequisite for this type of product is the presence of a side fastening, which is most often made in the form of a welded nut - with its help, the pipe is mounted/suspended on a wall or ceiling.

Leak repair clamps have a wider metal shell and a solid rubber gasket that seals the leak on the pipe. There are also specialized products for inserting an additional branch into a water supply system - with its help you can create a branch without the use of a welding machine. The only condition for its use is the absence of strong pressure in the system.

Repair clamp with rubber gasket

When purchasing, special attention should be paid to the sizes of plumbing pipe clamps - an incorrectly selected size will make the purchase in vain. The diameter of the pipe is determined by a caliper or, in the absence of one, you can simply measure the external cross-section of the pipe

The presence of a rubber gasket is also important - it is not always included in the basic package. If there is a choice between products with and without a seal, then you should give preference to the first option, even if its price turns out to be an order of magnitude higher - the gasket significantly increases the technical characteristics of the fastening

Sizing

Installation of fasteners

- The path of the future pipeline is marked and the location of the fastenings is noted. The distance between the fasteners is determined depending on the length and weight of the pipe - in standard situations it is about one to two meters;

- At the site of future fastening, a hole is drilled into which a plastic dowel is inserted, and a threaded pin is inserted at the end. The clamp is screwed onto the pin in the open state - you should screw it all the way, but you should not be too zealous so as not to deform the shell of the product;

Installing pipes is not difficult to do yourself

The pipe is inserted and the clamp is clamped

It is important here to create a floating clamp and not to overdo it - it should not be too tight to compensate for the thermal expansion/contraction of the material;

Repairing leaks

- Before placing the clamp on the pipe, it is advisable to turn off the water supply to the system. If this is not possible, installation is also possible, but you will have to get pretty wet;

- The clamp is placed over the broken area so that the crack/cavity is located approximately in the middle of the rubber gasket. The rubber seal should lie flat, without wrinkles. The fasteners are tightened as tightly as possible to avoid leakage;

Repairing leaks

The connection point is wiped dry, the water supply is restored and the pipe clamp is inspected for leaks. If this occurs, then the fastening is additionally tightened;

Pipe tapping

First of all, a hole of the required diameter is drilled, then an adapter is put on it. The main thing is that the sealing gasket fits without bending. After tightening the clamps, the connection is ready for installation of an additional water supply branch.

Inserting a branch into a water supply system

Homemade clamps

If your pipe bursts and you don’t have the necessary clamps on hand, you can temporarily fix the leak using improvised means. The answer to the question of how to make a pipe clamp is quite simple - you will need ordinary clamps of any design and a piece of thick rubber that will act as a gasket.

The leak area is tightly bandaged with rubber, after which clamps are put on at both ends - there should be at least two of them. In the absence of such, you can use ordinary wire, through which the joint is pulled on both sides. It should be noted that although such a “repair” may last for several years, this solution is temporary.

Rubber pipe bandage

Options for the mechanical part of the ties

Any model of fastening screw is equipped with a fixation unit. There are models with fastening at one point and those that are fixed in two or more places.

Products with fixation at several points are solid parts in which holes are made for installing self-tapping screws

Devices with fastening at one point can be equipped with a pin with a pointed end and threaded threads, or have a hole for mounting self-tapping screws. Fastening of such clamps is carried out using polymer dowels.

DIY clamp - a simple and effective solution to the problem

A clamp is a useful and sometimes irreplaceable thing in the household. With its help, it is always possible to ensure a tight connection of hoses, pipes, pipelines, both flexible and rigid. In technology, there are a great many types of clamps for various purposes. The thrifty owner will always have them in his tools for all occasions.

However, there are situations when there is no suitable device at hand, and the problem needs to be solved urgently. For example, a fistula has formed in the heating or plumbing system, and water threateningly rushes to the floor. To make matters worse, while driving a car, a pipe in the interior heating system or in the engine cooling system fell off. There is no mounting clamp among the tools.

What to do in such cases? Is it possible to make a clamp with your own hands? What is needed for this?

Seal onto a pipe - it's easy

Often in our homes, metal pipes rust and leak. Such areas require repair or replacement. However, our home craftsmen solve the problem quickly and efficiently with the help of clamps, which “decorate” the interiors of our apartments for many years.

How to quickly make a pipe clamp with your own hands? What will you need for this?

Tools needed for manufacturing:

- hammer, pliers, drill;

- drills with a diameter of 6 or 8 mm;

- metal scissors or grinder;

- caliper, ruler;

- spanners.

In addition, you will need the following materials:

- metal strip up to a millimeter thick (for example, stainless steel, galvanized sheet);

- a strip of rubber 3 mm thick;

- bolts, 6-8 mm nuts, washers for them.

How to make a pipe clamp

Making clamps requires certain skills. Experienced plumbers advise carrying out work in the following sequence:

- depending on the damage, a strip of metal of the required width is cut out;

- the circumference of the pipe is determined;

- the length of the workpiece is determined (4-5 cm must be added to the circumference);

- holes are drilled from one and the other edge of the strip at the same distance;

- using pliers or a vice, bend the fastener ears at right angles to the strip;

- a rubber strip is cut along the width of the device and along a length slightly less than the circumference of the pipe.

It is necessary to take into account that the small clamp is tightened with one bolt. It is advisable to tighten fasteners up to 6 cm with two bolts. Products wider than 6 cm must be secured with three bolts.

Installation

The device you made yourself should be carefully bent and adjusted around the circumference of the pipe so that the holes in its ears coincide coaxially.

Bending of clamps can be done on a piece of pipe of equal diameter with the pipe being repaired. Then, when installed in place, the clamp is slightly unbent and, with little effort, is installed on the surface to be repaired.

Previously prepared rubber is put on the leak site under the fasteners.

True, you need to remember that a home-made device is a means designed to temporarily eliminate the sealing problem. You should not delay repairing or replacing corroding pipes, as the corrosion process will continue underneath it, and over time the problem will “come out” again.

Making a wire clamp

Very often, home craftsmen need to seal rubber pipes or pipes tightly and securely. This can be while working in the garden, at the dacha or in the garage. In such cases, make a wire clamp with your own hands.

To make it, you need to have pliers and a screwdriver on hand, preferably a Phillips-head screwdriver. It is best to use a special wire - knitting wire (it is soft and quite strong).

Fold the wire in half and throw it over the hose, thereby determining how much it will be needed for fastening, taking into account 40-50 mm for twists. Then cut the desired piece and fold it in half again. At the bend, use a screwdriver to make an eyelet and turn it half a turn. Pull the ends of the wire apart and wrap them around the tube.

Using pliers, you need to twist the ends clockwise a few turns. Finally, tighten the wire clamp with your own hands using a screwdriver. In this case, you need to ensure that the tightening force is sufficient for sealing and does not lead to wire rupture.

With some skill and practice, making and installing clamps is not difficult. Homemade wire devices can serve without problems for a very long time. Replacing them with store-bought ones is a matter of the owner’s aesthetic taste.

Now you know how to make a clamp with your own hands. We hope that for every owner, home problems with repairing pipes, pipes and hoses will become an easy and unburdensome practice.

Your gratitude for my article is to click on any button below. Thank you!

What to do in case of a serious water pipe break

If a serious accident occurs that you cannot handle yourself, it is better to entrust the repair of the water pipe to professionals. It is especially dangerous when a hot water supply pipe breaks, as you can easily get burned. The algorithm of actions in such a situation is as follows:

- Call emergency services and report the problem.

- To prevent water from splashing around the room, wrap a towel or any rag around the pipe.

- Turn off the tap in the apartment or the entire riser in the basement. The door to it is usually locked, and one of the residents has the key.

- Wait for the plumbers to arrive, who should quickly and efficiently fix the leak.

And finally, remember that in order to avoid a breakthrough of a metal, PVC or metal-plastic pipe, you need to monitor the condition of the pipeline and promptly replace it if necessary.

A pipe break is a serious problem that threatens to flood not only your apartment, but also the neighboring ones. Therefore, if you cannot quickly fix the problem, or the breakthrough is serious, do not waste your energy, but call the experts from San Remo. And if the pipes are very old, our plumbers will quickly and inexpensively replace the pipes.

By clicking the “We’ll call you back” button, I accept the terms of the Personal Data Privacy Policy and give my consent to the processing of my personal data.

Plumbing pipe clamp - how to fix communications?

When it is necessary to connect pipes, and also not to disturb the design, the designer must think about the fact that they need to be hidden in those places where these communications will not be visible to residents and will not create inconvenience to people working there. Using a steel pipe clamp, you can achieve a strong fixation, while easily obtaining a completely sealed fastening. The standard design consists of a ring secured with a screw and nut.

To avoid corrosion, a special material with anti-corrosion coating is used for the clamp. Inside, a layer made of durable microporous rubber is applied to the surface of the ring; it is needed to reduce vibration, which can destroy the pipes. The most important indicators for the device include such characteristics as the data of the steel tape, the maximum tightening limit, and the diameter of the clamp ring. When choosing, do not forget about the load under which we are purchasing a plumbing pipe clamp, and determine whether it will withstand it.

Reliability of fastening is also important, otherwise the clamp may break off the pipe. Various varieties, specially created for difficult working conditions, are able to withstand quite strong impact and pressure from the outside, without stretching or deforming. Such pipe clamps can be used many times, because their characteristics are preserved after use, which allows them to be used further for fastening.

How effective the fastening will be, how long the pipeline and the clamp itself will last depends on the quality, reliability and manufacturer. It's not worth saving. We must also not forget that the product market today is flooded with fakes - for example, a Chinese-made clamp will cost an order of magnitude cheaper, but will also have the appropriate quality, which will soon make itself felt. And by purchasing products from trusted companies operating in large cities and countries, you can save yourself from counterfeits.

Nuances of operation

Before installation, it is recommended to lubricate the screw connections with machine or silicone oil. This will not only make it easier to tighten the screws, but will also prevent further corrosion. Just keep in mind that industrial oil will corrode some types of rubber.

When installing, always balance the force applied and the dimensions of the fastener. In addition, when compressed, the spring clamp can jump off and fly to the side. Be careful.

Make sure that no dirt or dust gets on the work surface. Not only will it scratch the pipe, but it can also lead to premature corrosion.

Tighten screw connections periodically, especially if the pipe is subject to vibration. If the tool is difficult to operate, buy a wing clamp instead of a screw. No tool is required to tighten it.

Do not allow dust to contaminate the screws. This will not only extend the service life, but will also ensure that the clamp can be reused after removal. A clamp in good condition without signs of corrosion is designed for a minimum of 50 installation-disassembly cycles.

And always follow safety precautions. And also do not skimp on fasteners, because most often the pipe fails precisely at the joints.

An overview of useful tools for working with clamps from China in the video below.

Installation instructions

The installation of dowel clamps is almost no different from the installation of conventional dowels - the slight difference is that first a clamp is put on the cable, and then it is carefully hammered into the prepared recess. The drilled hole should fit the diameter of the fastener, but the depth should be 10 mm greater than the length of the dowel. The maximum distance between installed fasteners should not exceed 25 cm, on turns - no more than 10 cm.

Each type of fittings has its own installation method. The determination of fixation points takes into account the parameters of the fence, horizontal and vertical directions of wiring, the number and radius of corners, the weight of the cable, and the environment. These data are decisive for the optimal choice of how exactly to fasten hardware, their required quantity, installation technology, as well as wiring and installation schemes.

Hidden

The hidden method of main laying is used in residential premises if the material of the supporting base allows the installation of grooves. To lay wires in grooves or prepared cable channels, additional installation of dowel clamps is possible. A single cable is most often secured with alabaster, but this method is ineffective if we are talking about a large specific gravity or many wires. Alabaster successfully replaces clamps that split many wires into a system group. Often, electricians mark wiring using tags mounted on cable ties. The same method is used to secure cables installed in special boxes.

Installation of flat cable using a dowel clamp

Using a level and an auxiliary tool such as a cord, points are marked on the wall for securing hardware. Pre-drill holes for dowels with an electric drill.

Fix the clamps in the correct places. The cable body is threaded through the frame of the clamp, tensioning it so that there is no sagging.

Fixation on a self-adhesive pad

On painted or varnished surfaces, covered with plastic facades, covered with wallpaper, you have to use a self-adhesive pad. The base of such a platform is double-sided tape. It must be remembered that the adhesive composition will “flow” at temperatures above 450 degrees, and at low humidity it will lose elasticity, the base will dry out, harden and fall off the wall. Self-adhesive pad is the fastest installation method. The protective film is removed from the back side, and the platform itself is pressed forcefully against the surface of the supporting base. A tie is inserted into the fastener grooves to secure the wires and cables.

- Cable clamps. For such fixation, a general installation plan is drawn up, and attachment points are marked on the surface. Mounting holes for dowel fixing points are drilled. Taking into account the chosen type, clamps are installed. They can be fixed with self-tapping screws or screws in the fastening device, inserted into the holes with serrated ends. Anchors are screwed into wooden surfaces.

- The “helicopter” dowel is pre-assembled from two halves, waiting for the final click. The assembled “helicopter” is inserted into the prepared hole, and the spacer wedge is carefully driven in. After this, the line is fixed with a clamp loop.

Open

A similar method of laying backbone networks is used in non-residential buildings intended for production or storage.

Fixing a thin cable

In such cases, it is customary to use clamps with a nail. Thin television and Internet cables are lightweight and do not require reinforced construction. Small nails installed in clamps do this perfectly.

Styling using clips

Clips are used for mounting low-voltage cables on soft surfaces of wooden walls. Hardware is fixed to the surface using self-tapping screws; each product has a pair of holes. The cable is pressed into the bracket until it is firmly fixed.

- A metal dowel “bug” grabs a pipeline or cable with a single-leg bracket, fixes it to the surface, and then screws it into a clean drilled hole.

- The plumbing screw-on clamp with rubber pads is pre-disassembled. The dowel is mounted on the wall, after which the bracket is screwed onto the stud, the pipe is inserted into it and secured with a second bracket.

- Dowel clamp with tape. Mounting such hardware to the wall is quite simple - a loop is made from the tape, wires are inserted into it, after which the tape is fixed on a supporting support, and the excess ends are cut off.

The following video describes the installation of dowel clamps.

How to make a wire clamp - step-by-step diagram

Step 1: Measure the required length of wire

First of all, let's bite off as many wires as the diameter of our connection requires. We don’t need measuring instruments, just wrap the edge of the wire around a piece of pipe

and think about the ends for twisting by eye, in most cases 50-60 millimeters are enough. Then we fold the wire in half and use pliers to bite off the excess. We bring the ends together so that they are at the same level.

Step 2: Correct clamp arrangement

Now that you have a wire bent twice in your hands, you need to make the correct “eye” at the bend, and the diameter of the “ear” should be the same as the screwdriver, which must fit freely into it. To maintain this size, just straighten the ends, insert a screwdriver between them and bring them together again. Of course, a Phillips screwdriver is best suited for this purpose; it is even along its entire length and has no magnification, unlike a flat one. Next, you need to bend the resulting “ear” to the side, relative to the length of the wire, it will act as a lock.

Step 3: Detailed installation of a homemade clamp

You have just made a wire clamp with your own hands, it’s okay if it doesn’t look attractive, the main thing is that it performs its functions well. All that remains is to install it in its own main place and twist it tightly. To do this, bend it around a piece of pipe

, first of all in the form in which it is, and specifically doubly, and cross the ends together. Then we place a screwdriver in the “ear,” hook the other end and turn it clockwise a couple of times until a tight connection occurs. Do not forget that when clamping you should not be too zealous; you must feel when you need to stop so that the wire does not burst. If there are very long ends left on the newly installed clamp, we recommend cutting them off with wire cutters.

It is very likely that the first time you will not be able to install a wire clamp made with your own hands, maybe you will not be able to twist it at all, or you will overtighten it, but do not despair, you need to repeat the procedure of making the fastener again. We are confident that after several attempts you will get a good and tight connection, and this simple technique will always help you out in difficult times. Perseverance and work will grind everything down! But still, in the future, keep several clamps of various diameters in your use; they will come in handy first of all!

It is literally impossible to do this with your own hands.

A standard tool at hand won't help much either.

You need to use either a specialized tool or make something similar.

At the dawn of my working career, I personally made hand tools for crimping hydraulic hoses. In those days there was no professional instrument yet.

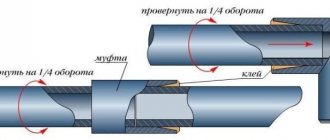

First you need to understand how a hose under high pressure is pressed.

Here it is with the tip pressed on:

In the photo you can see the working part with a thread and already on the hose there is a bushing (coupling) that is pressed in a circle.

In cross-section, the fitting with the coupling already pressed on looks like this:

The pressing process is as follows:

- the hose is cut so that the end is even.

- A coupling is placed on top of the hose and pushed further down.

- A nut is placed on the nipple with the thread facing outwards.

- the nipple is inserted into the inside of the hose until the end of the hose stops.

- the coupling also returns back to the stop or the end of the hose.

- a special crimp is put on the coupling and compresses it in a circle 360 degrees

All processes, with the exception of the last one, are done by hand and only the last one is used with a tool.

There are two ways to crimp a coupling without special equipment (during crimping, you need to create strong pressure, since the coupling is made of a fairly strong and thick material); clamps cannot tighten such a coupling, and different types of pliers do not have an even shape and do not press evenly on the coupling.

Technical characteristics of plastic clamps

Plastic options are inferior in strength to steel ones, but have increased elasticity and the ability to withstand high vibration. Suitable for creating movable supports, can be used to fix channels to a wall, ceiling or floor.

The main characteristic of plastic clamps is the diameter of the fastener ring. The largest diameter of the plastic model allows working with bends with a cross-section of 110 mm

It is important to remember that the internal cross-section of the plastic fastener must be equal to or slightly smaller than the outer diameter of the pipe

The main parameters for the design and dimensions of polymer clamps are set out in GOST 17679-80.

Criterias of choice

When purchasing clamps for repair work, various parameters must be taken into account. Among them, experts highlight general requirements.

- The product cannot be used if its length is less than the outer diameter of the pipe.

- When repairing a pipeline with a diameter greater than 350 mm, it is important to use a bandage whose length is 150 mm longer than the damaged area.

- For large structures, repairmen recommend purchasing a patching product whose length is 200 mm greater than the length of the damaged area.

- To “treat” a polypropylene pipe, it is necessary to use clamps whose length exceeds one and a half times the length of the fistula or crack.

- If a clamp is used to join two pipes, their ends should be 10 mm apart.

How to make and install a clamp on a pipe.

If you have a piece of galvanized sheet metal left over after installing windows, and there are old cameras lying around in the garage, then you can make a clamp yourself. For this you will need the following

Materials:

- A piece of galvanized sheet metal 0.5-1 mm thick.

- A piece of rubber 1.5-3 mm thick, usually this piece is cut from an old car inner tube, but any rubber can be used.

- 2 or 3 bolts M6 or M8 or M10 with washers and nuts, engravers are not required

Tools:

- Metal scissors, or a jigsaw with a metal file, or a grinder with a cutting wheel for metal.

- Drill with drill M7 or M9 (M10) or M12.

- Pliers or vice.

- Hammer.

- Spanners.

The principle of operation of the clamp is as follows:

- The rubber is pressed tightly against the defect on the pipe and does not allow water to flow out of the pipe; the more uneven the surface of the pipe, the thicker the rubber should be.

- To hold the rubber tightly on the pipe, you need tin - this is the frame of the clamp; the more uneven the surface of the pipe and the denser the rubber, the thicker the tin should be.

- The bolts tightly tighten the tin frame and provide the necessary tightness of the rubber to the pipe. The more uneven the surface of the pipe, the denser the rubber, and the thicker the tin, the larger the diameter of the bolts. The thicker and softer the rubber, the longer the bolts will be needed.

The clamp looks like this:

The sequence of making the clamp is as follows:

- Determine the diameter of the pipe using a caliper (or an angle and a ruler for large pipe diameters).

- Cut the tin frame of the clamp with a width of 4-8 cm and a length equal to the circumference of the pipe + 3-4 cm for the ears. The larger the diameter of the pipe, the wider the clamp is made. The circumference of the pipe is equal to the diameter multiplied by the number P = 3.14. Marking can be done with a marker, a children's felt-tip pen, or even a sharp screwdriver if you don't have a special scriber.

- Mark and drill holes for the fastening bolts on the ears; the more accurately you do this, the easier it will be to install the clamp. If you use wide washers, you can drill holes 2-3 mm larger than the diameter of the bolts, this will simplify installation of the clamp. For clamps wider than 6 cm, it is advisable to drill holes for 3 bolts.

- Mark the ears and bend them 90 degrees. holding a piece of tin in a vice, or using pliers.

- Bend the tin around the pipe on which you will put the clamp, so that the ears connect and the drilled holes match. If necessary, tap the tin with a hammer, but usually this is not required.

- Cut a rubber gasket with a width equal to the width of the clamp and a length equal to the circumference of the pipe - 0.5-1 cm.

- Insert the rubber gasket into the clamp.

How to quickly fix a leak?

A leaking water pipe can cause flooding of your home and damage to your property and that of your neighbors. You need to act quickly in such a situation:

- If possible, turn off the water supply to the system (area being repaired).

- Clear the repair area. Move the furniture aside and put down dry rags.

- Prepare tools: pliers, screwdriver, flexible wire or clamps, thin rubber.

- Cut out the desired piece of rubber sheet. It should cover the leak site with a margin of 2–3 cm in each direction.

- Press the pad firmly onto the fistula (crack). If it is too thin, wrap it in 2-3 layers.

- Holding the overlay with your hand, place the wire on top. Tighten it by making tight turns with pliers.

- Cut off the excess wire, leaving 5mm ends.

- Bend them so they don't protrude.

Pipes leak especially often in houses with old plumbing. In bathrooms and toilets where humidity levels are high, metal is at high risk of corrosion. Salts and various impurities in the water contribute. To prevent leaks, anti-corrosion paints and primers are used. Some of them can be applied directly to the rust.

If water comes out of the fistula under pressure, find something to plug the hole with. The easiest way is to block the flow with a chopper. Sharpen the end of the piece of wood to fit into the hole. Lightly tap the chop with a hammer.