The uninterrupted operation of the sewer system depends on the competent selection of components and correct installation of the network. Often home craftsmen install engineering systems on their own and are faced with the primary question: which sewer pipes in the house are better technically and financially.

We will help you sort out this difficult issue. The article we have proposed describes all types of pipes used, listing their positive and negative sides. The material is systematized to make it easier to compare product characteristics, service life, cost and application practice.

Characteristics of PVC pipes

Polymer pipes appeared not so long ago, but have already received great demand due to cheap raw materials and wide application.

Main characteristics:

- outer diameter - 21.3-1000 mm;

- internal diameter - 15.7-945.6 mm;

- wall thickness - 1.8-27.2 mm;

- a light weight;

- strength and rigidity;

- resistance to temperature fluctuations;

- service life up to 50 years.

On a note!

Plastic products provide serious competition to conventional analogues.

By material

Now - about the materials from which the sewage system is made.

PVC

The advantages of a socketed PVC sewer pipe are well known:

- Long (at least 50 years) service life;

The photo shows a PVC pipe after long-term use.

- Resistance to solutions of alkalis, acids and biologically aggressive environments;

- Very reasonable price. A two-meter bell-shaped gray pipe measuring 110 mm costs approximately 250 rubles; thicker-walled red sewer pipe for external sewerage - 300;

- Light weight, simplifying delivery and transportation to upper floors;

- Extremely simple installation using sockets with rubber O-rings.

Flare connection with rubber O-ring.

In order not to liken my article to an advertising brochure, I will also mention several shortcomings of the material:

- Straight horizontal sections sag over time under their own weight, forming counterslopes. Each counterslope is a potential site of permanent blockages;

The problem is completely solved by fastening pipes in increments of no more than 8 - 10 diameters. For example, a sewer pipe with a diameter of 110 mm is hung in increments of 0.9 - 1.1 meters.

- PVC is afraid of bends, impacts and defrosting. At low temperatures it becomes more fragile;

- The heat resistance of PVC is limited to a temperature of 60 degrees (with the possibility of short-term heating to 80C). If you often pour boiling water down the drain, straight sections may become deformed;

- Thin-walled PVC pipes serve as an excellent resonator and provide residents of the lower floors with unnecessary information about the toilet habits of their upstairs neighbors.

That is why vinyl sewer risers are often wrapped with roll insulation. The porous material dampens noise.

PVC pipes for external sewerage are often made in three layers, with a foamed inner layer. This improves the thermal insulation of the pipeline when it is laid in the ground at a shallow depth.

Polypropylene

The range of sizes, the joining method, and the rules for installing polypropylene pipes are the same as for PVC. The differences can easily be counted on the fingers of one hand of an experienced milling machine operator:

- With the same wall thickness, polypropylene pipes have greater rigidity;

- They tolerate high temperatures better: the softening of the polymer begins at approximately 120 C.

Externally, polypropylene is no different from PVC.

As a rule, white (silent) sewerage is made of polypropylene.

Polyethylene

The oldest polyethylene sewer pipes I came across were in houses built in the 70s. As a rule, one-piece combs were made from polyethylene for a specific kitchen and bathroom layout.

The main problem of the material was... the headlessness of the builders: during installation, the deformation of the pipe, its sagging during long-term use and periodic heating were not taken into account. As a result, the sagging comb became disconnected from the cast iron socket, and the connection began to leak.

In the 90s, the socket-shaped polyethylene pipes I already mentioned above, produced in accordance with GOST 22689.2-89, appeared on the market. The standard provides only 4 standard sizes: 40, 50, 90 and 110 mm. It is not difficult to guess that the material was used only for internal sewerage.

Polyethylene is easily recognized by its characteristic black color.

Compared to PVC and polypropylene, which have practically replaced it, polyethylene has the only drawback - low temperature resistance. It begins to deform even when heated to 60 C. But the list of advantages is very impressive:

- Pipes made from this polymer are not afraid of defrosting , since it remains elastic at subzero temperatures. The ice plug will only slightly stretch the pipeline, and after thawing it will return to its original size;

For comparison, a polyvinyl chloride sewer filled with water cracks when it freezes.

- Polyethylene sewerage can be installed with a bend . In the case of PVC or polypropylene, this will most likely lead to the destruction of the pipe;

- Elasticity and relatively thick walls (up to 5.6 mm with a diameter of 110 mm) make the polyethylene sewer riser almost silent.

Despite the same nominal diameter as PVC, polyethylene pipes measuring 110 mm do not fit into the socket of the PVC fitting. To connect, the socket must be slightly stretched with preheating or a cuff adapter must be used.

Currently, the main area of use of polyethylene in sewerage is the production of corrugated pipes. Their large size (from 160 mm) implies use outside buildings, including when installing sewer collectors. On the way to the corresponding section of the sewer network, the hottest wastewater has time to cool down to a temperature that is safe for the polymer.

Corrugated polyethylene sewer from the Korsis company.

Gray cast iron

This material had no alternatives for the installation of sewer systems until the 70s and 80s of the last century. Now it is still in demand, but only in specific conditions:

- For open installation of risers with strict noise level requirements;

- When laid in the ground at a shallow depth under large deforming loads (for example, under a dirt road).

The main problems of gray cast iron, which allowed polymers to seriously displace it in the market:

- Limited service life. After only 30 - 40 years, corrosion often leads to the destruction of sockets, especially those experiencing significant operational loads (simply put, when the riser rests on the socket and not on the clamp);

Cast iron riser in Khrushchev.

- Fragility. A relatively weak blow can lead to destruction of the bell;

- Considerable weight, making transportation difficult;

- High price. A two-meter pipe measuring 100 mm will cost the buyer 1300 - 1500 rubles;

- Labor-intensive installation. About him - a little more detail.

The socket connection on a cast iron sewer is sealed by embossing a cap - organic fiber impregnated with bitumen or resin.

Instead, when installing a cast iron sewer system with your own hands, it is much more convenient to use a graphite seal. It is more durable and does not require mandatory sealing.

The heel is placed in a socket around a smooth pipe in several turns and compacted with a special tool, which is called embossing. Then the socket is sealed with a cement-sand mortar prepared in a 1:1 ratio, or with pure cement.

Sealing one socket near a wall or under the ceiling sometimes takes an experienced mechanic 15-20 minutes. It is clear that the expenditure of effort and time is incomparable with plastic sewerage, which only needs to be docked and secured with a clamp.

The procedure for chasing a cast iron socket.

ductile iron

High-strength nodular cast iron differs from gray cast iron only by the addition of a small amount of magnesium to the melt, the presence of which leads to a change in the shape of the carbon particles. As a result, however, the physical properties of cast iron change quite radically: it acquires the ductility and toughness of steel, while maintaining the corrosion resistance characteristic of cast iron.

VChShG sewer pipes are used in sewerage areas with significant deforming loads. A typical way to connect them is with sockets with O-ring seals. The outside of the ductile iron is additionally protected from corrosion by a zinc coating, and from the inside by a cement-sand layer.

The only manufacturer of ductile iron sewer pipes in Russia is the Lipetsk plant Svobodny Sokol.

Structure of a sewer pipe made of ductile iron.

Asbestos cement

Asbestos-cement pipes GOST 1839-80 are used for external laying of free-flow sewerage. I have met them exclusively in storm drains and as outlets to wells.

This material is not very popular. Here are a few facts about him that the reader may find interesting:

- The standard provides only five standard sizes - 100, 150, 200, 300 and 400 mm (outer diameter);

- Wall thickness varies from 9 to 17 mm;

- Pipes are produced in lengths of 2950 or 3950 mm;

- They are produced with bells and smooth. In the latter case, couplings are used for connection;

- Despite the fact that asbestos-cement sewerage is free-flowing, pipes and couplings are tested with an internal pressure of 4 kgf/cm2.

Laying storm drains with asbestos cement.

Concrete, reinforced concrete

Their area of application is storm drains and collectors. Pipes are non-pressure, with a diameter of up to 2400 mm. Connections can be:

- Bell-shaped, with ring rubber seals;

- Rebated, sealed with sealant.

Due to their considerable mass, loading equipment is forced to be used for laying pipes. It, along with levers and clamps, is used for joining socket joints.

Non-pressure concrete pipes for external and storm sewerage.

Ceramics

In Russia, ceramic sewerage is produced in accordance with GOST 286 - 82. The instructions contained in the text of the standard directly indicate the possibility of using ceramics for domestic and storm drains; however, the high cost of the material forces it to be used only where there are no cheaper alternatives - when transporting high-temperature and particularly aggressive industrial wastewater .

What is useful to know about ceramics?

- GOST provides for diameters of 150 - 600 mm;

- Sewage elements must withstand internal pressure of at least 1.5 kgf/cm2;

- When fired, both the outer and inner surfaces of the pipes are covered with a glaze with increased resistance to acids and alkalis;

- Along with rubber sealing rings, the sockets are sealed with hemp strands impregnated with bitumen or resin (still with the same heel). To seal the compacted socket, the already familiar cement-sand mixture, asbestos cement or asphalt mastic is used.

Ceramic drainage systems are designed for use in particularly harsh conditions.

Purpose of PVC pipe

PVC sewer pipe is needed directly for drainage. Its type directly depends on the purpose. For installation in buildings, PVC sewer pipes are used for internal sewerage.

To completely remove wastewater from several buildings, systems with higher strength and a larger flow area are needed. Therefore, when placed externally, PVC sewer pipes are used for external sewerage.

Choosing a diameter according to building codes

In contrast to cast iron products, a number of plastic shaped modifications are much richer. ]polymer pipes[/anchor] produce products with diameters from 16 mm to 6000 mm.

The need for a diverse range makes sense:

- the capabilities of pipeline engineering systems are expanding;

- The pipe size is selected taking into account certain tasks;

- it is possible to replace a section of the main line with a pipe with the smallest possible diameter - when laying a sewer system for a private house, this will reduce the budget for repair work.

The most popular standard sizes for the internal drainage network: 50/100/150 mm.

The diameter of the pipe is selected in accordance with the service area. For example, a pipeline of 100, 110 or 150 mm is installed under a vertical riser and toilet

Scope of application of pipes based on the flow area:

- 16-25 mm – removal of uncontaminated liquid from ventilation units, air conditioners and dehumidifiers;

- from 32 mm – connection of a washbasin or sink used for washing conditionally clean dishes (glasses, wine glasses, etc.);

- from 40 mm – drain for a bathtub, shower, kitchen sink, dishwasher or washing machine;

- 50 mm or more – simultaneous connection of a shower and bathtub, laundry room;

- 60-75 mm – combined connection of three and five devices, respectively, with the exception of the toilet.

Dimensions are measured from the inside and reflect the nominal diameter of the line. Considering the wall thickness, the external size exceeds the internal size.

In addition to the diameter, when choosing polymer pipes you should pay attention to the following points:

Image gallery

Photo from

Marking of polymer pipes by ring stiffness

Use of pipes with low ring stiffness

Connecting elements of polymer pipes

Polymer pipes for external sewerage

PVC pipes for internal sewerage

Such PVC sewer pipes are designed to ensure the operation of indoor sewage systems. These include drainage from kitchens, baths and toilets.

Main characteristics:

- external and internal diameters are 21.3 and 15.7 mm, respectively;

- gray color, which performs the function of conditional camouflage (it is neutral and does not stand out against the background of the walls);

- low price.

Designed for low pressure and small waste volume. Not used outside buildings.

Conclusions and useful video on the topic

Video #1. Comparison of sewer pipes intended for the construction of external and internal sewage networks:

Video #2. Evaluation of the effectiveness of silent sewage systems Raupiano and Skolan:

From the point of view of financial benefit and practicality, polypropylene pipes are the optimal choice for organizing the internal part of the sewer system. The PP pipeline is affordable, easy to implement and guarantees uninterrupted long-term operation of the new engineering system.

Please write comments in the block below. Tell us about what pipes were used to repair the sewer system in an apartment or to install a system in a country house. Ask questions, share useful information, post photos related to the topic of the article.

PVC pipes for external sewerage

This type is used as an intermediary for the drainage of water waste from all internal networks into a septic tank or city sewer. Designed for high loads.

They differ significantly from internal ones:

- large diameter providing high throughput;

- bright orange color, which allows you to detect and avoid their unintentional damage, for example, during excavation work;

- thickened walls;

- increased heat resistance;

Such materials have an increased service life. Due to the greater strength of the materials used in production, the cost is higher.

Connection methods

Depending on the type of sewer pipe selected and connecting fittings, the following connections are classified:

- Bell-shaped - the pipe socket is put on a fitting or other part. Fixed with an O-ring. For socket joints of cast iron pipes, cement is used instead of an O-ring;

- For gluing (usually used for assemblies made of plastic pipes). The installation adhesive is made from a mixture of PVC and tetrahydrofuran;

- Using clamps and levers. This method allows you to increase the mechanical force;

- Threaded. Quite rarely used to connect cast iron parts.

The connection method should be carefully considered - the operation of the entire network depends on the correct connection of the nodes.

Types of PVC pipes

For proper installation of the pipeline, you need to select the appropriate pipe option. It must be suitable for a specific situation.

Pressure and non-pressure

Pressure ones are designed for high pressure (up to 10 atm). They are used in systems with constantly increased exposure to various environments. Non-pressure ones are used in wastewater networks with low pressure (the liquid moves itself at a moderate speed). They are in most cases used outside buildings.

Corrugated

To increase strength, a corrugated shape with greater mechanical rigidity was developed. Folds increase the wall area. Due to this, pressure is redistributed, as a result of which the systems can withstand increased loads. Today they are produced in 2 types. Single-layer ones are made with a ribbed surface inside and outside. They are cheaper, but in them the drains drain with difficulty and there is a high probability of blockages. The two-layer ones have a folded outer surface and a smooth inner surface. Therefore, growths and blockages do not form in them, the flow passes freely.

On a note!

They are connected using a special socket method using special rubber cuffs and cold welding.

What technical characteristics do the structures have?

PVC - this is the designation for any type of polyvinyl chloride. It is obtained when vinyl chloride is polymerized. The new material has the following advantages:

- Resistance to corrosive processes.

- Ultraviolet resistance.

- The ability to withstand the negative effects of various substances.

- Long service life.

- They have great strength. It also has a 50 mm PVC pipe for sewerage.

Plumbing products measuring 250 mm, which are made from this material, also have positive qualities. They are lightweight, making installation and transportation much easier.

Low price attracts buyers the most. Compared to cast iron and steel analogues, products made from this material are the cheapest.

Installation is simple and can be done by the owner himself without additional assistance. It is enough to use suitable fittings. But it is not without its drawbacks, just like other materials.

Plastic is very susceptible to negative temperatures. It can also be deformed at high temperatures - from 70 degrees or more. Water flows through such a pipeline quite noisily.

PVC sewer pipe size chart

The dimensions of PVC sewer pipes must be known for high-quality installation and proper operation of the system. They are enshrined in the state standard for each type, which is marked GOST 32413-2013.

The measurements are based on 2 main characteristics: the nominal outer diameter of PVC sewer pipes and the thickness of their walls in millimeters. The length that manufacturers set independently is also taken into account.

Dimensions for internal systems can be presented in table form.

| Nominal diameter, inch | External diameter, mm | Minimum wall thickness, mm | Design internal diameter, mm | Weight, kg |

| 1/2 | 21,3 | 2,8 | 15,7 | 0,238 |

| 3/4 | 26,7 | 2,9 | 20,9 | 0,313 |

| 1 | 33,4 | 3,4 | 26,6 | 0,476 |

| 11/4 | 42,2 | 3,6 | 35,0 | 0,640 |

| 11/2 | 48,3 | 3,7 | 40,9 | 0,759 |

| 2 | 60,3 | 3,9 | 52,5 | 1,012 |

| 21/2 | 73,0 | 5,2 | 62,6 | 1,592 |

| 3 | 88,9 | 5,5 | 77,9 | 2,098 |

| 4 | 114,3 | 6,0 | 102,3 | 2,991 |

| 5 | 141,3 | 6,6 | 128,1 | 4,062 |

| 6 | 158,8 | 7,1 | 144,6 | 5,253 |

| 8 | 219,0 | 8,2 | 202,6 | 8,020 |

| 10 | 273,1 | 9,3 | 254,5 | 11,234 |

| 12 | 318,8 | 10,3 | 298,2 | 14,895 |

| 14 | 355,6 | 11,1 | 333,4 | 17,558 |

| 16 | 406,4 | 12,7 | 381,0 | 22,960 |

Classification

Technical characteristics of PVC pipes.

Communications made of polyvinyl chloride are classified according to the degree of rigidity. The following types of pipes are distinguished:

- Class L (2 kN/sq. m).

- Class N (4 kN/sq. m).

- The thickest-walled products belong to class S (8 kN/sq. m).

The second group of materials can be used for installation of sewerage systems at a depth of 0.8 to 6 m, and pipes representing the third class are intended for installation deeper than a level of 6 m. According to their intended purpose, the following types of products are distinguished:

- light type, communications are used during the construction of sewer systems in areas with low load (green areas, sidewalks);

- medium type, pipes of this group are used when laying systems passing under roads with low-intensity traffic;

- heavy type, communications of this design are used in areas characterized by heavy traffic loads.

The service life of the entire sewage system will depend on how correctly the products are selected. Therefore, when choosing, you should pay attention to the features and parameters of the pipes. The range of standard sizes of PVC communications is very wide. Thus, the outer diameter of the products varies from 11 to 63 cm, and the wall thickness can correspond to any value from the range from 3.2 to 15 mm.

The shade makes it easy to navigate when choosing communications for laying external sewerage systems. The main colors of this type of product are: brick, gray, red.

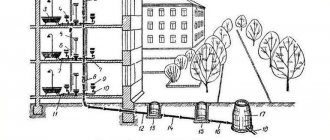

How is the external sewage system arranged?

Yellow or orange colors indicate plumbing elements that are used for laying external sewers, where the diameter size is 50 mm.

Their walls can be different: with one layer and a smooth surface, or with three layers and corrugated. These options fully comply with GOST 51613 2000.

Wall thickness and strength become the most important parameters for representatives of this group. According to these characteristics, smooth structures can be divided into three more categories.

- SN8. Plumbing products with the greatest strength. They can be laid even under busy highways, at great depths.

- SN4. It is better to lay them under roads without much traffic.

- SN2. Can't withstand heavy loads.

1.1-6.3 centimeters is the most common diameter for external sewerage.

When installing outdoor external networks, specialists use the following types of connecting elements.

- Single-plane cross with right angle. Or - a tee that supports angles of 45, 67 and 90 degrees. This rule corresponds to GOST 51613 2000.

- Right angle tee, three-socket type.

- Reduction.

- Plumbing inspection hatches for structures measuring 50 mm.

- Siphons equipped with two elbows.

- Check valves.

- Bends with two sockets, rectangular in shape.

- Plumbing bends with a large number of possible angles: 15, 30, 45, 67 and 90 degrees.

- Clutch. The main thing is that it complies with GOST 51613 2000.

About the construction of the pipeline, the use of adapters

Products in gray color are most often used by those who install risers and wiring inside the house. They are made from unplasticized polyvinyl chloride.

This is a smooth-walled type of pipes and fittings. Its sizes can be any. 5, 11 centimeters are the most widely used sections.

When it comes to internal sewerage, fittings equipped with rubber seals are most often purchased. Here they help arrange turns in the pipeline and connect elements to each other.

Adapters are divided into several types according to their functions:

- Compensation pipes. They become indispensable assistants when performing repair work. They will help connect PVC pipes with a diameter of 250 mm for external sewerage.

- Rotary bends. Sold at 90, 30 and 45 degree angles.

- Tees with different angles - from 45 to 90 degrees. To connect several pipes with a diameter of 50 mm, crosses are also used; they usually have a slope of 45, 90 degrees.

- Inspection hatch. These types of equipment are necessary when specialists are checking the system and performing diagnostics.

- Elements with different diameters are connected using reduction.

- Couplings are used where it is not possible to use a socket connection. Or they help perform installation where there is a PVC plumbing pipe, where the diameter does not matter.

Varieties. Features of the structure

Most often, a special extension, the so-called socket, is installed on one side of the pipe. Without this element it is impossible to create a high-quality connection. The end with a smooth surface is connected to the socket and inserted inside.

The type of product determines the composition and subtleties of the structure, possible color design. PVC plumbing pipes for sewerage are no exception, where GOST 51613 2000 defines clear requirements for them. For more information about what GOST 51613 2000 is, see here.