The operation of sewer pipelines is influenced by numerous factors, including cold. In order for the system to function normally even at very low temperatures, it is necessary to select the correct insulation for sewer pipes and install it.

Thermal insulation materials are presented on the market in a wide range, and deciding on a purchase is sometimes quite difficult, don’t you agree? We will help you resolve this issue. The article provides an overview of various types of insulation, describes their characteristics, installation features and application.

Rules for choosing insulation

There is a huge selection of insulation materials on the construction market, but not all can be used as insulation for sewer pipes.

The main task of insulation is not to heat the outlet, but to reduce heat exchange between the external environment and the liquid circulating through the pipes.

In order for pipe insulation to effectively perform its main function - heat preservation, it must meet 7 basic requirements:

- have a thermal conductivity coefficient as low as possible;

- retain their properties for a long time;

- withstand large temperature changes;

- have good waterproofing properties;

- be resistant to aggressive environmental influences;

- do not support combustion and do not emit toxic smoke;

- be easy to install.

External sewerage pipes and a main line laid in an unheated room are subject to insulation. The only exceptions are those regions where even in winter it never drops below 0°C.

For others, the only question is the choice of method and material. Insulation materials are chosen based on the reputation of the manufacturer or brand, but the surest way is to focus on the material of manufacture.

To better navigate the variety of insulation products produced, you need to proceed from 3 rules: if several materials are found that satisfy the requirements for them, choose the cheapest, easiest to install, long known on the market and well-proven

Most often, sewer pipes are insulated with mineral wool, expanded clay, styrofoam and polyurethane foam insulation. Liquid insulation also finds its use. All of them are used for passive insulation.

Image gallery

Photo from

Laying an external line without insulation

Insulation of sewerage next to the hot water riser

Insulation of pipes before laying in a trench

Thermal insulation during construction

In addition to them, there are 2 more options for protecting pipes from frost - laying below the freezing level of soil layers and using active insulation. The latter includes cable insulation.

Materials for external drain networks and their prices

Insulation for external sewerage should be chosen correctly, and the price in this case is an important factor

It is important to understand that the insulating coating laid in a well or septic tank will be the key to reliability

Watch the video

Of the most popular materials for external drainage systems, we can highlight:

- Styrofoam. It consists of small granules. This option does not require additional waterproofing. This building material is produced by sintering granules. This product is very easy to use, is environmentally friendly and lasts a long time.

- Mineral wool. It belongs to the traditional options and is characterized by low cost. However, it is not preferred for sewer mains. Mineral wool cakes over time, plus it has a high hydroscopicity rate. Insulation made from wet mineral wool completely loses all the necessary protective properties.

- Foamed polyethylene. This method of insulation for external sewerage is characterized by ease of installation. It is also not afraid of dampness; in such conditions, unlike the previous insulation, it will not lose its properties from getting wet. This type of insulation in rolls has a small thickness, so many layers must be wound onto pipelines for high-quality insulation. You can buy foamed polyethylene in the form of a canvas or in the form of ready-to-use covers of various sizes.

- Expanded clay. This method is preferable for external insulation. They simply fill the trench where the highway is located. Only expanded clay is allowed to be used in dry recesses, otherwise its protective properties are lost.

- Folgoizol. Produced in two types: SRF and FG. This building material is equipped with fiberglass, which is glued with plastic film. In the production of foil insulation, aluminum or corrugated foil and a bitumen-polymer binder layer are used. A special feature of this type is its very long service life in external communications.

- Foamed synthetic rubber. This is a flexible, closed-cell insulation material. It goes on sale in the form of sheets and pipes. Tubular casings can be used for pipelines of any volume. Recently, the popularity of foamed synthetic rubber has decreased.

- Expanded polystyrene. Made from suspension polystyrene. During the production process, a foamed material is obtained, consisting of granules securely welded together. The advantage of the material is its high rigidity.

- Penoplex. This is a foamed type that consists of a large number of granules. This option is called the most suitable because penoplex is able to withstand large mechanical loads. This property becomes very important in the current situation. It should be added to the above that penoplex, as an option for drain lines in the ground, can be used in conditions of high humidity.

- Isopon. Most often used as thermal insulation when laying domestic and industrial systems. Its main advantage is its strength and resistance to moisture. Laying isopon is very fast.

- Polyurethane foam. The peculiarity of this type is installation using a special installation, and this costs a lot of money.

- Extruded polystyrene. Has a cellular structure. Ideal for insulating pipelines that are subject to severe loads during operation.

- Basalt. It is made from basalt fibers, which are stitched with glass lines.

- Glass wool. It is characterized by high density. It is often used to insulate metal-plastic sewer pipes. During the thermal insulation process, it is necessary to use additional insulators that protect the insulation from negative environmental factors.

There are also other thermal insulation materials on the market that have certain differences. So, a popular option is considered to be insulation that has a foil layer. This layer reflects thermal energy, which improves the efficiency of insulation.

Speaking about options for drain lines in the ground, it is necessary to note their affordable cost.

The exact price can be checked with managers when ordering. Also, when ordering, you can receive complete information about the selected product and its characteristics.

Expanded polystyrene heat insulator for pipes

Foam shells are a popular insulation material for insulating sewer pipes. Two percent of its composition is small, from 1 to 5 mm, polystyrene granules, the remaining 98% is air. After processing the material with a gas-forming agent, the granules become light, elastic, attract each other and stick together.

By pressing followed by high-temperature steam treatment, the material is given the desired shape.

It's basically just foam, but in a shell shape that's designed to last over and over again. The difference between the thermal conductivity coefficient of polystyrene foam insulation (0.03-0.05) and mineral wool is small. The shell, which has the shape of a hemisphere, copes with the task of preserving heat quite effectively.

The foam shell can consist of 2 or 3 elements. On their sides there are locks with a device for fastening. The shell is selected according to the diameter of the pipe and, having been placed on it, is snapped into place.

Since foam plastic is not very resistant to mechanical stress, manufacturers provide shells with an outer coating of aluminum foil, fiberglass and other materials.

High thermal insulation properties are provided by thin-walled microcells that do not allow heat to pass through. The service life of the thermal insulation shell is quite long - about 50 years.

There are 2 types of this material - ordinary and extruded polystyrene foam. The characteristics of the latter are higher, but the cost also differs significantly.

Despite a lot of positive qualities, polystyrene foam also has disadvantages. It does not tolerate ultraviolet radiation, so when laying pipes in open areas, additional protection from the sun is required. This material is dense, but fragile, and when burned it can cause poisoning, because The smoke it produces is poisonous.

Installation work is so simple that it does not require special qualifications. Having placed the insulation segments on the sewer pipe, they overlap, displacing them along the length relative to each other by 200-300 mm. To avoid the appearance of cold bridges, the thermal insulation elements are joined together using a quarter or tongue-and-groove system.

After the connection is made, both parts are strongly compressed. The contact points are taped with tape. Sometimes the joints are coated with glue, but then the insulation loses such an advantage as the possibility of reuse, because When dismantling it will have to be cut.

The shell is covered with a protective covering, which comes with it, or simply wrapped with plastic film if it is not available.

The shell is used both on above-ground routes and for laying highways underground. This insulation can be put on a pipe with a minimum diameter of 1.7 cm and a maximum of 122 cm. Already with a diameter of 200 mm, the cylinder consists of 4 elements, and for large products there can be 8.

Trenches with sewer pipes are first filled with sand to a height of about 0.2 m, then with earth. In regions with very cold winters, thermal insulation in the form of a polystyrene foam shell is supplemented with an insulating cable, placing it under the shell.

Image gallery

Photo from

Polystyrene shell for pipe insulation

Shell made of ordinary foam plastic

Basement use

Expanded polystyrene shell with waterproofing

How to insulate a sewer pipe in the ground with your own hands. Video

When laying sewer pipes outside in a country house, you must take care of their insulation. It is quite possible to insulate pipes without outside help if you follow our step-by-step instructions and tips. All pipes that are close to the surface of the earth or placed above the ground are at risk of freezing. We suggest you find out how to insulate a sewer pipe in the ground with your own hands.

Insulation of sewer pipes in a private house

The simplest method of insulation is to lay pipes below the freezing depth of the soil. The level of freezing depends on the region, soil characteristics, and proximity to water. If these indicators are outside the norm, this method is not suitable. If the ground freezes to a depth of one and a half meters, and groundwater flows at a depth of one meter, the sewer system will always be filled with water from the ground, and the pipes will freeze.

Another method involves the use of more expensive and efficient equipment. Laying pipes with a heating cable in a private house allows you to maintain a stable temperature and does not allow the water in the pipes to freeze. The self-regulating cable runs like a heating tape and heats the pipes along their entire length.

The heating power is 30 watts per meter of pipe. When using aluminum-coated tape, it is glued to the pipe. The cable can be cut to the desired size and plugs into a regular outlet. Such a system must be provided with uninterrupted power supply. Pipes with cable (tape) need to be thermally and waterproofed

Laying pipes with insulation in a country house allows you to efficiently and reliably protect the external sewer system

When purchasing insulation for pipes in your home, you need to pay attention to its characteristics.

Water resistance, durability, thermal conductivity, reusability, price - all this is very important when choosing

Types of materials for insulating sewer pipes in a house

The variety of materials for sewer insulation is quite wide, so you should choose taking into account the terrain and the characteristics of the operation of the pipes. Polystyrene foam is a compound of granules measuring about 0.5 centimeters. The granules bond when exposed to temperature. This insulation is a hollow cylinder that is placed on the pipe and secured with construction tape or clamps. Polyfoam is easy to use and safe.

Penoplex or extruded polystyrene foam consists of a foamed substance with a large number of granules. Penoplex can withstand significant loads underground. It has high rigidity and is used in wet conditions. Penoplex, in addition to insulating sewer pipes, is used for insulating foundations, basements and blind areas.

Foil-coated isolon is quite often used to insulate communications. It ensures that pipes are protected from freezing and destruction for many years. This high-quality and inexpensive material is quite easily mounted on pipes. The roll is cut into strips and wound in a spiral onto a pipe. The insulation is fixed using electrical tape, adhesive tape, and plastic clamps.

Insulation of sewer pipes is often carried out using ready-made or sprayed polyurethane foam (polyurethane foam). PPU is applied using a special installation. Instead of spraying an expensive substance, you can purchase ready-made blocks with any suitable diameter. The blocks are secured with clamps, aluminum tape or other connecting materials. This material is resistant to moisture and dampness. It is easy to remove and lasts a long time.

Watch the video: How to properly lay sewer pipes in a country house

Each method of insulation is good in its own way, so the material is selected individually. Knowing how and with what to insulate sewer pipes in a private house, you can save a lot. Protect your sewer system during the initial pipe installation to ensure your home renovations are inexpensive and long-lasting.

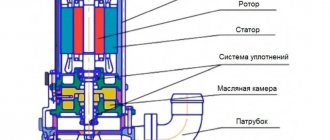

Polyurethane foam shells

Polyurethane foam cylinders are a good alternative to their foam counterparts. They differ in comparison with their higher density, and the thermal conductivity coefficient is almost the same.

Polyurethane foam also has higher resistance to mechanical stress. It also has a wider temperature range in which it can be operated without loss of strength characteristics.

The normal temperature regime for polyurethane shells is -180⁰ – +130⁰. This material also has a high fire safety indicator - it lights up at 415⁰ and subsequently self-extinguishes

Thermal insulation has the form of half-cylinders equipped with transverse or longitudinal latches. To increase the reliability of protection, the shells are sometimes enclosed in special galvanized casings equipped with locks, but more often they are simply coated with a special coating.

Application of foamed polyethylene

Foamed polyethylene is often used as insulation for sewer pipes. This is not a very dense material - up to 40 kg/mᶾ. The thermal conductivity coefficient is within 0.05.

Does not change its properties when used in the temperature range -50°С – + 90°С. The small thickness of the material allows you to save space, so its use is justified where there is a very small gap between the pipes and the wall.

Foamed polyethylene tolerates well even prolonged exposure to moisture. It is fire resistant. Withstands more than 300⁰. When the material burns, its emissions into the atmosphere do not contain dangerous toxins

The advantage of insulation is lightness, durability, and affordable price. This insulation is produced by such manufacturers as Magniflex and Penofol , Energoflex , Thermoflex . It is produced in the form of cylinders of different diameters and in rolls. There are foil one and two sided options.

This option of thermal insulation in the installation of sewer pipes is rarely used; it is used to insulate communication areas located in basements and above ground.

Using foil insulation for pipe insulation

Most often, the material is used for external communications made of metal-plastic pipes. There are 2 types of folgoizol - SRF and FG. In its production, foil is used - corrugated or aluminum and a bitumen-polymer layer for the binder.

It goes on sale in the form of rolls. The material is durable, environmentally friendly, and has a long service life. Has proven itself well in regions with different climates.

Is it necessary to insulate

Freezing of sewer pipes in winter is not so rare. This is especially true for external communications laid on the territory of country houses above the freezing point of the soil. House owners laying sewer lines often do not take into account the depth of soil freezing. The popular opinion among some craftsmen that the pipe is warmed by wastewater is justified only in regions with a mild climate and warm winters.

The depth of soil freezing in different regions of the country is not the same.

At prolonged low temperatures, an uninsulated pipe freezes. Remains of flowing water, especially at bends and turns of the highway, crystallize and form sagging. Gradually, the walls of the pipes become covered with a thin crust of ice, which thickens over time.

Consequences of freezing sewer lines:

- the formation of an ice plug that completely blocks the movement of wastewater;

- When the liquid freezes, it expands, which can cause the pipe to rupture at the point where the plug forms.

As a result, the permeability of the pipeline is disrupted, and wastewater does not flow into the septic tank. Repairing a sewer system in winter is labor-intensive and expensive.

The only correct and economically feasible solution is to insulate sewer pipes.

It is important! Particular attention must be paid to the thermal insulation of the segments located at the exit from the house.

Foamed rubber as insulation

This insulating material is made on the basis of natural or combined rubber. It is characterized by high fire safety and elasticity. Pipe insulation using this material is performed by gluing. As a result of the interpenetration of surfaces, a strong seam is obtained.

The structure of foam rubber is closed and porous. Because of this, it has increased flexibility. On the construction market, this thermal insulation is presented in the form of sheets, cylinders, rolls

Thermal insulation is produced by such manufacturers as the Italian company K-FLEX , the German companies ARMAFLEX and KAYFLEX . Due to the high cost, foam rubber is used extremely rarely for insulating sewer pipes.

Features of internal laying

Installing a heating cable for sewerage inside a pipe is more difficult than outside. Such devices are subject to more stringent safety requirements, so they are more expensive. The outer sheath of the wire must have high strength to withstand the conditions of an aggressive environment. Installing a heating element requires making a technological hole and sealing it tightly.

Internal electrical cable is the only option for asbestos-cement and concrete pipes with thick walls that have low thermal conductivity. Electricity consumption in this method of heating the sewer is less.

Installing the heating cable from the inside

Installation of the device begins with inserting a tee, through which the cable is inserted into the pipe using a coupling. After this, the hole is sealed and electricity is connected. Disadvantages of this method:

- due to the technical hole, the reliability of the pipeline will decrease;

- the wire reduces the internal diameter of the line;

- a foreign object increases the risk of blockage;

- a large number of bends in the pipeline complicates the internal installation of the electrical cable.

Internal cable installation diagram

Sewer insulation with expanded clay

The material is used for thermal insulation of sewer pipes laid underground. Its normal functioning is possible only in a dry environment, so insulation work is carried out in warm, dry weather.

The technology is simple:

- 2 layers of membrane are placed under the pipe with the sheet overlayed on the walls of the trench.

- Expanded clay is poured.

- Lay the edges of the panels overlapping on top of the expanded clay.

When exposed to moisture, this bulk material loses its properties. It is advisable to use it in areas with a temperate climate, because... it is not very effective as insulation.

Since the basis of this material is clay, it has retained all its characteristics. Expanded clay is chemically inert, does not support decay processes, but is unstable in relation to sharp impacts and absorbs moisture well

The density of the material depends on its brand. There are several types of expanded clay with different densities, shapes and sizes of granules. High-quality expanded clay has a regular round shape and a uniform internal structure.

Thermal insulating paint as insulation

Visually, heat-insulating paint resembles regular paint. Its advantage is that it can be applied to a surface of any shape. A layer of paint forms a sealed elastic coating that works on the principle of a thermos.

The coating with high energy-saving characteristics is a multi-level system, which includes evacuated microspheres of various types, an acrylic binder, and modifying additives that resist the appearance of rust on the surface of metal pipes and mold

To produce microspheres, ceramics, perlite, foam glass and other substances with thermal insulation properties are used. The paint is very easy to use and creates a durable coating.

The effect of coating with such paint is the same as that of insulation with mineral wool or expanded polystyrene. It is applied either manually using a roller or brush, or by spray.

Thermal insulation for metal products underground

To properly install a metal sewer system, it is necessary to purchase not only high-quality components, but also to ensure the functionality of the system.

Insulation of sewerage in a private house Do-it-yourself sewerage in a private house Vacuum valves

The choice of options in this situation is simply amazing in variety. But, before making a decision, it is recommended to get acquainted with their technical characteristics.

Experts recommend shells as the highest priority thermal insulation option for metal sewers.

This thermal insulation is easy to select for a metal pipeline of any volume. When choosing a shell, craftsmen advise choosing options made from polystyrene foam. Plastic is slightly inferior in that it is susceptible to combustion and can allow a little steam to pass through it.

Shell-type insulation for metal sewer pipes can be produced with additional protection against moisture. And this type of thermal insulation is most suitable for metal sewers laid in the ground.