The stove is considered a traditional design for heating buildings.

But if it is installed in a large house with several floors, then its power may not be enough to heat all rooms evenly. The solution here may be a furnace coil, which is also called a heat exchanger. It is connected to a heating device, then it is carried out through each room, thereby ensuring ideal and uniform heating of the entire building.

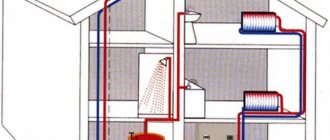

Features of organizing stove heating with a water circuit

A stove with a water circuit combines the advantages of two types of heating and distributes heat evenly throughout all rooms.

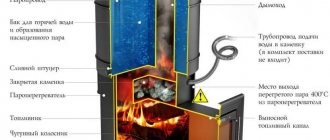

In fact, an ordinary stove becomes a kind of variation of a solid fuel boiler, only in addition to the coolant in the combined system, the housing is also heated, which also provides heating. After combustion ends, the batteries cool down quickly, but for some time the heat will emanate from the heated walls, which contributes to a smoother cooling of the room. A unit with a water circuit differs from a conventional wood-burning stove by the presence of a radiator (aka coil, boiler, heat exchanger).

It can be installed directly into the firebox, but this is fraught with leaks or even an explosion caused by boiling of the coolant. A safer option is to install coolant in the chimney cap. In addition, this will increase the efficiency of the furnace; most of the hot vapor will go to heating the coolant, and not the street.

Furnace construction: heat exchanger installation

More often, the heat exchanger is made of pipe or sheet steel with a wall thickness of at least 3-5 mm. The minimum size of the thermal jacket is 4 mm. You can purchase a ready-made cast iron coil. In any case, the thermal gap between the furnace and the register must be at least 1-1.5 to ensure the possibility of sufficient expansion.

It is better to organize a stove heating system with a circuit at the stage of planning a house, but only after weighing all the pros and cons. The stove model is chosen based on the size and layout of the heated home. The water circuit is designed based on the rules for arranging heating structures.

You can make a heat exchanger from sheet steel yourself

It is also possible to rebuild an existing stove, but in such cases the heat exchanger often takes up a significant amount of the usable area of the stove, which was not designed for it. To compensate for this factor, the heat exchanger is prepared in advance, and the furnace is rebuilt based on its dimensions.

How to choose?

When choosing, the price of the heat exchanger for the furnace plays a fundamental role. The design decision depends on the choice of material. The second most important aspect is the possibility of manufacturing.

And the final choice is the place where the stove will stand. You need to take into account what exactly you want to achieve. You need a heating and cooking stove or garage heating, whether it be a heater for a bathhouse or a stove for heating a country house. Each option has its own characteristics and subtleties.

The main thing is to accurately calculate what area needs to be heated, whether hot water is needed, how many units of fuel can be spent during the heating season, and much more. The result of all estimates should be the same - focusing on finances, available materials, needs, choose the most suitable design.

What is better in different options:

- For a bath - needs a complex option. The primary task is to heat water and two rooms. Dressing room and steam room, plus possibly a shower. Here it is better to use a coil for stove heating and water heating. Also, additional heating of the steam room improves the quality of steam in a Russian bath. Read also: DIY heat exchanger for a sauna stove.

- For home – consider the necessary functions. The choice of design depends on this. Most often, in village houses they try to build universal heating and cooking stoves. It is possible to install here widely used heat exchangers, which are easy to manufacture and solve at least three problems - heating, cooking, water heating. A common option for using a heat exchanger in a brick oven for heating, with a container.

- For a garage, the choice is simpler here, because here water heating is not necessary and only heating is important. Such conditions simplify the choice. Homemade horizontal heat exchangers for a heating furnace, built from scrap materials - old cast iron batteries, car radiators and the like - are perfect.

Materials for heat exchangers

Most often, the heat exchanger is made as a pipe structure. This is understandable, because the pipe already in its finished form has a cavity through which water or other liquid can move. And accordingly, pipes made of different materials can be used in the process of manufacturing a heat exchanger.

- Plastic pipes, this also includes metal-plastic. If we compare them with steel pipes, it can be noted that their thermal conductivity is two hundred times lower than that of steel.

- But a copper pipe has a higher thermal conductivity than a steel pipe. And this difference is 7.5 times.

Now imagine how many meters of each pipe are needed so that they equally provide heat to the coolant passing through the pipes. Offhand it looks like this:

- The metal-plastic pipe will need 4000 m.

- Steel – 25 m.

- And the copper one is only 3.5 m.

Heat exchanger design

Now it becomes clear which material is better and which should not be used at all. Let us immediately make a reservation that these compared indicators are taken for pipes of the same diameter. The only thing that confuses me about this ratio is the cost of the pipes. For example, 3.5 m of copper pipe costs almost the same as 25 m of steel pipe.

In addition, steel is stronger and can withstand thermal loads better. But copper is more ductile, which allows you to avoid complex installation and assembly processes and give the heat exchanger a different shape, moreover, without much difficulty. That is, these small deviations still have to be taken into account when choosing a material for making a heat exchanger with your own hands.

A furnace with a copper heat exchanger, of course, works several times more efficiently. The plasticity indicator of a material makes it possible to minimize its size, for example, by twisting it into a spiral. By the way, the size of the heat exchanger itself does not in any way affect the performance of the device, because in this design the most important indicator is the heat extraction area. This means that the more turns of the spiral there are in the device, the larger the contact area.

Made from copper

Currently, a homemade copper heat exchanger can work in different ways. There are two ways to heat the coolant:

- Pass it through the internal cavities, transferring thermal energy from an external source. This is basically how all traditional heating boilers and furnaces work.

- Pass the coolant through the inter-tube space, and pass the energy carrier, for example, saturated steam, through the internal cavities of the heat exchanger.

That is, the technology for heating the coolant will depend on what heat source you will use. By the way, such systems can work not only for heating, but also for cooling.

Steel version

Steel structure

- To make a heat exchanger with your own hands, you need a heat-resistant steel pipe with a wall thickness of at least 5 mm.

- A qualified welder can weld such a thickness without leaving shells or other defects.

- It is necessary to select the design of the unit so that it exactly matches the design of the boiler combustion chamber. And not only in terms of size, but also in shape, and in the precise and uniform arrangement of parts and components. This requires engineering knowledge.

- It is necessary to understand the issues of heating engineering. A small mistake can lead to the fact that the heat exchanger seems to be in the heat energy extraction zone, but it turns out to be insufficient to provide the heating system of the house.

The main nuances of creating a coil with your own hands

There are some rules that should be considered when creating a coil yourself:

- Voids may form in the heat exchanger, which should not be more than five millimeters. Otherwise, due to exposure to hot gas vapors from the furnace, the water in the device may boil;

- For the coil, pipes more than three millimeters thick are taken, otherwise, with a smaller pipe wall size, burnout of the elements may occur;

- When the device is located internally, a gap of twelve millimeters must be left between the firebox compartment and the heat exchanger device to compensate for the possible expansion of metal parts during the heating of water.

Design Features

So that you can imagine how a heat exchanger works, we would like to offer you one very simple design, which has recently gained immense popularity among summer residents. In fact, this is an ordinary solar battery, because the heat source will be the sun's rays, which are in abundance in the summer.

Principle of operation

To do this, you will need a wooden platform, which is best painted black. Now assemble a coil on it from rubber hoses, steel or copper pipes, plastic pipes. This is at your discretion, do not forget about thermal conductivity indicators. Connect the pipes into a coil. The more turns, the better. One end of the coil is connected to the water supply, the other to the hot water collection point. For example, to a summer shower mixer.

Place the platform at an angle so that the sun is always directed towards it. Here's a ready-made, cheap, DIY heat exchanger that uses free solar energy.

This example shows what a heat exchanger for a furnace is and how it works. The most important thing is that it is not difficult to make it yourself. It is important to know its design, dimensions and choose the material for manufacturing.

It was already mentioned above that there are a fairly large number of heat exchangers that differ from each other in purely design features. Let's look at two more types that are very different from the coil.

There is a heat exchanger called a water jacket. In this case, the process of heat exchange occurs from one container to another. It doesn’t matter whether these containers are partially closed or completely open. The design of such a furnace with a heat exchanger is that one container is inserted into another. By the way, this type is most often found in solid fuel boilers of small capacity.

Type of heat exchanger

Not a bad device, in some cases even economical. But it has one drawback - such a heat exchange device cannot operate at high coolant pressure. That is, such boilers can only be used in systems with natural coolant circulation. It is difficult to make a heat exchanger of this type with your own hands; of course, if you are a high-class welder, then there should be no problems.

And the most complex design, but also the most effective, is a heat exchanger called a tube sheet. Essentially, these are three different volumes:

- Two represent containers.

- The third is the pipe system connecting these tanks.

Why complicated? Imagine two vertically standing containers with a rectangular or cylindrical cross-section, and they are connected by a huge number of pipes.

- Firstly, both containers must be hermetically sealed. For their manufacture, metal sheets with a thickness of at least 5 mm are usually used.

- Secondly, they are connected by steel pipes, for each of which a hole of the appropriate diameter is cut in the containers.

- Thirdly, all pipes are welded to the tanks on both sides. Probably, there is no need to even remind you that welding seams must be at the highest level.

So this whole structure works to extract thermal energy from an external source. But the main part is still taken from the pipe part of the assembly. By the way, this structure can be assembled from both steel and copper pipes. The second option is more difficult, because you will have to flare each edge of the pipe, and this process is not easy and not every home craftsman can do it. Moreover, we are talking about a sealed structure.

Latest announcements

Gas boiler Protherm (Proterm) Bear 20 klom

New in box, everything is sealed, warranty receipt dated 09/1/19. I’m selling because it doesn’t fit our old system, but to return...

- Region: Moscow region

11.09.19

Water heating gas boiler VK-21(KSVA-2.0 GS)

We offer steel water heating boiler KSVa-2.0 Gs (VK-21). For a wholesale order (from 2 boilers) a price discount is possible Type...

- Region: Kirov region

05.08.19

Steam generator KV-300

We offer steam boiler KV-300 (KP-300). Steam capacity for normal steam, kg/hour – 300; - permissible excess...

- Region: Kirov region

28.06.19

Steam generator for 500 kg steam

Technical characteristics: — steam output — 500 kg/h; - boiler type - two-pass, fire-tube with reversible...

- Region: Kirov region

28.06.19

Steam generator for 1600 kg steam

Technical characteristics: — steam output — 1600 kg/h; - boiler type - two-pass, fire-tube with reversible...

- Region: Kirov region

28.06.19

Water heating boiler KSV-0.63

We offer a water heating boiler KSV-0.63. Technical data and characteristics: - rated heating capacity, ...

- Region: Kirov region

28.06.19

Water heating boiler 850 kW gas diesel

Technical characteristics: - nominal heating capacity - 0.85 MW; — Efficiency – 92%; - boiler type - two-pass, ...

- Region: Kirov region

28.06.19

Automatic coal boilers Lugaterm

The boiler model combines three main parts: a water-cooled firebox, a heat exchanger with automatic mechanical ...

- Region: Moscow

15.03.19

SOLID FUEL WATER BOILERS ON THE KVR MINE FIRES

Type of fuel: firewood of any moisture content Power from 0.2 to 2.5 MW Purpose: obtaining hot water at a nominal temperature ...

- Region: Kirov region

05.02.19

WATER HEATING BOILERS FOR WORKING WITH WOOD PROCESSING AND LAWMILLING WASTE KVM

Type of fuel: wood waste (sawdust, wood chips, bark) – without humidity limitation Power: from 0.2 to 2.5 MW Purpose: ...

- Region: Kirov region

05.02.19

Announcements by topic:

- Boilers and equipment for boiler houses

- Cooling towers

- Heat networks (all about pipelines)

- Materials

- Water treatment

- Cogeneration

- Autonomous heat supply

- Pumps, fans, smoke exhausters

- Pipeline accessories

- Heat exchange equipment

- Metering devices

- instrumentation and automation

- Repair equipment

- Heating devices

Installation of a heating device

There are three main ways to organize a combined heating system:

- With the construction of a new furnace. The need to build a new heating device makes it possible to choose the most suitable furnace model and heat exchanger, as well as to develop a competent scheme for the main project.

Diagram: device of a heating furnace with a water circuit

- Installing a heat exchanger in a finished furnace. This option is the most difficult to implement. First of all, this is due to the need to correctly calculate the dimensions according to which to make the coil. After this, you will have to disassemble part of the furnace, install the register and, if the draft was normal, reassemble everything in the same order. You can do this yourself if you have some experience as a stove maker or at least a mason.

- Installation of a factory furnace with a ready connection to the water circuit. Fireplaces, potbelly stoves and stoves with an installed water circuit have long been available for sale. All that remains is to create a closed system, connect pipes, radiators and the necessary equipment.

- Cost-effectiveness of the system. Construction of a stove or re-equipment of an already finished one will not require serious financial investments, and as a heating device it does not require complex and expensive maintenance.

- You can combine a stove with a fireplace and get not only a heating device, but also a unique decorative element that can become the main attraction of the interior.

The appearance of the stove can be chosen by the home owner

- The house creates a special coziness and atmosphere that can only be created with the help of this living heating method.

- Relatively high efficiency. If the stove is built by a competent specialist according to a good design, its productivity will be quite high, up to 60% in comparison, for example, with an oil-fuel boiler.

Heat exchangers for brick stoves can be made with your own hands from metal 2.5 mm thick. The basis of the design will be two containers - a cylindrical upper one and a rectangular lower one, connected to each other using pipes. The joints must be joined with a minimum gap, and the diameter of the pipes must be calculated based on the dimensions of the furnace and the area of the heated room. After checking the accuracy of the calculations and re-measuring the workpieces, the parts are connected by welding.

The strength of the finished structure is determined after welding the lower pipe, pouring water and connecting the outlet holes with the radiator tanks. When installation is completed, it is necessary to fill the system with compressed air, monitoring the pressure using a pressure gauge. Well-welded seams will not leak.

When installing thermal units and putting them into operation, you must follow the installation technology and avoid emergency situations. The high temperature in the heating chamber places increased demands on the quality of the metal, the efficiency of the heat exchange unit and the quality of welding. Knowing a few simple rules will help ensure long-term and reliable operation of the furnace heating system.

The supporting contours of heat exchangers should not be attached to walls using fixed connections. The temperature to which the pipes are heated causes the metal to expand, which can lead to changes in their size.

The cross-section of the pipelines must be at least an inch. At smaller values, the circuit will become inertial, and the fluid flow in it will seriously slow down. An increase in heat loss in heating lines will lead to a decrease in efficiency - the room will become colder with the same fuel consumption.

Functions

- Most often, heat exchangers are used to create a second heating circuit. Without it, the fuel burns and heats the walls of the firebox. Interacting with air, heated bricks give off heat. But it flies away through the flue.

- With the help of a heat exchanger in a brick kiln, hot air transfers excess heat to the circulating fluid. Allows you to increase efficiency by obtaining a double output coefficient per fuel unit.

- Heat exchangers are used in stoves for baths, garages, and houses. In each listed option, the heat exchanger has its own function - heating water for a shower, heating the coolant for heating, and the like. Various designs increase the range of applications.

Features of stove masonry

To build a stove, select a suitable building material. Normally fired brick is considered the best option, but for the walls of the combustion chamber and smoke duct it is better to buy refractory brick.

Kiln masonry

- Before laying a brick, it is immersed in water and held until air bubbles stop appearing;

- Each row and corner must be tied;

- The solution is applied immediately along the entire row, in a layer of approximately 5 mm, and on the end of each brick immediately before laying;

- When laying the firebox, it is recommended to distribute the clay solution not with a trowel, but with your hand;

- Having laid about 5 rows, carefully cut off the mortar between the seams and rub the seam with a wet sponge;

- Of course, the verticality and horizontality of the walls being erected must be controlled.

Economic indicators

A. Thermohydrodynamic perfection.

The power spent on pumping coolants in the heat exchanger determines to a large extent the heat transfer coefficient, i.e., the overall heating performance of the device. Therefore, an important indicator of the perfection of a heat exchanger is the degree to which power is used to pump coolant to ensure the required heat exchange.

The thermohydrodynamic perfection of the apparatus can be characterized by the ratio of two types of energy: heat Q transferred through the heat exchange surface, and work N spent on overcoming hydrodynamic resistance and expressed in the same units for all flows. Thus, the measure of the use of work expended on heat transfer can be expressed by the relation

E = Q/N

The greater the value of E, the more perfect, other things being equal, the heat exchanger or its heat exchange surface from a thermohydrodynamic (energy) point of view. The energy coefficient E is a dimensionless quantity, therefore the numerator and denominator of the expression E = Q/N can be referred to an arbitrary, but the same unit, for example, to a unit of heat exchange surface (thermal indicator), to a unit of mass of the heat exchange surface (mass indicator) or to unit of volume (volume indicator). When comparing apparatuses, the value of E can be related to all heat and to all work expended, or to a unit of surface, mass or volume of the apparatus.

The analysis shows that, all other things being equal, a change in the coolant speed has different effects on various quantities characterizing the operation of the heat exchanger: the heat transfer coefficient changes proportionally to the speed (or flow rate) to the power of 0.6-0.8, the hydrodynamic resistance is proportional to the speed to the power 1.7-1.8, and the power for pumping coolant is to the power of 2.75.

With an increase in the speed of the coolant, the power to pump it grows much faster than the amount of heat transferred, i.e. for a certain apparatus or a certain heat exchange surface, the value of the energy coefficient E decreases with increasing speed of the coolant. Therefore, the absolute value of the coefficient E cannot serve as a measure of the thermohydrodynamic perfection of a heat exchange apparatus, but is useful only when comparing two or more apparatuses.

B. Efficiency.

The thermal indicator of the perfection of a heat exchanger is its efficiency coefficient (efficiency):

n=Q2/Q1

where Q1 is the maximum possible amount of heat that can be transferred from a hot coolant to a cold one under given conditions; Q2 is the amount of heat transferred from the hot coolant to the cold one, or the heat expended in the technological process.

The maximum possible amount of heat, or available heat, depends on the initial temperatures and water equivalents of the coolants.

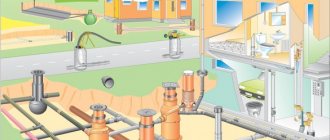

Features of water circuit pipe routing

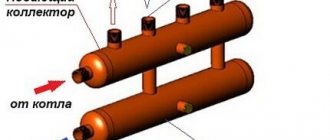

The pipe system is connected to a heat exchanger installed in the furnace through sockets that are inserted through one of the walls. The water circuit in such a system is often arranged in the form of a two-pipe system. The wiring can be either lower or upper.

Register for the stove from an old battery

Naturally, the heating circuit must be fully equipped. The expansion tank is installed at the highest point of the line, safety and air valves are installed, and a safety unit with a pressure gauge is also included in the system; valves are connected at the inlet and outlet of the radiators.

The water circuit can be connected to a circulation pump; it significantly increases efficiency and allows for a more flexible approach to solving the issue of pipe routing. But there is a problem with this approach. If the pump stops working due to a power outage, the water will not circulate and will begin to boil in the coil.

In the cold winter, when the boiler is working at full capacity, one minute can be enough for the consequences to be disastrous. The stove, unlike a gas boiler, cannot be turned off quickly. For these reasons, it is recommended to use a combined wiring method.

Exiting pipes for heating

In the supply pipe, after it leaves the furnace, an acceleration manifold is installed, raising the pipe vertically by 1-1.5 m, and then lowering it to the level of the radiators. Sections of the highway are located at a slope of 3-5°. In case of emergency mode, coolant circulation will be natural.

It is better to install the circulation pump in the return circuit as close as possible to the expansion tank using a bypass, and the pump axis should be located strictly horizontally.

Inspection of welded joints and bends

Each welded joint is subjected to external inspection and measurement to identify displacement of the edges and fracture at the joint (Fig. 8). The displacement b of the welded edges refers to the parallel displacement of the pipe axes among themselves. Kink k is a deviation in the form of a skew of the axes of the joined pipes. The displacement of the edges and fracture of the joint is measured with a special ruler 400 mm long with a cutout in the middle, which is installed tightly along the generatrix of one of the pipes with a cutout at the joint, and the deviation is determined along the other pipe with a feeler gauge at a distance of 200 mm from the axis of the joint. Measurements are carried out in 3 - 4 places around the circumference of the joint.

The inspection reveals such defects as burning (melting) of pipes in places of contact with the jaws and the machine body, creeping edges, and incomplete removal of the outer burr.

a - displacement; b - fracture;

Figure 8 — Deviation of welded pipe edges

To check the quality of welds, as well as devices for automatic control of welding process parameters, express tests of control welded joints (samples) are carried out. Samples are received before the start of each shift. Welding is allowed to be performed only if there are positive results of express tests of control samples. As a rule, express samples are subjected to metallographic examination.

Checking the mechanical properties and metallographic examination of welded joints is carried out on samples made from control welded joints, or on samples of welded joints cut from the manufactured product. In the case of cutting from finished products, the volume of control joints must be at least 1% (but not less than three joints) of the total number of identical welded joints performed by each welder in one shift.

By running the ball with compressed air, the completeness of removal of internal flash (or metal leakage) is checked - ensuring the specified flow area in welded joints. When inspecting welded joints on straight pipes (braids), a ball with a diameter of 0.86 in.nom is used, on coils 0.8 in.nom. of pipes. The reduction in the diameter of the ball when monitoring the flow area in the coil is caused by the ovality of the pipes in the bends. A ball catcher is placed on the free end of the coil, which ensures safe operation.

Ovality control of pipe bends and heating surface coils is selective (at least 10% of bends of the same standard size). The maximum ovality along the entire bend length should not exceed the permissible value. The maximum and minimum outer diameters of the pipe at the bending point are measured in one control section.

The ovality of the section in places where pipes are bent can be determined

where and are, respectively, the maximum and minimum outer diameter of the pipe at the bending point, measured at one section of the section, m.

Permissible ovality for boiler heating surfaces

where R is the bending radius of the pipe, m;

— outer diameter of the pipe, m.

The thinning of the pipe wall at the bending point on the stretched (outer) side is determined selectively by an ultrasonic thickness gauge. It is recommended to check the thinning when changing bending tools, setting up the machine and accessories.

For pipes with a diameter of up to 60 mm, bent without heating, high frequency currents (HFC), waviness (corrugations) on the inside of the bend and bulges on the stretched side should not exceed 0.5 mm in height with a minimum step of at least three heights.

Disadvantages of combining a furnace and a water circuit

- No matter how high-quality the stove is, it still remains a fire-hazardous heating device.

- Another significant disadvantage of such a system is the labor-intensive operation and prolonged heating of the system.

- Stoves will take up a significant part of the area and surrounding space in the house.

- Some uneven heating will remain one way or another. The air temperature near the stove will be slightly higher than near the walls.

Operating the stove requires constant human presence

- The likelihood of carbon monoxide accumulation due to improper operation of the stove.

- Due to dust, sawdust from firewood, soot and ash, the room where the stove is installed will have to be cleaned more often.

- It is impossible to precisely regulate the combustion process and retain heat, but only with the help of dampers.

A combined system of a combustion furnace and a water circuit undoubtedly has the right to exist, and in some cases it may not only be the only possible option, but also completely justified. But all this is provided that the heating scheme is designed correctly, taking into account all the nuances and fully meets safety requirements.

Quality indicators

Quality indicators serve to evaluate the operational merits of the unit, the main ones being: technical level, reliability and durability, structural, aesthetic and ergonomic characteristics of the unit.

A. Technical level.

There are absolute, relative and long-term technical levels.

The absolute technical level of a product is characterized by its performance indicators. Their number should be minimal. In order to avoid multiplicity and vagueness in assessing the absolute level, it is necessary to limit ourselves to only the most important of them - productivity, efficiency, process continuity, degree of automation.

The relative technical level characterizes the degree of perfection of a product when comparing (according to relevant indicators) its absolute technical level with the level of the best modern world - domestic and foreign - samples and models of similar purposes.

The promising technical level determines the intended and planned trends in the development of a given industry in the form of a set of its promising indicators.

B. Durability and reliability.

These indicators are the most important of the quality indicators.

Durability is the ability of a unit to remain operational with as few interruptions as possible for maintenance and repairs until destruction or another limiting state. The main quantitative indicators of durability are technical resource and service life.

Technical resource - the total operating time of the unit during the period of operation.

Service life is the calendar duration of operation of the unit until destruction or to another limiting state (for example, until the first major overhaul). The service life is limited by the physical and moral wear and tear of the unit.

Reliability is a property of a unit, determined by the reliability, durability and maintainability of the unit. Quantitative indicators of reliability: operating time, probability of failure-free operation, availability factor.

Running time is the duration or volume of operation of a unit, measured by the number of cycles, the number of manufactured products, or other units.

The probability of failure-free operation is the probability that, under certain modes and operating conditions, no failure occurs within a given operating time. Availability factor is the ratio of the operating time of the unit in units of time over a certain period of operation to the sum of this operating time and the time spent on finding and eliminating failures during the same period of operation.

B. Ergonomics and technical aesthetics.

Creation of modern heat exchangers that meet the best designs and international standards in terms of quality, ease of maintenance and appearance. The design of an industrial heat exchanger must be based on technical specifications and, at the same time, on the requirements put forward by new scientific disciplines - ergonomics and technical aesthetics.

Ergonomics is a scientific discipline that studies the functional capabilities of a person in labor processes in order to create perfect tools and optimal working conditions for him. Technical aesthetics is a scientific discipline, the subject of which is the field of activity of the artist-designer. The goal of artistic design is (in close connection with technical design) the creation of industrial facilities that best meet the needs of operating personnel, that best meet the operating conditions, have high aesthetic qualities, and are in harmony with the environment and setting.

A beautiful appearance usually corresponds to a rational and economical design. The appearance of the product largely depends on its color. Color is the most important factor, not only determining the aesthetic level of production, but also influencing worker fatigue, labor productivity and product quality.

Mechanism of operation

A metal stove placed in a house, garage or bathhouse must be equipped with a chimney to remove carbon monoxide and organize draft. During the process of heating the furnace, this pipe can reach very high temperatures, about 200-500 ℃, which is unsafe for people in the room.

If you install a heat exchanger on the chimney, you can significantly increase the efficiency of the stove, and also protect yourself from direct contact with a hot surface. In a tank or coil installed on the chimney, the coolant will be water, however, you can also install an air heat exchanger on the chimney pipe. Due to the direct contact of the chimney with the coolant, their temperature indicators are balanced, that is, the water or air gradually heats up, and the walls of the pipe cool down.

As the temperature of the water inside the register rises onto the pipe, it rises upward, where it enters the water tank through a special fitting. Through the inlet fitting located at the bottom of the heat exchanger, cold water enters it, replacing warm water. This circulation continues constantly, and the water can heat up to very high values.

An air radiator on a chimney pipe has a similar operating principle. Cold air enters the heat exchanger from below, and after heating it rises up and is supplied through the pipeline to the heated rooms. In addition, the radiator fins also give off heat. An air heat exchanger is optimal for heating attics in a country house or dressing rooms of a bathhouse, if such rooms are heated only from time to time. It is not advisable to organize water heating in them, since you will have to constantly fill and drain water from the system.