Of course, a modern house with a stove is an anachronism. A thrifty owner installs a comprehensive, economical heating system.

types of chimney pipes

However, what could be better than sitting in front of the fireplace on a cold evening or taking a steam bath in a Russian bath? But a fireplace and a good stove in a Russian bath cannot do without stove pipes and chimneys. This equipment will also be relevant in the construction of stationary grills and barbecues. The design of chimneys and chimneys is quite simple, but has some nuances.

Types of stove chimneys

Chimneys for baths are different:

- according to the material of manufacture;

- according to design features and installation location.

For many years, sauna stove chimneys were traditionally made from baked bricks. Nowadays, metal products are becoming increasingly popular.

Depending on their location and design, they come in two types:

- chimneys installed indoors and passing through the ceiling and roof;

- structures brought out through the wall and rising along it from the outside of the building (read: “How to make a chimney in a bathhouse through a wall - device options”).

The best option is selected taking into account the advantages and disadvantages of each type of smoke exhaust pipe.

Brick chimney structures

Previously, chimneys were laid out of bricks, since during the construction of this element of the stoves there was no alternative to this building material. Creating brickwork is a labor-intensive process. In this case, it is impossible to do without using a laying scheme and mandatory compliance with all design parameters.

Brick chimneys are strong and durable, which has been proven over time. A material such as brick has a structure that can accumulate thermal energy and release it evenly. A brick structure is much more fireproof than a prefabricated metal chimney made according to the latest technologies.

A significant disadvantage of a chimney made of bricks is that their internal surface is rough and has corners. Soot collects on it, which over time begins to interfere with the passage of smoke and reduces draft, which negatively affects the degree of heating of the heating unit.

A brick pipe for a sauna stove, heavily covered with soot deposits from the inside, can cause the sauna to smoke or even catch fire during the kindling process from sparks that hit it (read: “Why does a sauna stove smoke and how to fix it”). As a result, such a situation can lead to dire consequences.

Polymer

This is a new type. Polymer chimneys are made from a special material that is very light and flexible. The service life is quite long, but it can only be used when the temperature of the exhaust gases is not higher than 250 degrees. This applies to gas boilers and water heaters.

This system is convenient for repairing brick chimneys in ancient buildings, thanks to them it becomes possible to carry out a neat maximum reconstruction.

Just a note! You can often hear about such a system as “gas flues”; you need to know that this is a polymer pipe for chimneys from gas water heaters or boilers.

Metal chimneys

It is much easier to install a metal chimney than a brick building and its installation will cost much less. The sandwich structures currently in use are made with insulation. They are practical compared to single-walled metal products, but they lack the ability to retain heat inside the unit for a long time.

The main advantage of metal structures is the presence of a smooth inner surface with no edges. Thanks to this feature, the smoke will freely escape out under the influence of a turbulent flow.

Metal chimneys also have a disadvantage. When there is a sudden change in temperature, condensation may form on the inner surface. If such a design for a heating device is planned to be installed in a region with long, harsh winters, then it is necessary to give preference to pipes that have the thickest possible layer of heat insulation.

Calculation example

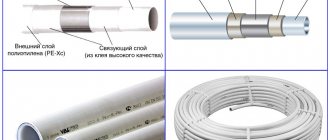

For example, there is a house of 60 sq. meters. On average, heat loss is 100 W/sq.m., the required heat flow is 6000 W. We apply a safety factor of 1.2 - 6000 * 1.2 = 7200 W In the table, the maximum approximate value will be 7185 W at a flow speed of 0.5 m/s. In the leftmost column, the internal diameter of the pipe will be 15 mm. Using the manufacturer's table, we find the required outer diameter of the pipe. For example, for the closest value in the direction of increase - 18 mm. This is a universal multilayer pipe (PE-Xc\Al\PE) 25 mm. We look the same way. A 25 mm Stabi polypropylene pipe is suitable for us.

External and internal smoke exhaust system

When choosing a chimney, you should consider what type of installation will be used - internal or external. Each installation method has its own advantages and disadvantages, and you also need to know about them before deciding which pipe to use for your sauna stove.

At one time, American architects came up with a way to place the smoke exhaust structure on the outer surface of the building wall. This option for installing a chimney began to be used in domestic baths due to the simplicity of the device. The pipe connected to the stove does not rise to the ceiling of the room, but is led out through the wall of the building.

The advantages of a chimney mounted in this way include increased safety and the fact that it is not necessary to make insulated transitions in the roof and attic. Laying the pipe out through the wall prevents the building from the possible flow of precipitation through the cracks and gaps formed between the roof covering and the pipe.

But the external chimney has a significant drawback - it quickly cools down, which means that condensation forms inside it. To eliminate this problem, the pipe should be thoroughly insulated.

Another negative point inherent in chimney structures placed outside is the inability to give off additional heat despite the fact that fuel consumption increases.

There are also combined chimneys. In them, a metal pipe is removed from the device, and then taken outside to the street. Then it enters a brick-lined chimney built into the wall and rising to the required height.

The metal smoke exhaust structure located inside the bathhouse is placed on top of the heater and raised to the ceiling, laid through the attic and roof to the level of the ridge located on the roof.

Such chimneys have a great advantage, since all the thermal energy received in the furnace firebox, when moving through stainless steel or steel pipes, will simultaneously heat the attic and rooms of the bathhouse building. This means that indoor air takes longer to cool, resulting in significant savings in fuel consumption.

Provided that the internal smoke exhaust structure is installed correctly and the integrity of the connection points of the elements is constantly monitored, the system can serve without repair for many years.

Such options have a drawback, which is the need to lay the pipe through the floors and roof.

Choosing the right one

Any owner knows that building a house begins with a heating stove. When choosing pipes for a chimney, you must first consider what fuel will be used.

Usually it comes in the form:

- gas;

- liquid fuel;

- solid fuel;

- bulk fuel.

It must be taken into account that each type of fuel has its own characteristics, certain features, that is, it is different:

- combustion temperature;

- temperature of exhaust gases;

- chemical composition of smoke.

When choosing pipes, you need to pay attention to the following:

- If the chimney pipe is intended for wood-burning home and sauna stoves, solid fuel boilers, fireplaces, then they must be able to withstand high temperatures of up to and more than 700 degrees Celsius, but should not exceed more than 1000 degrees.

- For gas flues, the operating temperature should be about 200 degrees Celsius and no more than 400 degrees.

- If chimneys are chosen for sawdust, pellet, liquid fuel boilers, then their operating temperature ranges from 250 to 400 degrees Celsius.

An important indicator is the thickness of the inner wall of the product:

- for diesel, gas, pellet boilers up to 0.5 mm;

- for stoves, sauna stoves, fireplaces from 0.7 to 1.0 mm;

- for coal stoves – 1.0 mm.

You need to know how to wrap a chimney pipe. Usually this is basalt thermal insulation. It is also always of different thicknesses for different systems.

- If the boilers are gas, liquid fuel, pellet or sawdust, then the thickness of the thermal insulation should be from 28 to 50 mm. It is necessary to take into account the materials used in the building structures of the house;

- If fireplaces, stoves, solid fuel boilers, then the insulation thickness is up to 100 mm, the type of material of the building structures is also taken into account.

We must remember! Ceramic chimneys are considered the most unpretentious; they are ideal for all appliances and no matter what material the houses are built from.

Materials for building chimneys

All necessary materials must be purchased after choosing a smoke exhaust design option.

To install a brick chimney, you should purchase heat-resistant bricks and a special composition intended for masonry, which is a dry mixture. Some experienced stove makers prefer to work with a clay-based solution. You will also need material to create a fungus over the pipe.

To install a chimney for a sauna stove made of stainless steel or steel, first a detailed design drawing is drawn up with all the bends of the pipe drawn on it, and only then the required parts are purchased.

The places where the smoke exhaust system passes through the enclosing elements of the building should be reflected on paper. At the turning points of the pipe, indicate the approximate bending angle. Based on the prepared diagram, sales consultants of a specialized store will always select all the necessary materials for installation work.

In addition, you will need two metal sheets with holes that are similar to the diameter of the pipe. They will be required for mounting on the ceiling of the bathhouse and on the floor of the attic. Heat-resistant material is also required for installation around the pipe in the attic. It will serve as protection for flammable elements located around the smoke exhaust structure.

To install waterproofing around a pipe on the roof of a building, you will need adhesive sealant and a special rubber seal that is placed on the chimney.

Frequent errors and problems during installation

The most serious mistake is the lack of a condensate collector and elements with hatches for cleaning.

In places where structures pass through ceilings, it is strictly forbidden to install joints of individual elements - leaking hot smoke can cause a fire.

A very significant mistake is the absence of a deflector or at least a cap over the chimney.

Snow and rain should not get inside the pipe - they increase the formation of condensation, and ice can block the cross-section of the pipe.

Pipe selection criteria

When purchasing these elements for a chimney system, be sure to take into account the following:

- The size of their internal cross-section. Pipes for sauna stoves made of stainless steel or steel are calculated taking into account the designed power of the unit. For bath buildings, the internal diameter is usually 15–20 centimeters. If the cross-section is too large, the heat will not be able to be retained in the furnace, and pipes of too small a parameter will not create the draft required for smoke removal. In this case, in no part of the structure the diameter should be less than that of the outlet pipe of the heating unit.

- The length of the chimney pipe cannot be less than 5 meters, and the more precise value of this parameter depends on the installation location on the roof. If they plan to install it in the middle of the slope, then the pipe must be raised above the level of the ridge by 50 centimeters. The best location for the chimney on the roof is considered to be 1.5 meters from the ridge, but this value is not mandatory and largely depends on the location of the stove in the room. The quality of traction is affected by the height of the pipe.

- In order for the structure to last for a long time, the thickness of the metal for making pipes must be at least 1 millimeter.

- Provided that a tank for heating water is planned to be installed in the chimney system, this tank will function according to the “samovar” system - it is welded to the chimney pipe.

Variety

Chimney pipes are needed to get rid of various combustion products from the firebox. Their task is also to ensure the combustion process. A special nozzle on the chimney pipe helps improve the process. It is suitable for any type of product.

There are 4 main types of chimney pipes:

- Brick.

- Metal.

- Ceramic.

- Polymer.

The price of each type depends on various factors.

Installation of internal metal chimneys

After the installation of the heaters is completed, they begin to arrange the chimney structure, performing work from the sauna stove pipe. This can be either the beginning of a metal chimney or a section of the smoke exhaust structure connecting the heating unit to a brick pipe.

Since chimneys come in two types, their installation is different. When the pipe is placed inside a bathhouse building, almost the entire structure is located vertically. The installation of individual elements is carried out in such a way that each part located above is placed on the one below. This method is called “smoke” installation.

When using sandwich pipes shown in the photo, they are installed differently, using the “condensate” method. Its essence is that to arrange the internal part of the system, the upper pipe is placed in the socket of the lower element. For the outer part of the structure, the “smoke” method is used.

Thanks to this chimney arrangement, the moisture accumulated in the pipe can freely flow down and enter the condensate collector, without touching the heat-insulating material, which, if there is an excess of moisture in it, loses its inherent properties.

The joints of the elements should be located so that the connection is not at the roof level, and also does not fall on the attic and interfloor ceilings. If the heating unit is planned to be installed in close proximity to wooden walls, they must be protected from fire or overheating. For this, heat-resistant materials are used, such as asbestos boards, which are fixed in two layers.

When installing samovar-type water heating tanks, they should be located near the combustion chamber, directly above it or in the attic, if hot water will need to be distributed not to one room, but to two - a washing room and a shower room.

Before you begin installing the pipes, their joints should be coated with heat-resistant sealant and, after completion of the work, additionally secured with special wide clamps.

When, when connecting individual parts of the chimney, significant gaps remain between them, the part that needs to be inserted is sealed. To do this, an asbestos cord is used to wrap the pipe.

The first section of the structure, attached to the unit’s branch pipe, cannot be made multilayer; it must be made of a single-walled metal pipe with special connections, in which there is a valve. This chimney adjustment element (damper) is used to create and maintain the required draft level while the bathhouse is warming up. After the combustion is completed, the valve allows the heating unit to retain thermal energy for a long time.

To make it easier to lay the pipe through the ceiling, it is advisable to use a box. The height of its walls should exceed the thickness of the barrier by 30–40 centimeters. A distance of at least 18–20 centimeters is left between the walls of the box and the pipe.

The installation procedure for this element is as follows:

- A square hole is cut in the ceiling so that a box fits into it, the lower part of which is fixed to the ceiling.

- Through a hole made in the bottom, the smoke exhaust pipe is led into the attic.

- Then the box is filled completely to the very top with heat-resistant material that is light in weight, for example, mineral wool or expanded clay of the middle fraction. The insulation must be laid as tightly as possible.

- In the attic, the box is covered with a metal lid equipped with a round hole. It is placed on the protruding part of the pipe.

As a rule, chimney elements are placed vertically in the attic, but sometimes they can get on the sheathing bars. In this case, a slight bend is made in the structure using bends.

When a pipe is laid through the roof of a building, a sheet of metal or asbestos is attached to the attic side. It should have a round or oval hole - it depends on the angle of the roof. Around the pipe, in order to protect the elements of the rafter system from possible fire, heat-resistant insulation should be laid using asbestos boards or mineral wool (read also: “How to insulate a pipe in a bathhouse - proven insulation methods”).

After the roofing material is laid, waterproofing measures are carried out, since moisture can sometimes get into the gaps between the roofing of the building and the pipe. An elastic element is placed on the pipe. It is fixed to the roof surface using moisture-resistant sealant, and then securely fastened using roofing fasteners. A protective umbrella is installed on top of the pipe - it will prevent various debris, dry leaves, branches, dust and precipitation from getting inside the structure.

Diameter

In order to calculate all the parameters, it is now necessary to decide on the material that will be used in the construction process. It is most convenient to carry out the calculation on paper, creating a sketch of the future structure; it is necessary to take into account some nuances:

- The diameter of the chimney for a fireplace must have a certain relationship with the firebox. Calculating this value has its own subtleties. For example, when calculating the diameter of a pipe that connects to an open firebox structure, a proportion of 1:10 is used. This method is only correct for a cylindrical type of chimney.

- The calculation of the cross-section for a square type device contains proportions of 1:15. But the diameter should be smaller than the size of the blower. If the resulting heat transfer is less than 300 cal/hour, the cross-section should not be less than 140 x 140.

- In order to determine the optimal diameter of the fireplace chimney, you can take as a basis state standards, which stipulate the permissible cross-section under certain conditions.

- In addition, the height and diameter are calculated in accordance with the area of the room.

Standard dimensions of internal diameters and cross-sectional areas of brick chimneys

It would be a good idea to show your calculation to specialists and analyze it together. In addition, a suitable calculation scheme can be posted on the Internet.

It must be remembered that the calculation of these parameters must be done correctly; the efficiency of the heating device depends on this.

Installation of external metal chimney structures

If the chimney installation scheme provides for its external placement, the pipe coming from the heating unit is laid through the wall of the building. To ensure the safety of the operation process, experts advise laying brickwork, which will insulate the wall when the chimney is brought out through it.

To turn the pipe in the direction of the wall, you will need a product such as a bend or elbow. These structural elements have bends at an angle of 45 or 90 degrees. They are selected taking into account the installation diagram of the smoke exhaust system.

The pipe to the stove in the bathhouse can be routed through the wall, either through a duct or through the attic floor. The box is filled with stone wool. Since there may be small gaps around the pipe, they are treated with heat-resistant sealant.

A tee is installed on the outside of the building. From here the structural elements will be installed further: upward, along the wall and to the condensate collection point located below.

For vertical fixation of the chimney, holder mounts are used. To ensure good traction, the pipe should rise above the height of the ridge by about 50 centimeters. A protective fungus is placed on top of the head.

How to position the smoke channel correctly

It is advisable to take care of the location of the smoke duct at the design or construction stage of the house. This will minimize the cost of time and materials for the construction of the chimney shaft, its sealing and lining.

If the installation of a fireplace is planned during the operation of the building, it is necessary to contact an engineer to develop a layout of the fireplace and chimney, taking into account the specific layout of the house.

If the chimney is located inside the building, it is advisable to install it in a warm room. When installed near a cold load-bearing wall or outside the house, it must be insulated.

Important! Installation of the chimney occurs only after installation of the fireplace insert. The firebox should be located at least 15 cm from the wall. The wall itself near the fireplace must be additionally insulated using foiled basalt wool.

The fireplace smoke collector must be strictly vertical, i.e. be on the same axis with the firebox. The axis of the chimney must also coincide with the axis of the smoke collector. To ensure that the structure is installed correctly, you must use a plumb line or level.

Chimneys made of bricks

A chimney made of brick can be root or mounted. For stoves installed in bath buildings, the first option, which is placed next to the heating unit, is more suitable.

If the stove is built of bricks, then a chimney is attached to it. When the unit is made of metal, it is connected to the brick smoke exhaust system via a metal pipe.

An approximate diagram of a chimney made of bricks consists of the following elements:

- Smoke valve , which regulates the internal draft of the heater. It is installed in close proximity to the ceiling. The intensity of fuel combustion and the time the stove remains hot depends on the valve.

- Fluffing (cutting) . Designed for laying pipes through the attic floor. This is what is commonly called the thickening of the chimney walls, provided that the size of its internal cross-section is maintained. This structural element is needed to protect the materials used to make the ceiling from overheating and subsequent fire.

- A riser is a straight piece of pipe. It is located above the fluff and runs through the attic.

- Otter . It is laid out at the point where the chimney exits through the roof. Its purpose is to protect the rafter system from possible overheating. In addition, due to the bricks protruding outward from the structure, the otter covers the gaps between the roofing material and the chimney masonry.

- The neck is the place where the pipe narrows to its initial external parameters.

- Header . It is located above the neck. When arranging it, the bricks are laid out so that they protrude outward beyond the walls of the chimney. As a result, the head provides additional protection from precipitation.

- Metal cap . Installed at the very top of the chimney. Does not allow dust, dirt, or water to penetrate into the system.

Expert advice

A few tips from experienced stove makers:

- You should not place chimneys in corners and places where walls intersect, so as not to weaken their strength.

- Before laying a brick smoke duct, you should prepare a row (layer-by-layer) layout for its installation.

- The otter and fluff masonry, which is an integral part of the brick structure, can be reinforced with metal rods or plates.

- You cannot smooth out the internal roughness of a brick pipe with clay. This causes condensation and dampening of the brick.