Hello, dear reader!

The normal operation of the sewer system largely depends on the correct installation of the pipeline. In this case, attaching sewer pipes to the wall plays an important role. It must be carried out in accordance with standards, compliance with certain rules established by regulatory documents. Let's consider what types and methods of fastening for sewer pipes exist, and how best to use them in various distribution locations.

Mounting methods

Securing drains serves several purposes:

- Ensure ease of assembly and installation of the entire system.

- Avoid cases of pipes sagging under their own weight and the weight of the transported medium.

- Prevent loosening of joints under the influence of vibration and thermal expansion of polymer pipes.

Based on this, two methods of fixing the pipeline to the wall surface are used: rigid and floating.

Hard

The method involves tightly crimping the pipe with a clamp and securely fixing it to the wall or floor structures. This method of fastening eliminates the movement of the element, ensures the immobility of the joints, and protects against the effects of vibration.

At the same time, the pipeline, including the sewer pipeline, is designed and installed so that the pipes can move freely within the boundaries of the normalized value of thermal expansion.

Floating

While cast iron pipes in a home sewer network are little subject to change, their polypropylene counterparts have a significant coefficient of thermal expansion. For example, PN20 pipes are capable of increasing in length up to 9-10 mm per meter when the ambient temperature increases to 70 degrees.

To compensate for such changes, movable fasteners are used. They are the same clamps. In them, the clamping of the pipe element is performed with incomplete tightening by bolts. There are options without bolts: such clamps simply snap into place, leaving a gap for the outlet to be secured. This method of fixation is called floating.

Which is better?

Fixed fasteners are used in heated rooms, where the temperature difference is small and does not lead to significant linear changes in communications.

In rooms without heating the situation is different. Here, the temperature difference inside the sewer channel and the environment reaches 50-60 degrees. The pipes will either get very hot or cool down to street temperature. Accordingly, their sizes will change depending on the material of manufacture. In this case, a floating fastener option in combination with fixed supports is the best solution.

At the same time, in practice the rule of alternating rigid and movable fastenings is used.

Why do you need to fix sewer pipes?

Correct and reliable operation of the sewer system depends on many aspects: the correct choice and proper quality of materials, error-free installation and fixation of the pipeline.

On the one hand, reliable fastening of the sewer pipeline to the wall helps to facilitate the installation of the system, and on the other hand, it reliably fixes the pipes and eliminates sagging and excessive movement of the pipe under the influence of the movement of wastewater. This is especially important at joints. If the pipe is not securely fastened, the connections will quickly become loose and, over time, lose their tightness. The smell from sewage, as well as liquid waste, penetrates outside and seriously poisons the lives of people in the room where the sewer pipe is leaking.

Attention! When installing a sewer system, it is necessary to pay attention to the quality of materials. In order for the system to work for a long time and be reliable, it is important to use high-quality fasteners.

Types of fasteners

Today, manufacturers offer a wide range of holders; you can purchase a set of different types for wiring of any configuration. First of all, they are divided according to the material of manufacture. They also differ in design and fastening technology.

Plastic

Plastic clamps and clips are used mainly for the installation of horizontal polymer bends with a cross-section of 5 cm. At the same time, ease of installation, reliability of fasteners and low price expand their use, both as fixed and floating fasteners.

Metal

Steel clamps are in demand primarily where strong and rigid fixation of the pipeline to the wall surface is necessary. To protect against corrosion, they produce fasteners[/anchor], as well as self-tapping screws for clips, with a galvanized coating.

Clips

This type of fastener is made of plastic and is intended for installation of lightweight polypropylene pipes whose diameter does not exceed 50 mm.

The clip is fixed to the wall through a dowel with a self-tapping screw, the outlet snaps into the holder's legs and is securely fixed. According to regulations, it is recommended to use clips when laying sewerage systems indoors.

Brackets

Used for fastening sewer channels in basements and crawl spaces. Metal brackets are welded to the floor using embedded elements and height-movable racks with clamps are installed on them, which allows you to adjust the slope of the laid branches.

Another use is to create the necessary distance from the wall. Special brackets create a minimum gap between the wall and the pipeline without compromising the reliability and tightness of the connections.

Hairpins

With the help of these elements and the corresponding dowels, the clamps are attached to the surfaces of walls and ceilings. They are a galvanized steel rod-screw with a thread. They are sold either complete with fasteners or separately, often with a suitable dowel.

Important! When selecting a stud, you are also guided by the thread size of the clamp.

Clamps

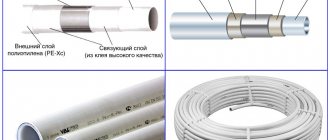

The design of the clamp consists of two galvanized halves of the ring, fastened with screw ties, and a mounting nut welded to the lower half-ring. A rubber gasket is placed inside the ring, which prevents damage to the polymer pipes when the ties are tightly tightened, and reduces the impact of vibration and noise.

This type of fastener allows you to tightly fix the pipe, secure it through dowels into the wall with studs or using anchors. The pipes will be securely fixed in both horizontal and vertical positions.

Very convenient for installation are polymer clamps, which are installed without drilling walls, using dowel nails (pictured).

Fixation of metal products

Fastening such parts is carried out using two methods:

- Metal clamps;

- With staples.

Fixation with staples is much cheaper than the first method, but it is not very reliable. Therefore, steel pipes are fastened with special clamps. In principle, its design is similar to the parts securing plastic pipes.

Its design includes a support installed in the wall using a dowel, which is connected to the support. The pipe is fixed to the wall with a removable semicircular part of the clamp that has a thread.

What's better?

Clamps seem to be more universal means of fastening. They can implement both rigid and floating fastening technologies. To do this, it is enough to adjust the tightening force of the screw connections.

They can handle any pipe diameter and are suitable for installing sewer lines made of both metal and polymer. The use of products with dowel nails increases the speed of pipeline installation by an order of magnitude, without in any way reducing the quality of fastening.

Ceiling and wall fixing options

Some installation features and expert advice

Fastening of sewer pipes is carried out taking into account the following features:

Fastening the sewer riser with clamps

- fittings and guide clamps are installed in areas of slopes;

- in areas where the system branches or makes bends, turns, as well as at joints, branches are required;

- floating, fixed and rigid clamps should be alternated with each other - this will ensure uniform load distribution.

Experienced craftsmen resort to a little trick when laying a pipeline - they install sewerage into shallow grooves on the wall. This allows you to increase the strength and reliability of the entire system and save on the number of installed elements. In addition, laying pipes in the wall channel will play an important role in the design of the room.

Related video: Pipe fasteners - how to choose

Publications on the topic

Options for fastening drainage systems

How to repair a hole in a concrete wall or ceiling

Selection and application of sealant for sewer pipes

Fastening rules and technology

Installation of sewer pipeline holders requires compliance with certain fastener installation rules and technological conditions.

- The attachment points are determined directly near the socket connections and branches in order to increase the rigidity of the pipeline (pictured).

- The installation of fixed fasteners is alternated with floating ones. At the same time, it is taken into account that between rigid fastening units the rules allow the placement of no more than two movable compensating connections.

- The distance and distance between rigid and movable holders must also comply with the standards. Thus, rigid supports on polypropylene pipes with a diameter of 110 mm are attached at a distance of no more than 2 m, floating ones - at a distance of no more than 10 branch diameters.

- On horizontal sections of the sewer system, the slope should be 20 mm for each meter of communication.

To Wall

Installation of fasteners is carried out in the following sequence.

- Using the wiring diagram, mark fixation points on the wall taking into account technological requirements.

- Installation begins from the bottom of the riser, where a fixed support is installed. Subsequent fasteners are made in such a way as to ensure alignment and verticality of all segments.

- When the riser is installed correctly, its deviation from the vertical axis should not be more than 2 mm per meter of pipe.

- Further fixation of the pipeline to the wall surface is done with clamps or clips (if the cross-section of the bends does not exceed 50 mm).

- Plastic and metal clamps are fastened using a self-tapping screw or metal pin with a fastening pitch for polypropylene bends - 2 m, metal-plastic - 1.5 m, steel - 1 m.

- In critical places where heavy elements of the system are located, rigid supports are used.

- Brackets are used to provide distances from the wall of waste pipes.

To the ceiling

Installation of sewer outlets along the ceiling is carried out in the basement and is carried out using the same methods.

Features are:

- Fixing clamps with anchors.

- The use is mainly of floating supports.

- Use of hanging fastener with strap.

- Minimum distance between holders.

To the floor

As a rule, cast iron sewer pipes are not attached directly to the floor. Polymer ones, in contrast, can become deformed and sag, which will affect the slope. If it is not possible to attach them to the wall, they are attached to the floor using plastic clips and galvanized screws.

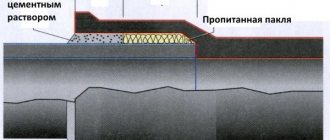

According to building codes, laying sewer outlets in the floors of residential and administrative premises is not allowed. In other places, it is possible to carry it along the floor using hidden wiring in the concrete screed.

Installing waste pipes along the floor is practiced in bathhouses, where they discharge wastewater into drainage pits.

In the basement

The basement is an unheated room. There is a high temperature difference here and the problem of thermal expansion requires resolution. Fixed supports in basements and technical undergrounds of buildings alternate with floating fasteners.

Fastenings often have to be made along the floor and to the ceiling; for this, various types are used: clamps with studs, hangers with punched tape, plastic holders with galvanized screws.

General system requirements

A single sewer riser must pass through all floors of the building. Pipes laid horizontally flow into it. They can be fixed to the wall at an angle that ensures adequate fluid flow in the channel. The magnitude of the slope is specified in SNIP and depends on the internal diameter of the sewer.

For a 50 mm channel, the minimum slope is 0.03. This means that for every meter of pipe a rise of 3 cm must be observed. For a 110 mm channel, the minimum slope is 0.02 (2 cm per meter).

From the vertical riser the drain is carried out into a drain of a larger diameter, which is located in the basement of the building. It drains water from the house to the external sewerage system. Pipes in the basement should be attached to the walls or ceiling.

Recommendations and common mistakes

If the walls are well leveled, it is more convenient to use clips to fix the plastic outlets. It is better to attach adjustable clamps to walls with uneven surfaces.

When choosing between plastic and metal clamps, take into account the appearance of the future wiring.

For floating fastenings, clamps with an internal cross-section that exceeds the outer diameter of the channels being laid by 1-2 mm are used.

The most common errors are related to failure to maintain the proper slope of the horizontal parts of the highway. Let us remind you that it must be at least 20 mm for each meter of bends.

It should also be noted that the slope needs to be constant all the time, it cannot be interrupted. Otherwise, a counter-slope will form, where dirt will begin to accumulate and a blockage will appear.

Types of fasteners

To reliably fix the sewer pipeline, it is necessary to select the correct pipes. Before you go to the store, you should study what types of sewer pipe fastenings are available:

Sewer pipe fastening - diagram

- crimp fasteners are used to fix the joint at the junction of the fitting and the outlet, this ensures a hermetically sealed connection between the structural elements;

- in places where the pipeline is installed on supporting surfaces, guide elements are used to position the elements;

- Sewer pipes are fastened directly to the wall using support fasteners. An additional installation element is rubber compensators that protect against vibrations;

- in difficult sections of pipeline laying, additional fastening is required to provide support for the structures. Safety pipes are used for this purpose.

If we consider the types of fasteners from the point of view of the type of fixation, then for the rigid version it is necessary to take support or crimping devices. Safety and guides are more suitable for floating mounts.

Rigid or floating fixation

Please note that there can be two ways to secure a sewer pipe with a clamp: screw the fastener tightly and make it absolutely motionless; leave the screws slightly undertightened to compensate for the thermal expansion of the pipes - this type of fastening is called floating. In this case, you can use the same clamps.

At the same time, there are types of fasteners on sale that are only suitable for free, floating type of installation. As a rule, such products do not have tightening bolts. However, they are attached much easier - with latches, so no special devices are needed for their installation.

The design of the clamps must have special gaskets. They are placed between the pipe and the clamping part of the clamp. The main task of such a gasket is to absorb noise resulting from the load on the sewer pipe and vibration from the movement of wastewater.

Having understood the types of fasteners and the main materials for clamps, we present several main rules that are relevant when installing fasteners on sewer pipes.

Step by step installation guide

When installing sewerage equipment, pipe sections are secured in the following sequence:

- With the help of fittings fasteners and joints, branches are laid to the heated zone. The pipeline is rigidly fixed.

- Floating support parts with linear expansion compensators are fixed. They will protect the line from vibration and deformation even with possible linear expansions.

- After drawing the sewer center lines on the walls, a pipeline is laid. According to the marks, guide fasteners are placed and the pipe is laid. The slope of the pipe sections and the number of fittings for the sewer system are also determined.

- Fittings are installed with fixation by support and crimp fasteners to avoid negative vibration and temperature effects.

- When installing a new system, the line is inserted into the clamp part in the form of the letter “U” and applied to the collapsible tie. The bolt clamp is tightened. Do not tighten the dismountable fasteners too much until the sewer system is completely installed.

- Supporting parts are mounted according to the number of joints and fittings. An empty area without shaped elements is secured with guide and safety clamps.

Even more reliably than clamps, the line is fixed in a groove, which acts as a channel for laying the pipe product. If you install the pipeline into a special channel in the wall, this will securely fix it and will not spoil the design of the room.

Modern fasteners are structurally adapted to make installation of them and the entire pipeline as a whole easy. Installing any type of fastening does not require the use of specialized tools or professional skills.