Today, polymer pipes are used in various fields. Polypropylene sewer pipes are very popular. Such products are distinguished by their versatility and high inertia, so they are ideal for any drainage structures. In addition, a wide range of such parts allows you to select suitable elements for different communications.

Polypropylene sewer pipes are suitable for all types of drainage systems

Features of polypropylene pipes for sewerage

The low weight of these products simplifies transportation and installation. Compared to their metal counterparts, they are incredibly comfortable. Metal pipes for the same purpose typically weigh 10–15 times more. Connecting fittings for polypropylene sewer lines are quite cheap, even when compared with other polymer parts. Docking the structure is also more accessible due to the ease of welding.

Polypropylene products have a low electrical conductivity coefficient, so even when laid in special environments (for example, saline soil), they will function without problems and will not fail over time. These pipes are also resistant to corrosion.

The smooth inner walls of the pipes do not allow debris to accumulate in the structure and prevent the formation of salt build-ups. Even with prolonged downtime of communication, the smoothness of the walls does not allow the system to clog. In addition, polypropylene products are resistant to aggressive substances.

If necessary, chemical cleaning of the sewer network can be carried out.

What raw materials are they made from?

All pipes from the original group are called polypropylene. The composition of raw materials may differ for different samples. For example, mineral or organic substances are added to the original polymer. This allows you to specify specific sets of properties.

The composition of raw materials is an important factor for those who want to choose the best option for polypropylene pipes. The most information can be obtained from the labeling. PPR80 is considered the most optimal solution.

Advantages

PP sewer pipes appeared relatively recently, but have already become widespread. This became possible due to a number of advantages over pipes made from other materials.

The high strength of PP pipes allows them to be used for a long time even under heavy loads, for example, underground

Main advantages of PP products:

- no need for painting;

- no need for thermal insulation of the structure;

- operating temperature 95 °C;

- corrosion resistance;

- low electrical conductivity;

- resistance to active chemicals;

- sound insulation;

- smooth walls;

- light weight;

- ease of installation;

- durability (up to 50 years);

Important! However, like any product, polypropylene pipes also have some disadvantages. When installing communications, special pipes are required. This is caused by the thermal expansion of parts. In addition, an increase in temperature in the system can harm polypropylene elements.

Standard parameters

When choosing communications for internal sewerage or external installation, the following characteristics are taken into account:

For internal sewerage, pipes of smaller diameter are used.

- tensile strength of the material - up to 35 N/mm²;

- yield strength - 25 N/mm²;

- roughness coefficient indicator - 0.00011;

- density varies from 93 to 95 g/cm³;

- the coefficient of linear expansion is higher than that of analogues with a reinforcing layer - 0.15;

- thermal conductivity is low - 0.24 W/m*K;

- resistance to fracture during bending - 1200 MPa;

- the material begins to melt at +149°C;

- range of wall thicknesses: from 18.3 to 2.9 mm;

- The average service life of external sewerage is 50 years, the internal pipeline lasts longer.

Taking into account the tendency of the material to expand under the influence of high temperatures, a gap is provided in the socket to compensate for the change in size.

Types of connecting parts for polypropylene sewerage

The range of polypropylene connecting elements for sewerage is quite diverse. Let's look at the main, frequently used parts:

- Removable bell. Typically used on pipes with a cross-section of 310 mm or more. The function of this element is to provide a socket joint.

- Transition pipe. Thanks to this part, pipes with different diameters can be joined. Such elements are designated by a letter and two numbers that correspond to the diameters of the products (for example, ∅ 50/75).

- Knee (abduction). This connecting element allows you to join two pipes at different angles. The elbow marking indicates the letter, the diameter of the product being joined and the angle at which the connection occurs (for example, ∅ 50/45).

- Clutch. Connection using these blanks eliminates the use of sockets. The ends of the couplings are equipped with special extensions, thanks to which the connection occurs.

- Tee. Allows you to connect three pipes. There are tees with different sections, so you can join products with different diameters.

- Cross. A connecting element that connects four pipes. They can also have different sections.

Pipes are connected to each other by couplings, bends, tees and other elements

Scope of application

Polypropylene pipes have many positive properties that allow them to be used when laying internal and external sewers. Such products are also actively used to create heated floors.

Less commonly, polypropylene is used to create external sewerage systems. This is due to its softness. However, due to the many advantages of polypropylene over other materials, modern manufacturers produce models that are corrugated on the outside. They are smooth from the inside, which eliminates the formation of lime deposits.

Polypropylene products are actively used when installing internal gutters. They are exposed to significant temperature fluctuations. For cold-type water supply pipes, pipes that can withstand a pressure of 1.6 MPa are used.

Technical characteristics of sewer PP pipes

As you know, the production of metal products is regulated by GOST parameters. The production of polypropylene products, in contrast, is regulated by technological documents. First of all, all polypropylene pipes are divided into:

- for pressure sewerage

- for non-pressure (gravity-flow).

The PP free-flow sewer pipe may vary in diameter (from 16 to 2000 mm). Pipes with a diameter of 2000 mm are used for laying external sewerage. The most common diameters are 50 and 110 mm. The first products are used in domestic internal communications, and parts with a cross-section of 110 mm are used for docking with the system riser. The length of such parts can vary from 2 to 12 meters.

Note! Pressure polypropylene sewerage has a larger range. In some cases, products for the pressure system are used when installing gravity structures.

The diameters of the pressure elements can range from 32 to 1600 mm. The length of such pipes can exceed 12 m. For pressure systems, as well as for non-pressure systems, the most popular cross-sectional sizes are 50 and 110 mm.

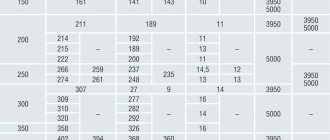

Characteristics of PP pipes for internal sewerage are presented in Table 1.

Table 1

| Du, mm | Length, mm | Wall thickness, mm | Weight, kg |

| 32 | 250–2000 | 1,8 | 0,16 |

| 40 | 250–2000 | 1,8 | 0,20 |

| 50 | 250–2000 | 1,8 | 0,26 |

| 75 | 250–6000 | 1,9 | 0,41 |

| 110 | 250–6000 | 2,7 | 0,86 |

In addition, all sewer pipes are usually divided according to the type of walls into:

- smooth;

- corrugated.

Corrugated pipes are stronger than smooth ones, so they are used in pipelines operating in difficult conditions

Corrugated pipes are incredibly durable elements. They are used for the installation of structures that are designed to transport wastewater in large volumes. They are also indispensable when laying communications in difficult conditions. In addition, corrugated pipes are resistant to mechanical stress.

About the quality and advantages of our product

Customers of the SanTexWorld store are offered external sewerage (Russia), which has been operating since 1999. It is one of the ten largest manufacturers of PE, HDPE, PP and PVC pipes in the Russian Federation. Its products were used in the construction of the Scarlet Sails residential complex, sports facilities for the 2014 Sochi Olympics and a number of other projects.

We chose the brand’s product for the following reasons:

- Reliability of the supplier - among the sewer pipe buyers working with our store are retail points of sale and small developers who require uninterrupted supplies. Their company provides;

- Stable quality - we have been on the market for a long time and we know that the composition of Politek pipes for external and internal sewage systems does not change from batch to batch. The material created by the plant is durable and not subject to defects such as color loss or cracks after several years;

- Average price - it fully corresponds to the quality. Thanks to the capabilities of Politek, its external sewerage pipes can be purchased at the same cost as good analogues from China.

Mounting options

There are several options for installing PP pipes for sewerage. Namely:

- Installation using sockets.

- Using welding.

- Connection using couplings.

Helpful information! Installing a sewer structure is not a very difficult task. In order to cut the parts into the required parts, you can use a regular knife.

The socket connection is the most popular and widely used when installing sewer lines.

Joining individual pipeline elements by welding requires a welding machine. During the high-temperature welding process, the ends of the pipes are soldered together, resulting in a strong, permanent connection. This is a very convenient option, however, dismantling such a structure is impossible without damaging the pipes. It is important to remember that the use of welding implies the presence of additional shaped products: bushings, plates.

An external sewer pipeline, as a rule, is installed using special couplings that provide reliable, socketless coupling of individual elements. If corrugated pipes are used when installing sewer networks, then their installation is carried out using special sliding elements. This design has high tightness due to the fact that it uses additional rubber seals.

Most sewer pipes are characterized by a socket type of connection.

Let's look at the stages of installation using socket connections:

Installation of a sewer pipeline using the socket method is carried out in several stages. These steps are the same for both smooth and corrugated pipes:

- First, a pre-measured section of pipe is cut. The cutting angle must be strictly 90 °C.

- Next, the cut should be processed until a chamfer with an angle of 45 °C is obtained.

- The resulting segment must be positioned so that the socket of the second pipe is opposite it.

- Next, you need to install a rubber sealing ring into the socket.

- At the last stage, you need to insert and join the resulting parts. It takes some effort to do this.

Note! If it is necessary to connect several parts at different angles, a variety of fittings are used. Installation of fittings can be done using special glue.

Thanks to this type of joining of polypropylene sewer pipes, reliable and durable connections are obtained. Ease of installation makes this type of installation the most popular. In order to carry out installation work, you do not need to have special construction skills. It is enough to follow the above instructions.

Some numbers

- The density of the polymer is 900 kg/m³, but at the same time its weight is small, and installation of the system will not take much time.

- The high viscosity of PP makes it possible to absorb impact energy at a high level, so the degree of withstanding mechanical loads is quite high.

- The temperature at which PP drainage can be used varies in the range – 15ºС to +140 ºС.

- The chemical inertness of polypropylene according to GOST allows for disposal through the wastewater system, which contains up to 60% sulfuric acid.

- During the heating process, PP acquires plasticity, which makes it possible to produce segments with a diameter of 16 – 1200 mm.

- Raw materials for the manufacture of pipes are determined by GOST 26996-86. Non-pressure pipes are suitable for sewerage.

conclusions

Sewage pipes made of polypropylene are lightweight, durable, flexible and resistant to chemicals. They are often used when installing water pipes and drains. Polypropylene pipes are also used to create utility networks. The many positive properties of this material ensure its popularity among private developers. Buying polypropylene pipes is economical, and they will last for decades.

Recommended Posts

Cast iron bathtubs

Sewerage in a country house: septic tank

Adjusting the pressure switch for the hydraulic accumulator

Install automation on the pump

Installation of storm drainage systems in apartment buildings

Sewage system in a private house