Device and installation tips

In order to improve the operation of the sewer system and protect yourself from the penetration of unpleasant odors, experts advise installing fan ventilation also in one-story buildings. The work itself does not require special knowledge and skills and can be fully implemented on its own. The fan ventilation system itself consists of the following elements:

- Ventilation duct (it goes from the riser to the roof; the vent pipe will be placed in that direction). Such an element should be provided at the stage of building a house. If it is not there, the removal of fan ventilation may “persistently ask” you for enormous financial and physical costs.

- Connecting pipes and fittings (they are needed to connect to the sewer riser).

- The fan pipe itself.

When creating a ventilation system using a vent pipe, you should follow the following tips from experts:

- The most serious thing is that the diameter of the fan pipe is equal to the cross-section of the riser. In addition, experts advise using the same type of materials (polymer or cast iron). If you do not want to make a fan pipe from cast iron (this material is quite heavy and difficult to install), then you must use a rubber adapter as a connecting element.

- It is allowed to connect a pair of fan pipes. Along with this, you need to use sewer plastic tees with an angle of 45 degrees.

- In addition, it is allowed to change the direction of the fan pipe (using the same tees). Along with this, the place of direction transformation should be located above the topmost plumbing unit.

- Some sections of fan ventilation will be able to run horizontally. In this case, it is necessary to maintain a small slope towards the exit of gases, it should be 0.02%.

In addition, experts advise fulfilling the requirements that apply specifically to the drain pipe itself. Among them it is possible to highlight the main ones:

- When installing a vent pipe onto the roof, you need to follow the advice on its height above the roof. This indicator should range from 30 to 50 cm.

- When the house has an attic space that is used for residential purposes, the pipe should be raised to 3 meters.

- To prevent odors from the sewerage system from entering the room through windows and balconies, the distance from the pipe to these elements must be at least 4 meters.

- you should take care of insulating the riser or pass it through heated rooms.

- Since plastic pipes are used much more often for arranging fan ventilation (due to ease of installation), they must be protected from mechanical action. When laying pipes through floors and roofs, iron sleeves are used.

- If your house is equipped with a chimney system, then installing a chimney pipe in the same ventilation duct is not allowed.

- To protect against insects and small debris from entering the sewer, it is worth equipping the pipe outlet with a mesh.

Some buildings with a huge area can accommodate a couple of plumbing units located in different parts of the building. In this case, in order not to pile up the roof with countless pipes, it is possible to combine all the risers into one fan ventilation; it is best to make connections in the attic. This is done using sewer tees of the same diameter as the pipe. At the same time, remember to tilt towards the exit of gases.

Life time

Caps for ventilation pipes have a long service life if they are not subjected to strong mechanical stress (hurricane wind, falling branches). Products made from asbestos cement and steel last 10–15 years. Modern models, based on polymer plastic with UV protection, are designed for a long service life - 50 years. Their service life depends on several factors:

- corrosion resistance;

- product thickness;

- the presence of a container for collecting moisture;

- the quality of the installation performed;

- insulation of the ventilation duct with heat-insulating materials.

Modern models of fungus can last up to 50 years

Installation and repair of drain pipes

Installation of fan pipes is carried out according to the following scheme:

If the installation is carried out on an old riser, you will have to first disassemble the drainage system and, if necessary, replace the pipes with those that provide such a structural element. When choosing a fan pipe, take into account the diameter of the riser

This is important for the disposal of large volumes of wastewater. Installation of fan products is carried out at the extreme support point of the riser. This is the foundation level

It is first necessary to make a hole of the required size in order to connect the drainage system to the roof. It is forbidden to combine a fan hood with a gas one, as this can lead to an explosion. They install the plumbing unit and only finally install the fan pipe and check valve. Seals of corrugated parts, if any, are pre-lubricated with soap or silicone to facilitate installation. To fix fan pipes, only metal clamps are used. They are reliable and able to compensate for small deviations from the markings. To soundproof the structure, use foam or insulation, fixed with clamps. In the first case, repair and dismantling of the site becomes difficult.

When installing fan products, it is recommended to take into account that the outlet to the roof must be of sufficient height (below 50 cm) and placed on the leeward side of the building so that unpleasant odors do not fall to the ground. The structure is placed in a warm room, and its output is placed in a cold room. This will further encourage air movement in the right direction.

Structural repair includes dismantling old parts and installing new parts.

All risers in the house are connected to one fan pipe. On the rest, a check valve is installed. When a large volume of wastewater is discharged, a vacuum appears inside the valve, due to which it draws air from the room. Once the pressure has stabilized, the spring mechanism closes the valve.

Types, shape and designs

Depending on the room in which the fungus is installed, a regular or heat-resistant type of structure is selected. Regular hoods are suitable for the bathroom, toilet, kitchen and basement area, cellar. Heat-resistant fungi are mounted on pipes exposed to heating and installed in the boiler area.

The volume of gas removed from the room determines the size of the air duct and fungus. The diameters of the structures are different, they range from 1–3 cm. The simplest option consists of a pipe and an umbrella made of sheet metal. More expensive models are practical and aesthetically pleasing and include a larger set of elements (a glass for excess moisture, thermal insulation material). Both types of ventilation fungi are installed on the roof and secured with fasteners.

Types and forms of fungi

When does a drain pipe need to be replaced?

After years of use, the sewage system begins to bother the owners of houses and apartments with too frequent blockages and the constant penetration of an unpleasant odor into the living space. This is a sure sign that the drain pipe will need to be replaced.

Installation of a drain pipe

Replacement of the ventilation riser is carried out in accordance with the design documentation and consists of the following stages:

- Dismantling of the old pipeline;

- Installation of new system elements.

Replacing plastic elements is a fairly simple procedure; you can do it yourself. If old cast iron pipes are installed on the riser, this makes replacing the device somewhat more difficult.

Dismantling a cast iron sewer is a complex task that requires skill and dexterity. In addition, the heavy weight of the pipeline (about several hundred kilograms) can injure a person if handled incorrectly. That is why such a replacement must be carried out by a specialist.

Conventionally, the dismantling process can be divided into the following stages:

- Make sure the drain pipe is completely disconnected. In practice, in an apartment building, this means notifying all neighbors of the need not to use the plumbing facilities for some pre-agreed time.

- Phased disconnection of all sewer lines that go to the riser. You will need a grinder, a sledgehammer and considerable physical effort.

- This completes the dismantling.

Installation of a drain pipe

Next, the actual replacement is carried out - the installation of new system elements. The best option for a sewer riser is a drain pipe made of polymer materials; it has a number of important advantages:

- Light weight, which significantly speeds up and simplifies the installation of the internal sewerage network;

- Complete chemical inertness;

- High level of sound absorption;

- Long term of use;

- Low cost.

If several sewer risers are installed in a private country house, as a rule, the drain pipe is mounted on one of them, and a check valve device is placed in all the others. Externally, the riser can be hidden in a specially equipped box, but it is worth providing a place for inspection.

What it is

When a private house is built, it is necessary to connect various communications to it. One of them is sewerage. At first glance, you might think that it is enough to equip it with only a sewer drain. In fact, this is not enough.

In order to explain the purpose of the vent riser, you need to remember how the toilet flushes in more detail. After the sewage is drained, a certain amount of water then gets there. Some of it remains in the toilet. It is actually a water seal, the role of which, in particular, is to prevent the unpleasant odor from the drains from entering the living quarters

It is important to understand that this protective layer of water is located inside the toilet.

If several such plumbing fixtures are installed in the house, then each of them, which is not currently in use, has such a water seal.

When one of the toilets is flushed, the pressure drops for a short period of time immediately after the sewage and drained water flows out. Since all the others are connected to this pipe, their water seals are broken and an unpleasant odor penetrates into the premises.

Diagram of the design and operation of the sewerage ventilation systemSource profidom.com.ua

It is important to note that this situation exists not only in relation to toilets, but to all drains that are connected to the sewer system. For example, we can talk about a water seal in a bathroom or in a sink, if they are connected in the specified way. This situation could be avoided if the pipe had an additional outlet through which air could freely flow into it

In this case, low pressure would not arise at the drainage point and the water seals would not be broken anywhere.

This situation could have been avoided if the pipe had an additional outlet through which air could freely flow into it. In this case, low pressure would not arise at the drainage point and the water seals would not be broken anywhere.

Odors from the sewer could also escape through such a pipe. A sewer riser is a pipe that performs the specified functions, which is connected to the sewer system of the house and led outside it.

How necessary is it? In fact, the system in question is actively used in apartment buildings. In the sewer system, drainage from apartments occurs in a vertical pipe.

A system of vertical sewer pipes that performs the function of a drain riserSource ar.decorexpro.com

Its lower end is connected to the drainage system, and the upper end is brought out onto the roof and actually serves as a drain riser.

Technical requirements

The outlet pipe does not have any specific diameter requirements. Typically, a pipe similar to a sewer pipe is used for this purpose in apartment buildings.

Let’s assume that in a private house, a pipe with a diameter of 5 cm is used for drainage from the sink, the opening of the flush tank is 7 cm, and the pipe from the toilet is 10 cm. In this case, a drain pipe on the roof with a diameter of 10 cm can be used for the drain riser.

Practice confirms that such a pipe is sufficient to ensure constant pressure in the drainage system and to provide ventilation in it. If we are talking about a one-story private house in which only one toilet is installed, then here you can do without installing a vent riser.

Air supply and exhaust system Source gardeneer.me

This is due to the fact that the drain in this case will not be able to create a strong enough decrease in pressure so that unpleasant consequences can be felt.

However, in some cases, roof risers are necessary:

- If the house has at least two apartments with fully equipped sewerage systems, provided that they are connected to a common network.

- A sewer outlet to the roof for ventilation of the riser is required in a house with more than two floors .

- If there is an equipped horizontal sewer distribution system , provided that three or more plumbing fixtures are connected to it.

Fan exhaust pipe on the roof Source teplogidromash.ru

It is also necessary to provide:

- risers usually have a diameter of 10 cm, however, sometimes there are situations when a pipe with a diameter of 5 cm . Then the outlet of the vent pipe to the roof is mandatory .

- If the house has a swimming pool that discharges water into the sewer system , the use of the design in question is also necessary . This is due to the fact that in such a situation a large amount of water can be discharged.

- A vent riser and access to the roof are needed in cases where the drainage occurs into private septic tanks located next to the house .

- If the house is one-story , but the bathroom and toilet are located on different levels, and the drainage occurs in one pipe .

Fan pipe with outlet to the roof Source forumhouse.ru

See also: Catalog of companies that specialize in water supply and sewerage.

Metallurgical products

Metal devices, when arranging sewage systems in private and apartment buildings, have been used for a very long time, but have not lost their relevance today, due to the following positive characteristics:

- cast iron alloys have a high level of strength, and the rigidity and density of the metal structure allows for safe and uninterrupted operation of the drain pipe for a long time;

- increased wear resistance allows the use of metal fan pipes in regions with unfavorable climatic conditions;

- the material is very resistant to mechanical damage and can easily withstand even significant external loads;

- metal fan devices are impervious to ultraviolet rays and are suitable for installation for long-term operation in open space conditions.

The disadvantage inherent in any metal sewer drainage devices is their susceptibility to corrosive changes, to prevent which special treatment of the material is carried out.

Protective treatment can be galvanizing or spraying.

Among other things, such pipes, as a rule, have significant weight, which complicates transportation to the installation site and installation.

The main disadvantages are considered to be the high cost of metals, the need to purchase special fittings and the use of special equipment during installation.

Check valve for waste riser

The design of a standard vent riser assumes that the pipe is led out to the street most often through the roof. It does not require any additional devices to help it function normally. However, for a number of reasons, it may be necessary to install a riser that does not have an outlet to the roof. In this case, you cannot do without a special device called a check valve. The design is equipped with two holes with air-tight cuffs.

The device operates very simply. Weak springs installed under the cuffs are compressed when a vacuum occurs in the system. The holes open and the valve begins to suck in air, thereby equalizing the pressure in the riser. As soon as it returns to normal, the valve closes. The device not only prevents unpleasant odors from appearing in the room, but also prevents:

- entry of mechanical impurities into the system;

- return of wastewater to plumbing equipment;

- entry of rodents into the premises.

There are several types of check valve. The device can be mounted outside or inside the drain pipe. Internal installation requires the installation of a special insert, which is not included in the kit and must be purchased separately. Before installation, the pipe is thoroughly cleaned of possible contaminants and degreased. The valve is placed in the direction opposite to the movement of the drains, so that the petals are bent towards the plumbing equipment.

A check valve or, as it is also called, a vacuum valve is installed on the drain pipe. In this case, there is no need to bring the structure to the roof

Is it necessary to put it on the roof?

Sometimes in apartment buildings, residents of the upper floor themselves dismantle the riser pipe leading upward.

Check valve operation diagram Source ufa-santehnik.ru

The motivation for this decision is insufficient knowledge of the principles of sewerage operation and the idea of a drain riser as something superfluous and unnecessary. Soon after this, a persistent smell from the sewer pipe appears on the upper floors.

The situation can be improved. In this case, there is no need to install vent pipes on the roof. It is enough to attach a special valve to it. It will not release air outside, but when a low pressure zone forms, it will let air in, which will prevent the water seals from breaking.

There is no need to put such a riser on the roof. The valve must be installed at the top of the sewer pipe system. Although this is convenient (there is no need to install a pipe passing through the roof), such a device is not highly reliable.

Vacuum valve for installation at the top of sewer pipes Source drive2.ru

Fan pipe placement

There may be several options for placement and it is better to think in advance about how ventilation will be arranged in your house, but there may also be cases when a septic tank is installed, the house is built and the outlets for the bathrooms are planned. What should the homeowner do in this case?

Of course, the first installation option is most preferable, as shown in the picture. There is no need to install a fungus on the riser, as condensation can freeze on it and block the pipe as a result of rising warm air. But care should be taken to install a device to protect the pipe entrance from precipitation. If the ventilation riser is located far from the toilet, then it is necessary to install a sewer check valve on this plumbing fixture.

It is not advisable to place the pipe outlet under the eaves, because the draft may decrease. If you bring the riser under the roof overhang through the wall, in winter the pipe may fail as a result of snow melting. It is also not recommended to install a pipe outlet in the attic, since the presence of unpleasant odors there will not be a pleasant sensation if you need to climb there, and it can also penetrate to the lower floors.

It is advisable to extend the vent pipe up onto the roof, at least 30 cm, as close as possible to the ridge, so that when the snow melts from the roof, it does not tear it off. It is intended both to protect hydraulic locks and to ventilate sewer pipes. If the height of the house is more than 2 floors and there are long horizontal internal sewer lines inside it, then the installation of a second vent riser will probably be required. The riser is made as straight as possible, because the ventilation is not forced, but gravity-fed; narrowings and bends should also be avoided - they can create resistance to air flow.

Carrying out installation

When installing a riser, it is important to pay attention to some points:

- There is no need to underestimate the diameter of the outlet pipe. If it is too narrow, then its thickness may not be enough for quality work. A pipe with a diameter of 100 mm is most suitable for this purpose.

- The horizontal part of the sewer system should not be located at the same level . In this case, there is a risk of water or air locks forming. It is recommended that the pipe be installed with a slight slope . It is usually considered sufficient to use a slope of two centimeters per meter of length for this purpose.

- Sometimes when installing the system, the riser is led not to the roof, but to the attic . This is strictly not recommended. Exposure to escaping air insulation to become saturated with moisture. Another consequence may be rotting of the rafters.

- a deflector is sometimes installed on its hole . It will protect against precipitation and random debris. Additionally, its effect in windy weather will be expressed in increased traction . But there is another opinion. It is believed that this or another additional device installed above the pipe opening contributes to the formation of condensation , which in frosty winter weather will lead to icing of the pipe from the inside. As a result, it will be partially clogged and may cease to perform its functions.

Example of an L-shaped fan pipe Source allremont59.ru

When carrying out installation, you need to consider:

- to move the sewer riser pipe away from the vertical sewer drain. If for some reason this is difficult to do, then the transition connection is best made using corrugated pipes.

- It is believed that the height of the pipe above the roof should be 50 cm . It is recommended to locate the roof exit at a distance of at least 4 meters from balconies or windows.

- The reliability of the system will be higher if you install a check valve. It is installed where the drainage into the public sewer pipe. Its effect is that drains from an apartment or house pass freely , and gases and liquids the opposite direction at all.

Installation sequence

Installation of the drain pipe should be carried out only after familiarization with the design. The installation of this element should be considered at the design stage of internal utilities. For better ventilation performance, it is recommended to make fewer bends and slopes in the system.

Ideally, a sewer riser installed in a private house should be in a vertical position. The pipe is led out, bypassing the ceilings, straight to the roof. But, as practice shows, this is not always possible. In the case of some country houses, the use of additional elements for connection is required.

It is also practiced when several risers are connected to one air duct. Installation of such a plan is more in demand, since thanks to this, air pressure is evenly distributed throughout the system.

climate control equipment or with a carbon monoxide removal system

It happens that the air riser breaks and the drain pipe needs to be replaced. The principle of operation is similar to how other parts of the system are repaired. The main difference is the materials from which the elements were made and how they are connected.

Replacement of an element must be carried out subject to certain conditions:

- When dismantling work is carried out, the house must have good ventilation.

- When starting to replace an element, you should wear a respirator and rubber gloves.

- After completing the work, you should make sure that the system remains tight.

If different materials are combined, for example, plastic and cast iron, it is important to use a rubber adapter.

The fans are connected at angles of 45 and 135 degrees. The horizontal section should have a slope of 0.02% in the direction where the gases escape.

How does a fungus work?

Initially, the roof fungus was made of galvanized steel. Especially popular are designs made of impact-resistant polypropylene, which is slightly exposed to the sun, frost, and corrosion. In some types of hoods, the inner tube is made of a steel alloy. The ventilation fungus includes a number of elements:

- 2 pipes (for gas removal, fastening with a horizontal section of the air duct);

- fastening units (flanges);

- container for condensate accumulation;

- an air valve responsible for the necessary air circulation;

- rings for support, fastening;

- aerator (a device that saturates the room with oxygen);

- deflector (a device that increases the draft of air flows);

- valves

Ventilation fungus on the roof

Types of products

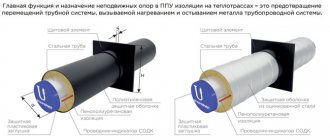

The classification of fan pipes into types is carried out according to the materials of manufacture, according to which polymer and cast iron products are distinguished. Cast iron, by and large, is practically not used now - it is a relic of the Soviet era; such solutions can be found in multi-storey buildings in which major sewerage repairs have not been carried out.

The cast iron fan pipe has a number of serious disadvantages, the main ones being heavy weight, high cost, and labor-intensive installation. In terms of performance characteristics, it is completely inferior to plastic products; its only advantage is durability and high mechanical strength.

A plastic sewer pipe can be made from two types of polymers - low-density polyethylene (HDPE) and polypropylene (PP). We recommend using products made from HDPE - this is one of the most rigid types of plastic, which has high crack resistance and resistance to deformation.

Let's consider the advantages of plastic fan pipes:

- minimum cost;

- low weight and, as a result, ease of installation;

- durability – service life over 50 years;

- resistance to chemically aggressive substances;

- resistance to corrosion.

Note that due to the perfectly smooth inner surface of the pipe, with rare exceptions, it does not need sound insulation, since the sound of air circulating through the system is not audible.

Basic noise insulation is carried out by installing the line using damping clamps with a rubberized fixing ring that dampens vibration. If practice shows that the fan pipe produces a lot of noise, sound insulation can be made using sleeves made of foamed polyethylene or mineral wool.

Installation and replacement

The fan pipe is installed so that the lower part of the riser is placed in a heated room and the upper section is exposed to the open air. In this case, the pressure drop caused by the temperature difference will ensure effective removal of sewer gases.

When installing a drain pipe, you must follow the following rules:

- You cannot use a drain pipe whose diameter is smaller than the diameter of the sewer riser (standard – 110 mm);

- if a plastic pipe is connected to an old cast-iron riser, a rubber adapter must be installed at the junction to ensure the tightness of the entire system;

- several risers of an apartment building can be connected to one fan ventilation channel using adapters and bends; in this case, the horizontal parts of the line must be laid with a slope of 2% from the plumbing fixtures;

- the minimum distance between the roof of the building and the upper opening of the drain pipe is 30 cm; if the attic of the building is used as a living space, the distance increases to 3 meters;

- the outlet point of the waste sewer pipe should be 4 meters away from the nearest balcony;

- when installing plastic products in places where they pass through the concrete floors of a house, steel sleeves must be installed;

- It is strictly prohibited to combine fan ventilation and smoke exhaust into one channel;

- It is necessary to install a fan fungus on the outlet hole, which will prevent insects and leaves from entering the system.

Fan pipe on the roof of a house

Replacement of drain pipes in multi-storey buildings is carried out by responsible representatives of housing and communal services, since the drain part of the sewer system is located outside the residents' apartments.

You can repair the riser yourself, the cast iron parts of which can rot during operation and cause serious problems in the apartment. Repairs must be coordinated with neighbors higher up in the house, who must not use the bathrooms during the period of replacement of areas.

Sewer riser replacement technology:

- The water supply to the toilet is shut off and the toilet drain hose is removed.

- The toilet is dismantled, the room is cleared of foreign objects.

- Using a hammer, chisel and grinder, the damaged part of the riser is dismantled - this is an extremely labor-intensive process that can take more than one hour of work.

- Rubber cuffs are installed on the end parts of the old riser, secured with sealant.

- A new riser is assembled from plastic segments with a diameter of 110 mm, which is equipped with an additional socket for connecting drain pipes from the toilet, bathtub and sinks.

- Plumbing fixtures are supplied to the riser via corrugated plastic pipes installed with a slope of 5 in the direction of the drain.

Material of manufacture

Fan riser and plastic pipe

Since the riser outlet is one of the components of the in-house sewer system, the same materials are used for its production as for other wiring elements. Mainly cast iron and plastic pipes are used. The former have high strength, but when defects appear, they begin to collapse due to corrosion. In addition, it is quite difficult to strengthen a heavy cast iron pipe in a vertical position.

An alternative option is the use of polymer pipes. They are durable and lightweight, do not corrode and have a low cost. Installing a sewer system using plastic pipes and fittings is much easier than connecting cast iron elements. The advantage of polymer products is their smooth internal surface, which eliminates silting of the pipe system. Cast iron products are rough on the inside, which is one of the causes of operational blockages.

For normal operation, the diameter of the fan pipe must correspond to the largest cross-section of the pipe connection. According to SNiP rules, toilets have the largest diameter of pipes for connecting to the drainage system: 100-110 mm, therefore, the outlet pipe must have a cross-section of the same size - 110 mm.

Purpose of the fan riser

Installing a sewer drain is an ideal way to solve this problem. This is what we will talk about in this article.

According to current construction standards, it is allowed to install a sewer system without sewer lines in low-rise buildings. But sometimes installation of a sewer system is still required in such houses. This is necessary in the case of simultaneous use of a bathtub and toilet, when draining a large amount of water at a time, that is, when the volume of a single drain completely covers the cross-section of the sewer riser.

The toilet is installed on a pipe with a cross-section of 110 mm, and the diameter of the tank drain hole is 70 mm. The combination of the bathtub and the sewer has a cross-section of 50 mm. That is, when draining only a bathtub or only a toilet, the diameter of the sewer communication is not completely blocked. Plumbing fixtures and household appliances (such as washing machine drains) create small volumes of one-time waste. Therefore, if the house has one toilet and a bathroom, a sewer pipe can be installed at the discretion of the owner.

A drain pipe is required in the following cases:

- When a house has more than two residential levels (floors), and each of them has bathrooms;

- When a pool or equipment is installed in the house that can release a large one-time volume of waste;

- If a sewer riser with a cross-section of 50 mm or less is installed;

- If a septic tank is installed near the house.

Why extend the riser to the roof?

Figure 1. Sewage system in an apartment building: 1 - Exhaust ventilation pipe; 2 - Riser; 3 - Bath; 4 - Washbasin; 5 - Sink tank; 6 - Toilet; 7 - Outlet pipe; 8 - Revision; 9 - Sink or sink in the kitchen; 10 - Hydraulic valve; 11 - Floor siphon; 12 - Issue; 13 - Inspection well from the yard network; 14 - Yard network; 15 - Control well; 16 - Connecting well; 17 - Inspection well of the street network; 18 - Street network.

Of course, we will talk about the ventilated part of the sewer riser - the decompression or vent pipe. It is designed to serve as a connecting element between sewer communications (centralized or local) and the atmosphere. The vent pipe helps solve two extremely important problems:

- Compensation for decompression, that is, the vacuum created by the flow of waste liquid moving inside the pipe (Figure 2.1). The magnitude of the vacuum can reach emergency thresholds, at which water is sucked into the sewer from the water seals of sinks, shower trays and even toilets. Of course, decompression may not reach a critical level with insignificant water removal. However, during large volley discharges from several plumbing points, the waste flow can almost completely block the cross-section of the pipeline. Such a water “piston”, falling inside the riser at high speed, will cause a significant decrease in pressure in it. The result is broken water seals of siphons, which cuts off direct access of harmful stench from the sewer to the premises.

- Free removal from sewers of gaseous products resulting from the breakdown of human waste (Figure 2.2). Conditions of abundant moisture, heat and organic matter are almost ideal for the development of a variety of microorganisms. When processing organic raw materials, they release significant volumes of gases such as methane and hydrogen sulfide. Their concentrations in a confined space are fire and explosive, and accidental entry into a living space can pose a serious threat to human health.

Purpose of the drain pipe

A sewer riser is relevant if the house is two-story or equipped with two or more bathrooms, which will ensure stable pressure in the system.

With the help of this element, the riser is connected to the atmosphere, which allows maintaining stable pressure.

Sewage without a drain pipe is not allowed if there are more than two toilet rooms in the house. The rule applies in the following situations:

- A two or more level house, where each floor has a sewer system and water supply.

- The cross-section of the sewer riser has a diameter of 50 mm.

- The building contains a swimming pool or water handling equipment that consumes a significant amount of liquid and discharges it as waste.

- The septic tank is installed near the house, and you need to be aware that this can lead to unpleasant odors.

In a word, a toilet drain pipe is required in order to stabilize the pressure in the pipeline and maintain the quality of water drainage. Installing the element helps prevent blockages and stagnation of the sewer system. The sewer riser begins to function many times more efficiently, and this provides protection for the system from waste water return in large volumes.

Some tips

To install a fan riser, you should pay attention to the following:

- When bringing the pipe to the roof, you need to cover the hole with a grill . This is necessary to protect against birds.

- Sometimes when this system operates, a low, unpleasant noise . In order to get rid of it, you will need to wrap the pipe with a soundproofing coating.

- It is not always possible to bring from each to the roof . In this case, you can provide one pipe for several risers .

Options for exhaust pipe outlets Source td-intech.ru

When is it necessary to install drain pipes?

Based on standard building codes, a sewer riser in a private house may not be installed if:

- the building has no more than two floors;

- a small number of plumbing points;

- small volumes of wastewater over a certain period of time.

If the amount of wastewater simultaneously covers the entire diameter of the installed sewer line, then installing a ventilation system is necessary.

This situation may arise if in one house they simultaneously flush water from a full toilet tank and a filled bathtub into a small-diameter sewer. However, if the diameter of the waste line is more than 110 mm, then the occurrence of vacuum in the system is practically excluded.

According to the standards, a sewer ventilation pipe in a private house must be installed in cases where:

- The building has two or more floors and each of them has a bathroom.

- The building has a swimming pool.

- The sewerage system is connected to a closed septic tank.

In multi-storey buildings, the installation of such ventilation is mandatory, regardless of the number of bathrooms and the diameter of the sewer lines.

Basic installation rules

In modern construction, there are two main options for installing ventilation. In the first option, the diameter of the drain pipe must be greater than or equal to the diameter of the sewer pipes; in the second option, the diameter may be smaller, but the end section must have an outlet to the atmosphere and ensure rapid removal of unpleasant odors.

In most old multi-storey buildings, a cast iron drain pipe is installed, which is closely connected to the main riser and is an integral part of it. Modern buildings use newer materials made of high-strength plastic, which greatly simplifies the installation of sewage systems and weighs significantly less.

In some cases, it is possible to install ventilation with an exit through the wall, where the exit hole is closed from the outside with a decorative grille or fungus. If a private house uses one sewer riser, then the ventilation is vented to the roof of the building and a fan valve is installed on it, which prevents the reverse direction of air flow and ensures the removal of unpleasant odors.

Expert advice

Craftsmen with extensive experience in installing sewer systems and ventilation advise using several recommendations when arranging the system:

- The drain pipe on the roof should not be lower than 50 centimeters from the roof, otherwise wind turbulence may be created that will disrupt the work.

- The ventilation line must have the same diameter as the sewer riser pipe.

- If the house uses two or more risers, then they can be combined by one air line in the upper part so as not to spoil the appearance of the roof with many ventilation pipes.

- It is strictly forbidden to combine vent pipes with natural ventilation ventilation shafts.

- The external exit must be located no closer than 4 meters from the nearest window or balcony.

Using the tips and recommendations listed above, you will be able to install ventilation on sewer risers yourself, while avoiding many common mistakes.

Do-it-yourself manufacturing and installation

A roof hood for roof ventilation can be made at home, using tools and materials at hand. To do this, it is enough to take two metal pipes (larger and smaller diameter), a flat disk, and a welding machine.

The source material is selected depending on the size of the air duct. Installing fungus will require intervention not only in the ventilation, but also in the roof of the building. A hole is cut in the roof pie through which the pipe is routed. The vent fungus is installed on the top of this air duct pipe.

Material selection

The service life of a roof cap is determined not only by the quality of installation, but also by the choice of material for its manufacture at home. When preparing for work, consider the following:

- the main pipe must be made of polymer plastic or stainless steel;

- it is better to make ventilation hoods from plastic (high temperatures will lead to a change in configuration);

- opt for fasteners made of aluminum and stainless steel (they are not subject to corrosion);

- exclude wood, sand-lime brick, black steel and asbestos cement as the starting material (they quickly collapse).

Calculation of dimensions

Exhaust hoods are installed in the roof of the building, completely eliminating the possibility of smoke from a working furnace getting into them. The internal cross-section of the fungus is taken into account: it must be no less than the cross-section of the supply channel. For example, the diameter of the flue is 30 cm, then the cross-section of the hood should be the same. The cap installed on the roof slope should rise by more than 20 cm. When using the roof as a recreation area, the pipe is raised by 2–2.5 meters.

Installation features

An ideal ventilation system includes several air passages that exit in a strictly vertical direction without horizontal bends. When installing a ventilation outlet, the following algorithm of actions is observed:

- A hole is cut in the roof of the building (metal shears or a reciprocating saw are used for this), and a metal gasket, pre-sealed with liquid sealant, is mounted on top of it. The gasket is attached with self-tapping screws.

- A special adapter is installed on the gasket, which will henceforth protect the outlet from the penetration of precipitation and secure the cap.

- The fungus is mounted inside the adapter, inserted into the air duct pipe, secured with bolts and nuts.

- Using a building level, the verticality of the installed fungus is checked.

It is advisable to install the air duct pipe with the ventilation fungus at the highest point of the roof. This will provide strong draft and air circulation. The best option is the ridge of the building, which separates the parts of the gable roof. If this option is not possible, the fungus is located as close to the ridge as possible. The ventilation outlet, located far from the ridge, is equipped with a tall fungus. Insufficient height of the structure will lead to low pressure in the pipe, resulting in ineffective ventilation.

Possible mistakes

The most common mistake when installing a fungus is the lack of insulation on the ventilation duct and the product itself. Basalt wool is often used as insulation; a stainless steel cylinder is fixed on top. Another option is to cover the channel with construction foam. Other errors are possible when installing the exhaust hood:

- joints are not sealed with special means;

- materials that are susceptible to corrosion are used as materials for ventilation ducts;

- pipes that come out of rooms at different levels are connected into a single passage;

- An unsuitable place is chosen for the ventilation fungus.

A ventilation fungus is a metal or plastic product that resembles a mushroom and is installed on the roof of a building. It protects the outlet pipe of the air duct from precipitation, increases draft in ventilation (removes polluted air, carbon dioxide and other gases).

Self-installation of a ventilation hood is not particularly difficult. The main thing is to follow the installation rules and select a high-quality exhaust fungus. You can use a ready-made factory design or make a ventilation fungus with your own hands. Correct calculation of dimensions and selection of suitable material is the key to effective ventilation, which will ensure a healthy and comfortable microclimate in the room.