Owners of apartments on the top floors of apartment buildings, as well as owners of private low-rise housing, often express their displeasure about the thick pipe in the toilet that spoils the interior, going into the ceiling and then onto the roof. The liquid does not drain through it - the drainage is carried out below, so some people want to get rid of this bulky structure for the sake of aesthetics. Is this possible, and in what cases? Why is this pipe needed at all? Let's try to figure it out by referring to the requirements of domestic construction standards, including SP 30.13330.2012 “Internal water supply and sewerage of buildings,” as well as taking into account practical realities.

Why extend the riser to the roof?

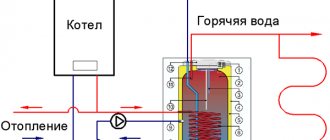

Figure 1. Sewage system in an apartment building: 1 - Exhaust ventilation pipe; 2 - Riser; 3 - Bath; 4 - Washbasin; 5 - Sink tank; 6 - Toilet; 7 - Outlet pipe; 8 - Revision; 9 - Sink or sink in the kitchen; 10 - Hydraulic valve; 11 - Floor siphon; 12 - Issue; 13 - Inspection well from the yard network; 14 - Yard network; 15 - Control well; 16 - Connecting well; 17 - Inspection well of the street network; 18 - Street network.

Of course, we will talk about the ventilated part of the sewer riser - the decompression or vent pipe. It is designed to serve as a connecting element between sewer communications (centralized or local) and the atmosphere. The vent pipe helps solve two extremely important problems:

- Compensation for decompression, that is, the vacuum created by the flow of waste liquid moving inside the pipe (Figure 2.1). The magnitude of the vacuum can reach emergency thresholds, at which water is sucked into the sewer from the water seals of sinks, shower trays and even toilets. Of course, decompression may not reach a critical level with insignificant water removal. However, during large volley discharges from several plumbing points, the waste flow can almost completely block the cross-section of the pipeline. Such a water “piston”, falling inside the riser at high speed, will cause a significant decrease in pressure in it. The result is broken water seals of siphons, which cuts off direct access of harmful stench from the sewer to the premises.

- Free removal from sewers of gaseous products resulting from the breakdown of human waste (Figure 2.2). Conditions of abundant moisture, heat and organic matter are almost ideal for the development of a variety of microorganisms. When processing organic raw materials, they release significant volumes of gases such as methane and hydrogen sulfide. Their concentrations in a confined space are fire and explosive, and accidental entry into a living space can pose a serious threat to human health.

Requirements for installation of a ventilated sewer riser

SP 30.13330.2012, as well as a number of construction standards, provide clear definitions of how the fan part of a ventilated riser should be arranged. Thus, the exhaust part of the vent pipe should be mounted as straight as possible (Figure 3, item 1) . It is installed with access to the roof separately or in a prefabricated ventilation shaft, and its height is standardized:

- above an unused flat or pitched roof - at least 20 cm;

- above the edge of the mine ventilation - at least 10 cm.

Figure 3. Options for arranging ventilation for the sewer system in a private house

On a pitched roof, it is recommended to install the fan outlet as high as possible on the slope, closer to the ridge. On the contrary, installing the pipe at the bottom of the slope or from under its overhang (item 2) is undesirable. In winter, more snow can accumulate in this part of the roof, which can block the aeration of the riser. There is also a danger of damage to communications as a result of sudden snow melting.

The open outlet of the decompression riser must be removed from the openable sashes of window and balcony glazing at a distance of over 4 m. If it is removed as indicated in position 5 , then the moist air from the sewer will contribute to accelerated rotting of roofing structures (Fig. 4), and a persistent stench in the attic is unavoidable. In addition, assembling the riser according to the scheme of positions 5 and 2 leads to a decrease in draft in it.

Figure 4. Consequence of improper ventilation of the sewer riser

When installing a ventilated sewer riser, it is PROHIBITED:

- narrow the internal diameter of the drainage part; it must be no less than the diameter of the main water intake sewer. For example, a ventilation pipe Ø 50 mm, when discharged into the sewer in one burst, is capable of passing almost 16 times less air volume than Ø 110 mm;

- frame the head of the fan riser with caps or deflectors. Firstly, they are capable of increasing aerodynamic drag. Secondly, in winter, condensation will fall from the moist air removed from the sewer. Freezing on the frame of the head, it can hamper or completely block gas exchange with the atmosphere.

Recommended diameters according to SNiP

According to SNiP, the diameter of the drain pipe must be no less than the diameter of the drain riser. In the case of combining the ventilation of several risers into one drain pipe, the size of the latter is selected according to the number of water consumers in a residential building. If it does not exceed:

- 120 - 100 mm;

- 300 - 125 mm;

- 1200 - 150 mm;

- 1200 - 200 mm.

A 50 mm drain pipe will not be enough to ensure normal ventilation of waste gases.

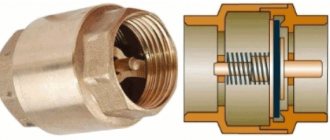

Requirements for a ventilated valve (aerator)

The installation of ventilated valves to allow air into the system (Figure 5), which guarantees normal operation of the sewer system, is carried out on the basis of appropriate calculations. The throughput of the aerator must correspond to the specified design parameters for the throughput of the riser. In turn, the fluid flow through the riser depends on its diameter, type (ventilated/non-ventilated) and height. The calculations also take into account the diameter of the dictating floor drain (with the highest waste flow), the angle of liquid entry through it, the height of the water seals and other initial data.

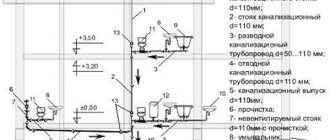

Figure 5. Operating principle of an aerator - air valve for sewerage: 1. In the operating position, the valve is closed - air from the sewerage does not enter the room. 2. When a vacuum occurs in the sewer riser, the aerator valve opens, the missing amount of air comes from the room, preventing the water seal from breaking.

In a simplified form, you can coordinate the flow parameters of the aerator and ventilated riser using tabular selections. Initially, you should refer to Appendix “B” of SP 40-107-2003 for the installation of internal sewerage from polypropylene pipes. It is to this that SP 30.13330.2012 refers to determine the characteristics of the aerator.

The largest valve with a live air flow cross-sectional area of 3170 mm2 ( Important! Look in the store not at the outer diameter, but at the size of its opening, roughly), if the design conditions are met, it is capable of compensating for decompression in risers ∅110 mm, the maximum throughput of which is indicated in table 1.

Table 1. Capacity of a riser made of polypropylene pipes ∅110 mm, equipped with a ventilation valve with a clear cross-sectional area of the air flow of 3170 mm2 and 1650 mm2.

| Diameter of floor outlet, mm | Angle of liquid entry into the riser, ° | Riser capacity, l/s | |

| 1650 mm2 | 3170 mm2 | ||

| 50 | 45.0 60.0 87.5 | 5.85 5.10 3.75 | 7.7 6.8 4.54 |

| 110 | 45.0 60.0 87.5 | 4.14 3.64 2.53 | 5.44 4.8 3.2 |

Next, you should find out the flow parameters of the sewerage system with similar initial data. For ventilated risers, they can be gleaned from tables 6-9 (SP 30.13330.2012).

Table 2. Capacity of ventilated risers made of polyvinyl chloride (PVC) pipes (SP 30.13330.2012 (Table 7)).

| Outer diameter of floor bends, mm | Angle of connection of floor branches to the riser, ° | Throughput, l/s, risers with pipe diameter, mm | |

| 50 | 110 | ||

| 50 | 45 60 87.5 | 1,10 1.03 0.69 | 8.22 7.24 4.83 |

| 110 | 45 60 87.5 | 1,10 1.03 0.69 | 5,85 5.37 3.58 |

This also takes into account the diameter of the floor outlet and the angle of its connection. From the tables it becomes clear that, for example, for some of the most popular PVC pipes today, Ø 110 mm with an outlet Ø 110mm/450 (outlet for connecting a toilet), the second throughput of the riser will be 5.85 l/s. This figure turns out to be slightly higher than with similar geometric parameters of a sewer system with an air valve (5.44 l/s (Table 1)).

Consequently , by removing the decompression pipe and installing a similar aerator, during a salvo discharge it is possible that a vacuum may occur with dehydration of the siphons.

How to properly insulate a pipe

To prevent emergencies during the cold season, it is better to insulate the sewer system. Many modern materials, such as polyurethane foam, fiberglass or mineral wool, have good thermal insulation properties. You can properly insulate a pipe by simply wrapping it with insulation and placing it in a shell made of a mixture of asbestos and cement.

Options for insulating external sewerage

You can also attach plastic film over the thermal insulation. In cold northern regions, to protect sewer pipes from freezing, the insulating layer is additionally equipped with an electric heating system. In any case, the pipeline network must be laid below the level of soil freezing depth, especially if snowdrifts that melt in the spring form on the surface. An interesting experience in laying external sewer pipes can be gleaned from the following video.

Is installing a high-performance aerator sufficient to eliminate the waste pipe?

So, having decided to get rid of the bulky drain pipe in the bathroom, according to clause 3.15 of SP 30.13330.2012, the property owner will receive nothing more than an unventilated sewer riser - without communication with the atmosphere. However, it is still important for him to ensure the normal flow of two processes (they are described in the section “Why extend the riser?”) - the removal of decompression loads and the removal of gaseous products from the system.

The first decompression task, as has already been found out, is helped by installing a suitable air valve.

The set of “Buts” is caused by the implementation of the second condition. Indeed, clause 8.2.22 of SP 30.13330.2012 clearly stipulates that such unventilated risers can be equipped if the ventilation mode of the external network is maintained. How will toxic gaseous products of organic decay be removed? Let's consider two typical situations - for sewers in a private house and in an apartment building.

In a private house

Owners of separate low-rise housing solve waste disposal problems by installing local treatment facilities, storage tanks, or through traditional cesspools. A prerequisite for the operation of these sanitary facilities is the installation of ventilation ducts. Depending on local conditions, they can be manufactured in various ways, for example, as shown in Figure 6, pos. 2-4.

Figure 6. If in a private house you cut off the drain pipe (item 1), installing an aerator (item 5), then the instructions in clause 8.2.22 of SP 30.13330.2012 on ventilating the external network - removing toxic gases from it, when using additional additional communications (items 2-4) – complied with.

In an apartment building

Ventilation of risers in apartment buildings was initially designed based on the free communication of the sewerage system with the atmosphere (Figures 1 and 2). In fact, it must be carried out through the highest point of sewage communications, that is, through a drain pipe leading to the roof. Refusal of the hood (Figure 7) is allowed only in exceptional situations. In SP 30.13330.2012 it is described for exploited roofs in clause 8.2.20. In this case, it is indeed permitted to install an air valve at the mouth of the riser on the top floor. However, according to clause 8.2.22, the regime for removing sewer gases from the external network must be maintained. Therefore, to ensure it, it is necessary to install auxiliary ventilation communications of the types indicated in Figure 6, pos. 2-4, which is quite problematic in urban areas.

Figure 7. Refusal of a drain pipe in an apartment building - sewer ventilation is impossible