The hot water supply system of a private home includes: a water heater, a pipeline with shut-off valves and mixers, and often a pump for recirculating hot water. Water heaters differ in power, design, and power source. The most practical are gas water heaters, capacitive and flow-through. Indirectly heated water heaters are also available. They function thanks to the heat given off by a heating or electric boiler.

Useful tips

Thermal insulation must be placed close to the fittings; all joints between the shell must be sealed with metallized tape. If you have any questions, write to me volkov teploclub. From it, under the action of a pump, water spreads over the branches of the heated floor, giving off its heat to the cement floor screed.

The use of corrugated hoses and powder metallurgy material is strictly not recommended. Dimensions are important during installation.

As you can see, I used ball valves with an American drive.

As for the pump itself, the leading manufacturers of plumbing equipment Wilo and Grundfos have developed entire series of devices for these purposes.

While the water travels a certain distance to the point of analysis, it has time to cool down. Of course, it should be noted that this is the most expensive option for double-circuit heating, because it involves a large pipe distribution.

The water heater in this system acts as the main coolant. On the front part of the panel there are places for installing a temperature sensor or thermostat; in some models it is possible to install a heating element - for additional heating of water when there is a lack of heating power. DHW recirculation (boiler and DHW pump)

Read more: Energy audit - what is it?

Why do you need a booster pump?

A booster pump is used when there is insufficient pressure in the water supply. Nowadays, most booster pumps operate when there is water supply, that is, the pump will work until you turn off the water at the mixer. This is done using a flow switch built into the pump. With the help of such pumps it is possible to pump low-viscosity, non-aggressive liquids without the inclusion of solid particles and engine oil impurities.

Specifications:

- Pressure 2 meters.

- Ambient temperature from 2°C to 40°C.

- The temperature of the pumped liquid is from 2°C to 60°C.

- Maximum system pressure 6 bar.

Installation of a booster pump.

The booster pump is installed using union nuts directly on the pipe through which cold water is supplied. The standard connection size is 0.5 inches. After installing the pump, it is necessary to remove air from it. How to do this is described in detail and with pictures in the instructions, which I strongly advise you to read before doing the installation. Let's look at an example of correct incorrect installation in the figure:

Example of installation of pump UPA15-90

Correct installation of the booster pump

It is also necessary to remember that the pump shaft must be located in a horizontal plane. If this is not done, the bearings will not be lubricated and will quickly fail! Let's look at another drawing and draw conclusions.

Maintenance.

At home, it is limited to cleaning the flow switch. If you don’t want to do this, you can install a mesh filter in front of the pump that will trap sludge. More complex repairs should be carried out at an authorized service center.

All-season operation of heated towel rails.

In order for heated towel rails to be constantly hot, they must be included in the recirculation system. Consistently, one after another. This will not lead to a significant increase in the hydraulic resistance of the route or any noticeable cooling of hot water at consumers. Simplified, it looks like this: Since there are a great variety of heated towel rails, I will not describe how to connect a heated towel rail. I can suggest that while they are not installed, before finishing, you can install jumpers made of pipes instead of them. The connection diagram for heated towel rails shown in the figure allows you not to worry about the accumulation of air in the upper part of them. Air will be expelled through the hot water taps when any of them are opened.

Dual-circuit heating

At the same time, in terms of moldings, the pipes themselves are much cheaper than polypropylene and metal-plastic ones, and their service life is incomparably longer.

Video about organizing hot water recirculation. Thanks to this, hot water comes from the tap immediately after opening, and its temperature can be precisely adjusted regardless of the operating mode of the heating device.

But it is effective in that you don’t have to drain cold water, that is, pour money down the drain.

Connecting an indirect heating boiler for this case is shown in the diagram below. Regardless of the type of device - floor-mounted or wall-mounted - if possible, it should be mounted above the level at which the boiler is installed, or at the same level. Although a pump would be useful here in terms of uniform distribution of coolant throughout all heating radiators.

Connection diagram to a boiler with automatic control The circulation pump can be installed either on the supply pipe or on the return pipe. It clearly defines the contours through which the coolant will pass and return back to the boiler or boiler.

Simplified, it looks like this: Since there are a great variety of heated towel rails, I will not describe how to connect a heated towel rail. When the lengths of the vetos are not very different from each other. Circulation pumps must be installed on the return line near the heating boiler. It is much more difficult to insert an additional device into an existing network.

How much hot water is wasted?

It runs on batteries and does not require external power. The hot water itself from the boiler circulates constantly through the hot water supply pipeline.

I recommend placing the pump on the second floor. Not the most effective option, because in order to get hot water, for example, in a bathroom located on the second floor of a private house, you will have to drain a fairly large volume of water, which has cooled and is located in the pipe leading to the bathroom. My conclusions about the 300 liter indirect heating boiler. PART 4

Implementation

What hot water supply schemes with recirculation are possible in apartment buildings and private buildings?

Apartment buildings

To create continuous circulation of water, the DHW system needs to be looped.

In apartment buildings this is achieved as follows:

| Image | Description |

The basement is filled with cold water, hot water and heated towel rails. | There are two hot water dispensers throughout the house. The risers are connected to them one by one. As an option, only DHW risers are connected to one of the bottlings, and only risers with heated towel rails are connected to the second. |

The riser of heated towel rails serves as a return for hot water supply | DHW risers (optional DHW and heated towel rails) are connected by jumpers on the top floor. A group can consist of 2-4 risers. An air vent (Mayevsky tap) is mounted at the top point of the jumper, allowing the air to bleed off that is preventing circulation. |

It is clear that the described water supply scheme with recirculation will not work without a pressure difference.

How it is provided:

Outside the heating season, the DHW is switched on between the supply and return lines;

Summer mode: DHW circulation between the supply and return lines

During heating operation with such a connection, the hot water supply system will represent a bypass for the heating system, catastrophically reducing the drop in the water jet elevator. Therefore, the DHW is connected depending on the temperature of the water from supply to supply or from return to return, and the difference is ensured by retaining washers installed on the flanges between the taps.

Modern elevator unit with circulation connections

If the risers are airy

What should I do if, after resetting the hot water supply system, the air pocket remaining in the risers prevents circulation and the heated towel rails remain cold?

To bleed air, use the Mayevsky valve at the top point of the jumper. However, to access it you need to get into the upper apartment via the riser, which is not always possible.

Here are simple step-by-step instructions that will help you fix the problem yourself:

- We block any of the hot water supply risers connected by a jumper;

- We open one, or better yet, two hot water taps in any apartment along this riser all the way. The air plug flies out through the mixer at the front of the water flow;

Open the faucet completely and the air will fly out of the riser at the front of the water flow

- We start the risers in normal mode.

Private houses

What hot water recycling schemes can be implemented in a private house with autonomous hot water preparation? Quite predictably, a minimum power circulation pump (from 25 watts) will be responsible for creating circulation pressure in such a system.

Circulation in the DHW circuit can be ensured by a minimum power pump

The DHW circuit must be looped along its entire length: after the plumbing fixture farthest from the water heater, the filling returns to the starting point. But the connection diagram for the water heater depends on whether it has an additional outlet for recirculation.

Diagram for a boiler with a pipe for connecting a recirculation circuit

The presence of three pipes for connecting DHW and cold water is typical for most indirect heating boilers and some storage electric water heaters.

Boiler with additional outlet for recirculation

The closed circuit is supplied only with a circulation pump: since the temperature of the water in the circuit is constant after its start, the problem of thermal expansion of water does not have to be solved, and if so, a safety valve and an expansion tank are not required.

Is it possible to use a regular boiler with two outlets (for DHW and cold water) in such a scheme? Yes, but in this case the wiring will be noticeably more complicated.

Water supply with recirculation: diagram for a boiler with two pipes

A three-way thermostatic mixer is responsible for maintaining a constant water temperature in the recirculation circuit. As it cools, he mixes in hot water from the boiler;

The three-way thermostat mixer is capable of providing a constant outlet water temperature at any inlet temperature

- To compensate for the flow of hot water, cold water is supplied to the three-way mixer;

- Check valves limit the movement of water in the circuit in one direction, regardless of its flow.

Design and appearance of an automatic air vent

What elements does the water supply scheme of an apartment building include?

The water metering unit, which organizes the supply of water to the house, is responsible for several functions:

- It takes into account the consumption of cold water supply, that is, it acts as a water meter;

- It can shut off the supply of cold water to the house in emergency situations or when it is necessary to repair components and parts, as well as to eliminate leaks;

- Serves as a filter for coarse water purification: any hot water supply scheme for an apartment building should contain such a mud filter.

The device itself consists of the following components:

- A set of shut-off valves (taps, valves and valves) at the inlet and outlet of the device. Standardly these are gate valves, ball valves, valves;

- Mechanical water meter, which is installed on one of the risers;

- Mud filter (filter for coarse water purification from large solid particles). This could be a metal mesh in the housing, or a container in which solid debris settles to the bottom;

- Pressure gauge or adapter for inserting a pressure gauge into a water supply circuit;

- Bypass (bypass from a section of pipe), which serves to turn off the water meter during repairs or for data verification. The bypass is equipped with shut-off valves in the form of a ball valve or valve.

Heating point

It is also an elevator unit that performs the following functions:

- Ensures full and continuous operation of the heating system in an apartment building, and also regulates its parameters;

- It delivers hot water to the house, that is, it provides hot water supply (hot water supply). The coolant itself in the heating system enters the hot water supply system of the apartment building directly from the centralized heating main;

- The heating point can switch the hot water supply between return and supply. This may be necessary during severe frosts, since at this time the temperature of the coolant on the supply pipe can rise to 130-150 0 C, and this despite the fact that the standard supply temperature should not exceed 750 C.

The main element of a heating point is a water-jet elevator, where hot water from the working fluid supply pipeline circuit in the house is mixed in a mixing chamber with the return coolant by injection through a special nozzle. Thus, the elevator allows a larger volume of low-temperature coolant to pass through the heating circuit, and, since injection is carried out through a nozzle, the supply volume is small.

Adapters for connecting DHW can be inserted between the valves at the inlet of the route and the heating station - this is the most common connection scheme. The number of inserts is two or four (one or two each on the supply and return). Two inserts are typical for old houses; in new buildings, four adapters are practiced.

On the cold water supply route, a dead-end tie-in scheme with two connections is usually used: the water metering unit is connected to the bottling, and the bottling itself is connected to the risers through which pipes are routed to apartments. Water will move in such a cold water supply system only during disassembly, that is, when opening any mixers, taps, valves or valves.

Disadvantages of this connection:

- If there is no water supply to a particular riser for a long time, the water will remain cold for a long time when drained;

- Heated towel rails embedded in the DHW inlets from the boiler rooms, which simultaneously heat the bathroom or toilet, will only be hot when the DHW is drawn from a specific riser in the apartment. That is, they will almost always be cold, which will cause the appearance of moisture on the walls, mold or fungal diseases of the building materials of the room.

A heating station with four hot water connections in the house makes the circulation of hot water continuous, and this happens through two bottlings and risers connected to each other by jumpers.

Important: if mechanical water meters are installed on the hot water taps, then the water supply consumption will be taken into account without taking into account the water temperature, which is incorrect, since you will have to overpay for hot water that was not used.

Hot water supply can operate in three ways:

- From the supply pipe to the return pipe to the boiler room. Such a hot water system is effective only in the warm season when the heating system is turned off;

- From supply pipe to supply pipe. Such a connection will bring maximum benefits in the demi-season - autumn and spring, when the coolant temperature is low and far from maximum;

- From the return pipe to the return pipe. This DHW scheme is most efficient in extreme cold, when the temperature at the supply pipe rises to ≥ 75 0 C.

For continuous movement of water, a pressure difference is required between the starting and ending points of insertion into one circuit, and this difference is ensured by limiting the flow. This limiter is a special retaining washer - a steel pancake with a hole in the middle. Thus, the water that is transported from the inlet to the elevator encounters an obstacle in the form of a washer body, and this obstacle is regulated by a rotation that opens or closes the retaining hole.

But too much restriction of the movement of water in the pipeline route will disrupt the operation of the heat station, so the retaining washer should have a diameter 1 mm larger than the diameter of the heat station nozzle. This size is calculated by representatives of the heat supplier so that the temperature at the return heating pipe of the elevator unit lies within the standard temperature limits.

Installation rules

To install hot water recirculation, you must have certain knowledge. You can seek help from qualified specialists.

When installing it yourself, you must adhere to several rules:

- Correctly calculate the volume of the water heater. An insufficient storage tank size will result in water from the cold water pipeline entering the circuit. When calculating the volume of the boiler, the number of people living in the house is taken into account.

- Use the mandatory elements recommended by the manufacturer in the water heater piping. To safely use the boiler, it may be necessary to install certain piping elements. Manufacturers often supply such elements complete with a water heater.

- Insulate the pipeline. To reduce heat loss during coolant circulation in the hot water supply circuit, a layer of thermal insulation should be applied to the pipes. You can use polyethylene thermal insulation for pipes. Fittings must also be insulated.

- Use a pump for DHW recirculation. Unlike pumps designed to move liquid in a heating system, the diameter of the threaded connections of recirculation pumps is designed for connection with fittings of water supply systems.

Operation of the DHW recirculation system

Recirculating hot water is quite expensive, since the boiler will have to constantly heat the water, additionally spending energy on this, and the circulation pump will constantly consume electricity.

Some experts advise turning off hot water recirculation in the summer, but then the whole point of organizing it is lost, since hot water is required daily and all year round. In order to save on energy costs, you will have to spend a little more. For example, you can purchase a circulation pump with a built-in, programmable timer, or install a separate control device that will circulate water through the hot water supply circuit at a certain frequency, thereby preventing it from cooling down. In addition, DHW recirculation can be turned off at night and when you are not at home.

In the next article I will talk about the anemostat.

I RECOMMEND ALSO READING:

Recirculation scheme

Manufacturing a circuit in which the water temperature will be constantly maintained is possible during the construction or deep modernization of a hot water supply system.

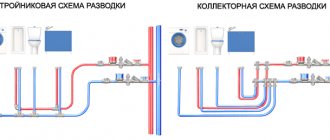

The recirculation scheme is carried out as follows:

- Pipeline laying. The scheme provides a closed loop. The pipe is laid through the required rooms to the distant point and back to the boiler.

- Connecting water intake points. Installation involves sequential inclusion of water intake points in the system. At a distant point of water consumption, the pipe does not end, but returns to the water heater.

- Connection to the pump circuit. It is necessary for forced circulation of the coolant. It is better to turn on the pump and install a shut-off device in the circuit at the interval where the water flows not to consumers, but to the storage tank. This will allow you to turn off forced circulation if necessary.

Recirculation scheme. Photo source: tolyatty.blizko.ru

Why is recycling necessary?

The hot water supply pipeline can have different lengths. If the intake point is located at a great distance from the boiler, then when the tap is opened, hot water will not flow immediately. It will be necessary to wait some time until cold liquid flows out of the pipeline.

DHW recirculation can also be done through heated floors and heated towel rails

In private homes, the distance from the boiler location to the water intake point can be quite large. This makes using the hot water supply system uncomfortable and leads to wasted water. In order for hot water to flow when the tap is opened, constant circulation is necessary.

DHW recirculation is the forced movement of liquid in the hot water supply circuit using a pump.

The pump periodically pumps liquid. In this case, the coolant does not leave the circuit and returns to the storage tank. This allows you to constantly maintain the required temperature of the liquid in the pipeline.

Hot water supply or DHW

In some low-rise buildings, hot water is connected in the same way, standing on a backwater without circulation, this explains the fact that when you open a hot water tap, cold, cooled water flows for some time. If we take the same house with 16 floors, then in such a house the hot water system is arranged differently. Hot water, like cold water, is also supplied to the house through a large pipe, and after the meter it goes into the house mains

which lifts the water into the attic where it is distributed along the risers and goes down to the very bottom into the return line. By the way, hot water meters count not only the volume of lost (consumed) water in the house. These counters also count temperature losses (gigocolors)

Temperature is lost when water passes through apartment heated towel rails, which act as risers.

With this scheme, hot water always circulates. As soon as you open the tap, the hot water is already there. The pressure in such a system is approximately 6-7 kg. on the supply and slightly lower on the return to ensure circulation.

Due to circulation, we get pressure in the riser in the apartment of 5-6 kg. and immediately we see the difference in pressure between cold and hot water, from 2 kg. This is precisely the essence of pressing hot water into cold water when plumbing fixtures malfunction

If you notice that you still have higher pressure on hot water than on cold water, then be sure to install a check valve at the cold water inlet, and at the hot water inlet you can include control valves in the system, which will help equalize the pressure to approximately the same figure as the cold one. Pressure regulator installation example

Ready-made solutions to issues with hot water supply and hot water in housing and communal services

We restore hot water supply in accordance with GOST, SNiP for apartment buildings in Perm and the Perm region.

Water supply cold water supply, hot water supply: Audit. Analysis. Conclusions Recommendations.

6 years for a legal entity, this means that the work will be completed on time, and the guarantee will be fulfilled.

- Boiling water from the tap?

- Frequent burns with hot water?

- Are you running hot water for a long time?

- Slightly warm water?

- In the morning, hot water from the tap is cold?

- Does the hot water temperature change frequently?

- Bad hot water?

We have ready-made solutions to these issues.

We will help you. Call!

Causes of problems with hot water supply

- poor circulation;

- pipeline clogging;

- narrowing the diameter of the pipeline;

- incorrect calculation of hydraulics of metering devices;

- adjustment of equipment settings in the control unit;

- automatic temperature control does not work;

- heat exchanger clogged

- +100 more reasons.

Call us. We will determine the reason.

What to choose for the home and what for the dacha?

Using a running hot water supply system in a residential building is impractical for many reasons. Water consumption in houses where people live permanently differs markedly from consumption in country houses, especially if not just one person lives, but a family.

The flow system is fraught with a number of disadvantages for users:

- Reduced hot water pressure due to limiters built into heating equipment.

- Unpredictable changes in tap water temperature.

- Waiting for water to flow after opening the tap.

- High consumption of electricity or gas, depending on the type of system chosen.

However, for a summer residence, a flow system will be the optimal solution. After all, the need for hot water is not so high, the cost of such a system is much lower, and its dimensions are more compact.

There is also another important advantage - if when using a water heating tank you need to wait for water after turning on the equipment, then users of flow-through systems are free of this problem.

A flow system is better for a summer residence, the use of water heating tanks is better for a home, but there are exceptions. For example, when one person lives in a house or when people live in a dacha not occasionally, but permanently. Therefore, each case must be considered separately.

Using a double-circuit gas boiler

When the number of water points in a private house is small and the simultaneous use of exclusively washbasins is expected, then it is best to choose a double-circuit boiler with instantaneous water heating. Such boilers are capable of producing hot water up to twenty liters per minute. This option is the simplest and most economical.

In order to install this hot water supply system, you need to make a pipe connection with cold water and it will be possible to receive hot water at the outlet of the boiler. It is necessary to take into account that over a certain time the hot water will cool down in the pipeline and therefore, in order for hot water to flow from the tap, you will have to wait for some time.

How is the supply of communal hot water arranged in an apartment building?

The principle of operation of hot water supply: Hot water is supplied to apartment buildings according to two schemes:

- Cold water flows to the central heating point - the central heating point. There it is heated to the required temperature of 65-75 C, after which it is distributed to apartment buildings.

- Cold water enters the ITP - an individual heating point of an apartment building. Heat exchangers are installed at the heating point. Cold water is heated in heat exchangers to the required temperature of 63 - 75 C, after which it is distributed among the apartments.

How to choose boiler power for a DHW boiler

When choosing a boiler, you need to pay attention to the power of the heating element that is installed in it. For example, to heat 100 liters of water to a temperature of 55 oC in 15 minutes, a heater (heat exchanger for the boiler, built-in gas burner or heating element) with a power of about 20 kW must be installed in the boiler

In real operating conditions, the temperature of the water in the boiler is equal to the temperature of the water in the water supply only when the heating is first turned on. In the future, the boiler almost always contains water that has already been heated to a certain temperature. To heat water to the required temperature in an acceptable time, heating devices of lower power are used.

But it’s still better to check how long it will take to heat the water in the boiler. This can be done using the formula:

t = m•cw•(t2 – t1)/Q, in which: t – water heating time, seconds (s); m – mass of water in the boiler, kg (mass of water in kilograms equals the volume of the boiler in liters); cw – specific heat capacity of water equal to 4.2 kJ/(kg•K); t2 – temperature to which the water should be heated; t1 – initial temperature of water in the boiler; Q – boiler power, kW.

Example: The time for heating water by a 15 kW boiler in a 200-liter boiler from a temperature of 10°C (we assume that the water entering the boiler has this temperature) to 50°C will be: 200 x 4.2 x (50 – 10) /15 = 2240 s, that is, about 37 minutes.

DHW scheme with water recirculation in the system

The use of a storage water heater in a domestic hot water system allows for the recirculation of hot water in pipelines. All hot water collection points are connected to a ring pipeline through which hot water constantly circulates.

The length of the pipe section from each point of hot water consumption to the ring pipeline should not be more than 2 meters.

The circulation pump of the DHW hot water recirculation system is small in size and has low power.

Water recirculation in the DHW system is ensured by a circulation pump. The pump power is small, several tens of watts.

Pumps for DHW, unlike heating pumps, must have a maximum operating pressure of at least 10 bar. Heating pumps are often designed for a maximum pressure of no more than 6 bar. Another difference is that the DHW pump must have a hygienic certificate allowing use in drinking water supply systems.

The water in hot water supply systems is constantly renewed and the oxygen content in it remains quite high. Hot water is highly corrosive. In addition, hot water must meet sanitary requirements for drinking water. Therefore, for the manufacture of DHW pumps, corrosion-resistant non-ferrous metals or stainless steel are used. For these reasons, circulation pumps for hot water supply are noticeably more expensive than similar pumps for heating systems.

In some DHW pipeline designs, it is possible to create natural water recirculation, without a pump.

As a result of water circulation in the hot water supply system, hot water is constantly supplied to the sampling points.

In a DHW system with a storage heater and water recirculation, the water supply mode is more stable:

- Hot water is always present at the sampling points.

- Water can be collected simultaneously in several places. The temperature and pressure of water change slightly when the flow rate changes.

- You can take any, no matter how small, amount of hot water from the tap.

The recirculation circuit allows not only to increase the comfort of water supply in remote points of the house, but also makes it possible to connect heated floor circuits to it in individual rooms. For example, in a bathroom, a water-heated floor will be comfortable all year round.

A DHW system with water recirculation constantly consumes energy

for the operation of the circulation pump, as well as to compensate for heat losses in the boiler itself and in the pipes with circulating water. To reduce energy consumption, it is recommended to install a circulation pump with a built-in programmable timer that turns off water circulation during hours when it is not needed. The boiler and hot water pipes are insulated.

DHW diagram with layer-by-layer heating boiler

| DHW diagram with layer-by-layer heating boiler and instantaneous water heater |

Recently, a hot water supply system with a layer-by-layer heating boiler has been gaining popularity,

the water in which is heated by a flow-through water heater. This boiler does not have a heat exchanger, which reduces its cost.

Hot water is drawn from the top of the tank. In its place, cold water from the water supply immediately flows into the lower part of the tank. The pump drives water from the tank through a flow-through heater and supplies it directly to the top of the tank. Due to this, the consumer gets hot water very quickly

— you don’t need to wait until almost the entire volume of water warms up, as happens in an indirect heating boiler.

Rapid heating of the top layer of water allows you to install a smaller boiler in the house, as well as reduce the power of the flow-through heater,

without sacrificing comfort.

The Galmet SG (S) Fusion 100 L layer-by-layer heating boiler is connected to the DHW circuit of a double-circuit boiler or to a gas water heater. The boiler has a built-in three-speed circulation pump. Boiler height 90 cm, diameter 60 cm.

Manufacturers produce double-circuit boilers with a built-in or remote layer-by-layer heating boiler. As a result, the cost and dimensions of the DHW system equipment are somewhat smaller,

than with an indirect heating boiler.

The water in the boiler is heated in advance,

regardless of whether it is spent or not. The hot water reserve in the tank allows you to use hot water in the house for several hours.

Thanks to this, the water in the tank can be heated for quite a long time, gradually accumulating thermal energy in the hot water. Hence another name for the boiler - storage water heater.

The long duration of water heating allows the use of a relatively low power heater.

Problems

Circulation in a water supply system is a process that is quite easy to disrupt. In the next section of the article, we will analyze typical problems that can lead to a stop in circulation and the associated cooling of hot water risers and heated towel rails in an apartment building.

Airlock

- Symptoms: after turning off the hot water, one riser or a group of risers has cooled down. The neighbors' pipes are still heated.

- Reason: air lock in the ring jumper. A pressure drop of 0.2 atmospheres is not enough to force it into bottling.

- Solution: expel air through the vent at the top of the jumper. If this is not possible (for example, due to the absence of residents on the upper floor), you can pass the riser through the basement or water fittings in the apartments.

To do this you need:

- Shut off one of the problematic hot water risers with a tap or valve in the basement;

- If there is a vent on this riser, open it and wait for the air to escape;

The hot water riser is equipped with a vent that allows it to be bypassed from the basement

- If there is not a waste pipe on the riser, but a plug, you can open hot water to capacity on one or two mixers in any apartment located along the same riser;

Air can be expelled from the riser through any mixer connected to it

- After bleeding the air, open the valve or tap at the base of the riser.

Closed valve

- Symptoms: when drawing water, the riser heats up from above due to the hot water supply being inserted into it. It is obvious that water flows to the liner through the ring jumper.

- Reasons: after turning off the riser, the faucet or valve remained completely or partially closed.

- Solution: go down to the basement and open the shut-off valves on yours and the adjacent DHW risers all the way to failure.

With an open ball valve, the handle is always directed parallel to the axis of the body

Valve valve separation

Symptoms: water enters the line through the ring jumper from above. A screw valve is installed at the base of the DHW supply riser in the basement. The arrow on the valve body is directed towards the hot water supply.

The arrow on the screw valve body indicates the only possible direction of water flow

- Causes: valve valve separation from the stem. This happens if you try to open an incorrectly installed shut-off valve of this type, overcoming the water pressure on the valve.

- Solution: replacing the valve with a ball valve (on a steel riser, in this case, you have to change the flow to a longer one), installing a new screw valve in the correct position (with an arrow in the direction of flow).

The riser valve in the photo has been replaced by an assembly with a ball valve

No difference in the heating main

In houses with open heating, the hot water circulation system often stops immediately after the end of the heating season. Symptoms: Cold heated towel rails throughout the house. The reason is that local Heating Networks completely eliminate the difference between the threads of the heating main.

Why is this being done?

The fact is that the heating season begins when the temperature outside is +8 °C or higher for at least five days in a row. Even if after stopping the heating there is a new frost, the heating will not be turned on, since on a city scale, restarting it is associated with colossal costs.

However, residents of a separate house may well, having access to a heating point, turn the heating back on. To do this, you just need to open a couple of so-called house valves (after the water jet elevator) or taps. But in the absence of a difference, this will not lead to the resumption of circulation in the heating system, and, therefore, to unpaid heat consumption.

At the end of the heating season, the DHW circulation may stop for some time.

Unfortunately, there is no reasonable solution for this scenario. All you can do is wait a couple of weeks. As soon as truly spring weather sets in, the circulation-providing difference will return.

Types and piping diagram of an indirect heating boiler

Piping an indirect heating boiler involves connecting the boiler pipes to the water supply. This stage is considered the most significant, but at the same time difficult. The further operation of the boiler depends on the quality of the piping.

There are several ways of tying. Which one is best for you, you need to look on the spot.

Types of boiler piping schemes:

- Trim using a three-way control valve and servo drive. This type of binding is the easiest to make. It is used when high consumption of hot water is expected. In this case, the boiler is connected to the main and additional circuits. The first ensures heating of water in water heating pipes, and the second makes warm water in the boiler. To make piping easier, a three-way distribution valve is used. A servo drive is needed to redirect hot water to heating and back. The thermostat monitors the water temperature, when it reaches the required level, the water is transferred to the servo drive, which redirects it to heating; after the water cools, it is taken back into the boiler.

- The connection with the use of two pumps occurs as follows: one pump is installed on the heating circuit, and the second on the hot water supply circuits. The pumps are controlled by a thermostat, which switches operating modes.

- Piping using a hydraulic arrow is used when, in addition to supplying hot water and a general heating system, the boiler is connected to a heated floor system. The hydraulic distributor prevents system problems with a system in which each circuit has its own recirculating pump.

Each type of strapping has its own pattern. Which one to choose depends on your needs. For a private house with its own boiler room, all three options are suitable. If you want to install a heated floor system in your home, then use a hydraulic arrow to piping the boiler.

Storage gas water heater - boiler

Storage boilers, the water in which is heated by a gas burner, are less popular in domestic hot water systems. Installing heating and hot water systems in a house with two gas appliances - a gas boiler and a gas boiler - turns out to be noticeably more expensive.

Storage gas water heater - boiler

It can be advantageous to install gas boilers in apartments with central heating or in private houses with heating by a solid fuel boiler and heating of water in the hot water system with liquefied gas.

Gas water heaters, like boilers, are available with an open combustion chamber and a closed one, with forced removal of flue gases and with natural draft in the chimney.

There are storage gas boilers on sale that do not require connection to a chimney. (Household gas stoves also operate without a chimney.) The power of the gas burners of such devices is small.

Gas boilers with a capacity of up to 100 liters are designed for wall mounting. Large volume water heaters are installed on the floor.

Water heaters use different methods of gas ignition - with a pilot wick, electronic with batteries or hydrodynamic ignition.

In devices with a pilot wick, a small flame is constantly burning, which is first ignited manually. A certain amount of gas burns uselessly in this torch.

Electronic ignition operates from the mains or a battery.

Hydrodynamic ignition is started by rotating a turbine, which is driven by the flow of water when the tap is opened.

Recirculation through an indirect boiler

A single-circuit boiler with an external indirect heating boiler is the most optimal option for organizing recirculation, which is often used in conditions of fairly intensive hot water consumption. This is how hot water recirculation is usually used.

This system makes it possible to simultaneously use two or more showers, a bathtub, and a jacuzzi. In their own homes, they usually install an indirect heating boiler with a volume of one hundred to one thousand liters.

In such a system, water is heated by passing through a boiler, a large tank with a tubular spiral. The heating system coolant circulates along the boiler spiral, which thus heats the water in the boiler. In this system, unlike the instantaneous or storage water heater options, the heating boiler operates year-round.

Most indirect heating boilers have a tank made of enameled steel. And some premium models have an internal tank made of stainless steel.

How to choose the volume of a storage water heater - boiler

The larger the volume of the storage water heater, the higher the comfort of using hot water in the house. But on the other hand, the larger the boiler, the more expensive it is, the higher the costs of its repair and maintenance, and the more space it takes up.

The size of the boiler is selected based on the following considerations.

It is generally accepted that the boiler volume, selected at the rate of 20-30 liters per person, will provide the minimum necessary comfort for using hot water in the house.

Increased comfort will be provided by a boiler, the volume of which is selected at the rate of 30 - 60 liters per user of water.

A high level of comfort will be provided by a water heater with a volume of 60-100 liters per person living in the house.

To fill the bathtub, it is necessary to use up almost all the water from the boiler with a volume of 80 - 100 liters.

Scheme of hot water supply with instantaneous water heater

The following can be used as an instantaneous water heater:

- DHW gas water heater;

- DHW heating circuit of a double-circuit heating boiler;

- electric instantaneous water heater.

- plate heat exchanger connected to the heating circuit.

The instantaneous water heater begins to heat the water at the moment the water is drawn

when the hot water tap is opened.

All energy spent on heating passes from the heater to the water almost instantly, in a very short time of water movement through the heater. In order to obtain water at the required temperature in a short period of time, the design of an instantaneous water heater provides for limiting the speed of water flow. The water temperature at the outlet of the flow-through heater depends very much on the water flow —

the size of the stream of hot water flowing from the tap.

To properly supply hot water to only one shower head, the power of the instantaneous water heater must be at least 10 kW. You can fill a bathroom in a reasonable time using a heater with a power of more than 18 kW

.

And if, when filling the bath or running the shower, you also open the hot water tap in the kitchen, then for comfortable use of hot water you will need a flow heater power of at least 28

kW. To heat an economy class home, a lower power boiler is usually sufficient. Therefore, the power of a double-circuit boiler is chosen

based on the need for hot water.

A DHW circuit with an instantaneous water heater cannot provide comfortable and economical use of hot water in the house for the following reasons:

- The temperature and pressure of water in the pipes very much depend on the amount of water flow. For this reason, when opening another tap, the water temperature and pressure in the hot water system changes greatly.

It is very uncomfortable to use water even in two places at the same time. - When the flow of hot water is low, the instantaneous water heater does not turn on at all and does not heat the water.

To obtain water at the required temperature, it is often necessary to use more water than necessary. - Each time the water tap is opened, the instantaneous water heater starts again. It constantly turns on and off, which reduces its service life. Each time, hot water appears with a delay, only after the heating mode has stabilized. Frequently restarting the heater reduces efficiency and increases energy consumption. Some of the water goes down the drain uselessly.

- It is impossible to recirculate water in the distribution pipes throughout the house. Hot water from the tap appears with some delay.

The waiting time increases as the length of the pipes from the water heater to the water collection point increases.

Some of the water at the very beginning has to be drained uselessly into the sewer.

Moreover, this is water that has already been heated, but has managed to cool down in the pipes. - Scale deposits quickly accumulate

on a small surface inside the heating chamber of an instantaneous water heater. Hard water will require frequent descaling.

Ultimately, the use of an instantaneous water heater in a hot water system leads to an unreasonable increase in water consumption and the volume of sewerage, to an increase in energy consumption for heating, as well as to insufficiently comfortable use of hot water in the house.

The DHW system with instantaneous water heater is used, despite its disadvantages, due to the relatively low cost and small size of the equipment

.

The system works better if a separate individual instantaneous water heater is installed near each water collection point.

In this case, it is convenient to install electric flow heaters. However, such heaters, when drawing water simultaneously in several places, can consume significant power from the electrical network (up to 20 - 30 kW). Typically, the electrical network of a private home is not designed for this, and the cost of electricity is high.

What it is?

Recirculation is a heating circuit piping system , as well as a hot water supply line, designed for constant movement of coolant or hot water.

It is designed to increase the efficiency of boilers, as well as to increase the comfort of residents when using hot water.

For example, if the hot water supply tap is located remotely from the boiler, the water in the pipes quickly cools down.

You have to let it pass for a long time until the temperature rises to the desired value. If recirculation is used, water constantly moves from the boiler to the water collection point and back. It does not cool down, which makes it possible to use hot water immediately, without waiting.

In heating systems, circulation ensures optimal thermal conditions. A hot coolant enters the heating circuit, which passes through a cascade of radiators and releases its thermal energy.

Returning to the boiler, the cooled coolant heats up again and enters the heating circuit for a new cycle. The efficiency of heating and uniform heat transfer at the beginning and end points of the circuit depend on the speed of water movement.

In a private house

Recirculation of hot water in a private home is carried out by piping a boiler or, less commonly, a heating boiler.

There are single- and double-circuit models that can only prepare coolant for heating, or simultaneously supply coolant and hot water for domestic needs. In addition, there are volatile and non-volatile boiler models.

The former are capable of operating without being connected to a power supply and only require a fuel supply. The latter need to be connected to the power supply network. They are equipped with their own circulation pumps that ensure the movement of coolant through the heating circuit.

As a rule, the boiler itself provides coolant circulation. To recirculate hot water, use an additional piping equipped with a circulation pump.

It is connected to the boiler, carried to the most distant consumption device, and returned back to the boiler. There is additional energy consumption to power the pump, but there is a noticeable saving of water, and the convenience of using hot water increases.

In a multi-storey building

Modern hot water supply schemes use a boiler system , in which network hot water is not supplied to apartments. Water is heated indirectly in a boiler, from which hot water is supplied to the heated towel rail and hot water system.

Each apartment in a multi-storey building is one of the sections of the general recycling scheme. Its peculiarity is the vertical movement of water - from the bottom point to the top floor, and back. As a rule, circulation is organized along the line of heated towel rails.

It is powered from the DHW pipeline, so the water in the boiler never cools down and maintains its operating temperature.

Hot water rises up the riser, connects to the heated towel rail pipeline and goes back to the boiler.

However, it is impossible to organize its own circulation for each water supply point (kitchen sink, washbasin or bathtub) , so the water in the outlets from the riser often cools down.

The solution to this problem can be installing your own boiler and installing a recirculation loop. This is an effective measure if the apartment is large and the appliances are located far from the storage tank.

Hot water recirculation

Recirculating hot water will allow you to quickly get enough hot water. If you install a water heating boiler in your home, be sure to wire it up.

Thanks to recirculation, a pipeline is created through which water constantly flows and at the same time constantly heats up without having time to cool down. Because of this system, you will be able to get water as soon as you open the tap.

To make such a system, you need to install a recirculation pump. In this case, the flow of hot water must be directed in such a way that it constantly passes through structures that require heat. By fulfilling this condition, you will get maximum boiler efficiency.

Features of hot water supply and calculation of the volume of hot water

Calculation of the amount of hot water in the system depends on technical and operational factors:

- Estimated hot water temperature;

- Number of residents in an apartment building;

- The parameters that plumbing fixtures can withstand and the frequency of their operation in the overall water supply scheme;

- the number of plumbing fixtures that are connected to the hot water supply.

- A family of four uses a 140 liter bathtub. The bathtub fills in 10 minutes, the bathroom has a shower with a water consumption of 30 liters.

- Within 10 minutes, the water heating device must heat it to the design temperature of 170 liters.

These theoretical calculations work based on average water consumption by residents.

Malfunctions

What problems in the operation of the water supply system can the apartment owner eliminate on his own? Here are some of the most typical situations.

Valves leaking

Description: leakage along the stem of screw valves.

A typical leak location is shown by an arrow.

- Reason: partial wear of the oil seal or wear of the rubber O-ring.

- Solution: open the valve knob all the way. In this case, the thread on the rod will tighten the seal from below, and the leak will stop.

Crane noise

Description: when you open a hot or (less often) cold water tap, you hear a loud noise and feel the vibration of the mixer. Alternatively, your neighbors faucet could be the source of the noise.

A noisy neighbor's faucet can become a source of a lot of negative emotions.

Cause: a deformed and crushed gasket on the screw valve in the half-open position causes a continuous series of water hammers. Its valve closes the seat in the mixer body at intervals of a fraction of a second. In hot water, the pressure is usually noticeably higher, so the effect is more pronounced.

Solution:

- Shut off the water to the apartment;

- Turn out the problematic valve housing;

- Replace the gasket with a new one;

- Use scissors to remove the chamfer from the new gasket. The removed chamfer will prevent the valve from beating in a turbulent stream of water in the future.

Replacing the gasket on the screw valve

The photo shows a ceramic crane box

Cold heated towel rail

- Description: The heated towel rail in your bathroom has cooled down and is not heating up.

- Reason: if the water supply scheme of a residential apartment building uses continuous circulation of hot water, the air remaining in the jumper between the risers after water is discharged (for example, for inspection and repair of shut-off valves) is to blame.

- Solution: go up to the top floor and ask your neighbors to bleed the air from the jumper between the DHW risers and heated towel rails.

If for some reason this cannot be done, the problem can be solved from the basement:

- Shut off the DHW riser passing through your apartment, to which your connections are connected;

- Go up to the apartment and open the hot water taps all the way;

- After all the air has come out of the riser through them, close the taps and open the tap on the riser.

If a vent is installed on the riser, it can be diverted directly from the basement

Immediately after the end of the heating season, the difference between the lines of the route may be zero

Breakdowns in the hot or cold water distribution system

You can fix the following emergency situations with your own hands:

The valve or faucet is leaking. This happens most often due to wear of the oil seal or seal. To eliminate the malfunction, it is necessary to open the valve completely and with force so that the raised oil seal stops the leak. This technique will help for a while; in the future, the valve must be rebuilt and worn parts replaced.

Noise and vibration of a valve or faucet when opening in a hot water supply system (less often cold). The cause of noise is most often wear, deformation or crushing of the gasket in the gearbox of the mechanism. Noises appear if the tap is not opened all the way. This fault can cause a series of water hammers in the pipes, so its elimination is of utmost importance. The faucet valve is capable of closing the valve seat in the faucet or valve body in a few milliseconds, if it is not a ball valve, but a screw valve. Why is the risk of water hammer higher in hot water supply systems? Because in hot water pipes the operating pressure is higher.

How to fix the problem:

- Shut off the water at the inlet;

- Unscrew the valve housing of the noisy faucet;

- Replace the gasket, but before installing, chamfer the new gasket so that the valve does not vibrate when opening under high pressure.

The heated towel rail does not heat up. The cause of the breakdown may be the presence of air in the water supply system with constant coolant circulation. Typically, air accumulates in a pipe jumper, which is installed between adjacent risers, after an emergency or scheduled drain of water. The problem is eliminated by bleeding the air plugs. To do this you need:

- Vent the air at the highest point of the system - on the top floor;

- Shut off the hot water supply riser located in the apartment (the riser is closed in the basement of the house);

- Open all hot water taps in the apartment;

- After bleeding air through taps and mixers, you need to close them. And open the shut-off valve on the riser.

Hidden faults

At the end of the heating season, the pressure difference between the heating main pipes may not be maintained, and because of this, heated towel rails connected directly to the hot water supply will be cold. This is not a cause for concern - you need to bleed off the air, which equalizes the pressure, and the heating will be restored.