11.29.2019 Author: VT-METALL

Issues discussed in the material:

- What are the stages of pipe welding?

- What standards regulate types of pipe welding?

- What are the types of pipe welding?

- How to check the quality of pipe welding

Various methods are used to connect parts of pipelines, but welding remains the most common. This option is used both in domestic conditions and in industrial production, allowing pipe elements made of different materials to be joined together. Thanks to the technologies used, pipeline parts can be connected in any position, which greatly simplifies the work. Among the advantages of this treatment are the strength and tightness of the resulting joints. In our article we will talk about different types of pipe welding.

Stages and standards of pipe welding

The work of welders is carried out in accordance with the requirements of regulatory documents - GOSTs and SNIPs.

In 1980, the USSR State Committee for Standards approved GOST 16037-80, which came into force in July 1981 and has not lost force to this day. This standard replaced the previously existing GOST 16037-70. Changes to the document were made only once - in December 1990.

GOST requirements apply to welded joints of steel pipelines. It is necessary to be guided by its provisions in the following cases:

- when choosing the type of connection of workpieces;

- to determine structural elements and dimensions of welded joints when working with pipes and fittings.

The standard is mandatory for use, that is, all welders in the process of work are required to be guided by its requirements. An exception is the processing of workpieces made of strip and sheet metal.

Installation of pipelines is most often carried out using manual welding; when performing it, it is necessary to be guided by GOST 16037-80.

The standard sets requirements not only for the types of pipe welding (butt, lap and fillet), but also defines preparatory actions depending on the type of work.

Connecting elements requires preparation, which consists of:

- mechanical cleaning of workpieces, during which dust, traces of corrosion and oxide film are removed;

- chemical treatment designed to cope with traces of oil, fat, oxide film;

- cutting edges.

Before proceeding with the installation of workpieces, the edges and heat-affected zone are processed; the treated area is about 20–30 mm. It is necessary to remove mechanical impurities, traces of rust and oil and fat stains.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The quality of the joints has a significant impact on the safety of the finished pipeline. Strict adherence to Gosstandart standards during design, formation of the technological process and directly during processing is a guarantor of the required level of quality of seam joints.

The best effect is achieved with manual or automatic processing of pipelines. The work is performed using a consumable or non-consumable electrode (argon-arc welding).

Welding technology consists of three main stages, such as:

- Preparatory.

It includes two parts - welder preparation and pre-processing of the workpiece. Preparation of the master is an important step to ensure his safety during the work process. The use of special protective clothing and a mask, which protects the eyes from being burned by bright sparks, is essential. Pre-treatment of workpieces includes thorough cleaning of the part from traces of rust, paint and dirt. Before manual arc welding, treatment of the joints and the adjacent area is necessary. To do this, it is best to use a wire brush or sandpaper. Otherwise, there is a high probability of untreated areas appearing in the seam itself. - Welding process. The main thing when arc connecting elements (no matter whether the work is done manually or using an inverter) is to hold the arc. First of all, the electrode is activated and the arc is excited, after which the formation of the seam can begin. The welder selects the type of seam during processing. The method of working with an electrode and the technology of working with pipes depends on various factors - the arrangement of the elements, the material from which they are made, and the preferences of the master.

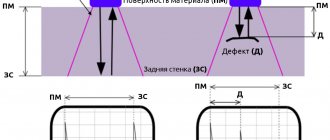

- Checking the quality of the welded joint. After completing the formation of the seam, it is necessary to remove the slag covering it, and then perform quality control of the finished joint.

The processing of elements of water supply, gas pipelines and other utilities is carried out in almost the same way. It is necessary to act consistently, based on the types of seams in different positions, since the ability to form them affects the quality of the finished product.

Cleaning the weld

A fresh weld has slag, scale and metal particles on the surface that are not needed there. In addition, the seam protrudes above the general plane, and this is not always acceptable. The final cleaning is intended to remove all of the listed shortcomings. The procedure is performed in several stages using special tools and mechanisms.

First, “rough” cleaning: scale and slag are knocked off with a hammer and chisel. Next, to level the joint, you can use a grinder with a grinding wheel. Please note that abrasives have different grain sizes. The higher the requirements for surface smoothness, the less grain the wheel should have. The soft metal joint is coated with tin solder.

Types of pipe welding

The use of one or another type of pipe welding depends on the material of their manufacture, as well as on the subsequent use. But in almost all cases, the work is performed using alternating electric current. This choice is determined by economic feasibility, since when using other types of electricity, financial costs increase. Welded joints are a number of elements connected to each other by welds.

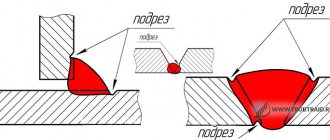

The following types of connections are mainly used:

- butt;

- corner;

- overlap

If the wall thickness of the workpieces being joined exceeds 3 mm, their edges must be cut. The opening angle of the joint should be within 60°–70°. The chamfers from the ends of the part must be removed. For this purpose, a mechanical or other method can be used.

Electrode selection

When choosing the diameter of the electrode, the thickness of the workpiece walls, the method of their connection, the weld leg, and the option of cutting the edges are taken into account. Below is a table of the direct relationship between the diameter of the electrode and the thickness of the metal of the workpiece.

| Workpiece thickness, mm | 1-2 | 3-5 | 4-10 | 12-24 | 30-60 |

| Rod diameter | 2-3 | 3-4 | 4-5 | 5-6 | 6-8 |

The values are approximate as other factors are not taken into account. For example, regardless of the wall thickness of the workpieces, experienced specialists take a maximum of “four” to form ceiling joints.

Welding pipes from various materials

- Welding copper pipes.

The choice of type of welding of copper pipes is influenced by the type of their subsequent use, the tightness of the connection, etc. The work is carried out using the electric arc, contact or gas method.

It is most effective to carry out processing using the electric arc method, during which a non-consumable tungsten electrode and filler wire containing deoxidizers are used.

This type of welding involves processing using nitrogen shielding gas, since this reduces the cost of the process.

Working with thin-walled copper pipes requires the use of argon.

- Welding of galvanized pipes.

Galvanized pipes require a special type of treatment that does not destroy the zinc coating. The joint is treated with flux, which protects it from fading of the coating. Under the influence of heat, zinc under a layer of flux acquires a viscous-liquid consistency, after which it melts, but does not burn out or evaporate. This ensures corrosion protection.

Working with galvanized workpieces requires good ventilation, otherwise it is possible to get a disease of the pulmonary system or suffocate.

- Welding of profile pipes.

Profile pipes are usually connected end-to-end. For this, arc or gas type of processing is used. The first method allows you to get the highest quality seam, and it is also easier to use. However, to process profile workpieces, the welder requires at least minimal experience.

The correct choice of electrode, which affects the arc power, is essential (a thicker electrode gives a more powerful arc). However, an element that is too thick can burn through the workpiece, and an element that is too thin can lead to a weak connection. The thickness of profile pipes varies from 1.5 to 5 mm, so “two” and “three” are suitable for working with them.

The speed at which the electrode will move across the part is also important. If you move it too slowly, you can burn through the workpiece; if you move it too quickly, the finished seam will be of poor quality. The optimal speed of movement is selected experimentally.

Process specifics

The welding process requires preliminary preparation. In addition to selecting the settings of the welding machine, electrodes, filler material, etc. you need to set the joint correctly. The parts should form a right angle. One of the elements is placed vertically, and the other horizontally. It is advisable to use special devices to accurately align the workpieces and securely fix them: magnetic squares, stops, clamps and other devices for pre-assembling the structure.

The edges of the T-joint must be cut. This procedure is not at all necessary for lap welding. Seams are formed in the corners formed by laying sheets on top of each other. A classic corner connection is two elements connected to each other. In this case, the end of one of them needs to be cut off.

ROTARY JOINTS

They are classified as complex jobs. So you need to adhere to the existing rules.

The speed of rotation of the part and the wiring of the conductor must be kept at par. For the latter, it is determined by the thickness of the part being welded. The more, the longer the welding takes. It is best when the weld pool is at an angle of 30 degrees.

Where a part is rotated 180 degrees, they work in stages. First, in 2 approaches, welding of the 2 upper quarters d of the pipe is carried out. One seam meets the other. Let's say 1 layer or two. Then turn 180 degrees, and weld the joint that remains. Then turn again 180 degrees and weld the seam until the very end.

Important Features

Some fillet welding methods have nuances that should be taken into account in the work. Otherwise, complications cannot be avoided.

Ceiling seams

In order for the ceiling seam to be welded properly, the melt must cool quickly. A similar requirement is imposed on the formation of vertical seams.

In order for the molten metal to cool faster, special electrodes with a refractory coating are used. When welding, you need to alternate circular and translational movements. And one more important note: ceiling seams should be laid only in cases where it is not possible to resort to welding in a different position.

When the rod is removed even a short distance from the working surface, the arc goes out. This occurs due to a lack of energy to maintain it. The metal cools quickly, the pool narrows, which is a precondition for a short circuit.

Moving the electrode in a protective environment

Working with inert gas has its own characteristics, and one of them is the method of moving the electrode. It is customary to distinguish between two methods – left and right. The difference between them is as follows:

- If you move the electrode to the right, you can better see the weld pool and make it easier to control the arc. The penetration is as deep and high quality as possible. Another advantage is that the amount of splashes is reduced to a minimum.

- If the electrode is moved to the left, visual visibility deteriorates, the metal is welded to a shallower depth, and the amount of spatter increases. This direction helps clean the weld pool. It is one of the most effective for welding aluminum workpieces.

Working in restricted areas

Similar situations often arise when working with pipelines. Sometimes complex situations arise that require a special approach. Especially when it comes to polypropylene pipes, which are quite common in private homes. When installing new elements, the conditions for welding differ from the usual ones. Then special tools are used:

- soldering iron;

- pipe cutter for plastic;

- set of nozzles;

- set of fittings;

- degreaser and other auxiliary tools.

The soldering iron melts plastic elements, which makes it possible to form any corner joints. In order to combine elements of different diameters there are special attachments.

Transmission welding

The method differs in that it does not involve direct contact. All work begins with preliminary preparation of the place where the workpieces will be combined.

The method is only suitable for thick-walled pipes of medium diameter. The chamfer is cut at an angle of 65-70 degrees. To ensure that the workpieces do not shift and remain on the same axis relative to each other, a centralizer is used. The gap should be 2.5 mm. The diameter of the rod is selected taking into account this parameter. The work is carried out using electric welding or an inverter.