How to weld a pipe in a hard-to-reach place

The work of a welder is difficult - sometimes you have to weld “on your knees” and in the most inaccessible places. Water and the crackling of hot metal, acrid, almost suffocating smoke, all this is associated with welding pipelines.

And if welding a fence or gate is one thing, then welding a pipe, and even in a hard-to-reach place, is a completely different story. Here welders have to be as sophisticated as they can, and they have their own secrets, which you can learn about below.

Welding methods in difficult to reach places

When connecting two parts of a pipeline near a wall or in a corner, you can use a special soldering iron to heat the junction of both pieces of pipe and, while they are still warm, make the connection. This method is only suitable for welding polypropylene pipes.

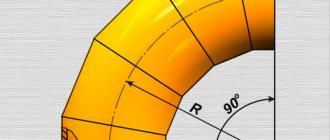

To weld metal pipes in places that are difficult for the machine to access, you can try using a special composite electrode in the shape of a hook so that you can hook it behind the pipe.

The operational or internal seam is used for welding in hard-to-reach places in cases where even a composite curved electrode cannot be inserted behind the pipe. The method consists of the following “operation”: a piece of one of the pipes being connected is cut out, a weld is made inside through the resulting hole, and after that the cut piece is welded into place like a patch.

Welding gas pipes under pressure

Welding special gas pipes for transporting high-pressure contents places increased demands on the process.

Gas pipe welding technology

Features of welding pipes for transporting high-pressure trains are determined by two characteristics:

- Thick walls and small diameter.

- Aggressive effects of transported gases.

Pipes up to 10 cm in diameter are welded manually, above - using semi- or automatic welding with manual welding of the root of the seam. For diameters greater than 6 cm, special rings are used. The weld is made multi-layered - from 4 layers and above, depending on the load on the pipeline and the characteristics of the material. After completing the work, a mandatory inspection is carried out - flaw detection inside and outside the welding site.

Yulia Petrichenko, expert

Video lesson on welding gas pipes

We carry out work in a confined space

When carrying out welding work, it is imperative to follow safety regulations. If welding takes place in a cramped small room, for example inside a gas boiler or electric furnace, safety precautions are taken especially seriously. It is necessary to use a special dielectric mat, the welder must wear a gas mask, dielectric shoes and the same gloves. The gas mask prevents damage to the respiratory tract from molten metal vapors. You need to think about lighting the room, protecting the light bulb with a metal mesh. There should be good air circulation in the room. Such work is quite dangerous, and it is highly not recommended to carry it out alone - find yourself an assistant, or better yet two.

Welding skill

Even with special tools, such as a composite electrode, welding pipes in hard-to-reach places is a very responsible and difficult task. If any significant defect occurs during work, it is better to immediately create a new connection. It is not recommended to disconnect the device from the power supply - it may be needed in working order at any time. Experienced craftsmen resort to all available means to obtain a high-quality connection, including improvised ones. Thus, there are frequent cases of using mirrors and welding by ear. To weld using sound alone requires many years of practice.

Useful video

Watch the video where an experienced welder shows how to easily and quickly weld pipes for beginners:

Video for beginner welders, welding pipes with a crescent:

Conclusion

So, welding pipes is a responsible task, but with the proper approach and careful attention, even beginners can cope with it. The main thing is to do everything according to the instructions, not to deviate from technology, to remember all the little things.

The main method of installing autonomous and centralized systems is heating welding. Unlike threaded connections, it does not require regular maintenance. When welding heating pipes, it is necessary to take into account that the connection is subjected not only to mechanical, but also to thermal influences. Therefore, it is necessary to choose the electrodes correctly, otherwise it may crack when heated.

Everything for welding

In our online store you will find everything you need that can be useful for modern welding work. The best ammunition from leading manufacturers, any consumables, welding machines of all systems - we have collected all this and more for you in one place. Call and order online!

- Saint Petersburg

- +7 (812) 748-26-90

- [email protected]

- st. Sofiyskaya, 17, BC "Formula"