For decades, heating systems have been installed using metal pipes - steel and copper. But pipelines made of ordinary steel have a number of serious disadvantages, and pipes made of stainless steel and copper are not available to everyone due to their high cost. These factors have led to the emergence of a new material with high performance - plastic pipes of several varieties, differing in functionality and cost, but with a price range accessible for everyday use.

Plastic pipes for heating, due to the specific operating conditions, occupy an independent niche in the group of polymer pipe materials, and therefore deserve separate consideration.

Main article about polypropylene pipes.

Is it possible to use plastic pipes for heating?

Plastic quickly loses technical characteristics when exposed to high temperatures. Therefore, when choosing plastic pipes for heating, you need to select products that meet a number of requirements:

- The plastic must be able to withstand the temperature of the coolant. The maximum temperature is 95 degrees. At this temperature, the pipes should not be deformed.

- The pipes must withstand high pressure so that water hammer occurring in the system cannot destroy the pipeline.

- Minimum coefficient of thermal expansion. Otherwise, individual elements of the pipeline will sag when heated. When temperatures drop, internal stresses may occur, which negatively affect the strength of the tubes.

- The pipes must be straight from the inside. If this requirement is not taken into account, plaque will accumulate on the inner walls, which will lead to blockages.

- Pipeline elements should not be destroyed when exposed to various chemicals that may be contained in tap water.

- The individual elements from which the heating circuit is assembled must be durable in order to function for a long time without breakdowns.

- The pipes must have a high level of sound insulation so that the flow of water cannot be heard in the rooms.

Plastic pipes meet all the necessary requirements, but they have one serious drawback - a high coefficient of thermal expansion. Because of this, long tubes can sag when heated. To prevent this, you need to install special compensators. They minimize the risk of tube deformation during thermal expansion and increase the strength of pipeline joints.

Types and general characteristics of plastic pipes

Plastic pipes are a polymer-based material, the functionality of which depends on the characteristics of the base. Plastic pipes are used in heating systems, cold and hot water supply, sewerage, ventilation, as sleeves and channels for electrical wiring. Each application area places specific requirements on this material, so the characteristics of plastic heating pipes are specific. But at the same time, there are common properties inherent in all types of polymer pipes.

Types of plastic pipes

Polyethylene pipes (PE, Russian abbreviation - PE) - are produced for the installation of high and low pressure pipelines (LDPE and HDPE pipes), used for internal and external wiring of water supply, sewerage and drainage systems; in heating systems, use can only be used as an expansion supply pipeline open type heating system tank.

Cross-linked polyethylene pipes are a polyethylene material in which molecular “cross-linking” is performed in one of four ways, increasing strength by creating additional cross-links between polymer molecules in the lattice. They are used in the installation of heating systems, as well as in the wiring of cold and hot water supply circuits.

Polypropylene pipes (PP, Russian designation -) are a group of several types of pipe material based on polypropylene, differing in the values of the main characteristics (operating temperature and pressure). Widely used in heating systems, cold and hot water supply, sewerage and ventilation.

Pipes made of polybutene (PB, Russian abbreviation - PB) are a high-quality material that differs from polypropylene in increased flexibility, frost resistance and maximum operating pressure.

Polyvinyl chloride (PVC) pipes are a material of two types (unplasticized and chlorinated), obtained from vinyl chloride by polymerization.

Important! Due to increased hardness and the release of chlorine upon contact with a hot environment, PVC pipes for the installation of heating systems, as well as SGV, are not used.

* Fiberglass pipes - the walls of this high-strength pipe material are made of fiberglass with a filler based on epoxy resins; these products have not found widespread practical use in heating systems due to the time-consuming connection method.

Metal-plastic pipes are products with a multi-layer wall structure, which provides the material with high technical characteristics and wide distribution in heating systems, especially when installing heated floors.

General characteristics of plastic pipes

- Strength – the ability to withstand loads characteristic of pipeline operating conditions, including water hammer.

- Plasticity and elasticity - maintaining characteristics unchanged after deformation from exposure to temperature and pressure loads.

- Corrosion resistance – neutrality of the pipe material to contact with moisture and compounds dissolved in it.

- Low coefficient of thermal conductivity - the material, along with external thermal insulation, participates in the process of reducing heat loss and condensation formation.

- Dielectric properties – absence of static electricity and stray currents.

- Low coefficient of friction - reducing the load on the circulation pump when overcoming the friction of the liquid on the inner surface of the pipeline wall.

- Resistance to biological influences - do not decompose and are inert to the presence of bacteria.

- No limescale formations on the internal walls.

- Durability is due to the characteristics listed above.

- High sound insulation properties - the movement of the medium in the pipeline is silent.

- Low specific weight – low transportation costs.

- Simplicity of installation technologies.

Plastic pipes for heating must have all the properties listed above, and some of them (heat resistance, flexibility) - to a greater extent than, for example, polyethylene or PVC products, which are not suitable for heating systems.

Thus, of the listed types of plastic pipes in heating systems, wiring only from the following materials is used:

- polypropylene;

- cross-linked polyethylene;

- high temperature-resistant polyethylene;

- polybutene;

- metal-plastic.

To have an idea of which plastic pipes are best for heating, let’s look at the products from this list of materials in more detail.

Characteristics

Technical characteristics determine the scope of application of the products. The manufacturer indicates them on the packaging of the pipes or on the plastic surfaces themselves. Options:

- the material from which the parts are made;

- diameter of plastic pipes;

- maximum coolant temperature;

- the maximum pressure that the pipe can withstand;

- sizes of plastic pipes for heating.

To indicate characteristics, a labeling system for products made from different types of plastic was developed.

Pipes for hot coolant

Polybutene pipes

Polybutene pipe products (PB, Russian abbreviation PB) are a modern high-quality material that combines the advantages of polypropylene and cross-linked polyethylene. In hot water supply and heating systems, polybutene pipelines have been used relatively recently, but they have already proven themselves to be a material that surpasses in technical characteristics products that are identical in application.

Advantages of polybutene pipes:

- preservation of strength characteristics at critical temperatures;

- a high degree of flexibility is maintained even at sub-zero temperatures;

- low coefficient of thermal expansion;

- possibility of installation using joint welding;

- low thermal conductivity;

- resistance to chemicals.

Polybutene pipe products are produced in coils and rods of both regular and pre-insulated versions. High technical characteristics determine not only the widespread use of polybutene in heating and hot water supply systems, but also their high cost today.

Marking

There are several types of plastic used to make pipelines:

- PVC pipes;

- polypropylene products;

- polyethylene parts.

A separate group includes tubes, during the manufacture of which a reinforcing layer of aluminum foil or fiberglass is placed between layers of plastic.

The marking varies depending on the type of polymer. There is no point in describing the designations on PVC, since this material is not used for the manufacture of water supply and heating pipelines. This type of polymer releases harmful substances when heated and has low performance characteristics.

Polyethylene marking:

- PE 32 is a type of polyethylene with the lowest density. It is rarely used for making pipes.

- PE 63 - used for assembling non-pressure systems. This could be sewer drains, an outdoor shower. This type of polyethylene cannot withstand high pressure and is destroyed by water hammer.

- PE 80 is a type of polyethylene with a high strength index. Used for assembling cold water supply systems. If the pipeline is laid outside buildings, additional insulation must be used.

- PE 100 - pipes made from this type of polyethylene have the highest strength index. They are used for the manufacture of industrial pipelines, hot and cold water supply systems, heating circuits.

The marking of polyethylene tubes contains the abbreviation SDR, followed by numbers. The lower this indicator, the stronger the product.

Marking of polypropylene tubes:

- PN10. Products with this designation can withstand pressure up to 1 MPa. The permissible liquid temperature is 45 degrees Celsius. Due to their low strength and heat resistance, such tubes are used for assembling sewage drains and cold water supply pipelines.

- PN16. The maximum permissible pressure level is 1.5 MPa. The coolant temperature should not exceed 60 degrees. Popular for the manufacture of cold water supply systems. Rarely used for assembling hot water circuits.

- PN20. Tubes made of this type of polypropylene can withstand pressure up to 2 MPa. The maximum permissible coolant temperature is 80 degrees. Used for assembling hot and cold water supply systems, heating circuits.

- PN25 is the most durable type of polypropylene. This material can withstand pressure up to 2.5 MPa. The coolant temperature can rise to 95 degrees. Withstands temperature surges - up to 110 degrees.

Marking of multilayer products:

- PPR - the outer layer of the tubes is covered with polypropylene;

- AL - has a reinforcing layer of aluminum foil;

- PP-RCT is a designation for modified polypropylene, which has increased thermostatic properties.

If there is a layer of fiberglass inside the pipe, the marking will contain the letters FG, FR.

Heating pipes made of polypropylene

Metal-plastic pipes

*

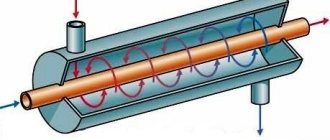

Metal-plastic pipe products are a material with a high-strength wall consisting of 5 layers: an aluminum pipe with an outer and inner shell made of cross-linked polyethylene, bonded with a high-quality binder.

The design of the outer and inner shells may differ in the stitching method or be made of polyethylene with increased heat resistance.

The technology for producing metal-plastic pipes is complex, but the cost is justified by the high technical characteristics of the final product, which is produced with an outer diameter from 16 to 40 mm and a wall thickness of 2-3.5 mm, the form of implementation is by the meter, coils.

The scope of application of metal-plastic pipes is industrial and domestic heating and hot water supply systems.

Advantages of the material:

- anti-corrosion;

- internal and external resistance to chemicals;

- low thermal conductivity;

- low coefficient of friction of the inner surface;

- small values of the radius of curvature during assembly bending;

- antistatic;

- dielectric properties;

- reliability of butt connections;

- durability.

Flaws:

- significant thermal expansion (the need to install compensators);

- lack of resistance to mechanical damage;

- the need to tighten compression fittings;

- low heat resistance relative to steel pipes;

- high cost of shut-off valves and fittings.

The main technical characteristics of metal-plastic pipes are present in the material markings, applied for convenience to each linear meter.

Performance characteristics of metal-plastic pipes:

Important! When the coolant temperature is above 140 °C, the inner polymer shell melts with delamination of the rest of the pipe structure.

Installation of metal-plastic pipes is carried out using fittings and special tools. If you have certain installation skills, it is possible to install a heating system or heating system from this material on your own.

Varieties

You can find different types of plastic pipes that are used to make pipelines. Types of pipes used for assembling heating circuits:

- Polypropylene. A material that is most often used in the manufacture of pipelines for heating, cold and hot water supply. This is due to the many advantages of this material and low price.

- Cross-linked polyethylene. Tubes made of this material are more expensive than polypropylene. Suitable for installation indoors and outdoors. Withstands temperatures from -50 to 100 degrees. Destroyed by prolonged exposure to ultraviolet rays. Because of this, they need to be mounted in protective housings.

- Metal-plastic products. Such tubes are often used in the manufacture of pipelines. The parts consist of several layers - an outer and an inner layer of polyethylene. Between them there is aluminum foil.

The choice of material depends on the operating conditions and required technical characteristics.

Choosing heating pipes or which pipes are better?

There are several types of material. The most common type is called Green Line Type One.

Product of the type “Flow Guard Gold Type Two”

It can be used in systems with media temperatures up to eighty degrees. More often this type is used in the installation of air conditioning systems and refrigeration units.

The type of material in question begins to undergo deformation already at a temperature of ninety-five degrees. Therefore, it must be used with extreme caution.

In the heating circuit from it, the temperature of the medium should not exceed the above limit.

Flow Guard Gold Type Two is a universal grade of chlorinated PVC.

Withstands temperatures up to one hundred degrees. It is used for arranging both the internal and external parts of the circuit. You can even install risers from this type of plastic. The table below shows the technical characteristics of CPVC and PVC.

| Properties | Chlorinated PVC | Regular PVC |

| Linear expansion coefficient | 0,62 | 1,2 — 1,4 |

| Density (g/cm2) | 1,57 | 0,95 |

| Thermal conductivity (W/Mk) | 0,14 | 0,22 |

| Tensile Yield Strength (MPa) | From 50 to 55 | From 18 to 26 |

| Design strength (MPa) | 10 | 6,3 |

| Oxygen permeability (upon reaching +70 in the system) | Less than 1 | 13 |

| Modulus of elasticity (MPa) | 2400 | From 550 to 800 |

Based on the information above, we can conclude that the chlorinated version of the material is characterized by a lower thermal conductivity. This property allows you to significantly reduce heat losses in the system. The structures will not get very hot. The likelihood of condensation will be minimal. These properties make it possible to construct a heating circuit without installing an additional thermal insulation layer.

Pipes made from the material in question are suitable for arranging a central water circuit and floor heating. They can be used in systems based on gas and solid fuel boilers.

Products made from other types of plastic are also suitable for solving this problem. But they also have their pros and cons. For example, polypropylene (PP) structures are less rigid, which reduces the number of fittings required when installing the system. However, they do not have sufficient resistance to high temperatures.

There is no clear answer to the question of which pipes are best for arranging a heating circuit. When designing a system, the smallest details must be taken into account. This is the only way to most effectively select the most suitable material for solving the problem.

Advantages and disadvantages

Advantages:

- Plastic pipes do not collapse when exposed to moisture for a long time.

- The material is environmentally friendly. It does not emit harmful substances when heated.

- Due to low thermal conductivity, water reaches the heat exchangers without cooling.

- The average service life under normal operating conditions without overload is 50 years.

- Thanks to the high sound insulation of the material, the sound of water flowing through the pipes is not heard in the rooms.

- Plastic parts are easy to transport and assemble together without the help of others.

- Plastic does not deform when exposed to chemicals that may be contained in pipeline water.

- Plastic tubes have smooth inner walls. Thanks to this, plaque does not accumulate on them.

Flaws:

- High coefficient of linear expansion. It must be taken into account when connecting individual pipeline elements.

- Low heat resistance. Therefore, when installing a pipeline outdoors, you need to use additional insulation.

- The material ages faster when exposed to ultraviolet rays.

If pipes are mounted on vertical surfaces, more fasteners must be used to prevent individual pipeline elements from sagging.

Easy pipe installation

Dimensions of plastic pipes for heating systems: how to choose the right one

The correct choice of diameter determines how successfully the system will function. When calculating the cross-section of pipes, it is necessary to take into account:

- wiring diagram;

- coolant movement speed;

- diameters of the boiler pressure and return pipes;

- calculated decrease in fluid temperature in batteries;

- the value of the resistance coefficient.

However, with a complex wiring diagram, especially when, in addition to radiators, a heated floor is also planned, standard calculation methods are not suitable. Then, to determine the diameter of the pipes, you will have to contact a specialist or consult with neighbors who have a similar system. If you plan to install heating with forced water circulation, it is preferable to choose options with a smaller cross-section. This will make installation easier and reduce the volume of heated water. However, you should not get carried away with minimizing the diameter, as this will cause a decrease in heat transfer due to an increase in water speed and the appearance of noise. The optimal speed varies from 0.2 to 1.5 m/s.

To independently determine the diameter of plastic pipes, you should assume that heating 1 m² of a room up to 3 m high requires 100 W of thermal energy. This means that for a room with one or two batteries of 20 m², you need 2 kW plus 20% reserve, resulting in 2.4 kW. The table indicates that pipes with a diameter of 8 and 10 mm are suitable for transmitting such power. The result is approximate, but it will help determine the cost of purchasing pipes.

Installation

To make a heating system from plastic pipes, you do not need to hire builders. To do this, you need to prepare tools, materials and do the work yourself. Stages of work:

- Prepare heating pipes in a private house or apartment. They are cut to the required sizes using special scissors. The edges are cleaned of dirt, dust, and degreased.

- Connections of individual elements can be made using couplings or butt joints. To do this you need to use a special soldering machine.

- After heating the individual parts on a heated soldering iron, they are connected to each other.

All that remains is to wait for the plastic to cool and perform a test run of the pipeline.

Plastic pipes are becoming more popular every year. This is due to the technical characteristics of the material and low price. To assemble heating systems, you can use different types of polymers. When choosing a material, you need to take into account a number of requirements and features. After purchasing individual pipeline elements, you can assemble it yourself. To do this, you need to study the technology and carry out installation work.

Difference between plumbing and heating system

Different types of plastic pipes have different performance characteristics, so it is worthwhile to clearly understand which type of pipe will be best suited for a particular project.

- For cold water supply networks, any types of polymer pipes can be used.

- In hot water supply networks, the medium has a temperature of 50–75°C, so only materials resistant to high temperatures are suitable for the construction of networks. It is not recommended to use PVC pipes here, since the material begins to melt already at 50-60°C.

- In heating systems, the temperature of the medium can rise to more serious values. Pipes made of cross-linked polyethylene, polypropylene or metal-plastic are suitable here.

As for the pressure of the working environment, in water supply networks this figure can be about 4 bar, in central heating networks (depending on the number of storeys of the house) - 2-12 bar, in private heating systems - 1.5-2 bar. This indicator can also affect the choice of pipe material. For networks with high pressure, it is better to use pipes with thick walls or reinforced products.

Polypropylene pipes

4. Polypropylene pipes and fittings (connecting parts) for polypropylene pipes.

They have taken a very good position in application.

Polypropylene pipes, due to their properties, are good for drinking water pipelines. Reinforced polypropylene pipes have proven themselves in heating systems, that is, where it is necessary to transport hot water or steam.

Advantages of polypropylene pipes:

- long service life of pipelines (up to fifty years!);

- polypropylene pipes are not subject to corrosion, which is why their internal diameter is not clogged with scale and other deposits;

- high chemical resistance: do not rust and therefore do not change the taste, color, composition of the water in them;

- low noise level (compared to metal ones) of liquid flow in them;

- monolithic connection of pipes to each other:

5. Monolithic connection of polypropylene pipes is an undeniable advantage of such a pipeline.

Thanks to this connection, polypropylene pipes can be hidden in walls, under plaster, or in the floor;

To weld polypropylene pipes, a welding machine is used (in common parlance, a “soldering iron”), which anyone can master in literally a couple of minutes.

6. Welding a polypropylene pipe with a fitting.

In this case, welding (soldering) takes literally seconds;

the polypropylene pipe provides high oxygen impermeability, so that the metal parts of the system are not subject to corrosion; polypropylene pipes are more profitable from an economic point of view, since they are more than 2 times cheaper than metal-plastic pipes, especially connecting parts (fittings); have high mechanical strength; resistance to defrosting; when water freezes in a pipe, you almost certainly don’t have to worry about the integrity of the pipe - the polypropylene will expand and when it thaws it will return to its original shape; polypropylene is environmentally friendly.

Disadvantages of polypropylene pipes:

- the quality of installation depends on the chosen material: it is necessary to choose reinforced pipes for heating systems, and ordinary pipes for water supply and sewerage systems;

- sensitivity to high temperatures - these pipes are not suitable for fire hazardous areas;

- When purchasing polypropylene pipes, you need to take into account their manufacturer, since the shortcomings of such pipes may be associated with violations of their manufacturing technology or caused by the use of low-quality raw materials.

The listed disadvantages apply only to certain batches of products that were manufactured without quality control. Basically, polypropylene products are manufactured in accordance with standards and GOSTs and are characterized by fairly high reliability.

Polypropylene pipes are suitable for almost any type of pipeline. Their only limitation is the coolant temperature (from +65 to +95 degrees). On average, polypropylene pipes have an operating temperature of up to 75 degrees at a pressure of 7.5 atm. Moreover, their guaranteed service life is 25 years. The maximum temperature this type of pipe can withstand is 95 degrees. But with such an “extreme” operating mode, the service life of the pipes is reduced.

However, there is such a type of polypropylene pipes as reinforced polypropylene pipes. They can be reinforced with either aluminum foil or fiberglass.

7. Polypropylene pipes reinforced with fiberglass are used for heating and hot water supply systems.

8. Polypropylene pipes reinforced with aluminum foil are also used for heating and hot water supply systems.

These pipes are designed for relatively high temperatures.

They have an operating temperature of 95 degrees, but for a short time they are able to withstand heating up to 110 degrees, which is why they are used in heating and hot water supply systems. Date: September 25, 2021

Metal-plastic pipes

These pipes, as the name suggests, consist of two materials and therefore receive the advantages of both. However, first things first.

Characteristics

Metal-plastic pipes combine the advantages of metal and polymer.

The basis of the metal-plastic pipe is a layer of cross-linked polyethylene, which is located inside. It plays the main load-bearing role and gives the product strength. Thanks to the ideally smooth inner surface of the plastic, the pipe has a minimal coefficient of hydraulic resistance, that is, a powerful pump is not needed to maintain fluid flow.

In addition, mineral deposits from the water do not accumulate on the inner walls of the pipe, as a result of which the engineering system maintains its throughput throughout its entire service life.

A layer of aluminum foil is attached to the inner layer of plastic using glue, which stabilizes the pipeline and prevents oxygen from penetrating through the polymer into the coolant. Thanks to the stabilizing function of aluminum, metal-plastic pipes have a minimal coefficient of thermal expansion, which makes them an excellent choice for installing heating systems.

On top, the reinforcing foil is protected by another layer of plastic, which simultaneously performs a decorative function. Both polymer layers prevent the formation of galvanic couples with steel parts of the heating system, reduce the thermal conductivity coefficient and prevent the formation of condensation on the surface.

The structure of a metal-plastic pipe.

That is, if you schematically imagine the described product, then it consists of the following layers:

- plastic layer inside;

- glue;

- aluminum foil;

- glue;

- protective plastic on the outside.

Thanks to this combination of several materials, metal-plastic pipes acquire many advantages, which I want to talk about in the next section.

Advantages

The heating system made of metal-plastic pipes has excellent performance properties.

The main advantages are:

- High throughput. According to this indicator, composite pipelines are 1.3 times faster than their ancestors, which were made only of metal.

- Anti-corrosion resistance. Plastic is absolutely not susceptible to corrosion, regardless of the installation location and operating conditions.

- Environmentally friendly. When heated, the polymer does not release hazardous chemical compounds into the air.

- Long service life. A metal-plastic pipe retains its technical characteristics and performance properties for at least 50 years (for comparison, steel pipes - 15 years).

Manufacturers promise that metal-plastic heating will last at least 50 years.

- Low weight. The products are easy to transport and after installation they do not exert significant load on the building elements. Due to their high plasticity, pipes are sold in coils and are easy to install in underfloor heating systems.

- Low thermal conductivity coefficient. According to this indicator, they are 170 times better than steel parts and 1300 times better than copper parts. That is, the coolant, flowing from the boiler to the radiators, practically does not lose thermal energy.

- Easy to install. When laying, metal-plastic pipes do not require angles and fittings for arranging turns. And the connection to each other, radiators, taps and other equipment is carried out using fittings (no welding equipment is required).

- Good maintainability. If the integrity of the pipeline is damaged, it can be easily repaired using a suitable piece of pipe without the need for bending or welding.

Bursts in metal-plastic pipes can be easily eliminated without the need for welding.

- Aesthetic appearance. Pipes after installation and during operation do not require additional decorative finishing. They are beautiful in themselves and fit organically into any interior.

It is impossible not to mention the shortcomings. First of all, metal and plastic have different coefficients of thermal expansion, so the joints (where steel fittings are used) may develop leaks over time. Therefore, detachable threaded fittings cannot be embedded in concrete.

Leaks may occur at the junction of pipes and fittings.

To minimize the risk of fittings depressurizing, I recommend laying pipes with a small margin so that they do not stand “tight”. In addition, compensation loops can be installed.

And one more point that novice masters do not pay attention to. Although the metal-plastic pipe is very flexible, it does not like repeated bends, especially with a too small radius. To make turns, you need to use pipe bending springs, which make it possible to preserve the internal cross-section of the pipe at the bend.

Due to their plasticity and long length (pipes, as I said, are sold not in sections, but in coils), I use such products for installing “warm floor” systems and when laying heating networks using a collector circuit.

Diameters

Manufacturers of metal-plastic pipes produce parts with a diameter from 16 to 63 mm. The most common products in private construction are those with a diameter of 16, 20 or 26 mm. If there is a need to lay main sections of wiring in multi-story or large buildings, pipes with a diameter of 32 or even 40 mm are used.

Pipes of different diameters are used for different sections of the heating system.

As for the length, the stores have coils of pipes ranging from 50 to 200 meters in length. This is enough to satisfy any needs.

Differences between plumbing and heating systems

Some people who are inexperienced in the design and installation of engineering systems believe that there is no difference between water supply and heating pipes, since these products perform the same function. It is precisely these specialists who later become my most private clients when it is necessary to urgently carry out heating repairs due to destruction of pipelines.

Incorrectly selected pipes often cause heating system breakdowns.

Therefore, I will present here the technical characteristics of household heating systems so that you can compare them with the parameters of water pipelines and understand that they are operated differently:

- The liquid pressure in the heating system reaches 6 atmospheres (and sometimes more), which is more than twice the same parameter for a water supply system.

- According to building regulations, the coolant temperature can range from + 95 to + 105 degrees Celsius, depending on the type of heating boiler. Accordingly, the walls of polymer pipes must maintain their integrity under such operating conditions.

Pipes must withstand the high temperature of the liquid flowing through them.

- Over the course of a year, the temperature of the liquid in the pipes and the surrounding air can vary over a fairly wide range. Therefore, it is necessary that parts for the heating system have the lowest possible coefficient of thermal expansion. Otherwise, you will have to install expansion joints, which will worsen the appearance of the pipelines.

Pipes must have a low coefficient of thermal expansion so as not to elongate when heated.

Below I will talk about three types of plastic pipes that I used in my professional activities.

Coolant pressure and temperature

You need to choose pipes, taking into account in which system they will be used - individual or centralized. The pressure in an autonomous system is usually 2-3 atm. In a centralized system, it is possible to increase the pressure to 16 atm during system startup.

Polypropylene can withstand 6-10 atm, so it is better to install them in an individual system. Metal-plastic ones are corrosion-resistant and durable, so they can be installed in a private house with an autonomous system, and connected to a centralized system supplied to the apartment.

Polypropylene products can withstand temperatures up to +90C, metal-plastic products – up to +95C.

Reinforced PPRC polypropylene pipes - overview and characteristics

Every modern room, regardless of its purpose, needs to be provided with water resources. The instrument for providing any building or premises has been and remains water supply. A water supply network is a network of various types of pipes through which water flows to the place of its use.

Advantages of using pprc pipe

This article will focus on pprc pipe, which is reinforced internally with reinforcement. So, pprc reinforced polypropylene pipes are pipe products made from Poly Propylene Random Copolymer. This material is a static random copolymer, which is produced by adding an ethylene molecule to a network of polypropylene molecules. This material belongs to the category of polyolefins, which are highly environmentally friendly.

Random copolymer pipe products, in addition to the long name, are distinguished by a fairly large number of positive characteristics.

- They have low thermal conductivity.

- They have a high coefficient of resistance to various chemicals.

- This type of product is not exposed to processes such as corrosion and rusting.

- Characterized by high sound insulation.

- During the operation of the pprc pipe, the formation of sedimentary materials, such as salt or lime, does not occur on the inner surface of the material.

- They have high impact strength.

- This type of material has high resistance to repeated bending, after which it retains the integrity of the skin and primary mechanical properties.

- When exposed to high temperatures, polypropylene products do not undergo deformation and remain in their original shape.

- As mentioned above, this type of pipe fittings is highly environmentally friendly. This is manifested in the fact that after the end of their service life and subsequent disposal, they do not emit toxic substances that can harm humans and nature as a whole.

- With proper installation and operation they have a long service life.

Reinforced PPRC polypropylene pipes: specifics of reinforcement

Reinforced pprc pipe products are pipes made from polypropylene water fittings, the design of which, in addition to the original material, includes a thin additional layer of aluminum or fiberglass. This type of pipe fittings can be used in cold or hot water supply systems, as well as for other pipe communications, the chemical composition of which will not harm polypropylene. This type of pipe materials can also be used in fire extinguishing systems. So, in more detail about the types of reinforcement of pprc pipe fittings and their features:

Reinforcement with a layer of aluminum foil. The metal layer can be located inside or outside the product. This treatment gives the pipe additional properties, which are manifested in increasing its strength and resistance to temperatures.

Reinforcement with glass fiber gives pipe materials strength and increases resistance to mechanical stress. This type of reinforcement eliminates the formation of delamination of the structure of the lining of the pipe product, which can occur in the case of aluminum reinforcement.

Reinforced PPRC polypropylene pipes: installation methods

Installation of pipe communications made of polypropylene is relatively easy compared to a similar process in the case of steel or copper pipes. To work with this type of material you will need specific tools. Firstly, this is a special welding machine for soldering pipe parts together. This device is a tool with holes for mounting materials. During the work, the necessary pieces of pipe are placed in these holes, and after heating, they are connected to each other using specialized fittings.

To cut pipe fittings into the necessary parts, special scissors and pipe cutters for polypropylene pipes are used. With the help of these tools, pipes are easily divided into the necessary pieces. The system easily attaches to almost any surface using any holders that are attached with screws or glue.

Thus, the article described all the main characteristics of pipes made of static random copolymer (pprc), as well as their advantages over metal ones. Their typological features and installation specifics were also characterized and shown.

Reinforced PPRC polypropylene pipes

Application of pprc pipe in various indoor pipe systems. The article describes the main characteristics of pipe communications in the installation of which pprc pipes were used.

Heating system in a private house: approximate action plan

Installation of a heating system in a private house, similar to the previous option, also requires careful planning and preliminary preparation. Note that in this case, the option with two-pipe wiring is more preferable. To begin with, you need to decide on the type of heating element (boiler).

As a rule, they are:

- solid fuel;

- gas;

- electric

Solid fuel boilers are quite difficult to maintain, and it is better to entrust the connection of the heating system to them to professionals. The use of gas boilers is relevant if there is a gas pipeline connected to the house. Compared to previous options, the installed electric boiler in this case is the safest.

An important factor in the situation with installing heating in a private house will be the type of coolant movement in the system.

The generally accepted division is into circulation:

- natural (gravitational);

- forced (pumping).

In the first case, the heating system design must include an air vent and an expansion tank to prevent sudden pressure changes. At the same time, it is recommended to install the expansion tank in a warm room to prevent the coolant from freezing.

It should also be taken into account that, despite relatively simple installation, systems with natural coolant circulation have some disadvantages. So, they take a long time to put into operation, and their total length should not exceed 30 m.

Once you have decided which polypropylene heating pipes are better, you can proceed to the next step: connecting them to radiators.

To do this, choose one of the existing methods:

- lower;

- side;

- diagonal.

The option with a bottom connection (this scheme is also called “Leningradka”) involves connecting both the supply and discharge pipes to the bottom of the radiator. This system is not recommended for multi-storey buildings. But it can be effective in a private home, especially since, if desired, the lower wiring can be hidden in the space under the floor.

In the case of a side connection, the supply and discharge pipes are located on one side of the radiator, one at the top, one at the bottom. This scheme is most often found in apartment buildings and is quite effective.

Conclusion

Now you know everything you need about plastic heating pipes. If you are interested in how to solder them, you can watch the video in this article. And I wanted to ask, what kind of pipes do you prefer to use to make a heating system for your house or apartment? Plastic, metal or some other? I will be glad to see your answers in the comments to the material.

Did you like the article? Subscribe to our Yandex.Zen channel

July 28, 2021

Types of pipes, Heating, Pipes

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!