Despite the impressive list of advantages, copper pipes for heating in our country are used less frequently than their plastic and steel counterparts. Perhaps this paradox is explained by their high cost. However, in money-conscious European countries, copper pipes are the most popular option for heating systems. Obviously, they calculated that the costs are more than offset by a long service life and lower repair costs.

Types of Copper Pipe

The range of manufacturers is extensive, which allows you to choose the best option for a specific heating project. Products differ in the following parameters:

- Wall thickness – 0.2-0.7 mm and 0.8-10 mm. The former are rarely installed in heating systems. For indoor installation, varieties of 1-2 mm are used.

- Depending on the manufacturing technology, drawn (cold-rolled) and pressed types are produced.

- Depending on the processing method, pipes can be rigid or plastic. The former are more durable, but break when elongated by 15%. They are made in straight sections of 6 m each. For the latter, after tempering at a temperature of 600 ⁰C, the strength decreases by 30%, but the elongation at break increases to 60%. Sold in coils of 25 and 50 m, which are convenient for installing heated floors.

- According to the material, the pipes can be made of pure copper and alloys with zinc and tin.

- Unlike welded ones, seamless types are made without seams.

- In addition to non-insulated varieties, pipes coated with plastic are produced. It protects them from mechanical damage. When using foamed polyethylene, heat loss is reduced.

Scope of application of copper pipelines

The scope of use of copper pipe products is extensive, but most often it is used for laying:

- heating systems;

- pipelines for water supply;

- highways along which compressed air or gas is transported;

- fuel pipelines;

- condensate drainage systems;

- structures for connecting technological equipment;

- pipelines supplying freon to refrigeration units;

- air conditioning systems, etc.

Advantages and disadvantages of copper pipes in heating systems

The advantages in use are due to the unique properties of the material. The products have the following advantages:

- Long (up to 50 years) service life without repairs or maintenance.

- The walls do not allow outside air to pass through, which increases the corrosion resistance of the entire system.

- Pipes can operate under pressure of 30 atmospheres and higher.

- Under natural conditions there is no corrosion or reaction to ultraviolet radiation.

- Copper does not interact with active chemical compounds, of which there are many in large heating networks. Chlorine contained in water forms a thin protective layer on the inner surface, which helps to increase service life.

- The low coefficient of thermal expansion makes it possible not to install expansion joints on pipelines. 1 meter will lengthen by 1 mm as the temperature increases from 20 to 90 ⁰C.

- The slight roughness of the internal walls prevents deposits from accumulating and helps reduce hydraulic pressure. Therefore, the use of lower power pumps and small diameter pipes is allowed.

- 100% environmentally friendly and antibacterial properties.

- Rigid copper products can withstand 3 defrosts of the system, while plastic ones can withstand 6 cycles without breaking.

- The attractive appearance of the material is often used as an element of room design.

- Despite the significant specific gravity, the mass of copper pipes is small due to the small wall thickness. For the same reason, their internal cross-section is larger than that of other species of equal external size. 1 m of 20 mm copper pipe weighs only 0.6 kg.

However, there are also disadvantages:

- the need to use thermal insulation when installing in walls and ducts to reduce heat losses;

- corrosion may form on the outer surface;

- high electrical conductivity attracts stray currents, which have a negative effect on the walls;

- poor compatibility with other metals, fraught with the appearance of electrochemical corrosion;

- installation complexity due to the specifics of soldering permanent connections;

- the highest price compared to other types of pipes.

Results

As you can see, copper pipes for heating are a good, but not ideal option. This material has many advantages, but no less disadvantages. Corrosion may occur - this may be the result of an incorrectly selected coolant composition, high pressure or water hammer. Moreover, it is worth considering that the service life of copper heating systems directly depends on proper design and installation, that is, even if high-quality components are used, but they are soldered or laid with “crooked” hands, there will be no long-term operation. And today there are very few specialists who competently work with copper, and their services (in addition to the materials) are also very expensive. Perhaps this is why they rarely install it today, especially since there is a good replacement - polypropylene (reinforced) or metal-plastic.

Finally, a few video lessons with useful information. This video has a little about the types of solders.

And this video material talks about how copper fittings are made. Interesting…

Labeling and cost

Round copper products for heating and plumbing with walls from 0.8 to 10 mm thick are manufactured in accordance with GOST 617-90. In subsequent years, the document was repeatedly refined, so a different digital value may be indicated in the marking. Depending on the purity of copper, its grades according to GOST 859-2001 are marked as M1, M1p, M2, M2p, M3, M3p. The composition of the material has little effect on the main characteristics of the pipes, so they are allowed to be neglected.

From the standard labeling you can find out:

- Preparation method. Drawn ones are indicated by “D”, and welded ones are indicated by “C”.

- Cross section shape. For the pipes in question, it is round, so it is marked “KR”.

- Precision manufacturing. Normal wall thickness and diameter size are designated “N,” and increased thickness is designated “P.” With normal accuracy of wall thickness and increased diameter, “I” is indicated, and if vice versa, then “K”.

- Length. “ND” is an unmeasured pipe, “MD” is a measured pipe, “KD” is a multiple dimension index, “BT” is a coil.

- About special conditions. Improved characteristics are designated by the letter P. Increased ductility is “PP”, strength is “PT”, accuracy is “PS”, cutting accuracy is “PU”.

Other manufacturing features are not significant. For example, they pay attention to increased accuracy in curvature “K” if they want to install a pipeline with an ideal appearance and are willing to overpay. The standard marking looks like this: DKRNM 30×2.0×2050 M1 GOST 21646-2003. This means:

- the pipe is made of M1 grade copper;

- drawn out;

- round shape;

- manufacturing accuracy is normal;

- soft;

- outer diameter 30 mm;

- wall thickness 2 mm;

- length 2050 mm;

- according to GOST 21646-2003.

According to European standards DIN 1412, copper pipes for installation of water supply and heating systems are marked EN-1057. It means that phosphorus has been added to their composition, which increases oxidation resistance. EN-1057 is the number of the standard to which the pipe is manufactured.

On average, prices for copper products with walls 1 mm thick for heating installation in an apartment or private house, depending on the size of the internal cross-section, are:

| Diameter, mm | 6 | 8 | 10 | 12 | 15 | 18 | 22 | 28 | 35 |

| Price per 1 meter, rub. | 110 | 145 | 180 | 210 | 220 | 235 | 295 | 380 | 600 |

Pipes with walls 1.5 mm thick cost one and a half times more. Prices are indicated for products of Russian manufacturers. Foreign analogues will cost more due to transport and customs costs.

Detachable and press connections

To make a press connection, you need a specialized tool - crimping pliers. They are available both manual and electric. After stripping the pipe and fitting, they are combined, pliers are applied to the joint from the outside and crimping is performed. The connection is considered permanent and quite reliable.

Detachable coupling is done following the example of metal-plastic pipes, since the principle of combining a brass fitting with a pipe is exactly the same. Accordingly, the cost of the connector is several times higher than that of a soldering fitting. But for installation you only need 2 wrenches. Details of the work are presented in the video:

Diameter

Previously, it was indicated in inches, but in the latest version of GOST 617 of 2006, the dimensions are given in millimeters. The new document specifies more than 70 standard sizes for outer diameters from 3 to 350 mm only for cold-deformed copper pipes. However, foreign and some Russian manufacturers still mark their products in inches.

To characterize a pipe, the nominal, external, or internal diameter can be indicated. In practice, when selecting connecting elements, they use the concept of conditional passage, meaning the size of the internal clearance. Domestic manufacturers indicate it in millimeters, while foreign manufacturers indicate it in inches.

The throughput of pipelines is calculated based on the internal diameter, and classification is made based on the external size. The nominal diameter is a value approximately equal to the nominal diameter, but with an indication of the exact value.

When converting units of measurement, it should be taken into account that the internal cross-section of an inch pipe (1″) is 33.5 mm, although in the metric system this value is 25.4 mm. The discrepancy is due to the fact that in the document it is indicated by the nominal diameter, and the outer size of imported products is in inches. Therefore, a 1″ pipe inside can be from 25.5 to 27.1 mm. To convert the cross-sectional value from one system to another, use the table:

| Inches | External diameter, mm | Conditional bore, mm |

| 1/4 | 13,5 | 8 |

| 3/8 | 17 | 10 |

| 1/2 | 21,3 | 15 |

| 3/4 | 26,8 | 20 |

| 1 | 33,5 | 25 |

| 1 1/4 | 42,3 | 32 |

| 1 1/2 | 48 | 40 |

| 2 | 60 | 50 |

| 2 1/2 | 75 | 70 |

| 3 | 85,5 | 80 |

| 3 1/2 | 101,3 | 90 |

| 4 | 114 | 100 |

| 5 | 140 | 125 |

When converting inches to millimeters and vice versa, an error is obtained that should be taken into account when choosing pipes of the required diameter. The result is rounded up. Frequently encountered data is shown in the table:

| Inches | Millimeters |

| 1/2 | 20 |

| 1 | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 89 |

| 4 | 100 |

Regulatory requirements according to GOST

External parameters, mechanical characteristics, alloy composition, assortment and marking designations are regulated by two main provisions: GOST 617-2006 (General purpose copper pipes) and GOST 11383-75 . European-made products meet the EN-1057 standard of 2006 .

Set of requirements:

- The internal and external surface of the pipe should not be contaminated to prevent inspection of the products. The presence of delaminations, rust, cracks and cavities on the pipe “sleeve” is unacceptable.

- A dent up to 0.25 mm deep is acceptable. The quantity limit is no more than two per linear meter and no more than 10% of defective products per delivery lot.

- No burrs at the ends of the pipes. The normalized cutting bevel for specimens with a diameter of up to 20 mm is 2 mm, for products with a cross-section of 20-170 mm - 3-5 mm, respectively, for pipe fittings with a diameter of 170 mm or more, a bevel of 7 mm is acceptable.

- For coils and soft pipes, ovality is not limited.

Each coil or batch of pipe sections must be accompanied by a packing slip and information label.

Mandatory data from the accompanying document: trademark of the enterprise, legal address of the manufacturer, marking of the composition and dimensions of pipes, batch number, production date, technical control stamp

Installation of copper heating pipes

During the work, you will have to cut and bend products, assemble assemblies and connections, solder or weld, and crimp fittings. In addition to the basic operations, you need to be able to calibrate and process the ends, remove burrs and burrs, apply flux, and then clean the surface of its residues, etc. During installation you cannot do without the following tools:

- pipe cutter;

- hand calibrator;

- gas burner;

- set of wrenches;

- files;

- flux;

- solder;

- sealing tape.

First, pipes with damage, kinks, or pinches are rejected. Their use will disrupt the operation of the heating system and reduce its reliability. The blanks are cut using a pipe cutter or a hacksaw with a new blade. Fastening to walls is carried out using brackets, plastic and metal clamps with rubber gaskets.

Features of operations

During preparation, it is necessary to ensure that the cut line is perpendicular to the axis of the pipe. The deviation should not exceed:

| Outer diameter, mm | Bevel size, mm |

| 6-18 | 2 |

| 22-42 | 3 |

| 54-76 | 4 |

| 88-108 | 5 |

When using a disc pipe cutter, you cannot apply great force; it is better to increase the rotation speed. When cutting annealed products, their ends may become deformed, which will lead to uneven mounting gaps and the impossibility of soldering. Therefore, it is necessary to calibrate the ends, starting from the inside, then from the outside. During soldering, solder can flow into the pipe, forming growths (burst) there. If they are not removed, the hydraulic resistance of the entire system will increase.

The high ductility of copper products allows them to be connected with sockets without fittings. However, the use of this method is allowed for workpieces of the same diameter in heating systems with a coolant temperature of no more than 110 ⁰C. To create sockets, special equipment is required.

The permissible bending radius of workpieces with a cross-section of up to 15 mm should not be less than 3.5 diameters, and for thicker ones - 4. When bending manually, the radius is limited to 8 values, otherwise the walls may be flattened. It is recommended to preheat rigid pipes.

Detachable connections

To create collapsible joints, compression fittings are used. These connections are not highly reliable and require periodic tightening. For plastic-coated pipes, the ends are cleared of the insulating layer, and burrs are removed from the ends.

First, put on the union nuts, then the ferrules. Then tightening is done. As the nuts are tightened, the rings will begin to press against the pipe, sealing the joint. The main thing is not to overdo it, so as not to disturb the shape of the ends, which may cause leaks. Sealing of transition fittings when connecting to devices made of other metals is carried out with FUM tape. The water flow should be directed towards the copper.

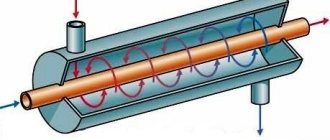

Solder connections

The method is based on the use of capillary effect, under the influence of which solder is able to fill gaps. The connection is made with fittings with an internal diameter larger than the outer size of the pipe by 0.1-0.15 mm. Soldering can be high or low temperature. The first, like welding, is used for joining thick-walled pipes with a diameter of more than 110 mm.

Low-temperature soldering is carried out according to the following algorithm:

- The ends of the pipes are cleaned of the polymer coating (if any) and burrs.

- The soldering area and the inner walls of the fitting are treated with fine sandpaper.

- After cleaning the dust, flux is applied to the surface.

- The ends of the pipes are inserted into the fitting.

- The connection is heated with a torch or blowtorch.

After reaching the required temperature, the solder placed on the surface, due to the capillary effect, will begin to melt and flow into the gap between the pipe and the fitting. During soldering and cooling, the structure is rigidly fixed. To prevent the strength of copper from decreasing, forced cooling should not be used.

Materials and equipment

Welding is considered the most reliable connection of copper pipes. It is recommended to carry out docking using the following devices:

- solders that are chosen for a specific material;

- additional fittings;

- flux in the form of a liquid or paste to clean the joint from oxide deposits;

- for cutting workpieces, a pipe cutter is used, with the help of which workpieces with a smooth edge are prepared;

- chamfer;

- to enlarge the holes, use a flaring tool;

- gas appliances for heating the welding site.

Types of Welding Torches

The choice of equipment directly depends on the volume of work to be done and the diameter of the pipes. To know how to weld copper pipes, you need to understand the characteristics of this metal. For example, you can carry out work using hard solder with a torch that can heat it to a temperature of 430°C - 450°C, while for soft solder it should not exceed 425°C. Among the large assortment on the market, we can highlight the following equipment for welding copper pipes:

- If the volume of work is large enough, then you can purchase an acetylene-oxygen apparatus, which provides uniform distribution of heat at the joint. This type of welding equipment requires skills to work with it, since the oxygen-acetylene mixture is explosive at high pressure. Typically used for working with hard solder.

- Household gas burners are more suitable for a self-taught welder and may differ in the composition of the gas in their cylinder:

- For welding small elements, a machine with a cylinder containing a mixture of gas and air is suitable. The container can be either stationary or removable.

- Mixtures with oxygen in burners are applicable when installing pipes of any diameter and wall thickness. They belong to the category of professional equipment and, as a rule, have stationary containers.

- Small hand tools can help you repair copper pipes and are inexpensive to the owner. They are equipped with a disposable propane or butane cylinder and can work with any type of solder. Typically, such a tool is sold with replaceable nozzles, which allows you to adjust the flame power.

The best equipment for a home craftsman are hand torches, since working with them does not require special knowledge and skills. They are equipped with flame deflectors and a special valve to shut off the gas supply, which provides additional protection for the inexperienced beginner.

- Induction welding of copper pipes is carried out by an inductor connected to a generator and, as a rule, is used by professional welders when installing industrial lines.

Welding copper pipes (the video shows this) with your own hands is quite within the capabilities of an inexperienced craftsman, if he has chosen the right tool for this. The simpler the unit, the easier it is to work with. In this case, an autonomous hand torch is the best choice.

How to paint copper heating pipes

To increase resistance to corrosion or give products a look that matches the decor of the room, they are coated with the desired color. You should not use oil paint for this purpose, as it darkens when heated and begins to smell. Heat-resistant polyurethane and alkyd enamels or ethinol varnish mixed with aluminum powder are better suited.

The composition is applied to a cleaned, degreased and primed surface. Since copper does not absorb paint, it must be carefully spread over the pipe with a brush. The use of aerosol cans allows you to obtain a uniform, high-quality coating.

Connection technique

When connecting copper pipes with your own hands, follow the following algorithm:

- cut the workpieces to the required size;

- the edges are cleaned for a quality connection;

- the holes are widened, but if copper pipes will be used in heating systems when the energy carrier is heated above 110°C, fittings are installed;

- parts of the parts are inserted into each other, while maintaining a gap;

- the seam is heated with a gas burner;

- fill the seam with liquid solder, preventing the formation of voids and lumps of solder;

- The connected parts are left for some time to completely cool the welding site; it is forbidden to move sections of copper pipes.

If all points of the copper pipe welding algorithm are followed, a reliable connection is achieved.

Flux for welding copper pipes

Installation instructions using fittings

There are two types of compression fittings - the so-called compression and compression. They create completely different connections, so before starting work you need to decide what kind of connections you would like to see: permanent or conditionally detachable.

Press fittings are similar to solder fittings, but have shallow recesses at the edges with sealing gaskets. Using special press pliers, which have a set of nozzles for different diameters, crimping is carried out.

As a result, it creates a sealed, permanent connection that cannot be repaired, and in the event of an accident can only be replaced.

In the store you can see parts that are identical at first glance, but they differ in characteristics (composition, wall thickness, etc.). Heating fittings are marked with green markings

Pressing creates a strong, reliable connection of parts, while maintaining the geometry of the pipes and does not deform the connecting elements. There is a nuance of pressing “soft” copper products: before the operation, a support sleeve is inserted into the pipe, which resists deformation of the pliable material

The pressing process is simple and does not take much time. The tools required are a standard set for cutting and processing pipes, as well as press pliers with the required attachment.

Pressing is considered a reliable method. If you plan to thermally insulate copper pipes, you can use insulating tubes, which are easy to put on even on curved structures. After pressing, the finished heating network can be masked in grooves, covered with decorative cladding and filled with screed.

The second type of fittings is compression. They differ in design and installation process.

A compression fitting for copper pipes is a prefabricated device consisting of three parts: a brass or copper body, a ferrule, also called a collet, and a nut.

The crimping procedure is as follows:

- a nut is loosely placed on the prepared end of the pipe;

- then the collet is put on;

- last of all, the fitting body is put on until it stops;

- the nut is screwed manually along the thread, while simultaneously pressing the split ring;

- The connection is tightened with an adjustable or sized wrench.

During the compression crimping process, the cutting ring tightly grips the pipe, creating a strong and airtight connection. The nut may become loose over time, so pipelines with this type of installation must be regularly maintained.

The connections are conditionally detachable, since they can be disassembled, however, if necessary, the fragment with the clamped ring will have to be removed and a new fitting installed.

Criterias of choice

Copper models, due to their high cost, must be carefully selected.

In order not to make a mistake, you need to get acquainted with the main selection criteria:

- Compliance with terms of use. The main advantage of the products is their versatility. Suitable for both plumbing and heating systems, because they are immune to constant temperature changes and high pressure. They can withstand loads up to 40 atmospheres and temperatures up to 500 degrees Celsius. They are resistant to ultraviolet radiation and have a low expansion coefficient (7 times less than polymer ones). Also, thanks to the active bactericidal properties of copper, it is absolutely safe for humans. But it is worth paying attention to the fact that copper reacts poorly to chlorine, so interaction with it will quickly render the pipes unusable.

- Cost of material and installation. The cost of copper is several times higher than its analogues (about 4 times higher than the price of plastic). But if we take into account all the work associated with the installation and additional elements, then the final cost of the work is no higher than that of metal-plastic. A press fitting for plastic is much more expensive than a solder fitting for copper. Consequently, the final installation cost directly depends on the footage and the number of fasteners.

- Life time. The trouble-free service life of a copper pipeline is 50 years or more, which is a very good indicator.

- Ease of installation. Pipeline installation takes place in several stages: preparation of the material, its processing and installation. The process itself takes a long time, because it is necessary to cut the pipes, bend them using a pipe bender, and also carry out complete installation of all elements. In the end, everything must be connected using fittings (soldering and crimping).

You should not combine copper with galvanized steel, because due to electrolytic processes the copper will simply be destroyed.

Pipes made from alternative materials

To figure out when which pipes can be used for heating, you need to compare them according to several parameters and answer a number of questions:

- What kind of heating system will there be - forced or gravity.

- Type of pipe installation - inside or outside the wall, simple or complex system configuration.

- Maximum and operating pressure and temperature in the system.

- Price

After analyzing this data, you can choose your option.

Iron pipes

Today, the market offers a large selection of iron pipes, although their use has been reduced to use in a gravity autonomous heating system using large-sized pipes. The main advantage of these pipes remains their strength; they cannot be damaged mechanically. They are resistant to high temperatures (over 1500˚C) and pressure. Moisture has little effect on metal, since with prolonged circulation of the same coolant in the system, oxygen quickly evaporates from it. The practice of operating iron pipes shows that their service life is more than 20 years.

The disadvantage is the complexity of installation; a qualified welder is needed to connect the pipes, which leads to a significant increase in the cost of the structure, and repairs in an already lived-in room will lead to damage to the wallpaper and furniture if it cannot be moved. Iron pipes are susceptible to corrosion, so it is not advisable to install them inside the wall. Also, iron pipes do not have a very attractive appearance and require painting every year. But high thermal conductivity indoors is an advantage; it increases heat transfer, whereas when passing through unheated areas, it can significantly lose heat and requires insulation. The price of such pipes is not high.

Propylene pipes

Propylene pipes retain their appearance for a long time

Unfortunately, a system made of polypropylene pipes is of little use for repairs. And the entire section will have to be replaced. The low rigidity of the pipes requires additional fastening so that under the influence of temperatures it does not bend too much. The pipes have a low heat resistance of no more than 70˚C, and the climatic conditions of the country require more heating of the pipes to ensure comfort in the home. The price is low.

Metal-plastic pipes

Metal-plastic pipes have become very popular because they combine the best qualities of steel and plastic pipes. The pipe consists of three layers. The base is aluminum foil, 0.2-0.3 mm thick, coated with a layer of plastic that protects the metal from the negative effects of aggressive environmental components, and an inner thin layer applied to the foil to prevent the appearance of various deposits inside the lumen of the pipe. The layers are connected using a special glue with high adhesion to both components - polymer and metal. It is the adhesive composition that gives the pipe strength and elasticity.

The advantages of metal-plastic pipes include a smooth surface, aesthetic appearance, ease of installation, which does not require special equipment. They also include durability - 50 years, savings in cutting and the absence of residues. Metal-plastic pipes do not conduct stray currents, they have no thermal expansion and can be safely mounted into a wall.

The disadvantages include the price of the entire system; the pipes themselves are inexpensive, but the accessories for them are not cheap. The connecting elements have a narrowed cross-section, this reduces the permeability of the pipeline, and at sub-zero temperatures a rupture will occur. They cannot be used in country houses.

Stainless steel pipes

not subject to internal pollution50 years

If we consider heating in an apartment, then in terms of reliability all pipes meet the requirements.

Copper and stainless steel are the most expensive but versatile materials, but still the advantage of metal-plastic pipes for heating in a modern apartment is their low thermal conductivity, it will be possible to avoid heat losses by installing them in the wall or under the baseboard, low price and the ability to install the system yourself heating without special qualifications. Copper pipes, which have high thermal conductivity, must be insulated in order to be laid inside the walls; they are expensive to install in an apartment. But in a country house, copper pipes will be a good solution for those whose finances are not limited. They are aesthetic, reliable and durable. Date: September 25, 2021

Reviews and operating experience

Some people consider copper pipes an excellent solution, while others do not accept them. But, in fact, this is typical for any technology and material. The only thing that people pay attention to and what is worth listening to is the fact that in an acidic environment, copper begins to deteriorate. Therefore, fill the system with either coolant with a neutral PH or slightly alkaline. It is also not recommended to use steel, aluminum or cast iron radiators. It is imperative to protect the system from stray currents (grounding and dielectric gaskets are required), otherwise chemical or electrochemical destruction begins. But in central heating systems you will not completely get rid of destruction: the coolant in them is saturated with iron, and if solid particles can be retained by a filter, then there is no escape from those dissolved in it.

Another piece of advice from an experienced installer: copper is very sensitive to contact with concrete (it oxidizes). The rate of destruction depends on the composition of the wall, but in any case it is better to lay the pipe in a PVC sheath or any insulator with similar characteristics.

Another tip from the master, but this already concerns soldering: it is important not to overdo it. Firstly, from an overabundance of diligence, you can weld the entire lumen (if a pipe of small diameter is especially important), secondly, when the soft solder overheats, the paste is overheated, which is why it cokes, which leads to the formation of fistulas, and thirdly , do not overdo it with the amount of solder. If you have no experience, practice welding on small pieces of pipe: you can check both the clearance and tightness of the connection. And after gaining at least some experience, you can begin welding the system.

Which pipe is better to use for heated floors?

When choosing pipes, many people wonder what material is best to buy pipes for heated floors from. The choice of purchase will be influenced not only by price and quality, but also by the ease of installation of the selected product.

It is also worth paying attention to the advantages and disadvantages of one or another type of material from which the coolants are made

When choosing between copper and corrugated stainless steel pipes, you need to compare their positive and negative qualities. For example, copper pipes are durable and reliable. They have good heat conductivity. You can fill the system not only with water, but also with antifreeze or antifreeze. With great strength and temperature resistance, they can be used almost anywhere. The low resistance coefficient of the inner layer allows liquid to circulate freely within the system. This allows you to select coolants with a minimum diameter (16 mm).

Corrugated stainless steel products are also strong, flexible and durable. However, when choosing which pipe is better from these two types, you need to know:

- Copper materials are afraid of acidity and water hardness. These factors significantly reduce the service life.

- The price of copper and stainless steel pipes is quite high.

- Installation of such pipes requires considerable financial costs. You need to hire specialists and have special equipment. True, these costs are recouped through the long-term operation of these systems.

- The main condition when using corrugated stainless steel coolants is that they are not exposed to electric current.

- The combination of copper and steel can lead to negative electrochemical processes.

When choosing between metal materials and metal-plastic, which pipes are better, preference is given to the latter. This is influenced by the lower price of the product.

Layout example

Metal-plastic, also durable in use. Unlike copper and stainless steel, water flows through these pipes almost silently. This material does not react with various chemical elements of water. Metal-plastic pipes are much lighter than copper and stainless steel pipes. Their installation is quite simple and does not require special technical skills. The heating system can be installed independently and quite simply.

The disadvantages of metal-plastic products include

- Short-term maintenance of temperatures above +100°C.

- This material is susceptible to open fire.

- When pressed with a mounting nut, a cut may appear on the pipe and subsequently leak.

- A poor-quality connection of pipes with fittings will result in the formation of a limescale layer at the joints.

You also need to pay attention to the large number of Chinese counterfeits of these products. Polypropylene coolants, although not very expensive, are used less frequently

This is due to the large bending radius (8 - 9 pipe diameters). During installation it is necessary to use additional special connections

Polypropylene coolants, although not very expensive, are used less frequently. This is due to the large bending radius (8 - 9 pipe diameters). During installation it is necessary to use additional special connections.

Their advantage is a fairly simple and reliable connection method (soldering). The joints are strong and monolithic.

Which polyethylene pipes are best to choose for heated floors can be determined by the product labeling, finding out the minimum crosslinking density. The price will depend on the value of this indicator. But it will be significantly lower than for pipes made of metal material.

The main disadvantage of polyethylene products is the need for rigid fixation during installation.

It is also worth paying attention to caution when delivering and installing such coolants. Defects in the anti-diffuser protective layer will lead to a decrease in service life

Having studied all the advantages and disadvantages of various types of material, everyone chooses for themselves which pipes are best used for warm water floors. It is more expedient to carry out a complete re-equipment of the heating system in a private house. Multi-storey buildings will require additional permits, which will entail unnecessary expenses.

Polyethylene consists of hydrocarbon molecules that are not connected to each other. However, new developments have made it possible to connect molecules by interacting carbon and oxygen atoms. Such technologies made it possible to create a new material – cross-linked polyethylene (PEX). With additional processing (under high pressure), it acquires greater strength.

Installation technologies and rules

First, let's look at the general rules regarding the installation of copper pipelines. As you know, metal is an excellent conductor. To provide protection from stray currents, as well as reduce the risk of corrosion, you can use products in a polymer shell.

Image gallery

Photo from

Possibility of using lead solder

Connecting copper and aluminum parts

Use of brass fittings and adapters

Which radiators are best for copper systems?

In private practice it is quite rare, but in industry the assembly of pipelines made of steel and copper is still used. In this case, it is recommended to use steel for risers, and copper for wiring, that is, steel products should be in the first position in terms of coolant current. Magnesium connectors are required.

There are several ways to connect products, the choice of each of them depends on the specific situation:

- capillary soldering with solder;

- compression fittings;

- pressed fittings;

- threaded installation.

The last method is practically not used because it has lost its relevance. Soldering and crimping differ in the degree of labor intensity, execution technique, and the presence of different tools, but are equally in demand. Let's look at three popular pipeline construction technologies.