Hello friends!

We continue the topic of heating and today I want to talk to you about choosing the diameter of polypropylene pipes that will be used for heating. When designing and installing a heating system, the question always arises: what pipeline diameter to choose.

The choice of diameter, and therefore the throughput of pipes, is important, because you need to ensure the coolant speed is within 0.4 - 0.6 meters per second, which is recommended by experts. In this case, the required amount of energy (amount of coolant) must be supplied to the radiators.

It is known that if the speed is less than 0.2 m/s, then air jams will stagnate. A speed greater than 0.7 m/s should not be done for reasons of energy saving, since the resistance to fluid movement becomes significant (it is directly proportional to the square of the speed), moreover, this is the lower limit for the occurrence of noise in pipelines of small diameters.

What pipes should be used for the heating system?

Polypropylene pipes are divided into several types, which have their own technical characteristics, and they are intended for different conditions. PN25 (PN30) brands are suitable for heating, which can withstand a working pressure of 2.5 atm at a liquid temperature of up to 120 degrees. WITH.

Data on wall thickness are given in the tables.

For heating, polypropylene pipes are now used, which are reinforced with aluminum foil or fiberglass. The reinforcement prevents significant expansion of the material when heated.

Many experts prefer pipes with internal fiberglass reinforcement. Such a pipeline has recently become most widely used in private heating systems.

Classification of propylene pipes according to the composition of raw materials

- PPR pipes . This category usually includes structures that are created using a static polypropylene copolymer, which is distinguished by the presence of a crystalline molecular structure. These products perfectly withstand temperatures in the range from - 170 to + 1400 degrees Celsius. At the same time, they cope well with shock loads, which is why they are widely used when carrying out work on the construction of sewerage, plumbing and heating. These products are most often used in the construction of residential buildings. If we talk about their sizes, they are about 16–110 mm. The signs of their classification may include, first of all, a parameter such as pressure.

- PPH pipes . The material used to create these structures is raw materials, which are mixed with modifying additives. The latter can be antistatic agents, fire retardants, and nucleators. The effect of introducing the latter into the composition provides an increase in the impact strength of the polymer. Using similar structures, external cold water supply systems, as well as ventilation and drainage systems are erected. At the same time, they do not seem to be the best option for creating heating systems based on them. The reason for this is due to the low melting point. The diameter of structures in this category is usually quite large, since most of them are used in the construction of industrial sewerage and drainage systems.

- PPB pipes . If we consider the structure of this material, then its basis is formed by homopolymer micromolecules having different structures, compositions and locations. It is the special molecular structure that is responsible for the property of this product, which is its high resistance to impact. For this reason, they are most often used in the installation of underfloor heating systems and cold water supply.

- PPs pipes . This category is represented by polymers of the highest class, the main feature of which is a unique molecular composition. The advantages include high resistance to loads and heat. They also have high wear resistance and strength characteristics. The diameter of structures created on the basis of such polypropylene is about 20–1200 mm. Most of them are used in the installation of ventilation systems, hot and cold water supply, and heating.

Questions about selecting the diameter of the heating pipeline

Pipes are produced in standard diameters, from which you need to make a choice. Standard solutions have been developed for selecting pipe diameters for heating a house, based on which in 99% of cases you can make the optimal correct choice of diameter without performing a hydraulic calculation.

Standard outer diameters of polypropylene pipes are 16, 20, 25, 32, 40 mm. The internal diameter of PN25 pipes corresponding to these values is 10.6, 13.2, 16.6, 21.2, 26.6 mm, respectively.

More detailed information on the outer diameters, inner diameters and wall thickness of polypropylene pipes is given in the table.

Materials and characteristics

Knowing the diameter is only half the battle, but when you come to the store, you will be faced with a variety of materials. Polypropylene pipes for heating comply with GOST R 52134–2003. They are made from three types of plastic, two of which can be used for hot water supply and heating systems:

- consisting of identical structural units. Their molecular bonds do not withstand heating and, accordingly, are not applicable for systems with high operating temperatures;

- consisting of different structural units. The heterogeneity of bonds between molecules makes them resistant to heat, while the material does not lose its natural elasticity;

- consisting of crystals. They have the most durable and temperature-resistant structure, but at the same time they lose elasticity.

The marking of polypropylene heating pipes indicates their outer diameter. Pay attention to this when you need to connect the outline of the apartment to the central riser. With an equal outer cross-section, metal and polypropylene pipes have different internal bores; for metal it is wider.

Be sure to choose reinforced products. Aluminum and fiberglass are used as reinforcement materials. It is better to give preference to the latter, since during installation there is no need to remove the reinforcement layer to the depth of the connection of the circuit with couplings and fittings. Aluminum reinforcement is carried out:

- monolithic layer;

- layer with multiple holes.

Reinforcement of polypropylene with perforated aluminum

Both aluminum and fiberglass reinforcement layers are sandwiched between two layers of plastic. Reinforcement is needed only to compensate for the increase in length of the contour when heated. There is no question of strengthening the product, since the plastic is already very durable. Non-reinforced products are not suitable because they have a too high coefficient of linear expansion, which is 0.15 mm/m. For comparison, for reinforced products it is 0.02 mm/m. Polypropylene pipes for heating have standard sizes. They are sold in lengths of four meters.

For clarity, let's carry out the calculation. Let's take one meter of circuit in which water heated to 80 degrees circulates. Multiply the temperature by the coefficient of linear expansion and get the following values:

- for reinforced products – extension by 1.6 mm;

- for non-reinforced products - extension by 12 mm.

The marking also indicates the nominal pressure. Denoted by the Latin letters PN. For example, a product marked PN16 can withstand 16 atmospheres, but this is not the maximum of its capabilities. It can withstand larger short-term increases. The nominal pressure is the indicator at which the service life of polypropylene pipes will be half a century. The calculation was performed using special programs, where the water temperature is set to 20 degrees. This is important; as the temperature increases, the service life will naturally be shorter, since when the plastic heats up, it changes its mechanical characteristics.

What diameters should I connect?

We need to ensure the supply of the required thermal power, which will directly depend on the amount of coolant supplied, but the fluid speed must remain within the specified limits of 0.3 - 0.7 m/s

Then the following correspondence of connections arises (for polypropylene pipes the outer diameter is indicated):

- 16 mm - for connecting one or two radiators;

- 20 mm – for connecting one radiator or a small group of radiators (radiators of “regular” power within 1 - 2 kW, maximum connected power - up to 7 kW, number of radiators up to 5 pcs.);

- 25 mm – for connecting a group of radiators (usually up to 8 pieces, power up to 11 kW) of one wing (arm of a dead-end wiring diagram);

- 32 mm – for connecting one floor or an entire house, depending on the thermal power (usually up to 12 radiators, respectively, thermal power up to 19 kW);

- 40 mm - for the main line of one house, if any (20 radiators - up to 30 kW).

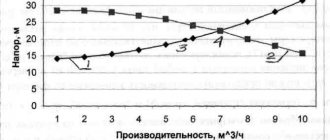

Let us consider the choice of pipe diameter in more detail, based on pre-calculated tabular correspondences of energy, speed and diameter.

Selection of pipes by power

The table shows that at a speed of 0.4 m/s, approximately the following amount of heat will be supplied through polypropylene pipes of the following outer diameter:

- 4.1 kW - internal diameter about 13.2 mm (outer diameter 20 mm);

- 6.3 kW - 16.6 mm (25mm);

- 11.5 kW - 21.2 mm (32 mm);

- 17 kW - 26.6 mm (40 mm);

And at a speed of 0.7 m/s, the supplied power values will be approximately 70% greater, which is not difficult to find out from the table.

How much heat do we need?

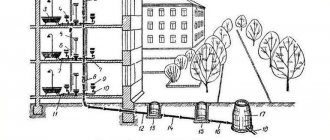

Sewerage

When arranging pipelines for the removal of wastewater, it is necessary to pay special attention to the arrangement of a riser made of polypropylene structures.

| Angle of connection of branches to the riser (degrees) | Indicator of the outer diameter of interfloor bends (mm) | Riser diameter value (mm) | |

| 110 | 50 | ||

| 87.50 | 110.00 | 3.60 | — |

| 60.00 | 110.00 | 5.40 | — |

| 45.00 | 110.00 | 5.90 | — |

| 87.50 | 50.00 | 5.20 | 0.66 |

| 60.00 | 50.00 | 7.80 | 1.00 |

| 45.00 | 50.00 | 8.40 | 1.07 |

| 87.50 | 40.00 | 5.50 | 0.76 |

| 60.00 | 40.00 | 8.25 | 1.14 |

| 45.00 | 40.00 | 8.95 | 1.23 |

When installing unventilated risers made of polypropylene structures, it is necessary to use the data presented below.

| Throughput values (milliliters/second) | Connection angle of interfloor branches (degrees) | Riser height value (meters) | ||||

| Outer diameter of the channel / value of the internal cross-section of the interfloor outlet (mm) | ||||||

| 110/110 | 110/50 | 110/40 | 50/50 | 50/40 | ||

| 1100 | 850 | 800 | 480 | 420 | 87.50 | 9.00 |

| 1120 | 1000 | 950 | 550 | 470 | 60.00 | 9.00 |

| 1150 | 1100 | 1040 | 600 | 500 | 45.00 | 9.00 |

| 1400 | 1000 | 960 | 480 | 420 | 87.50 | 8.00 |

| 1550 | 1200 | 1150 | 550 | 470 | 60.00 | 8.00 |

| 1700 | 1300 | 1200 | 600 | 500 | 45.00 | 8.00 |

| 1600 | 1200 | 1070 | 480 | 420 | 87.50 | 7.00 |

| 1800 | 1400 | 1300 | 550 | 470 | 60.00 | 7.00 |

| 2000 | 1550 | 1420 | 600 | 500 | 45.00 | 7.00 |

| 1800 | 1500 | 1420 | 480 | 420 | 87.50 | 6.00 |

| 2100 | 1700 | 1670 | 550 | 470 | 60.00 | 6.00 |

| 2350 | 1850 | 1770 | 600 | 500 | 45.00 | 6.00 |

| 2400 | 1850 | 1770 | 480 | 420 | 87.50 | 5.00 |

| 2700 | 2050 | 1950 | 550 | 470 | 60.00 | 5.00 |

| 3000 | 2250 | 2100 | 600 | 500 | 45.00 | 5.00 |

| 3000 | 2400 | 2300 | 480 | 420 | 87.50 | 4.00 |

| 3400 | 2700 | 2600 | 550 | 470 | 60.00 | 4.00 |

| 3700 | 3000 | 2800 | 600 | 500 | 45.00 | 4.00 |

| 4100 | 3300 | 3200 | 650 | 580 | 87.50 | 3.00 |

| 4600 | 3700 | 3500 | 740 | 660 | 60.00 | 3.00 |

| 5000 | 4000 | 3800 | 800 | 720 | 45.00 | 3.00 |

| 5900 | 4950 | 4700 | 970 | 880 | 87.50 | 2.00 |

| 6400 | 5500 | 5100 | 1050 | 910 | 60.00 | 2.00 |

| 6800 | 5800 | 5400 | 1120 | 960 | 45.00 | 2.00 |

| 9500 | 8400 | 8000 | 1650 | 1440 | 87.50 | 1.00 |

| 10100 | 9100 | 8500 | 1700 | 1520 | 60.00 | 1.00 |

| 10600 | 9500 | 8800 | 1800 | 1600 | 45.00 | 1.00 |

To calculate the parameter under consideration for sewer mains, it is necessary to resort to other calculation methods. In this case, the type of channel plays a big role. If we are talking about non-pressure systems, use the Lukin tables, which can be downloaded from our website.

With their help, the coefficient in question is calculated for products of a given size.

When creating pressure circuits, the calculation will be easier. The main thing is to accurately set the maximum contour filling parameter and the average speed of the carrier.

The easiest way to do this is using a table of the capacity of polypropylene pipes.

How much heat should the pipeline supply?

Let's take a closer look at the example of how much heat is usually supplied through pipes, and select the optimal pipeline diameters.

There is a house with an area of 250 sq. m., which is well insulated (as required by the SNiP standard), so it loses heat in the winter by 1 kW per 10 sq. m. To heat the entire house, 25 kW of energy is required (maximum power). For the first floor - 15 kW. For the second floor - 10 kW.

Our heating scheme is two-pipe. One pipe supplies hot coolant, and the other pipe cools it to the boiler. Radiators are connected in parallel between the pipes.

On each floor, the pipes branch into two wings with the same thermal power, for the first floor - 7.5 kW, for the second floor - 5 kW.

So, 25 kW comes from the boiler to the interfloor branch. Therefore, we will need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m/s. A 40mm polypropylene pipe is suitable.

From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm.

7.5 kW goes to the wing of the 1st floor - an internal diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm.

For each radiator, the power of which does not exceed 2 kW, you can make an outlet with a pipe with an outer diameter of 16 mm, but since this installation is not technologically advanced, the pipes are not popular; a 20 mm pipe with an inner diameter of 13.2 mm is more often installed.

Accordingly, we use a 32mm pipe on the second floor before branching, a 25mm pipe on the wing, and we also connect the radiators on the second floor with a 20mm pipe.

As you can see, it all comes down to a simple choice among the standard diameters of commercially available pipes. In small home systems, up to a dozen radiators, in dead-end distribution circuits, 25 mm polypropylene pipes are mainly used - “per wing”, 20 mm - “per device”. and 32 mm “to the main line from the boiler”.

Section of polypropylene pipes:

For sewerage

Today, most sewage disposal lines are constructed from polypropylene risers. This is due to the many advantages of the products in comparison with analogues from other substances.

1) For internal sewerage; 2) For outdoor

In everyday life, sewer pipes with an outer cross-section of 32, 40, 50, 63, 75 mm are most often used for indoor distribution, and with a diameter of 100 (110 mm) for equipping waste risers. In multi-storey buildings, polypropylene products with a diameter of 110 mm or more are used for sewerage installations.

For water supply and heating

The laying of water pipes from polypropylene parts can be carried out either by air or in the soil. For these purposes in everyday life, the most popular parts are made of polypropylene with a caliber of 16-75 mm.

For internal wiring of water mains, parts with a cross-section from half an inch to an inch are suitable.

External wiring is mounted from elements with a caliber of 40, 50, 100 mm.

For internal distribution of cold water, elements with an external cross-section from 20.00 to 40.00 mm with a wall thickness of 1.90-10.00 mm are suitable.

Systems for transporting hot liquids are mounted from polypropylene products with a cross-section of 20.00-100.00 mm and a wall thickness of 2.80-15.10 mm.

To keep your house or apartment warm, you need to choose the right caliber of polypropylene risers for the heating system.

Important! It should be remembered that the coolant temperature reaches almost 100℃ at a pressure of several atmospheres. To ensure high-quality heating, you need to buy reinforced polypropylene parts.

The design of the heating system is such that it is necessary to use products of various calibers, starting from 16.00 and ending with 63.00, or even 75.00 mm. The wall thickness should be in the range of 3.40-10.50 mm. The choice of risers is also influenced by the cubic capacity of the room and the type of boiler.

1) Water supply; 2) Air duct made of polypropylene

For ventilation

Metal air ducts have been replaced by polypropylene ventilation. For its arrangement, polypropylene risers of large sections are used - starting from 100 and ending with 200, 300 mm and more

With this article read: 4 main types of PVC pipes, their classification and main characteristics. Answers to popular questions, podcast.

Features of choosing other equipment

Pipe diameters can also be selected according to the conditions of hydraulic resistance for atypically long pipeline lengths, at which the technical characteristics of the pumps may be exceeded.

But this can happen for production workshops, but practically never occurs in private construction.

For a house up to 150 sq. m., according to the conditions of the hydraulic resistance of the heating and radiator system, a pump of type 25 - 40 (pressure 0.4 atm) is always suitable; it can also be suitable up to 250 sq. m. in some cases, and for houses up to 300 sq. m. . – 25 – 60 (pressure up to 0.6 atm).

The pipeline is designed for maximum capacity. But the system, if it ever operates in this mode, will not last for a long time. When designing a heating pipeline, you can take parameters such that at maximum load, the coolant speed is 0.7 m/s.

In practice, the speed of water in heating pipes is set by a pump that has 3 rotor speeds.

In addition, the supplied power is regulated by the temperature of the coolant and the duration of operation of the system, and in each room it can be adjusted by disconnecting the radiator from the system using a thermal head with a push valve.

Thus, with the diameter of the pipeline we ensure that the speed is within the range of up to 0.7 m at maximum power, but the system will generally operate with a lower fluid speed.

Source: teplodom1.ru/radiattopl/114-kakoy-diametr-trub-iz-polipropilena-dlya-otopleniya.html

Required data for calculation

The main task of heating pipes is to deliver heat to the heated elements (radiators) with minimal losses. We will build on this when choosing the correct pipe diameter for heating a house. But to calculate everything correctly, you need to know:

- pipe length;

- heat loss in the building;

- element power;

- what kind of pipe layout will be (natural, forced, single-pipe or two-pipe circulation).

The next point, after you have all the above data in your hands, will be necessary to sketch out a general diagram: how, what and where it will be located, what thermal load each heating element will carry.

Then you can begin to calculate the required cross-section of the diameter of the pipe for heating the house. You should also be careful when purchasing:

- metal-plastic and steel pipes are marked by the size of the internal diameter, there are no problems here;

- but polypropylene and copper - by outer diameter. Therefore, we need to either measure the internal diameter ourselves using a caliper, or subtract the wall thickness from the external diameter of the pipe for heating the house.

Don’t forget about this, because we need exactly the “inner diameter of the pipe for heating the house” in order to calculate everything correctly.

Calculation of coefficient

The coefficient of thermal expansion of polypropylene heating pipes is determined by the material used. There are special formulas for carrying out calculations and avoiding inconvenience during system installation.

To calculate the possible deformation of pipes in centimeters, you need to know their expansion coefficient and length. The operating temperature is considered to be room temperature.

First, the temperature difference is determined, then it is multiplied by the length of the pipe. The result is multiplied by the expansion factor.

Approximate calculation

If, after calculations, the coefficient is 20 mm, this means that during the operation of the heating system, the expansion of fiberglass-reinforced polypropylene pipes will reach 2 cm. That is, when laying the main line, these indicators will in any case need to be taken into account.

You can get rid of extra centimeters like this:

- carry out installation at right angles;

- you can add several loop-shaped parts;

- lay pipes in a U-shape.

If you doubt the correct choice of material, and whether the calculations of the elongation of polypropylene pipes when heated were made correctly, you can entrust this work to professionals.

Polypropylene pipes are becoming more and more popular every day. They are inexpensive and easy to install. An important factor for creating a high-quality highway is the vigilant choice of material. The purchased product must be of the highest quality.

It would be a good idea to consult with a plumber you know before purchasing. Directly when choosing pipes, inspect them for possible damage and cracks. And don’t forget about the type of products you choose.

Choosing the diameter for your heating

Do not expect that you will immediately be able to select the correct pipe diameter for heating your home. The fact is that you can achieve the desired efficiency in different ways.

Now in more detail. What is most important in a proper heating system? The most important thing is uniform heating and delivery of liquid to all heating elements (radiators).

In our case, this process is constantly supported by the pump, thanks to which, over a specific time period, the liquid moves through the system. Therefore, we can only choose from two options:

- buy pipes with a large cross-section and, as a result, a low flow rate of coolant;

- or a pipe with a small cross-section, naturally the pressure and speed of the fluid will increase.

Logically, of course, it is better to choose the second option for the diameter of the pipes for heating the house, and for these reasons:

- when laying pipes externally, they will be less noticeable;

- when laying internally (for example, in a wall or under the floor), the grooves in the concrete will be more accurate and easier to chisel;

- the smaller the diameter of the product, the cheaper it is, naturally, which is also important;

- with a smaller pipe cross-section, the total volume of coolant also decreases, thanks to which we save fuel (electricity) and reduce the inertia of the entire system.

And working with a thin pipe is much easier and simpler than with a thick one.

Manufacturers of polypropylene pipes

One of the most popular manufacturers can rightfully be considered the production and trading company Heisskraft, which began operating in 1998. The main principle of the enterprise is to produce only high-quality goods. Thanks to innovative developments, customers can constantly purchase modern solutions for arranging new or repairing existing structures.

Polypropylene risers and fittings from the largest Russian full-cycle plant “PRO AQUA” are also in great demand among buyers. The company produces products in white and gray shades with a diameter of 20 to 110 mm. The high quality of the product is ensured by the presence of European equipment and constant monitoring of strict adherence to production processes. The plant uses imported Borealis raw materials.

Among hundreds of manufacturers of similar products in Russia, the well-known Moscow one should be highlighted. Its products are used in the installation of pipelines for supplying hot and cold water and sewer systems.

Sinikon: sinikon.ru

High-quality products from popular companies, Polytron, Almetyevsk TZ and many other enterprises.

Among imported manufacturers, the Chinese-foreign company ASB is very popular. In addition to risers, the company produces shut-off valves, fittings, and sets of plumbing tools.

Formula for calculating the diameter of a pipe for heating a house

For example, let’s select a cross-section for a copper pipe in direct proportion to how powerful the radiators are.

All pipes are manufactured in accordance with GOST. Consequently, all diameters are known in advance, as well as the volume of useful heat that they can pass through themselves, depending on the cross-section and pressure.

Therefore, there is no need to calculate every time what has already been calculated and recorded in special tables. All you need to do is simply find a table with data that suits you and use it to select the diameter of the pipe for heating your home.

How were such tables created? Yes, very simple. Take this formula for calculating the diameter of the pipe, count, and write down the result, and so on for all sections:

D= √(354*(0.86*Q/∆t)/V)

Wherein:

V – fluid velocity in the pipe (m/s); Q – required amount of heat for heating (kW); ∆t — difference between reverse and forward feed (C); D – pipe diameter (mm).

You can try to calculate everything yourself.

It is known that in individual heating systems the coolant moves at a speed of 0.2-1.5 m/s. It is also known that the ideal speed should be in the range of 0.3-0.7 m/s.

If the speed is greater than the optimal values, then the noise increases, and if it is less, then air jams may appear. There are ready-made tables for this. In them we choose the speed that suits us.

There are tables for copper, polypropylene, metal and metal-plastic pipes. They have ready-made solutions for operating at medium and high temperatures. For clarity, let's look at specific examples.

Tables for hydraulic calculation of pipelines

Appendix 3 (informative)

Tables for hydraulic calculations of pipelines made of PP-R, PN10

| Diameter pipes, mm | thickness , mm | Consumption water, l/s | 0,11 | 0,12 | 0,13 | 0,14 | 0,15 | 0,16 | 0,17 | 0,18 | 0,19 | 0,2 |

| 20 | 1,90 | v, m/s | 0,5339 | 0,5825 | 0,6310 | 0,6796 | 0,7281 | 0,7766 | 0,8252 | 0,8737 | 0,9223 | 0,9708 |

| 1000i, mm/m | 34,1279 | 39,7686 | 45,7961 | 52,2064 | 58,9955 | 66,1599 | 73,6966 | 81,6025 | 89,8750 | 98,5117 | ||

| 25 | 2,30 | v, m/s | 0,3367 | 0,3673 | 0,3979 | 0,4285 | 0,4592 | 0,4898 | 0,5204 | 0,5510 | 0,5816 | 0,6122 |

| 1000i, mm/m | 11,2694 | 13,1089 | 15,0716 | 17,1561 | 19,3610 | 21,6851 | 24,1274 | 26,6867 | 29,3623 | 32,1531 | ||

| 32 | 3,00 | v, m/s | 0,2073 | 0,2261 | 0,2450 | 0,2638 | 0,2827 | 0,3015 | 0,3204 | 0,3392 | 0,3580 | 0,3769 |

| 1000i, mm/m | 3,5406 | 4,1107 | 4,7180 | 5,3621 | 6,0425 | 6,7589 | 7,5107 | 8,2978 | 9,1199 | 9,9765 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 0,25 | 0,3 | 0,35 | 0,4 | 0,45 | 0,5 | 0,55 | 0,6 | 0,65 | 0,7 |

| 20 | 1,90 | v, m/s | 1,2135 | 1,4562 | 1,6989 | 1,9416 | 2,1843 | 2,4270 | 2,6698 | 2,9124 | 3,1551 | — |

| 1000i, mm/m | 147,0813 | 204,4629 | 270,4746 | 344,9726 | 427,8391 | 518,9752 | 618,2960 | 725,7279 | 841,2059 | — | ||

| 25 | 2,30 | v, m/s | 0,7653 | 0,9183 | 1,0714 | 1,2244 | 1,3775 | 1,5305 | 1,6836 | 1,8366 | 1,9897 | 2,1427 |

| 1000i, mm/m | 47,8105 | 66,2485 | 87,4037 | 111,2255 | 137,6726 | 166,7102 | 198,3085 | 232,4416 | 269,0865 | 308,2228 | ||

| 32 | 3,00 | v, m/s | 0,4711 | 0,5653 | 0,6596 | 0,7538 | 0,8480 | 0,9422 | 1,0364 | 1,1307 | 1,2249 | 1,3191 |

| 1000i, mm/m | 14,7703 | 20,3961 | 26,8328 | 34,0639 | 42,0756 | 50,8564 | 60,3965 | 70,6873 | 81,7212 | 93,4913 | ||

| 40 | 3,70 | v, m/s | 0,2997 | 0,3596 | 0,4195 | 0,4795 | 0,5394 | 0,5993 | 0,6593 | 0,7192 | 0,7791 | 0,8391 |

| 1000i, mm/m | 4,9733 | 6,8452 | 8,9814 | 11,3758 | 14,0237 | 16,9209 | 20,0641 | 23,4500 | 27,0760 | 30,9397 | ||

| 50 | 4,60 | v, m/s | 0,1913 | 0,2296 | 0,2678 | 0,3061 | 0,3444 | 0,3826 | 0,4209 | 0,4592 | 0,4974 | 0,5357 |

| 1000i, mm/m | 1,7004 | 2,3327 | 3,0524 | 3,8573 | 4,7457 | 5,7162 | 6,7675 | 7,8985 | 9,1082 | 10,3959 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 0,75 | 0,8 | 0,85 | 0,9 | 0,95 | 1 | 1,05 | 1,1 | 1,15 | 1,2 |

| 25 | 2,30 | v, m/s | 2,2958 | 2,4488 | 2,6019 | 2,7549 | 2,9080 | 3,0610 | — | — | — | — |

| 1000i, mm/m | 349,8322 | 393,8979 | 440,4049 | 489,3392 | 540,6879 | 594,4392 | — | — | — | — | ||

| 32 | 3,00 | v, m/s | 1,4133 | 1,5076 | 1,6018 | 1,6960 | 1,7902 | 1,8844 | 2,0729 | 2,2613 | 2,4498 | 2,6382 |

| 1000i, mm/m | 105,9917 | 119,2167 | 133,1614 | 147,8211 | 163,1915 | 179,2686 | 213,5286 | 250,5745 | 290,3826 | 332,9318 | ||

| 40 | 3,70 | v, m/s | 0,8990 | 0,9589 | 1,0189 | 1,0788 | 1,1387 | 1,1987 | 1,3185 | 1,4384 | 1,5583 | 1,6781 |

| 1000i, mm/m | 35,0390 | 39,3718 | 43,9363 | 48,7310 | 53,7543 | 59,0047 | 70,1820 | 82,2532 | 95,2100 | 109,0449 | ||

| 50 | 4,60 | v, m/s | 0,5739 | 0,6122 | 0,6505 | 0,6887 | 0,7270 | 0,7653 | 0,8418 | 0,9183 | 0,9948 | 1,0714 |

| 1000i, mm/m | 11,7606 | 13,2017 | 14,7186 | 16,3107 | 17,9773 | 19,7181 | 23,4202 | 27,4136 | 31,6950 | 36,2620 | ||

| 63 | 5,80 | v, m/s | 0,3616 | 0,3857 | 0,4098 | 0,4340 | 0,4581 | 0,4822 | 0,5304 | 0,5786 | 0,6268 | 0,6750 |

| 1000i, mm/m | 3,8465 | 4,3134 | 4,8044 | 5,3193 | 5,8579 | 6,4200 | 7,6142 | 8,9006 | 10,2784 | 11,7464 | ||

| 75 | 6,90 | v, m/s | 0,2551 | 0,2721 | 0,2891 | 0,3061 | 0,3231 | 0,3401 | 0,3741 | 0,4081 | 0,4422 | 0,4762 |

| 1000i, mm/m | 1,6599 | 1,8599 | 2,0701 | 2,2904 | 2,5206 | 2,7608 | 3,2707 | 3,8195 | 4,4066 | 5,0318 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 1,5 | 1,6 | 1,7 | 1,8 | 1,9 | 2 | 2,1 | 2,2 | 2,3 | 2,4 |

| 32 | 3,00 | v, m/s | 2,8267 | 3,0151 | — | — | — | — | — | — | — | — |

| 1000i, mm/m | 378,2033 | 426,1799 | — | — | — | — | — | — | — | — | ||

| 40 | 3,70 | v, m/s | 1,7980 | 1,9179 | 2,0377 | 2,1576 | 2,2774 | 2,3973 | 2,5172 | 2,6370 | 2,7569 | 2,8768 |

| 1000i, mm/m | 123,7511 | 139,3224 | 155,7533 | 173,0386 | 191,1735 | 210,1536 | 229,9749 | 250,6335 | 272,1258 | 294,4484 | ||

| 50 | 4,60 | v, m/s | 1,1479 | 1,2244 | 1,3009 | 1,3775 | 1,4540 | 1,5305 | 1,6070 | 1,6836 | 1,7601 | 1,8366 |

| 1000i, mm/m | 41,1121 | 46,2430 | 51,6528 | 57,3395 | 63,3016 | 69,5374 | 76,0454 | 82,8242 | 89,8726 | 97,1894 | ||

| 63 | 5,80 | v, m/s | 0,7233 | 0,7715 | 0,8197 | 0,8679 | 0,9161 | 0,9643 | 1,0126 | 1,0608 | 1,1090 | 1,1572 |

| 1000i, mm/m | 13,3039 | 14,9502 | 16,6844 | 18,5061 | 20,4145 | 22,4091 | 24,4895 | 26,6551 | 28,9055 | 31,2402 | ||

| 75 | 6,90 | v, m/s | 0,5102 | 0,5442 | 0,5782 | 0,6122 | 0,6462 | 0,6802 | 0,7142 | 0,7483 | 0,7823 | 0,8163 |

| 1000i, mm/m | 5,6946 | 6,3946 | 7,1316 | 7,9053 | 8,7154 | 9,5616 | 10,4438 | 11,3617 | 12,3151 | 13,3038 | ||

| 90 | 8,20 | v, m/s | 0,3527 | 0,3763 | 0,3998 | 0,4233 | 0,4468 | 0,4703 | 0,4938 | 0,5174 | 0,5409 | 0,5644 |

| 1000i, mm/m | 2,3302 | 2,6147 | 2,9140 | 3,2280 | 3,5565 | 3,8995 | 4,2569 | 4,6286 | 5,0145 | 5,4145 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 2,5 | 2,6 | 2,7 | 2,8 | 2,9 | 3 | 3,1 | 3,2 | 3,3 | 3,4 |

| 40 | 3,70 | v, m/s | 2,9966 | 3,1165 | — | — | — | — | — | — | — | — |

| 1000i, mm/m | 317,5982 | 341,5722 | — | — | — | — | — | — | — | — | ||

| 50 | 4,60 | v, m/s | 1,9132 | 1,9897 | 2,0662 | 2,1427 | 2,2193 | 2,2958 | 2,3723 | 2,4488 | 2,5254 | 2,6019 |

| 1000i, mm/m | 104,7734 | 112,6235 | 120,7387 | 129,1180 | 137,7605 | 146,6653 | 155,8315 | 165,2585 | 174,9453 | 184,8913 | ||

| 63 | 5,80 | v, m/s | 1,2054 | 1,2537 | 1,3019 | 1,3501 | 1,3983 | 1,4465 | 1,4947 | 1,5430 | 1,5912 | 1,6394 |

| 1000i, mm/m | 33,6590 | 36,1613 | 38,7469 | 41,4153 | 44,1664 | 46,9997 | 49,9150 | 52,9120 | 55,9904 | 59,1500 | ||

| 75 | 6,90 | v, m/s | 0,8503 | 0,8843 | 0,9183 | 0,9523 | 0,9863 | 1,0203 | 1,0544 | 1,0884 | 1,1224 | 1,1564 |

| 1000i, mm/m | 14,3277 | 15,3866 | 16,4802 | 17,6086 | 18,7714 | 19,9686 | 21,2001 | 22,4657 | 23,7653 | 25,0983 | ||

| 90 | 8,20 | v, m/s | 0,5879 | 0,6114 | 0,6349 | 0,6585 | 0,6820 | 0,7055 | 0,7290 | 0,7525 | 0,7760 | 0,7996 |

| 1000i, mm/m | 5,8285 | 6,2565 | 6,6984 | 7,1542 | 7,6237 | 8,1069 | 8,6038 | 9,1143 | 9,6383 | 10,1759 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 3,5 | 3,6 | 3,7 | 3,8 | 3,9 | 4 | 4,1 | 4,2 | 4,3 | 4,4 |

| 50 | 4,60 | v, m/s | 2,6784 | 2,7549 | 2,8315 | 2,9080 | 2,9845 | 3,0610 | 3,1376 | — | — | — |

| 1000i, mm/m | 195,0958 | 205,5580 | 216,2773 | 227,2531 | 238,4848 | 249,9717 | 261,7134 | — | — | — | ||

| 63 | 5,80 | v, m/s | 1,6876 | 1,7358 | 1,7840 | 1,8323 | 1,8805 | 1,9287 | 1,9769 | 2,0251 | 2,0733 | 2,1216 |

| 1000i, mm/m | 62,3905 | 65,7117 | 69,1133 | 72,5952 | 76,1571 | 79,7938 | 83,5202 | 87,3210 | 91,2010 | 95,1601 | ||

| 75 | 6,90 | v, m/s | 1,1904 | 1,2244 | 1,2584 | 1,2924 | 1,3265 | 1,3605 | 1,3945 | 1,4285 | 1,4625 | 1,4965 |

| 1000i, mm/m | 25,4661 | 27,8670 | 29,3015 | 30,7595 | 32,2708 | 33,8055 | 35,3733 | 36,9742 | 38,6032 | 40,2750 | ||

| 90 | 8,20 | v, m/s | 0,8231 | 0,8466 | 0,8701 | 0,8936 | 0,9171 | 0,9407 | 0,9642 | 0,9877 | 1,0112 | 1,0347 |

| 1000i, mm/m | 10,7268 | 11,2912 | 11,8690 | 12,4501 | 13,0645 | 13,6821 | 14,3129 | 14,9569 | 15,6140 | 16,2842 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 4,5 | 4,6 | 4,7 | 4,8 | 4,9 | 5 | 5,1 | 5,2 | 5,3 | 5,4 |

| 63 | 5,80 | v, m/s | 2,1698 | 2,2180 | 2,2662 | 2,3144 | 2,3627 | 2,4109 | 2,4591 | 2,5073 | 2,5555 | 2,6037 |

| 1000i, mm/m | 99,1981 | 103,3148 | 107,5101 | 111,7838 | 116,1357 | 120,5657 | 125,0737 | 129,6595 | 134,3229 | 139,0639 | ||

| v, m/s | 1,5305 | 1,5645 | 1,5985 | 1,6326 | 1,6666 | 1,7006 | 1,7346 | 1,7686 | 1,8026 | 1,8366 | ||

| 75 | 6,90 | 1000i, mm/m | 41,9748 | 43,7073 | 45,4726 | 47,2705 | 49,1009 | 50,9639 | 52,8593 | 54,7871 | 56,7472 | 58,7395 |

| v, m/s | 1,0582 | 1,0818 | 1,1053 | 1,1288 | 1,1523 | 1,1758 | 1,1993 | 1,2229 | 1,2464 | 1,2699 | ||

| 90 | 8,20 | 1000i, mm/m | 16,9675 | 17,6638 | 18,3731 | 19,0953 | 19,8305 | 20,5786 | 21,3396 | 22,1135 | 22,9002 | 23,6996 |

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 5,5 | 5,6 | 5,7 | 5,8 | 5,9 | 6 | 6,1 | 6,2 | 6,3 | 6,4 |

| 63 | 5,80 | v, m/s | 2,6520 | 2,7002 | 2,7484 | 2,7966 | 2,8448 | 2,8930 | 2,9413 | 2,9895 | 3,0377 | 3,0859 |

| 1000i, mm/m | 143,8823 | 148,7779 | 153,7508 | 158,8006 | 163,9273 | 169,1309 | 174,4111 | 179,7679 | 185,2011 | 190,7107 | ||

| 75 | 6,90 | v, m/s | 1,8706 | 1,9047 | 1,9387 | 1,9727 | 2,0067 | 2,0407 | 2,0747 | 2,1087 | 2,1427 | 2,1767 |

| 1000i, mm/m | 60,7641 | 62,8207 | 64,9095 | 67,0303 | 69,1830 | 71,3677 | 73,5842 | 75,8325 | 78,1127 | 80,4245 | ||

| 90 | 8,20 | v, m/s | 1,2934 | 1,3169 | 1,3404 | 1,3640 | 1,3875 | 1,4110 | 1,4345 | 1,4580 | 1,4815 | 1,5051 |

| 1000i, mm/m | 24,5119 | 25,3369 | 26,1746 | 27,0250 | 27,8882 | 28,7639 | 29,6523 | 30,5533 | 31,4670 | 32,3931 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 6,5 | 6,6 | 6,7 | 6,8 | 6,9 | 7 | 7,1 | 7,2 | 7,3 | 7,4 |

| 75 | 6,90 | v, m/s | 2,2108 | 2,2448 | 2,2788 | 2,3128 | 2,3468 | 2,3808 | 2,4148 | 2,4488 | 2,4828 | 2,5169 |

| 1000i, mm/m | 82,7680 | 85,1431 | 87,5498 | 89,9880 | 92,4578 | 94,9590 | 97,4915 | 100,0555 | 102,6508 | 105,2774 | ||

| 90 | 8,20 | v, m/s | 1,5286 | 1,5521 | 1,5756 | 1,5991 | 1,6226 | 1,6462 | 1,6697 | 1,3932 | 1,7167 | 1,7402 |

| 1000i, mm/m | 33,3319 | 34,2831 | 35,2469 | 36,2232 | 37,2119 | 38,2131 | 39,2268 | 40,2528 | 41,2913 | 42,3421 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 7,5 | 7,6 | 7,7 | 7,8 | 7,9 | 8 | 8,1 | 8,2 | 8,3 | 8,4 |

| 75 | 6,90 | v, m/s | 2,5509 | 2,5849 | 2,6189 | 2,6529 | 2,6869 | 2,7209 | 2,7549 | 2,7890 | 2,8230 | 2,8570 |

| 1000i, mm/m | 107,9352 | 110,6242 | 113,3444 | 116,0957 | 118,8782 | 121,6917 | 124,5362 | 127,4118 | 130,3182 | 133,2557 | ||

| 90 | 8,20 | v, m/s | 1,7637 | 1,7873 | 1,8108 | 1,8343 | 1,8578 | 1,8813 | 1,9048 | 1,9284 | 1,9519 | 1,9754 |

| 1000i, mm/m | 43,4053 | 44,4809 | 45,5688 | 46,6691 | 47,7816 | 48,9064 | 50,0435 | 51,1929 | 52,3545 | 53,5284 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 8,5 | 8,6 | 8,7 | 8,8 | 8,9 | 9 | 9,2 | 9,4 | 9,6 | 9,8 |

| 75 | 6,90 | v, m/s | 2,8910 | 2,9250 | 2,9590 | 2,9930 | 3,0270 | 3,0610 | 3,1291 | 3,1971 | — | — |

| 1000i, mm/m | 136,2240 | 139,2232 | 142,2532 | 145,3140 | 148,4056 | 151,5279 | 157,8647 | 164,3241 | — | — | ||

| 90 | 8,20 | v, m/s | 1,9989 | 2,0224 | 2,0459 | 2,0695 | 2,0930 | 2,1165 | 2,1635 | 2,2106 | 2,2576 | 2,3046 |

| 1000i, mm/m | 54,7144 | 55,9127 | 57,1232 | 58,3458 | 59,5806 | 60,8276 | 63,3579 | 65,9366 | 68,5638 | 71,2392 | ||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 10 | 10,5 | 11 | 11,5 | 12 | 12,5 | 13 | 13,5 | 14 | 14,5 |

| 90 | 8,20 | v, m/s | 2,3517 | 2,4692 | 2,5868 | 2,7044 | 2,8220 | 2,9396 | 3,0572 | 3,1747 | — | — |

| 1000i, mm/m | 73,9627 | 80,9818 | 88,3001 | 95,9163 | 103,8293 | 112,0379 | 120,5412 | 129,3380 | — | — |

Tables for hydraulic calculations of pipelines made of PP-R, PN20

| Diameter pipes, mm | Thickness walls, mm | Consumption water, l/s | 0,11 | 0,12 | 0,13 | 0,14 | 0,15 | 0,16 | 0,17 | 0,18 | 0,19 | 0,2 | |||||||||||||||||||||||||||||||||||

| 16 | 2,70 | v, m/s | 1,2471 | 1,3605 | 1,4739 | 1,5873 | 1,7006 | 1,8140 | 1,9274 | 2,0408 | 2,1541 | 2,2675 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 267,5406 | 312,7521 | 361,1955 | 412,8415 | 467,6638 | 525,6385 | 586,7440 | 650,9604 | 718,2694 | 788,6540 | |||||||||||||||||||||||||||||||||||||

| 20 | 3,40 | v, m/s | 0,8042 | 0,8773 | 0,9504 | 1,0236 | 1,0967 | 1,1698 | 1,2429 | 1,3160 | 1,3891 | 1,4622 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 91,9226 | 107,2812 | 123,7149 | 141,2128 | 159,7651 | 179,3630 | 199,9985 | 221,6643 | 244,3535 | 268,0599 | |||||||||||||||||||||||||||||||||||||

| 25 | 4,20 | v, m/s | 0,5085 | 0,5547 | 0,6010 | 0,6472 | 0,6934 | 0,7397 | 0,7859 | 0,8321 | 0,8784 | 0,9246 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 30,3415 | 35,3498 | 40,7008 | 46,3906 | 52,4160 | 58,7737 | 65,4610 | 72,4752 | 79,8139 | 87,4749 | |||||||||||||||||||||||||||||||||||||

| 32 | 5,40 | v, m/s | 0,3118 | 0,3401 | 0,3685 | 0,3968 | 0,4252 | 0,4535 | 0,4818 | 0,5102 | 0,5385 | 0,5669 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 9,3740 | 10,9008 | 12,5295 | 14,2589 | 16,0878 | 18,0152 | 20,0403 | 22,1621 | 24,3798 | 26,6928 | |||||||||||||||||||||||||||||||||||||

| 40 | 6,70 | v, m/s | 0,1980 | 0,2160 | 0,2341 | 0,2521 | 0,2701 | 0,2881 | 0,3061 | 0,3241 | 0,3421 | 0,3601 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 3,1766 | 3,6874 | 4,2315 | 4,8085 | 5,4179 | 6,0594 | 6,7327 | 7,4374 | 8,1734 | 8,9402 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 0,25 | 0,3 | 0,35 | 0,4 | 0,45 | 0,5 | 0,55 | 0,6 | 0,65 | 0,7 | |||||||||||||||||||||||||||||||||||

| 16 | 2,70 | v, m/s | 2,8344 | — | — | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 1186,1961 | — | — | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||||

| 20 | 3,40 | v, m/s | 1,8278 | 2,1933 | 2,5589 | 2,9244 | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 401,6571 | 559,9455 | 742,4654 | 948,8538 | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||||

| 25 | 4,20 | v, m/s | 1,1557 | 1,3869 | 1,6180 | 1,8492 | 2,0803 | 2,3114 | 2,5426 | 2,7737 | 3,0049 | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 130,5470 | 181,4163 | 239,9199 | 305,9291 | 379,3385 | 460,0593 | 548,0158 | 643,1418 | 745,3791 | — | |||||||||||||||||||||||||||||||||||||

| 32 | 5,40 | v, m/s | 0,7086 | 0,8503 | 0,9920 | 1,1338 | 1,2755 | 1,4172 | 1,5589 | 1,7006 | 1,8423 | 1,9841 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 39,6639 | 54,9305 | 72,4390 | 92,1471 | 114,0202 | 138,0290 | 164,1485 | 192,3569 | 222,6350 | 254,9657 | |||||||||||||||||||||||||||||||||||||

| 40 | 6,70 | v, m/s | 0,4501 | 0,5401 | 0,6301 | 0,7202 | 0,8102 | 0,9002 | 0,9902 | 1,0802 | 1,1703 | 1,2603 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 13,2306 | 18,2640 | 24,0215 | 30,4880 | 37,6512 | 45,5008 | 54,0278 | 63,2246 | 73,0843 | 83,6007 | |||||||||||||||||||||||||||||||||||||

| 50 | 8,40 | v, m/s | 0,2889 | 0,3467 | 0,4045 | 0,4623 | 0,5201 | 0,5779 | 0,6356 | 0,6934 | 0,7512 | 0,8090 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 4,5568 | 6,2702 | 8,2251 | 10,4160 | 12,8385 | 15,4887 | 18,3635 | 21,4600 | 24,7757 | 28,3085 | |||||||||||||||||||||||||||||||||||||

| 63 | 10,50 | v, m/s | 0,1805 | 0,2166 | 0,2528 | 0,2889 | 0,3250 | 0,3611 | 0,3972 | 0,4333 | 0,4694 | 0,5055 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 1,4809 | 20,307 | 2,6563 | 3,3558 | 4,1276 | 4,9706 | 5,8836 | 6,856 | 7,9158 | 9,0335 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 0,75 | 0,8 | 0,85 | 0,9 | 0,95 | 1 | 1,1 | 1,2 | 1,3 | 1,4 | |||||||||||||||||||||||||||||||||||

| 32 | 5,40 | v, m/s | 2,1258 | 2,2675 | 2,4092 | 2,5509 | 2,6927 | 2,8344 | 3,1178 | — | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 289,3334 | 325,7243 | 364,1255 | 404,5254 | 446,9131 | 491,2787 | 585,9069 | — | — | — | |||||||||||||||||||||||||||||||||||||

| 40 | 6,70 | v, m/s | 1,3503 | 1,4403 | 1,5303 | 1,6204 | 1,7104 | 1,8004 | 1,9804 | 2,1605 | 2,3405 | 2,5205 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 94,7684 | 106,5824 | 119,0382 | 132,1315 | 145,8586 | 160,2158 | 190,8076 | 223,8829 | 259,4203 | 297,4009 | |||||||||||||||||||||||||||||||||||||

| 50 | 8,40 | v, m/s | 0,8668 | 0,9246 | 0,9824 | 1,0402 | 1,0979 | 1,1557 | 1,2713 | 1,3869 | 1,5024 | 1,6180 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 32,0564 | 36,0175 | 40,1902 | 44,5729 | 49,1643 | 53,9631 | 64,1779 | 75,2087 | 87,0477 | 99,6879 | |||||||||||||||||||||||||||||||||||||

| 63 | 10,50 | v, m/s | 0,5416 | 0,5777 | 0,6138 | 0,6499 | 0,6860 | 0,7222 | 0,7944 | 0,8666 | 0,9388 | 1,0110 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 10,2180 | 11,4686 | 12,7848 | 14,1661 | 15,6119 | 17,1220 | 20,3329 | 23,7959 | 27,5082 | 31,4676 | |||||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 0,3822 | 0,4076 | 0,4331 | 0,4586 | 0,4841 | 0,5096 | 0,5605 | 0,6115 | 0,6624 | 0,7134 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 4,3951 | 4,9291 | 5,4908 | 6,0799 | 6,6962 | 7,3395 | 8,7062 | 10,1788 | 11,7561 | 13,4370 | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 0,2654 | 0,2831 | 0,3008 | 0,3185 | 0,3362 | 0,3539 | 0,3892 | 0,4246 | 0,4600 | 0,4954 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 1,8257 | 2,0458 | 2,2772 | 2,5197 | 2,7733 | 3,0378 | 3,5992 | 4,2036 | 4,8503 | 5,5390 | |||||||||||||||||||||||||||||||||||||

| Diameter pipes, mm | Thickness walls, mm | Consumption water, l/s | 1,5 | 1,6 | 1,7 | 1,8 | 1,9 | 2 | 2,1 | 2,2 | 2,3 | 2,4 | |||||||||||||||||||||||||||||||||||

| 40 | 6,70 | v, m/s | 2,7006 | 2,8806 | 3,0607 | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 337,8076 | 380,6250 | 425,8389 | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||||

| 50 | 8,40 | v, m/s | 1,7336 | 1,8492 | 1,9647 | 2,0803 | 2,1959 | 2,3114 | 2,4270 | 2,5426 | 2,6582 | 2,7737 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 113,1232 | 127,3478 | 142,3567 | 158,1451 | 174,7085 | 192,0431 | 210,1449 | 229,0104 | 248,6364 | 269,0198 | |||||||||||||||||||||||||||||||||||||

| 63 | 10,50 | v, m/s | 1,0832 | 1,1555 | 1,2277 | 1,2999 | 1,3721 | 1,4443 | 1,5165 | 1,5887 | 1,6610 | 1,7332 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 35,6719 | 40,1191 | 44,8075 | 49,7355 | 54,9016 | 60,3044 | 65,9425 | 71,8149 | 77,9204 | 84,2579 | |||||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 0,7643 | 0,8153 | 0,8662 | 0,9172 | 0,9682 | 1,0191 | 1,0701 | 1,1210 | 1,1720 | 1,2229 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 15,2205 | 17,1059 | 19,0922 | 21,1788 | 23,3650 | 25,6502 | 28,0338 | 30,5152 | 33,0940 | 35,7696 | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 0,5308 | 0,5662 | 0,6016 | 0,6369 | 0,6723 | 0,7077 | 0,7431 | 0,7785 | 0,8139 | 0,8493 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 6,2691 | 7,0404 | 7,8524 | 8,7049 | 9,5976 | 10,5301 | 11,5024 | 12,5140 | 13,5648 | 14,6546 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 2,5 | 2,6 | 2,7 | 2,8 | 2,9 | 3 | 3,1 | 3,2 | 3,3 | 3,4 | |||||||||||||||||||||||||||||||||||

| 50 | 8,40 | v, m/s | 2,8893 | 3,0049 | 3,1205 | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 290,1575 | 312,0469 | 334,6853 | — | — | — | — | — | — | — | |||||||||||||||||||||||||||||||||||||

| 63 | 10,50 | v, m/s | 1,8054 | 1,8776 | 1,9498 | 2,0220 | 2,0943 | 2,1665 | 2,2387 | 2,3109 | 2,3831 | 2,4553 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 90,8263 | 97,6248 | 104,6525 | 111,9085 | 119,3919 | 127,1021 | 135,0382 | 143,1996 | 151,5856 | 160,1956 | |||||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 1,2739 | 1,3248 | 1,3758 | 1,4268 | 1,4777 | 1,5287 | 1,5796 | 1,6306 | 1,6815 | 1,7325 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 38,5416 | 41,4096 | 44,3732 | 47,4320 | 50,5856 | 53,8337 | 57,1759 | 60,6119 | 64,1415 | 67,7643 | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 0,8846 | 0,9200 | 0,9554 | 0,9908 | 1,0262 | 1,0616 | 1,0970 | 1,1323 | 1,1677 | 1,2031 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 15,7832 | 16,9504 | 18,1561 | 19,4000 | 20,6820 | 22,0019 | 23,3597 | 24,7552 | 26,1881 | 27,6585 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 3,5 | 3,6 | 3,7 | 3,8 | 3,9 | 4 | 4,1 | 4,2 | 4,3 | 4,4 | |||||||||||||||||||||||||||||||||||

| 63 | 10,50 | v, m/s | 2,5276 | 2,5998 | 2,6720 | 2,7442 | 2,8164 | 2,8886 | 2,9608 | 3,0331 | 3,1053 | 3,1775 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 169,0289 | 178,0849 | 187,3631 | 196,8628 | 206,5837 | 216,5251 | 226,6865 | 237,0676 | 247,6677 | 258,4865 | |||||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 1,7834 | 1,8344 | 1,8854 | 1,9363 | 1,9873 | 2,0382 | 2,0892 | 2,1401 | 2,1911 | 2,2420 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 71,4800 | 75,2885 | 79,1893 | 83,1823 | 87,2673 | 91,4439 | 95,7120 | 100,0714 | 104,5218 | 109,0631 | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 1,2385 | 1,2739 | 1,3093 | 1,3447 | 1,3800 | 1,4154 | 1,4508 | 1,4862 | 1,5216 | 1,5570 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 29,1662 | 30,7111 | 32,2930 | 33,9119 | 35,5676 | 37,2600 | 38,9892 | 40,7548 | 42,5570 | 44,3955 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 4,5 | 4,6 | 4,7 | 4,8 | 4,9 | 5 | 5,1 | 5,2 | 5,3 | 5,4 | |||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 2,2930 | 2,3439 | 2,3949 | 2,4459 | 2,4968 | 2,5478 | 2,5987 | 2,6497 | 2,7006 | 2,7516 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 113,6950 | 118,4174 | 123,2300 | 128,1327 | 133,1253 | 138,2077 | 143,3797 | 148,6410 | 153,9916 | 159,4314 | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 1,5924 | 1,6277 | 1,6631 | 1,6985 | 1,7339 | 1,7693 | 1,8047 | 1,8401 | 1,8754 | 1,9108 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 46,2703 | 48,1813 | 50,1285 | 52,1116 | 54,1308 | 56,1859 | 58,2768 | 60,4034 | 62,5657 | 64,7637 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 5,5 | 5,6 | 5,7 | 5,8 | 5,9 | 6 | 6,1 | 6,2 | 6,3 | 6,4 | |||||||||||||||||||||||||||||||||||

| 75 | 12,50 | v, m/s | 2,8025 | 2,8535 | 2,9045 | 2,9554 | 3,0064 | 3,0573 | 3,1083 | 3,1592 | — | — | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 164,9600 | 170,5775 | 176,2837 | 182,0784 | 187,9615 | 193,9328 | 199,9923 | 206,1398 | — | — | |||||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 1,9462 | 1,9816 | 2,0170 | 2,0524 | 2,0878 | 2,1231 | 2,1585 | 2,1939 | 2,2293 | 2,2647 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 66,9972 | 69,2662 | 71,5707 | 73,9105 | 76,2856 | 78,6960 | 81,1416 | 83,6223 | 86,1381 | 88,6889 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 6,5 | 6,6 | 6,7 | 6,8 | 6,9 | 7 | 7,1 | 7,2 | 7,3 | 7,4 | |||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 2,3001 | 2,3355 | 2,3708 | 2,4062 | 2,4416 | 2,4770 | 2,5124 | 2,5478 | 2,5832 | 2,6185 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 91,2748 | 93,8955 | 96,5512 | 99,2417 | 101,9670 | 104,7270 | 107,5217 | 110,3511 | 113,2151 | 116,1137 | |||||||||||||||||||||||||||||||||||||

| Pipe diameter, mm | Wall thickness, mm | Water consumption, l/s | 7,5 | 7,6 | 7,7 | 7,8 | 7,9 | 8 | 8,1 | 8,2 | 8,3 | 8,4 | |||||||||||||||||||||||||||||||||||

| 90 | 15,00 | v, m/s | 2,6539 | 2,6893 | 2,7247 | 2,7601 | 2,7955 | 2,8309 | 2,8662 | 2,9016 | 2,9370 | 2,9724 | |||||||||||||||||||||||||||||||||||

| 1000i, mm/m | 119,0467 | 122,0143 | 125,0163 | 128,0527 | 131,1234 | 134,2285 | 137,3679 | 140,5415 | 143,7493 | 146,9913 | |||||||||||||||||||||||||||||||||||||

Calculation of diameter for a two-pipe heating system

We will calculate using the example of a simple two-story house. On each floor we have two wings. The house itself will have a two-pipe heating system with the following parameters:

- total heat loss – 36 kW;

- loss on the 1st floor – 20 kW;

- loss on the 2nd – 16 kW;

- polypropylene pipes were installed;

- system operation in 80/60 mode;

- temperature – 20 C.

Below is table (a) based on the data from which we will determine the required pipe diameter. In the table, cells with the best (optimal) fluid velocity are marked in green.

Let's count. Through the section of pipe that connects the first fork and the boiler, the entire volume of liquid passes through, therefore, all the heat, and this is 38 kW. Let's determine which pipe we need to take here.

We take our table, look for the corresponding line in it, then go through the green cells and look up. What do we see? And we see that with such parameters two options suit us: 50 and 40 mm. Naturally (this was written about above), we choose a smaller diameter of the pipe for heating the house, 40 mm.

Next we look at the fork, which divides the coolant movement into the second and first floors (16 and 20 kW). Again we look at the values from the table and find that in both directions a pipe diameter of 32 mm is needed.

We have two wings on each floor. The circuit is also divided into two branches. We count the first floor:

20 kW / 2 = 10 kW per wing

Second floor by analogy:

16 kW / 2 = 8 kW per wing

Again, we take our table and determine that in these areas we need a pipe with a cross-section of 25 mm. It is also clearly seen from the table that we will use this diameter until the load drops to 5 kW, then we will use 20 mm pipes.

Important! From personal experience I can say that it is better to switch to a pipe diameter of 20 mm when the heat load is not 5 kW, but 3 kW.

In this simple way, we calculated all the pipe diameters for heating the house of the polypropylene pipes we needed for a two-pipe heating system.

For the reverse supply of water, you do not need to calculate anything, everything is much simpler: you do all the wiring with pipes of the same diameter as for the direct supply. As you can see, there is nothing complicated. All you need is a good table suitable for a specific case.

Some nuances of calculating the diameter for metal pipes

If you decide that you will use metal pipes for the heating system, then you need to take into account that they lose heat. In small areas, it is practically unnoticeable.

But on extended systems, it may happen that the very last heating elements in the chain will be cold or slightly warm. This is also a consequence of incorrect choice of pipe diameter. Fortunately, heat loss can be easily calculated:

q = k * 3.14 * (tv-tp) q - heat loss per 1 meter (W/s); k – heat transfer coefficient (W * m/s); tв - temperature of hot supplied water (C); tп — ambient temperature (C).

Let's take a pipe with a diameter of 40 mm. Let's say the wall is 1.4 mm thick. Material – steel. Let's calculate:

q = 0.272 * 3.15 * ( 80 – 22 ) = 49 W/s

Here is another proof of why you need to take a pipe diameter for heating a house with a smaller diameter. After all, it is clear that the thicker the pipe, the much more heat we will lose.

And in this example, we received losses of almost 50 W per 1 meter of distance. And if the system is quite extended, then all the heat can be lost.

But don't be upset! Such accurate calculations are needed only for multi-storey residential buildings. For individual heating systems, everything is simpler: calculations are rounded up and this gives a certain margin.

Installation of heating systems using polypropylene pipes

One of the important stages of installing a heating system is resolving the issue with the scheme that will have to be followed when performing the work. And if we talk about the use of polypropylene structures, then the following options can be used:

- The movement of liquid in the heating system is by gravity . This option allows the owner to refuse to use a circulation pump, since the liquid in the system will flow naturally. A similar scheme can be implemented in rooms where the electricity supply is unstable, which makes it very difficult to maintain the pump in continuous operation.

- Bottom filling system in heating . A special feature of this scheme is the use of radial wiring, which is based on the use of a pump provided by an increase in water pressure, which is achieved due to a smaller diameter.

- An acceptable scheme is in which one- and two-pipe systems are connected to the radiator, which is realized through a side or bottom type of connection.

Where can I get the tables?

Everything is simple here. Usually, all detailed tables with all the necessary data can be viewed (or downloaded) on the websites of pipe manufacturers. But it happens that there are still no tables.

You can get out of this situation as follows. If there are no tables for the outer diameter, then take the one for the inner diameter and calculate according to it. Yes, there will be inaccuracies, but, as experience shows, for forced circulation they are completely insignificant and acceptable.

Having analyzed a huge number of already installed and perfectly working systems, experts noticed a certain pattern in the choice of pipe cross-section. It is mainly suitable for small-sized autonomous systems.

In private houses, the pipes that come out of the boiler are most often one-half and three-quarters in size. This diameter of the pipe for heating a house is used until the first fork, and at each subsequent fork the cross-section is reduced by exactly one step.

But this method is applicable only for apartments and one-story houses; for high-rise buildings, alas, everything will have to be calculated very carefully.

If we have a private house or apartment, autonomous heating for no more than 5-8 radiators and 2-3 forks, we can easily calculate everything ourselves. We need to know how powerful each heating point is, the heat loss in the room and a good table for selecting the pipe diameter.

However, as has already become clear, trust experienced specialists to calculate a complex multi-level system with numerous junctions and forks. Well, if you still decide to do everything yourself, then at least read articles like ours and consult with experts.

Source: eurosantehnik.ru/kak-vybrat-diametr-truby-dlya-otopleniya-doma.html

Thermal expansion coefficient values

It is worth taking into account that reinforced pipes have a higher coefficient of thermal expansion compared to non-reinforced products.

If you do not take into account the expansion of PP pipes, due to exposure to high temperatures, the fastening clips may break off, and sinusoidal deformation of the pipes may form on a flat section of the pipeline.

In such areas, air accumulates and throughput decreases. In heating systems, in this case, the temperature of the radiators decreases and the connections are destroyed.

For unreinforced polypropylene pipes, the coefficient of thermal expansion is 0.1500 mm/mK, and for products with additional fiberglass reinforcement it is 0.03-0.05 mm/mK. Naturally, the difference is obvious, and you should not neglect it during work.

As practice shows, a PP pipe 5 m long under the influence of heat increases by about 11-17 mm.

How to choose the correct pipe diameter for heating a house - table and calculations

It is not difficult for a professional to calculate the optimal cross-section of the pipeline. Practical experience + special tables - all this is enough to make the right decision. But what about the average home owner?

After all, many people prefer to install the heating circuit on their own, but do not have a specialized engineering education. This article will be a good hint for those who need to decide on the diameter of the pipe for heating a private home.

There are several nuances that you need to pay attention to:

- Firstly, all data obtained based on calculations using formulas are approximate. Various roundings of values, averaged coefficients - all this introduces a number of amendments to the final result.

- Secondly, the specific operation of any heating circuit has its own characteristics, so any calculations provide only indicative data, “for all cases.”

- Thirdly, pipe products are produced in a certain range. The same applies to diameters. The corresponding quantities are located in a certain row, with gradation by value. Therefore, you will have to select a denomination that is closest to the calculated one.

Based on the above, it is advisable to use the practical recommendations of professionals.

All Doo are in “mm”. In brackets - for systems with natural coolant circulation.

- The total line pipe is 20 (25).

- Battery outlets – 15 (20).

- With a single-pipe heating scheme, the diameter is 25 (32).

But these are general parameters of the circuit and do not take into account its specifics. More precise values are shown in the table.

Calculation by formula

The number of pipes for a heated floor is determined by the formula:

Where:

- L – pipeline length;

- S – area of the room or other premises;

- N – distance between pipes when turning;

- 1.1 – loss coefficient;

- P – distance from the beginning of the floor to the heating equipment and back.

The loss coefficient (1.1) is standard for any type of pipe and laying scheme.

The distance to the boiler (P) is determined in meters. The parameter can be found using a regular or laser tape measure.

Measuring the distance to the boiler

Determination of room area (S)

The surface area on which the heated floor is supposed to be installed is determined according to the following rules:

- the area of the room is found as the product of the length and the width of the room;

Parameters for calculating room area

- the resulting value must be reduced by the area occupied by large furniture. In this case, the area allocated for furniture is calculated in a similar way, based on the corresponding parameters of the furniture;

- A distance of 20-30 cm is required from the walls of the room. This distance is required for the damper tape.

Material for smoothing out the expansion of floor screed

When calculating the surface area under the floor, it is necessary to use parameters determined taking into account the thickness of the wall finishing. This approach will help save money when purchasing materials for an additional heating system.

Determination of pipeline laying pitch (N)

To achieve uniform heating of the floor, it is necessary to determine the optimal pitch for laying the pipeline. To do this, you must follow the following rules:

- the minimum distance between the turns making up the floor system is 10 cm;

- maximum distance – 30 cm;

- the selection of distance depends on the material of the pipes. For pipes with lower heat transfer, the laying pitch is reduced;

- The floor can be laid either with the same pitch or with different distances between the pipes. It is recommended to reduce the parameter in the area where external walls, windows and doors are located.

Warm floor with constant pipe laying pitch

Experts have developed a standard pipe flow rate at a certain distance.

Dependence of pipe footage on the pitch provided by the laying scheme

What is taken into account when choosing pipe diameter

Heat generator power. It is taken as a basis and determined individually for each building. What does the owner focus on when purchasing a boiler?

For the total area of all heated premises. This is exactly what the manager at the point of sale will definitely clarify if the buyer has questions about this item.

On a note! It is generally accepted that to ensure high-quality heating of a house, it is necessary to adhere to the following ratio - 1 m2 / 0.1 kW. But if we take into account the peculiarities of the climate and the gentle operating mode of the unit (so as not to “drive” it to the limit), then about 30% should be added. It turns out - 1/1.3.

Coolant speed. If it is less than 0.25 m/sec, then there is a risk of airing the system and causing traffic jams on the highway. Exceeding the value of 1.5 is fraught with “noise” in the highway.

This is especially noticeable when the pipes are metal, and even laid in an open way. But in any case, the movement of the coolant along the route will be clearly audible.

Practice has proven that for a private building (with an autonomous heating circuit) you should focus on an indicator in the range from 0.3 to 0.7. This is the optimal value for any system.

Circuit configuration. In private houses, when installing it, as a rule (regardless of the circuit), all the “threads” are connected to the collector. Each of them is “loaded” with a certain number of radiators.

There is no point in purchasing pipes of the same diameter for all lines, given that the larger the cross-section of the workpiece, the higher the price of 1 running meter.

Pipe diameter. The outer one does not play a special role, since products made from different materials have differences in wall thickness. This parameter only indicates the ease of fastening the product. The internal diameter is about the throughput of the route. It is he who is decisive.

On a note! It is customary to operate with the average value of the cross-section (the diameter of the nominal diameter). It is this parameter that is used in the calculations.

Pipe diameters are usually indicated in inches. For us, this is an unusual (non-metric) system, so you should know the rules for converting quantities. The ratio of inches to centimeters is ½.54 (or 25.4 mm). Pipe material – metal-plastic, steel, PP, PE.

Specifics of the structure. First of all, this relates to the effectiveness of its thermal insulation - what materials it is assembled from, what method is used, and so on.