Calculation of pipe diameter

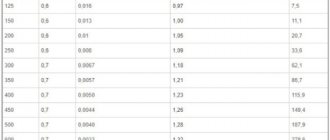

The calculation of the pipe diameter is carried out on the basis of two parameters - the permissible flow rate and the possible pressure loss per meter of pipe.

The criterion for choosing pipe diameters based on possible pressure losses is considered economic and consists in determining the balance between capital and operating costs. An increase in pipe diameter entails an increase in its cost, and to pump water through a pipe with a smaller diameter, you need to spend more energy to drive the pump.

For a feasibility study of the choice of pipe diameter, a graph of the dependence of capital and operating costs on the diameter of the pipeline is constructed. A good pipe diameter is formed at the intersection point of the capital cost curve and the operating cost curve.

The limitation of the flow rate in the pipes is caused by hygiene standards of the possible equivalent noise level dB. The maximum possible water speeds in the pipelines of the heating system depend on the diameter of the pipes and range from 0.8 to 1.5 m/s, and in the pipelines of the water supply system they are limited to 3 m/s.

The above program will calculate the required pipe diameter, the specific pressure loss of which will not exceed 100 Pa/m.

Clarifying the speed of fluid movement

Let us express from equation (20) the speed of fluid movement:

w = 4* Vc/(π* de2) = 4*1.61*10-3/(3.14*(0.033)2) = 1.883 m/s.

3.7.

Determining the mode of fluid movement

We will determine the mode of fluid movement using the Reynolds equation (formula (3)):

Re = W* de * ρcm /μcm = 1.883*0.033*864.9/5.48*10-4 = 98073.

The movement mode is developed turbulent.

3.8.

Determination of the hydraulic resistance coefficient

Let us take the average roughness value l = 0.2 mm, then the relative roughness will be ε = l/ dе = 0.2/33 = 6.06*10-3.

Let's check the condition Re ≥ 220*ε -1.125.

220*(6.06*10-3)-1.125 = 68729, i.e. less than Re = 98073. The movement area is self-similar and the coefficient of hydraulic resistance is found according to formula (14):

1/ λ0.5 = 2*lg(3.7/ε) = 2*lg(3.7/6.06*10-3) = -6.429. Whence λ = 0.0242.

3.9.

Finding local resistance coefficients

According to paragraph 3.2. and taking into account that the local resistance coefficients are as follows:

— pipe inlet ξtr = 0.5;

— normal valve ξven = 4.7;

— elbow 90 ξcol = 1.1;

— outlet from the pipe ξintr = 1;

— measuring diaphragm (at m = (de/D)2 = 0.3, then ξd = 18.2)

∑ ξms = ξtr + 3* ξven + 3* ξcol + ξd + ξintr = 0.5 + 3*4.7 + 3*1.1 + 18.2 + 1 = 37.1.

The geometric lifting height of the mixture is 14 m.

3.10.

Determination of total pressure loss in a pipeline

The sum of all lengths of pipeline sections is 31 m, P1 = P2. Then the total hydraulic resistance of the network according to formula (18):

ΔРnet = (1 + λ * I/ de + ∑ ξms)* ρ*W2 /2 + ρ*g*hgeom + (P2 – P1) = (1 + 0.0242*31/0.033 + 37.1)*864 .9*1.8832/2 + 864.9*9.81*14 = 168327.4 Pa.

From the relation ΔРnetwork = ρ*g*h we determine hnetwork = ΔРnetwork/ (ρ*g) = 168327.4/(864.9*9.81) = 19.84 m.

3.11. Construction of characteristics of a pipeline network

We will assume that the network characteristic is a regular parabola emanating from the point with coordinates Vc = 0; h at which the point with coordinates Vc = 5.78 m3/h and hnetwork = 19.84 m is known. Let’s find the coefficient of the parabola.

The general equation of a parabola is y = a*x2 + b. Substituting the values, we have 19.84 = a*5.782 + 14. Then a = 0.1748.

Let's take several values of volumetric productivity and determine the pressure h of the network.

Let's summarize the data in a table.

Table - Dependence of network pressure on pump performance

| Productivity, m3/h | Network pressure, m |

| 1 | 14,17 |

| 2 | 14,70 |

| 3 | 15,57 |

| 4 | 16,80 |

| 5 | 18,37 |

| 5,78 | 19,84 |

| 6 | 20,29 |

| 7 | 22,57 |

| 8 | 25,19 |

| 9 | 28,16 |

| 10 | 31,48 |

Based on the obtained points, we build a network characteristic (line 1 in Figure 2).

Figure 2 – Combination of network and pump characteristics:

1 – network characteristics; 2 – pump characteristics; 3 - design point; 4 – operating point.

How not to go wrong in the hydraulic calculation of heating pipes

Heat supply is especially important for human life, especially during winter and autumn. Moreover, in our time, a decent number of inhabitants of houses and apartments choose to benefit from individual heating. This can be explained by the fact that it is more reliable and of higher quality than the centralized one, and also has savings as a result of operation - it allows you to reduce the monthly fee for services to a minimum. Savings also occur due to proper installation and choice of system. In this, the hydraulic calculation of the heating system plays a very important role, since it is so important, it will have to be carried out in advance.

Content

The calculation is performed first of all to determine the resistance in the pipes of the heating system.

Low-quality installation of the frame itself brings many problems, so during installation and hydraulic calculations, you need to ask for help from professionals with the necessary knowledge and experience.

When installing and hydraulic calculations take into account:

- hydraulic resistance;

- pipe diameter;

- type of pipeline;

- silent operation of the system.

Accurate calculation is an expensive undertaking, but the data is needed for the subsequent reliable operation of heating systems.

Calculation of circulation resistance (measured in Pa) can be calculated for:

- heating systems using a circular pump (the required pump pressure is formed, and then the pipe diameter is indicated);

- systems in which circulation occurs due to the difference in densities (in this way) of the supply and return pipelines (calculated: the permissible speed of water circulating in the pipes; hydraulic resistance; at the last stage - pipe diameter).

We calculate the pipe diameter for heating, pipe diameter

The choice of pipes for systems with convective circulation and forced circulation is different. With a central system, the pipe diameter is calculated according to apartment heating systems. And with an independent, volumetric calculation of the pipe, pipe diameter, different diameters are possible depending on:

- pipe manufacturing material;

- type of circulation (performed using a pump or convective circulation);

- water flow speed;

- water pressure;

- heating system wiring;

- type of coolant.

Plastic heating pipes

When calculating the diameter, the first step is choosing the material. Based on this criterion, they distinguish:

- plastic pipes (notable for their low cost and ease of installation);

- steel or copper (high price, difficult to install);

- metal-plastic (inner wall made of food-grade polymer ethylene).

Heating system steel tubes

Profile pipes are increasingly fading into the background.

Which size is better, calculation of pipe area

It is also necessary to take into account the size of the riser. If you choose the wrong pipe diameter, you expose yourself to the risk of breaking the heating system when you start using it.

Metal-plastic heating pipes

When answering the question: what diameter of heating pipes to choose, adhere to the following rules:

- An excessively high diameter leads to low water pressure. If used in a small house, a circulation failure will lead to a violation of the temperature regime.

- Very small - contributes to the appearance of high pressure and noise.

- In a wide variety of situations, deliberate use of one or another pipe diameter is necessary.

to menu ^

Hydraulic calculation of a simple composite pipeline

,

Calculations of simple pipelines come down to three typical tasks: determining the pressure (or pressure), flow rate and diameter of the pipeline. Next, we consider a technique for solving these problems for a simple pipeline of constant cross-section.

Problem 1

. Given: pipeline dimensions and

the roughness of its walls

, properties of liquid

, fluid flow Q.

Determine the required pressure H (one of the quantities that make up the pressure).

Solution

.

The Bernoulli equation is compiled for the flow of a given hydraulic system. Control sections are assigned. The reference plane Z (0.0)

and the initial conditions are analyzed. The Bernoulli equation is compiled taking into account the initial conditions. From the Bernoulli equation we obtain a calculation formula of type ٭. The equation is solved with respect to H. The Reynolds number Re is determined and the mode of motion is established. The value is found

depending on the driving mode.

H and the desired value are calculated. Task 2.

Given: pipeline dimensions and

, the roughness of its walls

, properties of liquid

, pressure N. Determine flow rate Q.

Solution.

The Bernoulli equation is compiled taking into account the previously given recommendations. The equation is solved relative to the desired value Q. The resulting formula contains an unknown coefficient

, depending on Re. Direct location

under the conditions of this problem it is difficult, since when Q is unknown, Re cannot be established in advance. Therefore, further solution of the problem is performed by the method of successive approximations.

- approximation: Re → ∞

, define

2nd approximation:

, find

λ II ( R e II , Δ e )

and determine

The relative error is found

. If

, then the solution ends (for training problems

). Otherwise, the solution is carried out in the third approximation.

Task 3.

Given: dimensions of pipelines (except diameter d), roughness of its walls

, properties of liquid

, pressure H, flow Q. Determine the diameter of the pipeline.

Solution

. When solving this problem, difficulties arise with directly determining the value

, similar to the problem of the second type. Therefore, it is advisable to carry out the solution using the graphic-analytical method. Multiple diameter values are specified

.For each

the corresponding pressure value H is found for a given flow rate Q (the problem of the first type is solved n times). Based on the calculation results, a graph is constructed

. From the graph, the required diameter d is determined, corresponding to the given pressure value H.

System power designation for heating

The heat loss rate (K) is determined depending on the quality of the housing (the materials used in the construction of the house and the presence of insulation). There are average coefficients for a typical brick house:

- without thermal insulation, K=4;

- low degree of insulation (many large windows), K=2.5;

- average thermal insulation (few windows, building without specialized insulation), K=1.5;

- high thermal insulation (insulation on both sides, heat-saving packages), K=1.

The value 860 in the formula means the power conversion rate in kW, 1 kW = 860 kcal/h.

The heat supply power parameter allows you to judge the operating efficiency of the heating system.

Types of radiators

As for which heating is best for a private home, reviews from owners are quite varied, but when it comes to radiators, many prefer aluminum models. The fact is that the power of heating batteries depends on the material. They are bimetallic, cast iron and aluminum.

One section of a bimetallic radiator has a standard power of 100-180 W, cast iron - 120-160 W, and aluminum - 180-205 W.

When purchasing radiators, you need to find out exactly what material they are made of, since this is the indicator that is required for the correct calculation of power.

Calculating the diameter of heating pipes

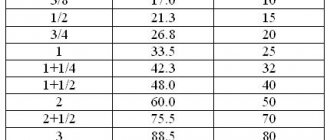

Pipe measurement is based on two systems:

- in millimeters according to the “conditional” diameter;

- in inches by thread diameter (1 inch is 25.4 mm).

We calculate heating pipes based on the type of pipes (plastic, metal-plastic, steel), professionals calculate the diameter using specialized tables and formulas.

Heating pipe calculations must be carried out at the beginning of the system design

When calculating the diameter, the required thermal load (heat flow), as well as the coolant flow rate, are specified on specialized tables. Thermal load refers to the sum of heat transfer from all devices of the heating system).

We study the baxi mounted boiler here.

Basically, such calculations are used in very heavy heating systems. In everyday life (in private houses, apartments) the following classic sizes are used:

- from 10 to 15 mm - pipe diameter, which are intended for water supply (or in inches from one second to three eighths);

- from 20 to 25 mm - pipe diameter used as a riser in the system (in inches from three-quarters to one).

Correctly determined pipe diameter contributes to very efficient operation of heating systems.

Hydraulic calculation is a fundamental point during the installation or replacement of a heating system. It is necessary to take seriously the determination of the values of all its components; it would be nice to have it carried out by a master. Failure to comply with any condition during installation and calculation can lead to a serious failure during the start of operation and complete failure of the heating system.

So, let's summarize the publication:

- hydraulic calculations are carried out to determine the resistance in the pipes of the heating system;

- when making hydraulic calculations, it is necessary to take into account the type of heating system: centralized or independent;

- As for the diameter of the pipes, with a central system the diameter is determined based on this by the heating systems of the apartments, and with an independent system the diameter is determined depending on: the material of the pipes; type of circulation (performed using a pump or convective circulation); water flow speed; water pressure; heating system wiring; type of coolant.

- in a wide variety of rooms and when operating various heating systems, it is better to use pipes of one diameter or another, taking into account that the diameter affects the pressure in the pipes (larger diameter - lower pressure);

- calculation of the heat supply power parameter allows us to judge the operating efficiency of the heating system;

- Basically, calculations for pipe diameters are used for very heavy heating systems; in everyday life, classic sizes are used (from 10 to 15 mm for water supply and from 20 to 25 mm for water riser);

- The more accurately the pipe diameter for a good heating system is determined, the more effective the system will work.

to menu ^

Application of polypropylene pipes

If polypropylene heating pipes are used for the heating circuit, how to choose the diameter according to the above formulas? Yes, exactly the same. But polypropylene pipes have a huge service life, up to 100 years, so a heating system, correctly calculated and carefully installed, will last a very long time. To the question - how to choose the size of pipes for heating, the answer can be found in the tables that can be downloaded on the Internet. The popularity of polypropylene pipes for creating heating systems is quite high, because they are much cheaper than metal ones, are environmentally friendly and have a good appearance. And the installation of system circuits when using such pipes is greatly facilitated. Special devices for welding pipes, various adapters, fittings, taps and other necessary components have been developed. The installation process itself is similar to assembling a system from a construction kit.

How to choose the diameter of heating pipes

In this publication we will consider systems with forced circulation. In them, the movement of the coolant is ensured by a regularly operating circular pump. When choosing the diameter of heating pipes, it is assumed that their main task is to ensure the delivery of the required amount of heat to heating devices - heating devices or registers. For the calculation you will need the following data:

- General heat loss of an apartment or house.

- The power of radiators (heating devices) in any room.

- Pipe length.

- Method of wiring the system (one-pipe, two-pipe, with forced or convective circulation).

In other words, before you start calculating pipe diameters, you calculate the total heat loss in advance, determine the boiler power and calculate the power of heating devices for any room. It will also be necessary to decide on the wiring option. Based on this information, draw up a diagram and then just start calculating.

To find out the diameter of the heating pipes, you will need a diagram with the thermal load values assigned to each element.

What else do you need to pay your attention to? The fact is that the outer diameter of polypropylene and copper pipes is marked, and the inner diameter is calculated (subtract the wall thickness). For steel and metal-plastic ones, the internal size is indicated when marking. So don't forget this little thing.

How to choose the diameter of heating pipes

It will not be possible to calculate exactly what cross-section of pipes you need. You will need to choose from several options. And all because the same effect can be achieved in different ways.

Let's explain. The main thing for us is to deliver the required amount of heat to the heating devices and at the same time achieve the same heating of the heating devices. In systems with forced circulation, we do this using pipes, a heat carrier and a pump. As a rule, all we need is to “drive” a certain amount of coolant over a specific time period. There are two types: install pipes with a smaller diameter and supply coolant at a higher speed, or create a system with a larger cross-section, but with less traffic intensity. In most cases, the first option is chosen. And that's why:

- the price of products with smaller diameters is lower;

- they are easier to work with;

- when laid open, they do not attract attention as much, and when laid in the floor or walls, smaller grooves are required;

- with a small diameter, there is less coolant in the system, which reduces its inertia and leads to fuel savings.

Calculation of the diameter of copper heating pipes depending on the power of heating devices

Since there is a specific set of diameters and a certain amount of heat that needs to be delivered through them, it is unreasonable to calculate everything the same every time. Therefore, specialized tables have been developed, according to which, depending on the required amount of heat, the speed of movement of the coolant and the operating temperature of the system, the permissible size is determined. In other words, to determine the cross-section of pipes in the heating system, find the necessary table and select the appropriate cross-section from it.

The diameter of the heating pipes was calculated using the following formula (you can calculate it if you wish). Afterwards, the calculated values were recorded in the table.

Formula for calculating pipe diameter of heating

D - required pipeline diameter, mm ?t° - temperature delta (difference between supply and return), °C Q - load on this section of the system, kW - determined amount of heat needed to heat the room V - speed of the coolant, m /s - selected from a specific range.

In autonomous heating systems, the speed of movement of the coolant can be from 0.2 m/s to 1.5 m/s. From our own operating experience it is known that a suitable speed is in the range of 0.3 m/s - 0.7 m/s. If the coolant moves very slowly, air pockets appear; if it moves faster, the noise level increases greatly. A good range of speeds and selected in the table. The tables are designed for a wide variety of types of pipes: iron, polypropylene, metal-plastic, copper. The values are calculated for typical operating modes: with high and medium temperatures. To make the selection process more clear, we will analyze certain options.

Determination of mixture characteristics

Since the problem statement does not specify a change in temperature, we assume the flow is isothermal, i.e. maintaining a temperature of 30°C throughout. The composition of a mixture of benzene and toluene allows you to determine the density and viscosity of the mixture.

Density at 30 C: benzene ρb = 868.5 kg/m3 and density of toluene ρt = 856.5 kg/m3, then the density of the mixture: ρcm = 0.7* ρb + 0.3* ρt = 0.7*868, 5 + 0.3*856.5 = 864.9 kg/m3.

Viscosity at 30 C: benzene μb = 5.6*10-4 Pa*s and toluene viscosity μt = 5.22*10-4 Pa*s, then the viscosity of the mixture: lg μcm = 0.7*lg μb + 0, 3*lg μt = 0.7*lg (5.6*10-4) + 0.3*lg (5.22*10-4) = - 3.261, and μcm = 5.48*10-4 Pa* With .

Calculation for a two-pipe type system

There is a house on two floors with a heating system with two pipes, two wings on each floor. Products made of polypropylene will be used, operating mode 80/60 with a temperature delta of 20 °C. The heat loss of the house amounts to 38 kW of heat energy. The ground floor has 20 kW, the second floor has 18 kW. The diagram is shown below.

Heating scheme with two pipes for a two-story house. Right wing (click to enlarge)

Heating scheme with two pipes for a two-story house. Left wing (click to enlarge)

On the right side there is a table from which we will determine the diameter. The pinkish area is the territory of suitable speed of movement of the coolant.

Table for calculating the diameter of polypropylene heating pipes. Operating mode 80/60 with a temperature delta of 20°C (click to enlarge)

- We find out which pipe needs to be used in the area from the boiler to the first branch. The entire heat carrier passes through this section, therefore the entire heat volume of 38 kW passes through. In the table we find the required line, follow it to the pink-tinted area and go up. We see that two diameters are suitable: 40 mm, 50 mm. For obvious reasons, we choose the smaller one - 40 mm.

- Let's look at the diagram again. Where the flow is divided, 20 kW goes to the 1st floor, 18 kW goes to the 2nd floor. In the table we find the necessary lines, find the cross-section of the pipes. It turns out that we are dividing two branches with a diameter of 32 mm.

- Any of the circuits is divided into two branches with equal load. On the lower floor there is 10 kW each to the right and left (20 kW/2=10 kW), on the second floor there is 9 kW each (18 kW/2)=9 kW). Using the table, we find the required values for such areas: 25 mm. This size continues to be applied until the thermal load decreases to 5 kW (as can be seen from the table). Next comes a section of 20 mm. On the lower floor we go 20 mm after the second heating device (look at the load), on the second - after the 3rd. At this point there is one amendment made by accumulated experience - it is better to switch to 20 mm at a load of 3 kW.

All. The diameters of polypropylene pipes for a two-pipe type system are calculated. For the return, the cross-section is not calculated, and the wiring is carried out using similar pipes as the supply. We hope the methodology is clear. If all the initial data is available, such a calculation will not be difficult to carry out. If you suddenly decide to use other pipes, you will need other tables calculated for the material you need. You can practice on this system, but only for an average temperature mode of 75/60 and a delta of 15 °C (the table is located below).

Table for calculating the diameter of polypropylene heating pipes. Operating mode 75/60 and delta 15 °C (click to enlarge)

Pipe diameter designation for a single pipe system with forced circulation

The principle remains the same, the methodology changes. Let's use a different table to determine the diameter of the pipes with a different principle of entering data. In it, the ideal area for the speed of movement of the coolant is covered with blue paint; the power values are not in a column on the side, but are entered in the field. Therefore, the process itself is somewhat different.

Table for calculating the diameter of heating pipes

Using this table, we calculate the internal pipe diameter for a simple “Leningradka” scheme for one floor and six heating devices connected gradually. Let's start the calculation:

- 15 kW is supplied to the system input from the boiler. We find values close to 15 kW in the good speed zone (blue). There are two of them: in a line measuring 25 mm and 20 mm. As everyone understands, we choose 20 mm.

- On the first radiator, the thermal load is reduced to 12 kW. We find this value in the table. It turns out that it goes further from it by the same size - 20 mm.

- On the third radiator the load is already 10.5 kW. We find the cross section - still the same 20 mm.

- The fourth heating device, judging by the table, is already 15 mm: 10.5 kW-2 kW = 8.5 kW.

- On the fifth there is another 15mm, and after that it is already allowed to install 12mm.

Diagram of a system with one pipe for six heating devices

Once again, you need to pay attention that the table above determines the internal diameters. Using them you can then find the markings of pipes made of the required material.

It seems that there should be no difficulties with how to calculate the diameter of heating pipes. Everything is clear enough. However, this is correct for polypropylene and metal-plastic products - their heat conductivity is low and losses through the walls are small, so they are not taken into account when calculating. Metals - steel, stainless steel and aluminum - are a different matter. If the pipeline length is significant, then losses through the surface will be significant.

Selection of standard pipeline diameter

The industry produces a standard assortment of pipes, among which it is necessary to select pipes with a diameter closest to the design one (clause 3.4.). Pipes are designated dн x δ, where dн is the outer diameter of the pipe, mm; δ – pipe wall thickness, mm. In this case, the internal diameter of the pipe din = dn – 2* δ.

The standard dimensions of pipes according to GOST 8732-78 are the following row, mm: 14x2; 18x2; 25x2; 32x2.5; 38x2.5; 45x3; 57x3; 76x3.5; 89x4.5; 108x4.5; 133x4; 159x4.5; 219x6; 272x7; 325x8; 377x10; 426x11; 465x13.

According to clause 3.4. the internal size of the pipe is 32 mm, then the external size dн = 32 + 2 * 2.5 = 37 mm. The closest pipe size is 38x2.5 mm. The standard internal diameter is 33 mm, so we take the equivalent diameter dе = 0.033 m.

Specifics of calculating the cross-section of pipes made of metal

For large heating systems with metal pipes, it is worth taking into account heat loss through the walls. The losses are not that great, but with a long length they lead to the fact that the temperature on the last batteries will be completely low due to the wrong choice of diameter.

Let's calculate the losses for a 40 mm steel pipe with a wall thickness of 1.4 mm. Losses are calculated using the formula:

q = k*3.14*(tв-tп)

q is the heat loss of a meter of pipe,

k is the linear heat transfer coefficient (for this pipe it is 0.272 W*m/s);

tw — water temperature in the pipe — 80°C;

tп — ambient temperature in the room — 22°С.

Substituting the values we get:

q = 0.272*3.15*(80-22)=49 W/s

It turns out that almost 50 W of heat is lost per meter. If the length is significant, this can become critical. It is clear that the larger the cross-section, the greater the losses will be. If it is necessary to take these losses into account, then when calculating the losses, the losses in the pipeline are added to the reduction in the thermal load on the radiator, and then, using the total value, the required diameter is found.

Designating the diameter of heating system pipes is a difficult task

However, for autonomous heating systems these values are in most cases not critical. Moreover, when calculating heat and power losses of equipment, very often the calculated values are rounded upward. This gives a specific margin, which makes it possible not to make such difficult calculations.

Current question: where to get tables? Almost all manufacturers' websites have such tables. You can read it directly from the site, or you can download it for yourself. But what to do if you still haven’t found the necessary tables for the calculation. You can use the diameter selection system described below, or you can do it differently.

Despite the fact that different values (internal or external) are indicated when marking different pipes, they can be compared with a specific error. Using the table below you can find the type and marking for a known internal diameter. Here you can also find the appropriate size pipe made of a different material. For example, it is necessary to calculate the diameter of heating pipes made of metal-plastic. You did not find a table for MP. But there is one for polypropylene. Select sizes for PPR, and then use this table to find analogues in MP. Naturally, there will be an error, but for systems with forced circulation it is allowed.

Correspondence table for different types of pipes (click to enlarge size)

Using this table, you can easily determine the internal pipe diameters of the heating system and their markings.

System selection

Selecting the type of pipeline

It is necessary to decide on the material of the heating pipes:

Steel pipes are practically not used today, since due to their susceptibility to corrosion their service life is short, installation is labor-intensive, and repairs are difficult. Experts do not recommend using metal-plastic pipes because of their ability to sometimes burst at bends when exposed to temperature. Copper pipes are the most durable and easy to repair, but also the most expensive. Various types of polymer pipes (for example, cross-linked polyethylene or reinforced polypropylene) are often the best choice

If you are heating a private house with plastic pipes, when choosing their brand, you must first of all pay attention to the indicator characterizing the permissible water pressure in the product. To prevent deformations and bends of plastic pipes, you need to avoid very long straight sections

It is also necessary to observe during the first start-up of the heating system for a sharp change in temperature

To prevent deformation and bending of plastic pipes, very long straight sections should be avoided. It is also necessary to observe during the first start-up of the heating system for a sharp change in temperature.

Basic parameters of pipes

Polypropylene heating pipes of different diameters

For a heating system, pipes are selected not only according to the chemical and physical properties of their material. In the design of an effective and economical system, their diameter and length play an important role, since the cross-section of the pipes generally affects the hydrodynamics. A fairly common mistake is choosing products with a diameter that is too large, which leads to a drop in pressure in the system below normal, and the heating devices stop heating. If the diameter of the pipes is too small, the heating system begins to make noise.

Main characteristics of pipes:

- Inner diameter is the main parameter of any pipe. It determines its throughput.

- The outer diameter must also be taken into account when designing the system.

- Conditional diameter is a rounded value expressed in inches.

When selecting pipes for heating a country house, you need to take into account that for products made from different materials, different measurement systems are used. Almost all cast iron and steel pipes are marked by their internal section. Products made of copper and plastic - by outer diameter

This is especially important if a system is to be installed from a combination of materials

An example of matching the diameters of pipes made of different materials

When combining different materials in a system, in order to select the pipe diameter accurately, you need to use a diameter correspondence table. It can be found on the Internet. Often the diameter is measured in fractions or inches. One inch equals 25.4 mm.

Choosing a pipe diameter for heating

This method is not based on calculations, but on a pattern that can be traced when analyzing a fairly decent number of heating systems. This rule was developed by installers and is used by them on small systems for private apartments and houses.

The pipe diameter can simply be selected following a specific rule (click to enlarge size)

From many heating boilers there are sections of supply and return pipes of 2 sizes: ? And ? inches. This is the pipe that is used to route until the first branch, and then at each branch the size will become smaller by one step. Using this method, you can determine the diameter of the heating pipes in the apartment. Systems in most cases are small - from three to eight heating devices in the system, maximum - two or three branches with one or two heating devices for each. For such a system, the proposed method is an excellent solution. The situation is almost the same for small private buildings. But if there are already two floors and a more extensive system, then you have to count and work with tables.

If the system is not the most complex and extensive, the pipe diameter of the heating system can be calculated on your own. To do this, it is necessary to have data on the heat loss of the room and the power of each heating device. Then, using the table, you can determine the pipe cross-section that will handle the supply of the required amount of heat. It is better to entrust the cutting of complex multi-element circuits to a specialist. In any case, calculate on your own, but try, at a minimum, to consult with.