When carrying out work related to the installation or repair/maintenance of a pipeline at industrial facilities or in private households, quite often the problem arises of how to measure the diameter of the pipe. It is not always possible to examine the markings; there are situations when the ends of objects are not accessible for visual observation and measurement. Provided that no special precision is required, measurements can be made using available material.

There are several ways to determine the diameter of a pipe if there is no marking on it.

Special devices for measuring pipe diameter

Of course, you can also resort to the help of specialized devices, which were designed to carry out this kind of measurements. These include laser meters, a ruler-circometer, etc. But they may not always be at hand. In addition, some professional tools are not always cheap, so their one-time purchase may not be justified from an economic point of view. Yes, and working with them will require some skills. So it makes sense to look at some other ways to measure pipe diameter.

Circometers are designed for accurate measurement of the diameters of pipes and other round-shaped products. The circometer is made of stainless, hardened spring steel, the markings are applied with a laser.

But before you start considering this issue, you need to decide what diameter you have to deal with. After all, there is a distinction between outer diameter and inner diameter. Moreover, it is not always measured in centimeters or millimeters. There are cases when the measurement is in inches. For information: one inch is equal to 2.54 cm. The outer diameter may be needed if its value has to be taken into account, for example, when applying threads to the outer wall of a pipe. This indicator will directly depend on the thickness of the pipe. By the way, the wall thickness can be calculated by subtracting the internal diameter from the outer diameter.

Plastic

Nowadays, their plastic counterparts have become an alternative to metal pipes. Moreover, their sizes vary widely. The material for such a product is:

- Polypropylene;

- Polyethylene;

- Metal-plastic.

Each manufacturer of such pipes sets its own size chart. Therefore, if one system is being manufactured, it is advisable to use parts from the same manufacturer.

Of course, there will definitely be discrepancies, but they will be minimal and will not cause any particular difficulties for a good master. If a person has little experience, he will have to make some efforts to fit all the sizes.

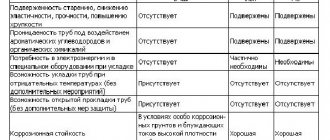

The table of sizes of plastic pipes for water supply using polypropylene of various densities shows the most popular models.

When all kinds of communications are laid, builders also use other diameters of plastic water pipes.

The diameters of water pipes in the table help you select the appropriate product for repairs or other work.

How can you measure the diameter with improvised tools?

If you don’t have a specialized tool at hand, but you still need to measure the diameter of the pipe, you can refresh your memory of the school formula for determining the circumference. Here it is: C = “pi” x d. Where:

- C is the circumference;

- “Pi” is a number with a fixed value, for convenience it is taken equal to 3.14;

- D is the diameter of the circle.

Therefore, in order to measure the diameter of the pipe, you will need the value of C (circumference) divided by 3.14. But this way you can only measure the outer diameter of the pipe.

To determine the circumference, a regular sewing tape is sufficient.

Take an ordinary construction tape measure or a tailor's measuring centimeter, then wrap it one turn around the pipe. You need to carefully ensure that the tape does not warp, but lies as evenly as possible across the pipe. When the measurements are made, all that remains is to perform the calculations described above. For example, if it turns out that the circumference is 12 centimeters, then dividing 12 by 3.14, the result is 3.8 centimeters. By the way, in this way you can measure the diameter of not only a pipe, but also any other round object. Even if you don’t have a tape measure at hand, you can use a not too thick cord or thread. It will be enough just to wrap the pipe with thread - and then attach it to the ruler. If it is necessary to obtain more accurate values, then the number “pi” can be taken not as 3.14, but as 3.1416.

Note! Often, foreign pipe sets use markings in a non-metric system. That is, in that case, the diameter is indicated in inches, and not in centimeters. Knowing that one inch is equal to 2.54 cm, it will not be difficult to convert inches to centimeters and vice versa.

For example, if it was indicated that the diameter of the pipe is 2.4 inches, then by multiplying this number by 2.54, you can get the result - 6.096 cm. If you need to do the reverse translation, then the value expressed in centimeters is divided by 2, 4. The above result of 3.8 cm will be 1.49 in inches.

We measure with a ruler and tape measure

If the cross section is visible on the pipe, then the diameter can be measured with a regular ruler. We apply it to the cut area so that the scale runs exactly in the center.

We take the distance between the required points (for the internal or external diameter). The distance between the extreme points will be the outer diameter. If you need an internal size, you can find out the wall thickness and subtract it from the resulting figure.

Everything is clear with a ruler, but how to measure the diameter of a pipe with a tape measure?

This tool is suitable for solid and large structures that are difficult to reach. We wrap the product so that the tape with the scale fits tightly, and find the place where it intersects. The resulting figure is the circumference. To get the diameter, divide it by Pi (3.14).

If you need to measure a very small pipe

It is usually recommended to measure the diameter of small objects using a caliper. This method is suitable when working with pipes up to 15 cm. One end (leg) of the device is pressed against one edge of the pipe, and the other against the other. In this case, special indicators on the caliper will show the outer diameter of the pipe.

A caliper is a universal tool for measuring internal and external dimensions, as well as hole depth, with an accuracy of 0.1 or 0.01 mm.

If you need to use it to measure the internal diameter, then you can press the edge of the pipe, the one that is “responsible” for its thickness, between the legs of the caliper. The pipe wall thickness is then subtracted from the outside diameter. This will be its internal diameter.

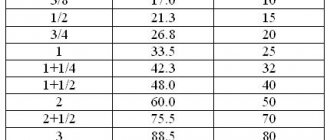

Metal products and their outer diameters

All types of metal pipes are manufactured at the factory, based on their outer diameter “Dн”. Standard diameters are shown in the table below.

In industry and construction, they mainly use products whose diameters are in the range of 426–1420 mm. Intermediate standard sizes of water pipes are taken from the table.

Small D metal products are mainly used for laying water pipes in residential buildings.

Medium D metal pipelines are used for laying city water supply. Such water pipes are used by industrial systems involved in the extraction of crude oil.

Large sizes of steel pipelines have found application in the creation and laying of main oil pipelines. They are also used in the gas industry. Through such pipelines gas is supplied to every corner of the planet.

Measurement by copying - photography

This method can be useful when there is no access to the pipe at all. It is suitable for both small and large diameter pipes. To scale, you will need to attach a ruler or any other large-scale object to the pipe, the dimensions of which are initially known. Then the pipe with the attached objects is photographed - and the resulting image will allow an analysis of the diameter of the pipe, based on a comparison of the sizes of a large-scale object for comparison.

Measuring labor using the copying method will allow you to determine the diameter of pipes located in hard-to-reach places.

In particular, this technique is used if it is necessary to calculate the dimensions of pipes in a car without the need to unload it. It will be possible to take just one photo and send the train on its way. Otherwise, it would be necessary to measure each pipe separately.

How can you control a pipe under production conditions?

If you need to determine the outer diameter of a pipe in large production conditions, then they resort to a more complex formula. Namely: D = C: 3.14 - 2∆p - 0.2 mm. Here the symbol “delta p” is responsible for the thickness of the tape measure. An indicator of 0.2 millimeters is taken in order to level out possible deviations from accuracy due to measurement error. At the same time, it is necessary to take into account deviations in measurements, which are inevitable due to the loose fit of the measuring ruler to the walls of the pipe. When taking measurements of pipes that have large diameters, deviations in calculations are allowed:

- For pipes with a diameter from 820 to 1,020 mm, the error can be within 0.7 percent. Usually, in order to measure such pipes as accurately as possible, it is necessary to resort to ultrasound;

- If wall thickness is measured in large production using a caliper, then its scale divisions should be 0.01 mm. A maximum downward deviation of no more than 5 percent is allowed;

Vernier calipers are among the most popular measuring instruments due to their simplicity of design, speed of operation and ease of use. - It is also necessary to measure the degree of curvature of the pipe. However, it should not be more than one and a half millimeters for every meter of pipe. The total curvature of the pipe in relation to its length should not exceed 0.15 percent. The ovality of the pipe end is determined by the ratio of the difference between the smallest and largest diameters to the nominal diameter of the pipe. Moreover, the value of this parameter cannot be higher than 1 percent for a pipe with a wall thickness of up to 2 cm and no more than 0.8 percent in the case of pipes with a wall thickness of more than 2 cm.

The ovality indicator of a pipe can be measured if you know the diameter of the pipe end using a special indicator flask or a device - a bore gauge in two planes intersecting each other at right angles.

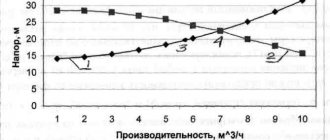

Determining the volume of the system

So, the volume of liquid inside the pipe matches the volume of that pipe, except for some minor errors. But when approaching the calculation of the volume of the heating system as a whole, it is important to take into account the fact that it includes pipes of various diameters, adapters, a boiler, a heating and expansion tank, a radiator and other structural elements.

Heating system for a private house

The final overall result of calculating the volume of the system is the sum of the volumes of liquids located in each individual element. Let's look at the process of calculating the volume of the entire heating system step by step:

- It is recommended to start with system elements, the volume data of which is known and indicated in the documents from the manufacturer (passport, certificate). For example, the volume of fluid from a radiator can be easily calculated. To do this, you need to multiply the volume of liquid in one section (it is indicated in the passport) and the total number of sections. Example: there is a bimetallic radiator with 7 sections, the documents indicate the volume of one 0.25 liter (equivalent to 0.0002 m³), by multiplying we obtain the total volume of the radiator 1.4 liters or 0.0014 m³.

- Determining the volume of the expansion tank. The simplest method to take this measurement is to simply fill it completely with liquid. Drain, and the resulting volume of liquid is the volume of the specific expansion tank.

- Calculation of all pipes of the system. In the case when all pipes in the system are of the same diameter, you simply need to multiply the resulting cross-sectional area by the total length of all pipes. If all the pipes are of different diameters, then it is necessary to calculate the volume of each pipe in a similar manner as above and summarize the results.

The simplest way to calculate the volume of liquid in pipes was discussed above. In other more detailed sources you can find other calculation methods and formulas, which take into account many additional factors, such as pipe material, roughness, etc.

What to do if the pipe is inaccessible for regular measurement

There are times when there is simply no way to approach the end of the pipe. For example, it is already installed in one or another pipeline system. Of course, it would be irrational to disassemble the entire system and even just one section of it just to measure the pipe diameter. But in this case, the diameter can also be measured using a caliper. To do this, you will need to press the legs of the device not to the end, but to the side of the pipe, trying to keep the measuring device as perpendicular to the pipe as possible.

Hard-to-reach pipe sections.

In this case, the length of the caliper leg must be more than half the diameter of the pipe that is being measured.

Introduction

The question often arises about the amount of liquid present in any system. As an example, when selecting an expansion tank, which largely affects the quality of the entire heating system, it is necessary to know the amount of all coolant fluid in it. To do this, first of all, you will need to find the volume of specific pipes with individual dimensions. This is a rather complex task that requires some knowledge and skills.

Pipes of different diameters

Less accurate, but very fast method

However, if there is no need for overly complex and precise calculations, then you can determine the diameter simply by applying an ordinary school ruler to the diameter of the pipe. You will only need to hold the ruler so that its scale coincides with the imaginary line of the pipe diameter. Small deviations in one direction or another are quite acceptable. After all, in stores, pipes, as a rule, are offered in standard sizes. If necessary, the sales consultant can adjust the diameter of the required pipe.

An ordinary ruler can help if there is no professional tool for measuring the diameter of the pipe, but do not forget about the error.

We measure with a micrometer

High-precision measurements (up to 0.01) of the pipe can be made using a micrometer. It should be noted that they are convenient for measuring small products.

The tool is a bracket equipped with a support heel and a stem with a high-precision thread (for screwing in a microscrew). On the stem you can see a scale with millimeters and their hundredths. This equipment allows you to obtain more accurate indicators.

How to measure the diameter of a pipe with a micrometer? We place the structure between the end of the screw and the heel. We begin to rotate the ratchet handle until it clicks three times. First, we look at the lower scale of the stem, showing the number of whole millimeters.

We check for the presence of a risk, which is located on the right. If it is not visible, we take readings from the drum. If there is a risk, add 0.5 mm to the resulting number. Measurements on the drum are determined relative to the line on the stem between the scales.

What can experts advise?

Sergey Voronenkov, master installer: As a rule, pipes made of steel intended for installation of water supply systems are characterized by their inner diameter. You can often hear from professionals about half-inch or inch pipes. This means that their internal diameter is 12.7 mm or 25.4 mm. But the outer diameter is the province of the plumber and plumber. Simply because most plumbing systems today are installed using a threaded connection. In turn, the thread is cut on the outside of the pipe.

Viktor Ivanovich Petrov, plumber: The use of a metal measuring tape during measurements is less preferable. Metal cannot ensure a tight fit of the tape measure to the pipe, which is why the error will be too large. The result will be much more accurate if you use the so-called flexible tailor's meter.