Cities and towns, factories and farms, residential buildings and public buildings - everything is entangled in a network of water pipelines distributing cold and hot water throughout the buildings. But any system must be closed - otherwise all the buildings will simply flood. At the same time, water from the system must be available to people at any time - this is the main purpose of creating a pipeline system.

We welcome our dear reader and offer you an article about what ball valves for water supply are - shut-off valves that block or open the free flow of water in a pipeline. A characteristic feature of such fittings is the shape of the locking element - in the form of a ball or its segment.

Purpose

Pipeline systems cannot be open all the time they are in operation. Any water supply system must be shut off at least twice: at the point of use and at the point where water enters the building or apartment. A large plumbing system must have shut-off valves that allow you to shut off any of its parts individually. Reliable, convenient and durable ball valves are becoming increasingly widespread in all areas of human activity.

The scope of application of ball fittings is very extensive:

- In industry. Pipelines and shut-off ball valves are found everywhere - in hydraulic and pneumatic drive systems, fuel, gas, chemical reagents, and water supply pipelines.

- In the infrastructure of cities and towns - in main heating systems, water and gas supply.

- In everyday life - in any house and apartment there is a pipeline for supplying gas, hot and cold water, heating.

Design and principle of operation

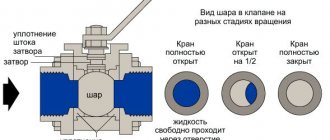

A ball valve consists of a body, a spherical-shaped shut-off element (plug), mounted on a rod (perpendicular to the axis of movement of the medium). The locking element has a round hole for the passage of the medium. The locking element (plug, valve) and seat are sealed with fluoroplastic or synthetic rubber. The rod (spindle) is turned by a handle.

To completely shut off the pipeline, it is enough to turn the handle that rotates the rod 90°. In this case, the ball-shaped valve rotates and its solid side reliably and hermetically blocks the flow of the medium. When the handle is opened, the valve rotates so that the axis of the through hole in the valve coincides with the axis of the pipeline and the liquid moves freely through the valve.

The design features of the ball valve make it possible to shut off the flow of the medium very easily and quickly, especially in comparison with gate valves and valves. Therefore, previously popular valves (valves), which had to be turned for a long time to shut off the flow, are becoming a thing of the past, and lever mixers are already installed in every apartment.

What materials are they made from?

There are many materials for the manufacture of ball structures:

- Carbon steel. The most commonly used steels are 20 and 09G2S (this steel can be used at temperatures down to -60°C). Steel products are inexpensive, strong, durable, but susceptible to corrosion - they are coated with chromium or nickel to protect them.

- Stainless steel, most often grade 12Х18Н10Т. Stainless steel products can be used in systems with aggressive environments, at low temperatures, they are strong and durable, but quite expensive.

- Brass is an alloy of copper and zinc. Brass is strong and ductile, does not rust, is durable, but loses strength already at 200°C. But in residential buildings such temperatures do not exist, and at the moment this is the most popular material for small-diameter taps in housing.

- Bronze is an alloy of copper and tin (varieties of bronze are alloys with aluminum, silicon, beryllium, lead). The quality of the products is similar to brass, the price is higher. They don't occur very often.

- Titanium. Lightweight, durable, expensive, not used in everyday life.

- Plastic. They are used for plastic pipelines, made of the same material (some are made of unplasticized PVC, polyethylene, polypropylene). Such taps have sufficient strength, are not prone to corrosion, and are chemically inert. Less reliable than metal products. In everyday life, they are used on water supply and heating systems, but not at the entrance to an apartment or house.

- Ceramics. New strong, durable material. Durable, non-corrosive, chemically inert. They are quite expensive and, despite their strength and wear resistance, they are fragile and resistant to shocks and falls.

- Cast iron. Archaism. Found in some old plumbing systems (not in households).

- Silumin. Aluminum alloy with silicon. In practice, we can assume that silumin fittings are fake. They don’t last long, they crack, the threads are cut off, and they start leaking at the most inopportune moment. In general - transfer of money.

Product prices

Water valve DU-15-125

The cost of valves depends on the design of the device, the material of manufacture, as well as resistance to aggressive environments.

The classic version of the DU-15-125 bolt device costs between 20-21 rubles. This type can withstand aggressive conditions and is resistant to changes in temperature and pressure. A shutter valve of this type, but with a larger diameter, costs a little more - 23 rubles.

Prices for water coupling taps vary from 90 to 400 rubles. For apartment buildings, it is recommended to use cast iron valves - model 15kch 19p with a diameter of 1.5 cm. They can withstand high temperatures of up to 100 degrees. However, the cost of such a valve is 326 rubles. The price of a sleeve valve made of brass varies significantly and ranges from 120 to 230 rubles. Bronze is a little more expensive - from 170 to 300 rubles.

Prices for ball mechanisms depend on the design and material of manufacture. Most use brass or alloys made from it. There are also plastic ball valves that are used to shut off cold water. The cost varies between 400 rubles. The price for steel and brass alloys is 320-340 rubles.

The price of bolt mechanisms varies depending on the material used and the manufacturer.

Different shapes of product handles

When choosing a bolt mechanism, first of all pay attention to the manufacturer. It’s better to pay a little extra and buy a high-quality valve from an Italian or German supplier. Chinese ones often leak and fail. And the consequences of a broken tap can be costly.

It is worth paying attention to the shape of the handle. Ease of use depends on this. The cantilever element is characterized by its mobility during rotation. However, for small rooms it is better to give preference to butterfly-shaped mechanisms.

In places where water pipes are joined, it is recommended to install a valve with a semi-slide.

When installing household appliances (washing machine or dishwasher), they focus on the practicality of the valve and its additional features - corner mechanisms, tees, with a fitting, with a filter for water purification (used in the kitchen).

It is recommended to install valve taps where it is necessary to control the flow rate. For aggressive conditions with elevated temperatures, it is better to use valves from the Italian supplier Bugatti. This mechanism can withstand from -20 to +120 degrees. It costs around 600 rubles.

Classification - types and differences

Depending on the method of connection to the system, ball valves are:

- Welded - they are welded to the pipeline and used in critical systems with high pressure.

- Flanged.

- Fittings - with external thread.

- Couplings - with internal thread.

- Combined - connected to the system from different sides in different ways.

According to the throughput capacity, cranes are:

- Full bore - the diameter of the passage in the plug is equal to the diameter of the pipeline.

- Standard bore (reduced) - the size of the hole in the ball is one standard size smaller than the diameter of the pipeline.

Structurally - there are straight and angular designs, two-way and three-way.

According to the locking mechanism

- With a floating ball. The floating ball is not rigidly connected to the handle rod and can be pressed against the sealing ring, improving the sealing of the closed tap.

- With a ball in supports. In the design with a ball in supports, the ball is installed and rotated in the supports; in the lower part it has an axial protrusion that fits into a recess in the body. The surface of the ball is pressed tightly against the seats and, when closed, the structure is reliably sealed.

Which tap is better to use for water supply as the main one at the entrance to the apartment?

No matter what material the pipeline in a house or apartment is made of, metal shut-off valves are always installed at the input. Metal structures are more reliable, and if they fail, they are easier and faster to replace.

Which type is better for plumbing?

It is impossible to say unequivocally which types are better. Steel products can rust and become overgrown with salts; Unusual titanium, ceramic, and stainless steel are rare, they are expensive and there is no particular point in installing them. What remains is brass (bronze) and plastic. The input is definitely brass; parts of the system made of plastic can also be made of polypropylene. If the system is mounted from cross-linked polyethylene, then the pipes are mounted using fittings, and it is most convenient to attach metal products to them.

Handle attachment

Even such a minor feature as the method of fastening the handle of a ball valve can affect its durability and safe operation.

Rice. 11. Ball valve handle attachment points

In Fig. 11 shows the most common design solutions for this unit. The most reliable fastening is considered to be with a self-locking nut (Fig. 11 B). A polyethylene ring integrated into the nut with an internal diameter smaller than the diameter of the rod prevents spontaneous unscrewing of the nut due to variable forces and vibration of the pipeline. Fastening the handle with a regular nut (Fig. 11 B) requires maintenance: from time to time the nut must be tightened. Weak tightening of the nut turns the handle into a lever that can be used to break the rod. The least successful is the unit in which the handle is secured with a screw (Fig. 11 A). The internal longitudinal thread in the rod significantly weakens it, since its live cross-section (along the thread cavities) is extremely small (Fig. 12).

Rice. 12. Broken rod on internal thread

Marking

The following is applied to the body:

- Manufacturer's emblem.

- Nominal diameter - DN - in mm and inches, but for small bodies the "inch" symbol may be omitted.

- PN - working pressure in bars. A bar is equal to 1 atmosphere and 0.1 MPa.

Advantages and disadvantages of ball valves

Advantages of ball valves:

- Compact dimensions.

- Simple reliable design.

- High tightness.

- Rapid shut-off of the medium flow.

- Management does not require much physical effort.

- Low hydraulic resistance, comparable to the resistance of a straight section of pipe.

- Small price.

- Metal taps can be used in high pressure systems.

- Can be used for viscous and contaminated media.

- High-quality seals provide cranes with a long operating life without repairs or maintenance.

Flaws:

- The use of fluoroplastics limits the operating temperature to 200°C.

- Plastic products cannot be used at high pressures.

What are water valves

Water valve design

A valve is a device that is used to close (close) a tap to prevent accidental leakage of water. The device has a high degree of tightness and prevents liquid leakage.

Previously, large and bulky locking products were used, but with the introduction of innovation, the compact valve was invented.

Tips for choosing

Almost the entire choice of the best ball valves for the home comes down to brass products - reliable, non-corrosive, durable, inexpensive and widespread. On polypropylene pipes, polypropylene structures are used to disconnect part of the system. Metal products are always placed at the input.

Leaking water systems are expensive, so you should buy products in fairly large stores, with a receipt and certificate. Do not focus on imported products - domestic manufacturers also produce good quality products.

The tap must be inspected - there should be no chips or cracks; the thread must have at least 4-6 full turns without nicks; the walls must be thick enough; it is necessary to inspect the inside of the faucet, check how the handle and the ball turn, whether there is a hole in the ball (and whether there is a ball - occasionally there are “dummies” in which the body is machined like a pipe, the handle does not turn, there is no ball in sight). In addition, you need to try to understand whether the body is silumin - the metal inside will be white, and the faucet will seem light - the density of silumin is less than that of brass (according to the standard - 8.5-8.7 g/cm³). You can’t buy silumin - sometimes it bursts during installation.

The handle is more reliable and practical than the butterfly handle, but when installing the faucet against a wall or in a cramped bathroom, you should consider whether there is enough space to turn the lever, or whether you should buy a butterfly handle. For the entrance, a faucet with threaded pipes of the “nut-fitting” type is most often chosen.

approximate price

Brass taps with running diameters of 15 and 20 mm cost from 150 rubles, polypropylene taps of the same diameters - from 110 rubles. A lever faucet for a kitchen will cost from 2,000 rubles (the simplest) to... there is no limit to perfection - there are faucets that cost tens of thousands, and for a shower they can reach up to 100,000.

Tips for installation and operation

Before installing the tap, wipe the threads with a rag and clean them from dust, shavings, and dirt; the old thread should be driven out with a die - this will clean the thread from rust and deposited calcium and magnesium salts. First, the faucet is tried on - screwed on without FUM tape and the number of turns is remembered. The direction of winding the tape must coincide with the direction of winding the reinforcement. Screw the tap on the same number of turns as during fitting. The minimum number of turns is 4. Then the bend is screwed in in the same way or the nut is screwed on the other side.

The system is filled with water and tested; if there is a leak, the connection will have to be unscrewed, a sealant (FUM) added, tightened and tested again.

During operation, it is necessary to close and open the tap at least once a month - this will remove salt deposits from the ball. The shutter cannot be kept partially open - this will lead to premature wear of the shutter. The handle position must be either open or closed.

How to install it yourself?

Proper installation of a water valve is important for its safe operation and longer service life. In principle, the installation itself proceeds according to the following scheme:

- The water supply system is shut off.

- Open all the taps to allow any remaining water to drain from the pipes.

- Dismantle the worn device. The choice of dismantling method depends on the type of connection of the old product:

- pin-type - use a wrench to loosen the union nut;

- coupling - by dismantling the coupling;

- flanged - loosen the bolts used to secure the mounting flanges;

- welded - a section of pipe is cut out using a welding machine.

- Clean the pipe at the installation site from residual sealant and rust;

- Install a new valve, sealing the threaded part of the fum connection with Tangit Unilok tape or thread. For a flanged valve, no sealing material is required. Unlike fittings with a collapsible type of connection, installation of a welded device will require a special apparatus for soldering pipes.

However, there are a number of nuances that should be taken into account when working:

- choosing a convenient place to install the product so that there is no interference with the movement of the lever or handle;

- The thread may need to be lengthened. If the valve is being replaced, then after dismantling the old device, you need to clean the threads of the pipe from any remaining sealing material and try to screw a new product onto it. Quite often, during operation, corrosion destroys the metal on two or three turns of the threaded part, so it is necessary to cut off the missing turns;

- The product must be installed taking into account the direction of flow of the working medium indicated on the body of this type of shut-off valve.