One day recently my battery leaked in a Soviet-built apartment. In my mind, I could close the taps on the radiator, fix the battery and continue to use it quietly. But bad luck, no taps were installed. I had to write an application to the local thermal power plant, pay to turn off the riser, and only then dismantle the battery. Don't want to face the same problem? Then let's look at the options for fittings for radiators and how they can help you during operation.

Why is a tap installed?

- First of all, taps are needed to be able to stop the battery’s activity (during periods of changing seasons, comfortable temperature outside, and, accordingly, indoors).

- It is also advisable to have taps on the radiator if you plan to flush the devices (this increases convenience, since you do not have to empty the entire pipeline network).

- Installing a tap allows for servicing the generator both manually and automatically (basically, setting the amount of heat supplied will depend on the initial temperature in the room).

- The operation of taps with thermal heads provides a high level of energy savings during the heating season.

- Manual valves are used to regulate the flow of the heat generator.

Disabling radiators without fittings

It is no secret that in most apartments to this day there are old cast iron radiators or steel convectors without any shut-off fittings, which makes it impossible to shut them off during the heating season. Moreover, according to the old heating scheme, convectors in high-rise buildings are connected to risers without straight sections - bypasses. Therefore, if an accident occurs with a coolant leak, you must act as follows:

- Try to provide some kind of container to collect hot water. If the stream flows to the side, wrap a thick cloth over the break site so that the water flows along it into a bucket.

- Call the dispatch service of your heating energy supply company and report the accident.

- While the service personnel are getting there, provide them with access to the basement, find the keys, open the door, and so on.

- Try to block the riser yourself.

While your water is flowing onto the floor, your neighbors below have a suspended ceiling turning into a bubble.

A few words about how to properly turn off the heating riser. Find in the basement the heating point of your entrance and vertical pipes embedded in a large-diameter main or into a common collector. Follow where they go to determine the emergency riser, and turn it off with a tap. Contact by cell phone someone in the household who can confirm that the geyser eruption in the apartment has stopped. If you couldn’t find your pipe, close all the valves one by one until you find the one you need.

Attention! Don't try to force yourself on basement valves that are stuck due to rust. When they cannot be closed manually, it is better to wait for a team of plumbers; they will find a way to stop the flow of coolant. Otherwise, a very awkward situation will arise when you also break the main fittings, leaving the apartment building without heat during repairs.

It is also worth considering the question of how to shut off the battery if it is hot in the apartment due to the service provider’s failure to comply with the temperature schedule of the boiler room. It would seem that if there are shut-off valves, the problem is solved by manually closing the taps. But after the temperature in the rooms drops, the valves will have to be opened again. This way you will get tired of turning the taps long before the end of the heating season, so you need to think about how you can adjust the heat output of the radiators. The options are:

- if possible, install a thermostatic valve on each radiator, limiting the flow of coolant and automatically maintaining the set temperature in the room;

- It is nice to cover the heating device with a blank screen with small holes if there are no shut-off valves on the connections.

Important. The ball valve is not a means of adjustment; it is intended only to completely cut off or open the passage of the coolant. In the “half closed” mode it will not give the desired effect and will fail much earlier.

Thanks to worn-out pipelines, district heating systems are notorious for dirty water that quickly clogs small passages. Therefore, ordinary valves with thermal heads will not last long here; you need to buy special valves with increased capacity, which are produced by the well-known brands Danfoss and Herz. How to install them on the connection to the radiator is shown below in the diagram and described in this material.

Radiator thermostat installation diagram

When it’s hot in an apartment in the middle of winter and there are no control valves, residents have no choice but to cover the radiator in the room with a decorative screen. The principle is simple: the radiator will heat the air inside the box, after which the intensity of heat transfer will sharply decrease due to the small difference in the temperatures of the air and the surface. That is, the coolant will give off less energy, and the amount of hot air coming out from under the screen will be limited by the size of the decorative openings. How to assemble and install a nice MDF box on a heating device is shown in the video:

Ball Valves

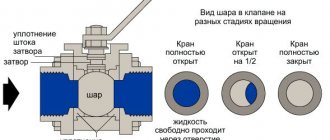

At the moment, the most popular type are ball valves . They are made using either brass or polypropylene. The necessary part in them is a steel ball with the required diameter, through which the water actually passes. The ball is connected to a rod, which, at a certain position, shuts off the heat generator.

There is a type of ball valve. She is wearing a ball valve with an American connection. It is a more advanced model than conventional ball valves. Using a crane with an American connection makes installation of the squeegee much easier than usual. When there is a need for sweeping, high precision is required when connecting pipes. But faucets with American valves allow for a slight deviation (about five degrees). And this is their huge advantage. Plus, with such an armature it is very convenient to maintain the radiator.

Typical sizes of ball valves for batteries

They range generally in diameter from half an inch to three-quarters of an inch. Taps that have a diameter slightly larger than one inch can also be used. Today, manufacturers in most cases mark cranes, indicating their exact dimensions and production characteristics. The markings indicate special symbols with which the indicators are deciphered (for example, D - diameter, P - working pressure). The location and type of thread, face-to-face length and height are also considered standard dimensions. The face-to-face length is determined by the distance from one end of the crane to the other. The construction height is determined by the distance from the lowest point of the crane to the highest.

Installation of ball valves

- The optimal location for installation is selected.

- Selecting a tap according to the required diameter so that there is a match between the tap and the pipe.

- The tap is screwed to the designated location, and before that, a tape made of fluoroplastic sealing material is attached (improving the quality of sealing).

- This tape should not provoke or allow rotation of the crane.

- Next, they start the water, carefully inspecting it so that nothing is leaking anywhere.

Useful tips

- If all steps are performed correctly, the crane should last at least 20 years. Long service life largely depends on the quality of the valves. The best option is products made of brass. This material is practically not subject to corrosion and has a presentable appearance. Unfortunately, there are many fakes on the market; they are of low quality and attractive prices. Therefore, when choosing valves, pay attention not to appearance and cost, but to the product labeling.

- Savings may later translate into additional replacement costs. Recommended pressure and temperature parameters should be at least 1.6 MPa and 150 degrees. Remember that by installing the faucet yourself, you automatically take full responsibility for the quality of installation. If a faucet breaks and the entire house is left without heating, the residents' claims and compensation for damage will fall entirely on your shoulders. If you are not confident in your abilities, it is better to entrust this work to professionals.

- It is strictly prohibited to install valves that block the flow of water throughout the riser. Before installation, it is recommended to seek advice from the housing office, obtain permission and document the work being performed.

Valve balancing valve

The next type of taps for radiators are valve taps . The valve itself is used to provide such functions as:

- closure;

- opening;

- regulation of fluid flow power, etc.

For smooth operation of heating systems, it is recommended to use valve valves (balancing). They perform functions such as:

- optimal creation of hydraulic pressure;

- high-quality consumption of thermal fluid (generator).

Valve taps consist of the following parts:

- frame;

- spindle;

- gate;

- nipple.

All parts are made using brass, which has high resistance to zinc leaching. It is because of this that the valve does not need all kinds of additional coatings.

Balancing valves are divided into the following groups:

- manual valves (to reduce pressure in heating systems);

- automatic valves (for a stable difference between the pressures of the supply and return pipelines).

Requirements for the operation of the balancing valve:

- high resistance to the presence of various substances in the heat generator;

- the presence of a sufficiently wide range of regulation;

- there should not be a lot of noise during operation;

- ensuring complete blocking of the flow.

Typical dimensions of valve (balancing) valves

They are determined in the region of one inch. Diameters vary depending on model. Today, manufacturers in most cases mark cranes, indicating their exact dimensions and production characteristics. The markings indicate special symbols with which the indicators are deciphered (for example, D - diameter, P - working pressure).

Installation of valve taps on the battery

- First of all, the water is shut off and drained.

- Cutting out the area that was selected for installation (in accordance with the valve parameters).

- The selected location is being prepared.

- Making threads at the ends of pipes.

- Preparations to ensure good fixation of the valve.

- Connections that are attached with threads are sealed.

- Valve connection.

- Fixing the valve, sealing the threads.

- A setting is made that is responsible for the operation of the valve (in particular, its throughput).

- Filling the heating system with liquid.

Methods for sealing connections

If the thread profile does not have a sharp edge, FUM tape can be used as a sealant. However, this modern material has not caught on among experienced specialists; they consider flax to be the most reliable sealant. A thin strand of this material, collected into a bundle, is wound around the pipe, starting from its end. The winding direction should be opposite to the thread direction. The flax should fill the thread to its full depth, and each new turn should partially overlap the previous one. The seal will be more reliable if the thread is equipped with a notch that prevents the flax winding from turning. Before installation, the threads of the part should be coated with UniPak packaging paste or similar.

Installation on polypropylene pipes using adapter couplings.

If the heating system is made of polypropylene pipes, then metal ball valves on the heating radiators are installed using adapter couplings. All threaded connections in this case are sealed according to the method described above.

Mayevsky taps are often equipped with a gasket made of rubber or other material, so they do not need to seal the FUM with tape or tow.

When the installation or replacement of all shut-off and control valves has been completed, it is necessary to perform a test run of the system. This will make it possible to check the tightness of all connections and the functioning of the valves under operating conditions. In this case, it is important to make sure that the system is completely de-aerated and the working medium circulates normally in it. A small amount of sealing material should be added to threaded connections that are found to be leaking.

Thermal head

The next type of radiator tap is a thermal head for a heating radiator.

If there is a need to provide automatic temperature control, then using thermal heads together with a thermostatic valve will come in handy. This type allows you to adjust the optimal temperature without any human intervention.

Features of the functioning of the thermal head?

The thermal head functions inversely depending on the air temperature in the room. If the temperature increases (much higher than the comfortable and optimal temperature - this phenomenon can be observed when there are a large number of people in the room, or the operation of many electrical appliances), then the bellows of the thermal head expands. The expansion of the bellows of the thermal head leads to the fact that a certain part of the valve (stem) begins to move and there is a decrease in the flow of the heat generator through the radiator. If the air temperature, on the contrary, decreases, then this mechanism works in the opposite direction in order to increase the temperature for a comfortable and optimal temperature for the room.

Typical dimensions of thermal head valves

Basically, the typical and most common head size is M30*1.5. But the sizes are individual for each model. Today, manufacturers in most cases mark cranes, indicating their exact dimensions and production characteristics. The markings indicate special symbols with which the indicators are deciphered.

Installation of thermal heads

- Using certain rods, the plate is attached to the wall.

- The thermal head is fixed on the plate itself.

- Next, fixation is performed on the wall of the capillary tube.

- The thermal head is installed according to certain marks.

- Tighten and fix the bolt.

Features and differences between corner taps and straight taps, their advantages

What are the positive characteristics of corner taps?

- There is a guaranteed ability to turn off the battery.

- Resume operation of the heating system at any convenient time, if necessary.

- Guaranteed ability to independently adjust the temperature, which will be comfortable and optimal for being in the room (if there are temperature changes outside, and so on).

- The angle tap is very convenient to use, especially when draining a heat generator. This greatly reduces the time for this procedure.

- Easy maintenance.

When choosing between corner and straight taps, it is recommended to mainly use corner taps due to the above-mentioned positive features.

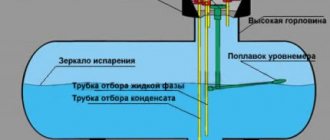

Circulation pump

It's easier with a pump. The pump itself is attached with detachable connections, so just two valves are sufficient. The pump, I think, is the most “delicate”, in terms of reliability, part of any heating. It does not last long compared to the boiler. Usually, for the purpose of quick and convenient replacement, the motor is mounted with a bypass. This is necessary in order not to disconnect the water from the mains. And the point is not only that in some systems circulation can occur without a pump through a bypass. It is also important that it would be good not to disconnect the boiler from the expansion tank and from the emergency valve. Heating of the pump, which is disconnected by valves from the valve and from the expansion tank, is fraught with a strong increase in pressure in the boiler and its failure. It can simply be torn apart.

Circulation pump and dirt filter on the bypass

Pay attention to the picture. We close the valves leading to the pump. Open the valve on the bypass. After this we remove the pump very easily. We just unscrew the two union nuts and the pump is in our hands. After this we have direct access to changing the sump and valves. To replace the valves, you still need to drain the entire system, but replacing valves is a very rare operation and usually you can wait until the end of the heating season to replace them. Modern valves, especially those made of yellow metal and a decent brand, do not break through at all, much less unexpectedly.

Which faucet is better?

This question will only be answered when specific conditions and characteristics that are a priority are identified. In the absence of any need for regulation or automation, simple structures (for example, common ball valves) are quite suitable. If the priority is the function of maintaining the optimal air temperature in the room without much effort (automatic adjustment), then it is preferable to choose a thermal head. The problem with the thermal head is that it cannot be used in systems with central heating. A more economical option is to use valve balancing valves.

And two more valves

Obviously, you need a valve to drain water from the system and a valve to let water into the system. Moreover, the second one will probably be part of the water supply system, not the heating system. This is described in more detail in the article about filling the heating system with water. Water can be drained through the emergency valve. He allows for discovery. But it’s better not to hope for this, because the stream of water through the open emergency valve is quite thin and draining will take a very long time and be very tedious. In addition, in this case the valve must be located strictly at the lowest point of the system, and this can be inconvenient.

Electrical and circuit diagram for connecting 220 Volt heating

This article will be useful for those who want to heat a small room of up to 50 m² or use such a boiler to heat their home at night, with a multi-tariff electricity metering.

Electrical connection diagram

When connecting electricity to the electrical circuit, the phase, through the switched on circuit breaker F1 and the closed contact S1 of the thermostat, supplies power to the heating element (heating element). Select the machine according to the power of the thermoelectric heater; if the load power is more than 3 kW (since the contacts of thermostats are usually designed for a current of 16 amperes), then it is necessary to use a contactor through the power contacts of which to connect more powerful heating elements. For more efficient operation of the heating system, it is better to add a circulation pump to the circuit, which is connected from contact F2 of a thermal relay with a rating specified in the engine passport, through contact S2 of a thermostat with a built-in air temperature sensor.

Schematic diagram of connection

The simplest heating system consists of a boiler water heating tank, a modular panel, thermostats and a circulation pump

Steel pipe boiler

You will need a steel pipe with a diameter of 200-300 mm, a length of 50-100 cm; two plates measuring 40x40 cm, thickness 4-5 mm; nut for the thread of the heating element; two drives with the diameter of the heating pipes. To manufacture a water heating tank, use the services of a professional welder. The plates are welded at the ends of the metal pipe, a hole is cut in one of them for the heating element, and a nut is welded on top of the hole into which the heating element will be screwed. On the side of the boiler, at a distance of 10 cm from the edges, two pipes are welded to connect the “return” and “supply” heating pipes to them.

Thermoelectric heater (TEH) with thread and thermostat

The heating element is standard for storage type water heaters with a threaded connection. It contains a thermostat that will be used to protect the heating element from overheating in the event of a rupture in the heating system and water leaving it.

Thermostat with submersible temperature sensor

The immersion sensor consists of a copper sleeve (tube) sealed on one side, connected through a capillary tube to a sealed control unit on the other side. The sleeve and capillary tube contain an inert gas. A change in temperature leads to expansion or compression of the gas, which affects the electrical contacts of the control unit, turning on and off the load connected to them. The thermostat sensor is attached to the pipe with clamps and covered with thermal insulation.

Thermostat with built-in air temperature sensor

Thermostat with a built-in air temperature sensor, works using a bimetallic plate, two metals with different thermal expansion are connected to each other, when the ambient temperature changes, the length of the plates changes, due to different thermal expansion, they bend affecting the electrical contact, turning on and off the load . The thermostat is installed on the wall a little further than the average distance along the heating supply pipe.

When to change batteries

Many factors will inform the consumer that it is time to replace heating radiators. Rotten batteries over time begin to leak, unable to cope with water hammer and increased pressure in the heating system. Due to salt deposits inside the radiator, the water pressure also increases and the clearance decreases, which is why the coolant does not flow to all ends of the battery, and the quality of heating the room decreases. Another reason for replacing the battery is incorrectly calculated device power. In this case, there is not enough heat, you have to connect additional heaters, which means increased energy costs.

If you live in a private house, it’s easy to add power, and with it heat, by turning up the heat on the heating boiler. In an apartment in a multi-storey building, this option will not work; there is only one way out: replacing the batteries. But even in a private home there is a need for modernization. Every year, manufacturers create more and more advanced models of radiators, reducing energy resources and increasing the efficiency of equipment. Over time, the installed radiator will become outdated, and for financial savings you need to think about new radiators. In addition, we must not forget that any technical device has its own service life. When it comes to an end, there is a high risk of a sudden breakdown, which will entail financial losses not only for replacing equipment, but also for eliminating the consequences.

The principle of adjusting the temperature of heating radiators

It is directly related to the design features of this element and its installation. The valve is a ball with a through hole.

The operation of the crane is controlled using a handle fixed to the ball by a rod.

Important! To install the device, you need to choose the location wisely so that turning the handle in the future does not interfere with other devices of the heating system.

The diameters of the tap and pipe must be identical.

The device must be fixed in parallel as it is twisted using tow or special tape. They provide the mechanism with additional protection against leaks. The correct installation is further verified by applying water pressure.

Photo 1. Ball valve device for adjusting the temperature in a heating radiator. Arrows indicate parts of the product.

Activating the handle promotes the movement of the mechanism around its own axis. Rotating the ball hole towards the nozzles and pipeline inlets makes it possible for the coolant to circulate through it , otherwise the fluid flow will be blocked.

The ball in such mechanisms can be fixed and movable. In the first case, it is attached to the rod so that it remains completely static. The tightness of such a connection is ensured by bolts or disc springs.

The movable ball is able to move depending on the degree of water pressure on it . Due to this possibility, this type of mechanism is more widespread than the first.

How to open a tap

This is done to supply the maximum possible amount of coolant in order to provide the room with heat. To adjust the mechanism, you need to turn the handle parallel to its own axis and the pipe.

For convenience, there are protrusions on the faucet body indicating restrictions on the degree of its opening. This is done counterclockwise.

How to close

With this action, the circulation of the coolant completely stops. This needs to be done when there is a need to reduce the radiator temperature to a minimum, for example, in the summer.

The handle of the device in the “closed” position should form an angle of 90 degrees with its axis and the pipeline. According to the protrusions, the movement of the handle to stop the fluid circulation should be done clockwise.

Reference. In both situations, in the absence of a handle, it is possible to determine the position of the tap by the groove . If it is aligned with the pipeline and the mechanism itself, then its position is “open”, otherwise the fluid flow is blocked.