The heating radiators are connected after the windows and doors are installed and the floors and walls are prepared for final finishing.

Connection options and types of radiators and pipes are selected in advance so that the room is ready for their installation. A modern heating system consists of a number of components. Among them, we can highlight the heating boiler itself, the pipeline and heating devices - radiators, which are presented in a wide range. The process of installing the battery itself is quite simple: you need to mark the installation site, connect the pipes, install the radiator itself and make the connection. Let's consider the process of installing radiators using polypropylene heating pipes in more detail.

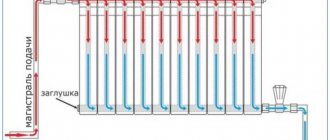

Let's find out what types of systems and connections can be used for this, which is necessary for connecting the heating system itself. Options for heating systems Today, two heating systems are used that can be used to install heating radiators in the house: single-pipe and two-pipe. is heating, in which hot water enters the entire building and flows from top to bottom through pipes and heating devices that are installed in individual apartments. This system is quite common today; it is used for apartment buildings. But this particular installation method has significant disadvantages: there is no way to regulate the temperature of the heating equipment (in rare cases there is a chance to install an additional expensive system); on the upper floors the temperature is higher than on the lower ones; if repair work is necessary, the entire riser is turned off; complete disconnection from the central heating systems are quite complex. A two-pipe system for connecting heating radiators involves supplying hot water through one pipe, and already cooled water through the other (this is the so-called return).

All radiators with such a system are connected only in parallel. A two-pipe heating system is used for private houses and cottages. It is not only very convenient and efficient, but also has such advantages as the ability to adjust the temperature of the radiators, which will be the same for all radiators, regardless of the number of floors. The heating system itself consists of elements such as: Two-pipe heating radiator connection diagram. heating radiators with a plug at the bottom and a valve at the top; radiator plug; thermostat and valve (for a two-pipe system); shut-off valve; shank; bypass (for a two-pipe system); couplings and locknuts for fastening heating radiators; risers in the form of heating pipes (can be made made of polypropylene, polyethylene, metal). Types of connections for radiators and pipes. Connection of batteries is divided into: Connection diagram for a heating radiator with an installed circulation pump. One-sided lateral pipe connection.

Is the most common. In this case, the inlet pipe of the system is connected to the upper branch pipe, and the outlet pipe is connected to the lower branch pipe. This method ensures maximum efficiency of the heating system, with the greatest heat transfer.

If hot water is supplied from below, that is, a reverse connection is used, then the total power of the system drops by about seven percent. A diagonal connection can be used if it is necessary to connect long-length batteries in the system. This makes it possible to heat the entire radiator evenly, avoiding temperature changes that affect efficiency. The supply pipe with hot water is connected to the upper pipe on one side, the outlet pipe is connected to the lower pipe on the other side.

If hot water is supplied from below, the power of the entire system drops by about ten percent. The bottom connection of the pipe to the battery is used only when the system is mounted in the floor. The power of such heating, in comparison with a conventional side connection, is ten percent less. Of the necessary conditions for connection, it should be noted that radiators should be installed only under the windows, but not on the sides, the height of the equipment, the distances from the wall and from the window sill are strictly regulated .To install a heating system, you must select the type of radiator. Different types of heating equipment differ in mounting to the wall, materials of manufacture, and pipe connections.

Today, manufacturers offer the following options: Construction of sectional radiators. Panel steel batteries, made in the form of relatively thin solid panels. The connection of such radiators can be lateral or bottom. Lightweight sectional, made of aluminum. Bimetallic ones are also often used.

Such batteries can be connected in one or several sections, the connection to the general system is lateral, polypropylene pipes are ideal. For apartments with central heating, bimetallic radiators are used (cast iron ones are used less and less, this is explained by their large weight, bulkiness, and fragility). This is due to the fact that the water supplied to the heating system often contains alkali and sand, which can damage other types of radiators. For a private home, aluminum and steel panel radiators are excellent, and all conditions for connection must be observed (for For copper pipelines, steel and aluminum radiators are used; for conventional radiators, only aluminum ones are possible). Accessories for connecting radiators Heating is a rather complex system, the connection of which requires the participation of a specialist. In addition to radiators and pipes, it is also necessary to prepare components, without which the connection will simply be impossible. The connection kit consists of: Accessories for connecting radiators.

a set that includes a plug, adapters, a manual air vent, a key for releasing air from the batteries, plus pipes; fittings, or adapters that have right-hand and left-hand threads; special tools for screwing on the adapters. Shut-off valves for batteries are also required, do not forget about the pipes . This also includes ball valves, valves for stopping the supply of the working flow or regulating it. Piping with polypropylene pipes: instructions Piping of radiators can be done using a variety of pipes, but experts recommend using polypropylene pipes. Ball valves for piping are also purchased in polypropylene; they can be straight or angular; this option is the simplest and most inexpensive.

Brass fittings are more expensive, and their installation is more difficult. Polypropylene piping is done in this way: a coupling with a union nut is inserted into a multiflex, which easily connects to any outlet; the pipes themselves are attached to the walls at a convenient height, they should not fit tightly to the surface, it is better to leave a gap of 2-3 cm. The pipes are secured using special brackets, which are fixed to the wall with nails or self-tapping screws. Radiator piping with polypropylene can also be carried out when laying pipes in the wall, in which case they come to the surface only at the connection points. radiators can be made using a variety of pipes, but experts recommend using polypropylene. Fasteners for batteries can be very different, most often it is a pin connection that is fixed on the wall surface. Corner brackets can also be used, which also allow radiators to be suspended at the required height.

For panel batteries, fasteners are supplied included; for sectional batteries, they must be purchased separately. Usually, two brackets or pins are enough for one section. The connection of the taps is carried out in this way: the tap is disassembled, the fitting and union nut are screwed into the radiator; the nut is screwed tightly with a special wrench. As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing wrench for American women, without which it is unlikely that you will be able to simply install a faucet. To install batteries and perform their piping, the following materials and tools are required: a set of special wrenches; seals for threaded connections; tow and thread paste; threads for threads. Features of connecting radiators Heating installation has some features: It is necessary to maintain a distance of 100 mm from the radiator to the window sill.

If the gap between the radiators and the bottom of the window sill is different, then the heat flow is disturbed, the effect of the heating system will be low. The distance from the floor surface to the radiator should be 120-150 mm, otherwise a sharp temperature change will occur. In order for the heat transfer of the equipment to be correct, the distance from the wall should be from 20 mm. At the same time, we take into account that the installation and efficiency of heating radiators is greatly influenced by the installation method: under an open window sill, the heating system efficiency is maximum - 96-97%, in an open niche - up to 93%, in part closed - 88-93%, completely closed - 75-80%. The heating radiator can be installed using a variety of methods; its piping is done with metal, polyethylene, polypropylene pipes. During installation, it is important to correctly position not only the pipes, but also the batteries themselves, and make the connection in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repair work. Share a useful article: Similar articles:

The installation or reconstruction of a heating system involves the installation or replacement of heating devices. The good news is that, if you wish, you can handle this yourself without the involvement of specialists. How heating radiators should be installed, where and how to place them, what is needed to carry out the work - all this is in the article.

It is possible to install heating radiators with your own hands

What is needed for installation

Installation of heating radiators of any type requires devices and consumables. The set of necessary materials is almost the same, but for cast iron batteries, for example, the plugs are large, and they do not install a Mayevsky valve, but instead, somewhere at the highest point of the system, they install an automatic air vent. But the installation of aluminum and bimetallic heating radiators is absolutely the same.

Steel panel ones also have some differences, but only in terms of hanging - they come with brackets, and on the back panel there are special arms cast from metal, with which the heater clings to the hooks of the brackets.

These are the arms that hook the hooks

What tools will you need?

The tying process is highly complex, so special tools are required, which include:

- Special keys.

- Seal for each threaded connection.

- Tow and thread pastes.

- Threaded threads.

This list is not exhaustive, because each system requires an individual approach.

Mayevsky crane or automatic air vent

This is a small device for releasing air that may accumulate in the radiator.

Placed on the free upper outlet (collector). It must be on every heating device when installing aluminum and bimetallic radiators. The size of this device is significantly smaller than the diameter of the manifold, so you will also need an adapter, but Mayevsky taps usually come complete with adapters, you just need to know the diameter of the manifold (connection dimensions).

Mayevsky crane and method of its installation

In addition to the Mayevsky crane, there are also automatic air vents.

They can also be installed on radiators, but they are slightly larger in size and for some reason are only available in a brass or nickel-plated case. Not in white enamel. In general, the picture is unattractive and, although they deflate automatically, they are rarely installed.

This is what a compact automatic air vent looks like (there are more bulky models)

Selection of components for strapping

You can tie the system using the following elements:

- shut-off elements – standard ball valves;

- plugs blocking other channels;

- Mayevsky cranes for air release at the time of seasonal start-up;

- sealants - special compounds or tapes.

Stopcock

Mayevsky crane

Plugs for radiators

To control the quality of communications, install:

- pressure gauge for checking the pressure level in pipes;

- manual or automatic thermostat, which allows you to set the radiator to a certain temperature.

When making polypropylene strapping, you need a special welding machine.

Rules for selecting elements of control, shut-off and adjustment types

Thermostats may not be used due to their high cost. Do-

it-yourself connection of radiators to the heating system involves the use of throttle and shut-off elements. The type of fittings depends on the number of communication circuits. For a single-circuit highway you will need:

- ball valves for turning off radiators – 2 pcs.;

- Mayevsky valve for air release;

- bypass with valve;

- throttles or thermostat valves for temperature control - may not be used;

- automatic air vents.

For the diagonal circuit, a flush valve is also used, but it can be replaced with a standard ball valve. When performing double-circuit piping, a throttle is additionally used. That is, for one radiator you will need a thermostat on the underwater pipe, a throttle on the return line and a flushing valve with a diagonal connection.

Stub

The side-connected radiator has four outputs.

Two of them are occupied by the supply and return pipelines, on the third they install a Mayevsky valve. The fourth entrance is closed with a plug. It, like most modern batteries, is most often painted with white enamel and does not spoil the appearance at all.

Where to install the Mayevsky plug and tap for different connection methods

Shut-off valves

You will need two more ball valves or shut-off valves that can be adjusted. They are placed on each battery at the input and output.

If these are ordinary ball valves, they are needed so that, if necessary, you can turn off the radiator and remove it (emergency repairs, replacement during the heating season). In this case, even if something happens to the radiator, you will cut it off, and the rest of the system will work. The advantage of this solution is the low price of ball valves, the disadvantage is the impossibility of adjusting heat transfer.

Radiator taps

Almost the same tasks, but with the ability to change the intensity of the coolant flow, are performed by shut-off control valves. They are more expensive, but they also allow you to adjust the heat transfer (make it less), and they look better externally; they are available in straight and angular versions, so the piping itself is more accurate.

If desired, you can install a thermostat on the coolant supply after the ball valve.

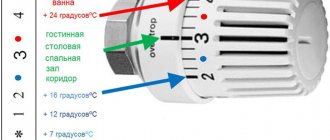

This is a relatively small device that allows you to change the heat output of a heating device. If the radiator does not heat well, you cannot install them - it will be even worse, since they can only reduce the flow. There are different thermostats for batteries - automatic electronic ones, but more often they use the simplest one - mechanical.

Special bottom and universal connection

Special lower connection of radiators is carried out if the battery design has lower threads located on the lower profile of the device. Most often, these threads are arranged in pairs and have an external design, but there are also models with internal threads.

To connect the connections, special connection units are most often used here - their design includes 2 shut-off and control devices, in modifications for single-pipe circuits - a bypass, with or without the ability to regulate it. Connection nodes can have a straight or angular shape; the actuating elements of the devices are built-in ball valves, manual or thermostatic valves (the latter with the possibility of installing a thermal head).

Instead of connection nodes, standard fittings (for each connection) of the appropriate size are sometimes used. This solution has its advantages - a pair of taps usually costs less than an expensive unit; in addition, the units are poorly repaired; if the device breaks down, it usually has to be replaced - if separate shut-off devices are used, the situation is simplified (it is necessary to replace the directly failed faucet or valve).

Universal radiators (according to the piping method) are equipped with all types of threads - bottom and side - here you can implement any of the above piping methods.

Related materials and tools

You will also need hooks or brackets for hanging on walls. Their number depends on the size of the batteries:

- if there are no more than 8 sections or the length of the radiator is no more than 1.2 m, two fastening points on top and one on the bottom are sufficient; for every next 50 cm or 5-6 sections, add one fastener on top and bottom.

You also need fum tape or linen winding, and plumbing paste to seal the joints.

You will also need a drill with drills, a level (preferably a level, but a regular bubble one will do), and a certain number of dowels. You will also need equipment for connecting pipes and fittings, but it depends on the type of pipes. That's all.

Definition of the term “battery strapping”

A set of fittings for connecting a radiator to the main line - there is a piping of batteries. The

piping of heating radiators is understood as a set of pipeline elements and fittings for connecting radiators to the main line. The piping is the most vulnerable area of communications due to detachable connections, the likelihood of using low-quality fittings and the lack of protection from mechanical stress in the circuit.

The principle of connecting the battery to the pipeline is unimportant; efficiency and reliability depend on the chosen circuit. The simplest horizontal technology is stable; when using the lateral method, you need to calculate the financial costs.

To lift the system from the floor, special metal tubes are used - they increase the reliability of the harness.

Where and how to place

Traditionally, heating radiators are installed under the window.

This is necessary so that the rising warm air cuts off the cold from the window. To prevent the glass from sweating, the width of the heating device must be at least 70-75% of the width of the window. It must be installed:

- in the middle of the window opening, permissible deviation - 2 cm; distance from the radiator to the floor - 8-12 cm; to the window sill - 10-12 cm; from the back wall to the wall - 2-5 cm. Distances from the heating radiator to the window

These are all recommendations, the observance of which ensures normal circulation of warm air in the room and its effective heating.

Read how to choose polypropylene pipes here.

Organization of heating of a private house using metal-plastic pipes

The wonderful idea of using metal-plastic products in heating systems has become a real technological breakthrough in the field of laying utility lines. The durable and flexible material confidently replaced heavy and inconvenient steel heating pipes and quickly took the leading position in the ranking of popular materials for heating systems.

The possibility of using this material in heating systems is of interest to many owners of apartments and private houses.

The excellent functionality of metal-plastic and the demonstration of good efficiency of the heating system, the ease of connecting metal-plastic pipes makes them the most popular type of pipe products for heating rooms in the cold season.

The main competitor of the material is products made of polypropylene, but the low cost of the material and the ability to assemble a heating pipeline with your own hands serve as strong arguments in favor of metal plastic.

The great popularity of heating from metal-plastic pipes is due to the special multilayer structure of the material. The design of the products consists of a solid aluminum tube, laser or ultrasonic welded, protected by an internal and external layer of cross-linked polyethylene.

Internal insulation increases the smoothness of the walls, which has a positive effect on the speed of the hot coolant. Rust and lime deposits cannot “stick” to polyethylene and therefore the risk of leaks in metal-plastic pipes is minimized.

The outer shell protects against mechanical damage and the appearance of condensed moisture.

Currently, the majority of metal-plastic pipe products are represented by five-layer models with additional adhesive layers that perform connecting functions between the aluminum walls and the polymer shell.

Characteristics and properties

The unique combination of technical properties of aluminum and plastic makes it possible to effectively use metal-plastic for heating not only low-rise private mansions, but also multi-apartment residential buildings and public buildings. The flexibility of the material and its high corrosion resistance make it possible to create a reliable heating system with a long service life.

The main characteristics of metal-plastic pipes in the table:

A metal-plastic heating pipeline creates excellent conditions for faster delivery of hot coolant to radiator batteries, and thereby increases the thermal power of the heating elements.

A metal-plastic heating system has many useful properties:

- Durability of the material . With the correct choice of heating piping method and compliance with installation technology, the service life of the system reaches 50 years.

- Light weight of the pipeline . It is known that 1 linear meter of heating pipeline f * 16 mm weighs slightly less than 100 grams. One person can assemble and install metal-plastic heating systems.

- High pipeline capacity . The internal cavity does not silt or become covered with limescale build-up, which allows the original throughput to be maintained for many decades.

- Flexibility of the material . Metal-plastic bends well and due to this the number of connecting fittings is reduced.

To assemble heating pipelines, it is not necessary to have the qualifications of a specialist plumber; you can install the system yourself with your own hands.

Application area

Due to the technical characteristics of metal-plastic, the material has found application in pipelines for cold and hot water supply, as well as sewage.

It is used for various heating systems:

- Underfloor heating device "warm floor".

- Connection to wall-mounted radiator radiators.

- Heating of soil in closed greenhouse complexes and greenhouses.

- Water heating device for swimming pools.

- Laying protective screens for power cables.

- Compressed air supply.

Metal-plastic products can be found in air conditioning systems and in transport routes for the movement of gaseous and liquid substances.

Choosing a diameter for heating installations

When choosing metal-plastic pipes for a heating device, you should pay attention to such technical parameters as the size of the internal and external diameters of the products:

- The main characteristic of throughput is the internal diameter of the product.

- The outer diameter of metal-plastic pipes ranges from 16 to 63 mm.

- An important indicator is the thickness of the walls. For metal-plastic pipes this figure ranges from 2 to 3.5 mm. As the cross-sectional diameters of tubular products increase, the wall thickness increases accordingly.

Heating of metal-plastic pipes in a private house or a separate apartment in an apartment building is made from materials with an internal diameter of 20 mm and a wall thickness of 3 mm.

Individual heating and utility networks of industrial enterprises are installed from pipes with a diameter of 32 - 40 mm with a wall thickness of 3.9 mm.

Source: https://trubarik.ru/metalloplastic/otoplenie-iz-metalloplastikovyh-trub-v-chastnom-dome

How to install correctly

Now about how to hang the radiator. It is very desirable that the wall behind the radiator is level - this makes it easier to work.

Mark the middle of the opening on the wall, draw a horizontal line 10-12 cm below the window sill line. This is the line along which the top edge of the heating device is leveled. The brackets must be installed so that the top edge coincides with the drawn line, that is, it is horizontal.

This arrangement is suitable for heating systems with forced circulation (with a pump) or for apartments. For systems with natural circulation, a slight slope is made - 1-1.5% - along the flow of the coolant. You can’t do more - there will be stagnation.

Correct installation of heating radiators

Wall mount

This must be taken into account when installing hooks or brackets for heating radiators. Hooks are installed like dowels - a hole of a suitable diameter is drilled in the wall, a plastic dowel is installed in it, and the hook is screwed into it. The distance from the wall to the heating device is easily adjusted by screwing in and unscrewing the hook body.

Hooks for cast iron batteries are thicker.

This is a fastener for aluminum and bimetallic When installing hooks under heating radiators, please note that the main load falls on the upper fastener. The lower one serves only to fix it in a given position relative to the wall and is installed 1-1.5 cm lower than the lower collector. Otherwise, you simply will not be able to hang the radiator. One of the types of brackets When installing brackets, they are applied to the wall in the place where they will be mounted.

To do this, first attach the battery to the installation site, see where the bracket “fits”, mark the place on the wall. Having placed the battery, you can attach the bracket to the wall and mark the location of the fasteners on it. In these places, holes are drilled, dowels are inserted, and the bracket is screwed. Having installed all the fasteners, hang the heating device on them.

Pipes

What pipes can be used for piping, and what features should be taken into account?

Steel

It is used to tie bimetallic heating devices in central heating systems. The method of connecting pipes is welding; The batteries are mounted on sockets with threaded fittings.

Important: in central heating systems, there must be a jumper parallel to the riser in front of the valves and chokes on the connections. Otherwise, your throttling valve will regulate the flow of the entire riser.

Separately, it is worth mentioning galvanized steel. It is considered an unsuitable material for heating, and absolutely undeservedly. Among other things, galvanizing was used to tie cast-iron heating radiators in Stalin buildings built in the middle of the last century; These pipes are now in no different condition from new ones.

The only drawback of galvanizing is that all connections have to be threaded: the zinc that burns out on the welds makes the pipe vulnerable to corrosion.

Metal-plastic

Tying heating radiators with metal-plastic pipes is possible, but with several restrictions.

- It is only applicable for self-contained systems with their limited pressure.

- It is advisable to use press fittings.

- If compression fittings are used, then the use of a calibrator is mandatory. Otherwise, when the pipe is combined with the fitting, the rubber O-rings on the fitting are lifted, which leads to leakage after several heating and cooling cycles.

Polypropylene

Tying heating radiators with polypropylene can also be lightly recommended only for autonomous circuits.

And there are a couple of restrictions:

- Reinforced pipes with a working pressure of PN25 are preferred.

- Long straight sections of the pour are equipped with compensators - ring or U-shaped bends, which dampen the elongation of the pour when heated.

Schemes for piping heating radiators with polypropylene must include expansion joints in straight sections.

Floor fixing

Not all walls can support even lightweight aluminum batteries. If the walls are made of lightweight concrete or covered with plasterboard, floor installation is required. Some types of cast iron and steel radiators come directly with legs, but not everyone is satisfied with their appearance or characteristics.

Legs for installing aluminum and bimetallic radiators on the floor

Floor installation of heating radiators made of aluminum and bimetallic is possible. There are special brackets for them.

They are attached to the floor, then the heating device is installed, and the lower collector is secured with an arc to the installed legs. Similar legs are available with adjustable height and some with a fixed height. The method of fastening to the floor is standard - with nails or dowels, depending on the material.

Adding sections to an aluminum radiator

If you need to add several sections to the device, the question arises of how to connect aluminum radiators. To do this, the previously installed battery must be dismantled and placed on a floor covered with film, with the outer side facing you.

You can add heating radiator sections as follows:

Installation and piping of a heating boiler in a private house

- We remove the plugs from the ends of the collector outlets.

- We put a rubber gasket on one side of the nipple without thread.

- After this, insert the nipple into the manifold and tighten it.

- Now we connect the section that we plan to add to the other side of the nipple. Use a wrench to tighten the connector. During this process, both sides will be tightened at the same time because each side has opposite threads. Tighten the connection as tightly as possible.

- We check how tightly the sections are connected. For this purpose, you need to pour slightly colored water into the device and wait several hours.

Advice! To avoid distortions of the device, we tighten the nipples on the lower and upper manifold by the same number of turns. To do this, they need to be counted during rotation.

Options for piping heating radiators

Installation of heating radiators involves connecting them to pipelines. There are three main connection methods:

- saddle; one-sided; diagonal.

Connection options

If you install radiators with a bottom connection, you have no choice. Each manufacturer strictly binds the supply and return, and its recommendations must be strictly followed, since otherwise you simply will not get heat. There are more options with a side connection (more about them is written here).

Features of radiators for side connection

There is a concept called “sectional radiator piping”.

This is a kit for making a lateral connection of a radiator in order to adapt the latter to the heating system. In addition to the radiator itself, this includes adapters, plugs, manual air vents with plastic keys, and adapters. In addition, the set includes shut-off or control valves. As a rule, the package includes paranit or silicone gaskets, so you do not need additional sealing products.

When installing a sectional radiator, there is one feature. Before screwing on the fitting, you should make sure that a thin layer of paint is applied to the threads, or none at all. Excess paint can be sanded off with sandpaper, but many people prefer to use flax.

Sectional radiator

Panel radiators made of steel material do not require an additional installation kit. Everything necessary is already installed on them; all that remains is to screw in the taps and connect the pipes.

Some people mistakenly believe that nothing is installed on such a radiator at all. What if I have to dismantle it? In order not to drain water from the system, it is enough to provide the supply and return pipes with ball valves. This will allow the entire system to remain operational during repairs.

As a rule, an experienced craftsman uses the following fittings to strap a radiator:

- a pair of ball valves - with their help, the heating device is completely shut off from the entire system;

- throttle with ball valve - in addition to stopping, it helps to manually adjust the thermal output;

- a pair of chokes - with their help, basic balancing of a two-pipe heating system and subsequent adjustment of heat transfer are performed;

- thermal head with throttle - allows you to regulate the temperature in the room automatically.

There is another important feature - a bypass is installed in front of the shut-off or throttling device, which allows adjustment only on a specific radiator.

Whatever type of radiator you choose, whatever circuit you use to connect it, you must perform calculations and install it correctly. For each specific case, one or another system is more optimal. If the houses have a large area, it is recommended to take advice from specialists who will assist in drawing up the project.

If the room is small, then it is possible to select a heating system and carry out installation work on your own. You just need to take into account all the features of your home, study the rules for installing radiators, and understand the feasibility of using a specific system.

During installation work, one should not forget that the types of materials for pipes and radiators must be the same. A plastic pipe connected to a cast iron battery will cause you a lot of trouble.

The correct choice of radiator connection option directly determines the operating effect of the entire heating system. With the optimal option, heat losses are minimized. This creates the opportunity to obtain maximum effect with minimal consumption of fuel resources.

You can carry out installation work yourself. You just need to provide everything so that the cold system does not disturb the comfort of your cozy home.

Strapping with one-sided connection

One-way connection is most often used in apartments.

It can be double-pipe or single-pipe (the most common option). Metal pipes are still used in apartments, so we’ll consider the option of tying the radiator with steel pipes on pipes. In addition to pipes of a suitable diameter, you need two ball valves, two tees and two bends - parts with external threads at both ends.

Lateral connection with bypass (one-pipe system)

All this is connected as shown in the photo. With a one-pipe system, a bypass is required - it allows you to turn off the radiator without stopping or draining the system. You cannot put the tap on the bypass - you will block the flow of coolant through the riser, which is unlikely to make your neighbors happy and, most likely, you will be fined.

All threaded connections are sealed with fum tape or linen winding, over which packaging paste is applied. When screwing the valve into the radiator manifold, much winding is not required.

Too much of it can lead to the appearance of microcracks and subsequent destruction. This is true for almost all types of heating devices, except cast iron. When installing all the others, please do not be fanatical.

Welding option

If you have the skills/opportunity to use welding, you can weld the bypass. This is what the piping of radiators in apartments usually looks like.

With a two-pipe system, a bypass is not needed. The supply is connected to the upper entrance, the return is connected to the lower entrance, taps, of course, are needed.

One-way piping with a two-pipe system

With bottom wiring (pipes laid on the floor), this type of connection is made very rarely - it turns out inconvenient and ugly; in this case, it is much better to use a diagonal connection.

Installation of heating with metal-plastic pipes – Pipes and plumbing

A metal-plastic heating pipe has a number of advantages over other types of similar products:

- withstands very high temperatures, sometimes reaching 95C˚;

- the minimum operating pressure is 10 atmospheres;

- even at a constant operating temperature of about 95C˚, the service life reaches 25 years;

- at a constant temperature of 20 degrees, the guaranteed service life of metal-plastic heating pipes, according to manufacturers, reaches 50 years;

- oxygen diffusion is 0 g/m³ in 24 hours.

The positive characteristics that metal-plastic for heating has are as follows:

- One of the main advantages of metal-plastic products is their durability. As practice shows, on average, an ordinary metal pipe will last no more than two decades, and less when used in a heating structure;

- attention should be paid to the anti-toxicity of metal-plastic and its resistance to the formation of precipitation and the occurrence of corrosive processes;

- metal-plastic products easily withstand the influence of aggressive environments;

- even after 10 years of operation, siltation does not form on the internal surfaces of such pipes, and they are not overgrown with plaque;

- the throughput of metal-plastic pipes for arranging heating structures and water supply systems exceeds this figure for competitors by 1.3 times (for comparison, metal and cast iron products were taken);

- This product is lightweight and has good ductility;

- When installing heating from metal-plastic pipes, the materials are used with virtually no waste, since they are sold in coils and the required footage is cut off as necessary. A minimum set of tools is required. Also, metal-plastic pipes can be placed under a screed without performing special processing of the products;

- repairs can be carried out without special welding and pipe bending equipment;

- metal-plastic heating pipes are characterized by noise-absorbing properties;

- metal-plastic conducts heat better compared to metal products by 175 times and 1300 times with copper samples;

- This pipe material does not require painting or welding during installation;

- a heating system made of metal-plastic pipes, such as in the photo, is not affected by stray currents;

- products made from this material are not destroyed if the coolant freezes;

- metal-plastic pipes are not capable of condensing moisture.

From all of the above, one conclusion can be drawn: such pipes are ideal for creating heating structures in apartments and houses.

Areas of application of metal-plastic pipes

Products made from materials such as metal-plastic are used in various fields of activity:

- they can be found in the internal systems of buildings that are recently constructed or reconstructed;

- they are used in arranging the transportation of gaseous and liquid substances in the industrial, agricultural and transport fields of activity;

- for compressed air supply;

- when replacing a pipeline that has become unusable, at any time of the year, without evicting people living in the building;

- in internal systems installed for air conditioning;

- as a screen to protect power cables.

Installation of metal-plastic pipes

If you look at the layers that make up metal-plastic pipes, you can see that high-density polyethylene is applied to the inner aluminum base of the products by extrusion using a special glue. The polyethylene layer serves as protection against mechanical damage and systematic influences.

Heat-resistant thin polyethylene, which makes up the inner layer, reliably protects aluminum from corrosive processes and creates an absolutely smooth surface inside the pipes.

This material does not contain harmful substances; for this reason, metal-plastic pipes are installed when creating drinking water supply systems.

Special polyethylene does not promote, but rather prevents, the spread and further reproduction of microorganisms harmful to human health in the aquatic environment.

Connecting metal-plastic pipes for heating during installation

Heating from metal-plastic is carried out in one of two ways:

- using laser welding to join the edges end to end;

- using ultrasound when pipes are connected overlapping.

Most often, laser is used in practice, since “seamless products” look much more attractive. This type of pipe, intended for heat supply systems, is produced on the basis of a “cross-linked” polyethylene base.

For the home, metal-plastic products are simply ideal, and they can be used anywhere you need to install a high-quality pipeline. When choosing structural elements for heating a house, the diameter of metal-plastic heating pipes must be selected so that the coolant circulates through them at a speed of 0.3 to 0.7 m/sec.

Metal-plastic heating pipe: installation of a metal-plastic heating system, diameter, pipe service life, photo and video examples Metal-plastic heating pipe: installation of a metal-plastic heating system, diameter, pipe service life, photo and video examples

Source: teplospec.com

[content-egg module=GdeSlon template=compare]

Correctly selected material for making pipes for organizing heating is the basis for the efficiency of the entire system. Until recently, there was no particular alternative - steel lines had to be installed. However, with the development of the polymer industry, it has become important to do heating with metal-plastic pipes in a private house with your own hands.

Features of metal-plastic for heating

The main performance qualities of heating pipes are a long service life with periodic temperature fluctuations, as well as minimal heat losses.

These parameters are fully met by heating using metal-plastic pipes.

A distinctive feature of these designs is the use of several materials that are different in nature and properties to achieve the required result.

The main manufacturing material is often cross-linked high-density polyethylene. But besides it, simple polyethylene or propylene can be used. To prevent oxygen molecules from entering the coolant, the pipe has a layer of foil.

They are attached to the outer and inner polymer shell using an adhesive layer. This is a mandatory condition, since it is impossible to make effective heating from metal-plastic with your own hands from highways without a waterproof shell.

Otherwise, supersaturation of water with oxygen will lead to an increased rate of corrosion of the metal elements of the system.

What is important for the consumer is not the technical, but the operational properties of heating pipes. Therefore, we will not consider the manufacturing technology in detail, but will focus on special aspects of metal-plastic:

- What is better to take - cross-linked polyethylene for heating or metal-plastic? The latter has varying degrees of thermal expansion of its elements - polymer shells and foil layer. Therefore, on long sections of the pipeline it is necessary to install compensation loops;

- The operating temperature is limited to 95°C. Exceeding this value will lead to deformation of the structure;

- To connect the elements of the highway, you can use several types of fittings - glued, threaded or clamped. If you need to make reliable heating of a private house with metal-plastic, it is recommended to use the latter type of connectors.

What else is the difference when choosing - metal-plastic or polypropylene for heating? Easy to install first. To connect polypropylene pipes, a special welding machine is required.

Metal-plastic pipes are installed using a pipe “gas” wrench. But the requirements for professionalism in their installation are much higher.

Its reliability will depend on the degree of effort applied, the correct cut and drawing up the heating scheme.

A metal-plastic pipe can be bent to a radius of 12 mm. This applies to models whose diameter is 20 mm or less. As the cross-section increases, the minimum bending radius increases. This must be taken into account during installation.

Selection of pipes and components for the heating system

To organize heating from metal-plastic with your own hands, you need to choose the right pipes and components. First of all, the optimal diameter is determined - the throughput of the system will depend on it.

Metal-plastic pipes

What is more convenient for heating installation - metal-plastic or polypropylene? Metal-plastic pipes are supplied in coils, the length of which ranges from 50 to 200 m. Polypropylene products are manufactured in lengths up to 6 m. Also, when choosing a material for making heating from metal-plastic pipes, you need to take into account their quality, namely:

- The minimum thickness of the foil shell should be 0.3 mm;

- The connection of the aluminum layer must be carried out using seamless technology;

- There should be no delamination on the pipe cut.

It is imperative to ensure that there are no bends in the bay. This may affect the integrity of the aluminum shell.

Pipes from Rehau, Oventrop and Henko are distinguished by a high degree of reliability. In their product range you can select fittings and other additional components for the pipeline.

Fittings for metal-plastic pipes

It is best to use press fittings for connections. They have the same design regardless of what was chosen - cross-linked polyethylene for heating or similar metal-plastic.

Models with a double seal circuit have the best performance characteristics. They are made of stainless steel and copper alloy (brass). The latter are characterized by a more affordable cost, but have a shorter maintenance-free service life.

An important factor when organizing heating of a private house with metal-plastic is the cost of components. This parameter directly depends on the manufacturer, as well as the technical characteristics of the elements.

If the main parameter for choosing metal-plastic or polypropylene for a heating system is the cost of components, then the first will “lose.” This is due to high labor costs during production.

The labeling must indicate that the product can be used in heating systems. Not all metal-plastic pipes are designed for high temperatures.

Installation of heating from metal-plastic pipes

To install metal-plastic heating yourself, you need to purchase special cutting scissors and a calibrator. It is designed to align the end of the pipe before installation into the clamp fitting. It’s not difficult to make it yourself, but there is a high probability of making a mistake in size - the permissible deviation is 0.5 mm.

After purchasing, the pipes must lie in a room with normal temperature (from 15 to 25°C) for at least 1 day. If you need to bend the line in a certain area, purchase a special spring.

Source: https://trubyisantehnika.ru/montazh-otopleniya-metalloplastikovyimi-trubami.html

Strapping with diagonal connection

Installing heating radiators with diagonal connections is the best option in terms of heat transfer. In this case it is the highest. With bottom wiring, this type of connection is easy to implement (example in the photo) - the supply on this side is at the top, the return on the other is at the bottom.

With two-pipe bottom wiring

With a single-pipe system with vertical risers (in apartments), everything does not look so good, but people put up with it because of the higher efficiency.

Coolant supply from above

Please note that with a one-pipe system, a bypass is again required.

Coolant supply from below

General rules for installing radiators

The battery is attached to the wall with special brackets. It can be installed openly, which is most optimal, recessed into a niche or covered with decorative finishing elements. When deciding how to properly install an aluminum heating radiator, you need to take into account that when closing the heat source, a loss of up to 30% of power is possible. Having made this choice, it is better to lengthen the heating devices through additional sections.

Any connection method will use three of the four radiator holes. Close the unused channel with a plug.

The two connection points to the system will act as input and output. On the third, always the top one, you need to connect the Mayevsky valve, through which air is removed after filling the system with coolant.

According to the design standards establishing how to correctly determine the connection location of an aluminum heating radiator, the following dimensions must be maintained:

- There should be a free space of at least 10 cm between the top of the radiator and the window sill. If the distance is made smaller, the rising warm air will heat the window sill rather than heat the room.

- The gap between the floor and the heater should not exceed 12 cm. As this gap increases, the heating of the lower part of the room deteriorates.

- You need to retreat from the wall to a distance exceeding 2 cm. At a shorter distance, the free upward flow of warm air masses behind the sections is impossible, as a result, thermal energy will go into the wall.

Often people, without thinking about where and how to properly connect a heating radiator in an apartment or other room, reduce the efficiency of this device. In this case, losses will account for a considerable part of the precious heat.

- Installation under an element protruding from the wall by 3 - 5 cm - about 4%.

- Placement in an open niche - up to 7%.

- Partially closing with a grill - up to 15%.

- By installing the grill over the entire area of the heated parts - up to 30%.

For lateral and diagonal connections, it is better to arrange the entrance through the top channel. When the coolant is supplied from below, the heating efficiency decreases by up to 15%.

The top plane of the battery must be in a horizontal position.

Trying to follow the conditions for how to most correctly and conveniently connect heating radiators, do not forget to use a supply tap that has a digital or dot scale on the adjustment handle. The presence of this option will allow you to easily set the amount of incoming liquid.

When assembling the connections of the coolant supply and discharge pipelines with outlets to the radiator and at the connection points of heating kits, taps should be used that allow you to disconnect the battery from the system if it is necessary to repair or replace it. This mechanism is called “American”.

The laying of pipes connecting the radiator to the system is carried out after installing the sections.

When choosing how to properly connect heating radiators, we will consider each combination of the type of system and method of connecting the heaters.

Strapping with saddle connection

With bottom wiring or hidden pipes, installing heating radiators in this way is the most convenient and least noticeable.

With a two-pipe system

With a saddle connection and lower single-pipe wiring, there are two options - with and without bypass. Without a bypass, the taps are still installed; if necessary, you can remove the radiator and install a temporary jumper between the taps - a squeegee (a piece of pipe of the required length with threads at the ends).

Saddle connection for one-pipe system

With vertical wiring (risers in high-rise buildings), this type of connection can be seen rarely - the heat losses are too large (12-15%).