Adjusting heating radiators in an apartment allows you to simultaneously solve several problems, the main one of which is to reduce the cost of paying for certain utilities.

This possibility is realized in different ways: mechanically and automatically. However, when changing the heating system parameters, the average room temperature does not increase. You can only reduce it to the desired level by adjusting the position of the fittings. It is advisable to install such devices on batteries in houses where it is cool in winter.

Why do you need to make adjustments?

The main factors explaining the need to change the heating level of batteries using locking mechanisms and electronics:

- Free movement of hot water through pipes and inside radiators. Air pockets may form in the heating system. For this reason, the coolant stops heating the batteries, as it gradually cools. As a result, the indoor microclimate becomes less comfortable, and over time the room cools down. To maintain heat in the pipes, shut-off mechanisms installed on radiators are used.

- Adjusting the temperature of the batteries makes it possible to reduce the cost of heating your home. If the rooms are too hot, by changing the position of the valves on the radiators you can reduce costs by 25%. Moreover, reducing the heating temperature of the batteries by 1°C provides savings of 6%.

- In cases where radiators heat up the air in the apartment very much, you have to open the windows often. It is not advisable to do this in winter, because you can catch a cold. To avoid having to constantly open windows in order to normalize the microclimate in the room, regulators should be installed on the batteries.

- It becomes possible to change the heating temperature of radiators at your discretion, and individual parameters are set in each room.

How to regulate radiators

To influence the microclimate in the apartment, you need to reduce the volume of coolant passing through the heating device. In this case, it is only possible to reduce the temperature value. The heating system is adjusted by turning the valve/faucet or changing the parameters of the automation unit. The amount of hot water passing through the pipes and sections is reduced, and at the same time the battery heats up less intensely.

To understand how these phenomena are interconnected, you need to learn more about the operating principle of the heating system, in particular, radiators: hot water entering the heating device heats the metal, which, in turn, releases heat into the air. However, the intensity of heating the room depends not only on the volume of hot water in the battery. The type of metal from which the heating device is made also plays an important role.

Cast iron has a significant mass and releases heat slowly. For this reason, it is not advisable to install regulators on such radiators, since the device will take a long time to cool. Aluminum, steel, copper - all these metals instantly heat up and cool down relatively quickly. Work on installing regulators should be carried out before the start of the heating season, when there is no coolant in the system.

In an apartment building, there is no way to change the average water temperature in the heating system pipes. For this reason, it is better to install regulators that allow you to influence the microclimate in the room in a different way. However, this cannot be realized if the coolant is supplied from top to bottom. In a private house there is access and the ability to change individual equipment parameters and coolant temperature. This means that in this case it is often impractical to mount regulators on batteries.

Detailed characteristics of shut-off valves

The normal operation of the heating system largely depends on the correct choice of the type of tap for the specific task. So it makes sense to take a closer look at the types of shut-off valves and their scope of application.

Ball Valves

A ball shut-off valve for a heating radiator is so called because its shut-off part is shaped like a ball with a hole in the middle. And the principle of its operation is that with one turn of the handle the water supply through the pipe is shut off.

This is very useful, for example, if the battery breaks, you can turn off the water supply almost instantly; if a screw device were used for the same purpose, you would have to spend much more time.

Ball valve with hole visible

In addition to ball ones, you can find analogues on sale with a conical or cylindrical locking part (these were used in Russian samovars). But in terms of performance indicators, it is the ball ones that are beyond competition. Conical ones, for example, are characterized by increased wear.

As for the choice of a ball shut-off valve, you need to take into account its dimensions and the type of metal from which it is made (it is necessary that, together with the metal of the radiator, it does not form a galvanic couple).

You also need to pay attention to the size of the hole in the locking part:

- full bore - in them the diameter of the hole exactly matches the internal diameter of the pipe itself. Thanks to this, once installed in the open state, it does not reduce the volume of water entering the battery;

In the full bore model, the hole in the ball is equal to the diameter of the pipe

- standard - their hole diameter is approximately 20% smaller than the internal diameter of the pipe. When using this model, we will reduce the heat transfer of the radiator by 10-15%;

- partial bore - due to the small hole in the ball, the liquid consumption is reduced by approximately half.

Note! Taking this into account, only full bore shut-off devices should be used for installation in front of the battery.

As for what the radiator shut-off valve device looks like, the section will show a metal ball and a gasket that ensures tightness when closed. Relatively recently, polymer shut-off valves have appeared on the market; they are suitable for installation on any radiator, regardless of what material it is made of.

Ball valve device

Note! Models with a plastic body are slightly inferior in strength to metal ones. But the thickness is greater; this must be taken into account when choosing.

Metal taps can be considered more traditional. Usually either brass or alloys containing it are used, so there should be no problems with the combination of metals.

It has only 2 working positions, which is why it belongs to the “shut-off valve” class. You can also find 3-way taps on sale; they can also be used when connecting radiators. The only difference is that there are 3 working positions, and the water flow can be directed in one of two directions.

A three-way valve is somewhat more complex than a regular valve

The price of such devices is low, and given the flexibility of the heating system, the additional costs are justified.

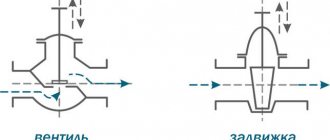

Stop valve

This category of devices can be used to connect heating radiators (in a 2-pipe heating system). Thanks to their design, valves, like ball valves, allow you to quickly shut off the flow of water into the battery, without interrupting the operation of the heating system. They can also be used to conveniently drain water from a heating device or fill it with liquid.

Simple shut-off valve

Note! The radiator direct shut-off valve does not include the installation of a drain valve in the basic configuration. But a useful addition can always be purchased separately.

As for the feasibility of the purchase, from a technical point of view there is no difference between installing a ball valve on the return line or choosing a shut-off valve. If there is at least a simple thermostat on the supply pipe, then both options will work the same.

But there are still differences in the design of a ball valve and a shut-off valve. The first can only be in the open/closed position, but the hex valve can regulate the coolant flow.

Diagram of draining water from the radiator

There are significant differences in appearance. Ball valves come with a clearly visible red butterfly, but the radiator shut-off valve looks much better.

It does not have a valve to turn, so it will not stand out much against the background of the pipes and the battery itself. Its cost is higher than that of a ball valve, but considering that the heating system is not built for 1 year, you can spend money.

The drain valve, used to drain water from the radiator, is installed on the shut-off valve. When you turn it with a special handle, the water supply to the radiator is shut off.

Valves and taps

Such fittings are a heat exchanger of a shut-off device. This means that the radiator is adjusted by turning the tap/valve in the desired direction. If you turn the fittings 90° all the way, the flow of water into the battery will no longer flow. To change the heating level of the heating device, the locking mechanism is set to the half position. However, not every fitting has this opportunity. Some faucets may leak after a short period of use in this position.

Installing shut-off valves allows you to manually regulate the heating system. The valve is inexpensive. This is the main advantage of such fittings. In addition, it is easy to operate, and changing the microclimate does not require special knowledge. However, there are also disadvantages to locking mechanisms, for example, they are characterized by a low level of efficiency. The battery cooling rate is slow.

Stopcocks

A ball design is used. First of all, it is customary to install them on a heating radiator in order to protect housing from coolant leakage. This type of valve has only two positions: open and closed. Its main task is to turn off the battery if such a need arises, for example, if there is a risk of flooding of the apartment. For this reason, shut-off valves are cut into the pipe in front of the radiator.

If the valve is in the open position, the coolant circulates freely throughout the heating system and inside the battery. Such taps are used if the room is hot. The batteries can be turned off periodically, which will reduce the air temperature in the room.

However, ball locking mechanisms must not be installed in the half position. With prolonged use, the risk of leakage in the area where the ball valve is located increases. This is due to gradual damage to the locking element in the form of a ball, which is located inside the mechanism.

Manual valves

This group includes two types of fittings:

- Needle valve. Its advantage is the possibility of half installation. Such fittings can be located in any convenient position: completely opens/closes the access of coolant to the radiator, significantly or slightly reduces the volume of water in heating devices. However, there is a drawback to needle valves. Thus, they are characterized by reduced throughput. This means that after installing such fittings, even in a fully open position, the amount of coolant in the pipe at the battery inlet will be significantly reduced.

- Control valves. They are designed specifically to change the heating temperature of batteries. The advantages include the ability to change position at the user’s discretion. In addition, such fittings are reliable. There is no need to frequently repair the valve if the structural elements are made of durable metal. There is a shut-off cone inside the valve. When you turn the handle in different directions, it rises or falls, which helps to increase/decrease the flow area.

Types of cranes

Ball

Ball valves have recently become very popular because they have an extremely simple design, which results in their long service life. In addition, they are easy to use, since to shut off the flow you only need to turn the handle 90 degrees.

The locking mechanism of this device is made in the form of a ball with a through hole. To block the passage, the ball should be turned with its hole perpendicular to the body.

The ball valve is controlled by a handle, which is connected to the ball via a rod. To seal the mechanism, two elastic rings are used that fit tightly to the ball.

The body of the ball device can be made of brass, aluminum or polypropylene. Plastic taps are installed together with plastic pipes for the heating system.

Note! All existing types of radiator taps are straight and angular. A radiator direct shut-off valve is usually installed with a lateral connection, when pipes are connected to the battery at the inlet and outlet levels. If pipes are supplied from below, for example, from the floor, it is more advisable to use corner fittings.

It should be noted that this fitting has the following disadvantages:

- Sensitivity to impurities in the coolant. Therefore, when using water, it is advisable to install filters.

- Not intended for smooth flow control. If it is used for these purposes, the mechanism will quickly fail.

Automatic adjustment

The advantage of this method is that there is no need to constantly change the position of the valve/faucet. The desired temperature will be maintained automatically. Adjusting the heating in this way makes it possible to set the desired parameters once. In the future, the heating level of the battery will be maintained by an automation unit or other device installed at the input of the heating device.

If necessary, individual parameters can be set multiple times, which is influenced by the personal preferences of the residents. The disadvantages of this method include the significant cost of components. The more functional the devices are for controlling the amount of coolant in heating radiators, the higher their price.

Electronic thermostats

These devices superficially resemble a control valve, but there is a significant difference - a display is built into the design. It displays the room temperature that needs to be obtained. Such devices work in conjunction with a remote temperature sensor. It transmits information to the electronic thermostat. To normalize the microclimate in the room, you just need to set the desired temperature value on the device, and the adjustment will be performed automatically. Electronic thermostats are located at the battery input.

Adjusting radiators with thermostats

Devices of this type consist of two units: lower (thermal valve) and upper (thermal head). The first of the elements resembles a manual valve. It is made of durable metal. The advantage of such an element is the ability to install not only an automatic, but also a mechanical valve, it all depends on the needs of the user. To change the heating temperature of the battery, the design of the thermostat provides a bellows, which exerts pressure on the spring-loaded mechanism, and the latter, in turn, changes the flow area.

Recommendations for installing devices

To be able to regulate the temperature of the battery in the apartment, consider any type of valve: they can be straight or angular. The installation principle of such a device is simple; the main thing is to correctly determine its position. Thus, the direction of coolant flow is indicated on the valve body. It must correspond to the direction of water movement inside the battery.

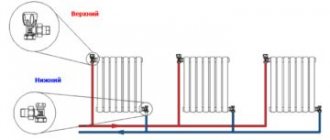

Place valves/thermostats at the inlet of the heating device; if necessary, install a tap at the outlet as well. This is done so that in the future it will be possible to independently drain the coolant. Regulating devices are installed on heating radiators, provided that the user knows exactly which pipe is the supply pipe, since a tap is made into it. In this case, the direction of movement of hot water in the riser is taken into account: from top to bottom or from bottom to top.

Compression fittings are more reliable, which is why they are used more often. The connection to the pipes is threaded. Thermostats can be equipped with a union nut. To seal the threaded connection, use FUM tape or flax.

Sometimes it becomes necessary to adjust the temperature in each specific room. This can be done by installing a thermostat for the heating radiator. This is a small device that regulates the heat transfer of a heating battery. Can be used with all types of radiators, except cast iron. One important point is that the device can lower the initial temperature, but if there is not enough heating power, it cannot increase it.

Stopcock installation

The whole process takes only a few minutes; you can do all the work yourself, without the help of specialists. You just need to take your time; for example, a slight misalignment when installing a tap on a pipe can result in a serious leak during the heating season.

Manufacturers produce shut-off valves with several types of connections. On sale you can find valves for welded joints, flanged joints, and coupling joints. The one-piece type of joint cannot be recommended due to difficulties with repairs in the future; the flange type of joint is used only in industrial enterprises, and in everyday life preference is given to detachable joints.

The photo shows an example of a combination of external and internal threads

Most often, taps with a union nut or an American one are used, the tightness is ensured high, and the labor intensity is minimal.

In this case, more attention is needed at the preparatory stage:

- you need to decide on the type of thread. The valves can be either coupling, external thread or combined, you need to choose based on the type of thread on the pipe;

- The type of handle also matters. If the pipe goes close to the wall, then you only need to choose the option with a butterfly; the long handle will simply rest against the wall.

Choosing the right option is not difficult

The installation instructions consist of several steps:

- the installation location of the crane is selected;

- the handle stroke is checked;

- Next, a threaded connection is made. It is mandatory to use a winding for additional tightness of the connection;

FUM tape guarantees the reliability of the threaded connection

Note! It is allowed to tilt the handle from the vertical by 45ᵒ on a horizontal pipe. So you don’t have to screw the joint all the way, but turn the tap a little to the side to make it easier to use.

- The final stage is checking the joint for leaks.

Design of thermostats for heating radiators

The thermostat for a heating radiator consists of two parts - a valve (thermovalve) and a thermostatic head (thermostatic element, temperature regulator). These products are produced for different pipe sizes and different types of heating systems. The thermostatic head is removable; regulators of different types and even from different manufacturers can be installed on the same valve - the seat is standardized.

The thermostat for a heating radiator consists of two parts - a special valve (valve) and a thermostatic head (regulator)

There are different valves and regulators, so before installing a thermostat for a heating radiator, you will have to become at least a little familiar with its structure, functions and types.

Thermal valve - structure, purpose, types

The valve in the thermostat is very similar in structure to a regular valve. There is a seat and a shut-off cone that opens/closes the gap for coolant flow. The temperature of the heating radiator is regulated in this way: by the amount of coolant passing through the radiator.

Sectional view of thermostatic valve

The valves are installed differently for one-pipe and two-pipe wiring. The hydraulic resistance of a valve for a one-pipe system is much lower (at least two times) - this is the only way to balance it. You can't mix up the valves - it won't heat. For systems with natural circulation, valves for single-pipe systems are suitable. When installing them, the hydraulic resistance, of course, increases, but the system will be able to work.

Each valve has an arrow indicating the movement of the coolant. During installation, it is installed so that the flow direction coincides with the arrow.

What materials?

The valve body is made of corrosion-resistant metals and is often additionally coated with a protective layer (nickel or chrome plated). There are valves from:

- bronze (nickel and chrome plated);

- brass (coated with a layer of nickel);

- of stainless steel.

Cases are usually brass or bronze with nickel or chrome plating

It is clear that stainless steel is the best option. It is chemically neutral, does not corrode, and does not react with other metals. But the cost of such valves is high and it is difficult to find them. Bronze and brass valves have approximately the same service life. What is important in this case is the quality of the alloy, and it is carefully monitored by well-known manufacturers. Whether or not to trust unknowns is a controversial issue, but there is one point that is better to keep track of. There must be an arrow on the body indicating the direction of flow. If it is not there, then you have a very cheap product that is better not to buy.

By method of execution

Since radiators are installed in different ways, the valves are made straight (through) and angular. Choose the type that will work best for your system.

Straight (way through) valve and angle

| Name/Company | For which system | Du, mm | Housing material | Operating pressure | Price |

| Danfos, angular RA-G, adjustable | single-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 25-32 $ |

| Danfos, direct RA-G with customizability | single-pipe | 20 mm, 25 mm | Nickel plated brass | 10 bar | 32 – 45 $ |

| Danfos, angular RA-N, adjustable | two-pipe | 15 mm, 20 mm. 25 mm | Nickel plated brass | 10 bar | 30 – 40 $ |

| Danfos, direct RA-N with customizability | two-pipe | 15 mm, 20 mm. 25 mm | Nickel plated brass | 10 bar | 20 – 50 $ |

| BROEN, direct fixed tuning | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 8-15 $ |

| BROEN, direct fixed tuning | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 8-15 $ |

| BROEN, corner, adjustable | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 10-17 $ |

| BROEN, corner, adjustable | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 10-17 $ |

| BROEN, direct fixed tuning | single-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 19-23 $ |

| BROEN, fixed angle | single-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 19-22 $ |

| OVENTROP, axial | 1/2″ | Nickel plated brass, enamel plated | 10 bar | 140 $ |

Thermostatic heads

There are three types of thermostatic elements for heating thermostats - manual, mechanical and electronic. They all perform the same functions, but in different ways, provide different levels of comfort, and have different capabilities.

Manual

Manual thermostatic heads work like a regular faucet - you turn the regulator in one direction or another, allowing more or less coolant to flow through. The cheapest and most reliable, but not the most convenient devices. To change the heat transfer, you must manually turn the valve.

Manual thermal head - the simplest and most reliable option

These devices are quite inexpensive, they can be installed at the inlet and outlet of a heating radiator instead of ball valves. Any of them can be adjusted.

Mechanical

A more complex device that maintains the set temperature automatically. The basis of this type of thermostatic head is a bellows. This is a small elastic cylinder that is filled with a temperature agent. A temperature agent is a gas or liquid that has a high coefficient of expansion - when heated, it greatly increases in volume.

Thermostat device for a heating radiator with a mechanical thermostatic head

The bellows supports the rod, which blocks the flow area of the valve. Until the substance in the bellows heats up, the rod is raised. As the temperature rises, the cylinder begins to increase in size (gas or liquid expands), it puts pressure on the rod, which increasingly blocks the flow area. Less and less coolant passes through the radiator, and it gradually cools down. The substance in the bellows also cools down, due to which the cylinder decreases in size, the rod rises, more coolant passes through the radiator, and it begins to warm up a little. Then the cycle repeats.

Gas or liquid

With such a device, the room temperature is fairly maintained at exactly +- 1°C, but in general the delta depends on how inert the substance in the bellows is. It can be filled with some kind of gas or liquid. Gases react faster to temperature changes, but are technologically more difficult to produce.

Design and principle of operation

Ball valve

Its bolt is a chrome plated brass ball with a high quality surface finish. To reduce friction when turning the shutter and to seal its connection with the body, a pair of saddles is used - rings made of heat-resistant plastic with a low coefficient of friction. The rod is equipped with a handle and sealed with a ring made of the same plastic or heat-resistant rubber.

This is how a ball valve works.

Throttle

A control valve for radiators is, in essence, a type of screw valve: a threaded rod, when screwed in, gradually closes the hole in the seat. The device dictates the requirements for installing the throttle: the coolant must flow to the seat from below; the direction of its movement is indicated by an arrow on the body.

The radiator angle valve is used to throttle the supply line.

Useful: chokes can be used both for adjusting heat transfer depending on weather conditions, and for one-time balancing of heating devices (for example, in two-pipe heating systems, where in order to uniformly heat the radiators, the passage of the connections of the devices closest to the boiler must be artificially limited).

Thermostatic valve

This is a type of throttle whose design involves changing the working position of the rod with an additional device - a thermal head.

Thermal head

The device works in conjunction with a thermostatic valve.

There are two types of thermostatic heads on sale:

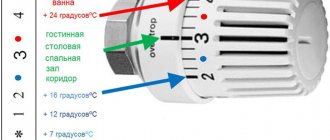

- Bellows uses an extension of a bellows filled with a liquid or gas with a high coefficient of thermal expansion to change the position of the rod. The low price (from 400 rubles) is accompanied by limited functionality: a thermal head of this type is only capable of maintaining the set temperature around the clock. To make adjustments, use a scale with the degree of air heating indicated on it.

Bellows head in section.

- An electronic thermal head for temperature monitoring uses a thermocouple - conductors connected in series from two different metals; When there is a temperature difference between sections of such a circuit, a weak current arises. The signal from the thermocouple is processed by a microcontroller and used to control a miniature servo drive.

A small operating current (no more than 100 mA) allows you to use a pair of AA batteries as power sources.

The cost of an electronic thermal head varies from 2 to 4 thousand rubles. The device allows you to program daily and weekly operating cycles.

Programmable electronic thermal head.

Please note: when installing it yourself, the thermal head is installed in such a way that it is located outside the upward flow from the radiator or liner. The instruction, as you might guess, is due to the fact that additional heating will disrupt its calibration and force it to maintain a lower temperature in the room.

Mayevsky crane

This needle butterfly valve is typically made of brass (sometimes with plastic parts). When the stem is unscrewed, the air escapes along the threaded channel into a small hole on the side of the tap.

How to install correctly

They install a thermostat for a heating radiator at the inlet or outlet of the heating device - there is no difference, they work with equal success in both positions. How to choose a place to install?

According to the recommended installation height. There is such a clause in the technical specifications. Each device is configured at the factory - they are calibrated to control the temperature at a certain height and usually this is the upper radiator manifold. In this case, the heat regulator is installed at a height of 60-80 cm; it is convenient to adjust it manually if necessary.

Installation diagrams for heat regulators for radiators

If you have a bottom saddle connection (pipes fit only from the bottom), there are three options - look for a device that can be installed at the bottom, install a model with a remote sensor, or reconfigure the thermal head. The procedure is simple; the description must be in the passport. All you need is to have a thermometer and at certain moments turn the head in one direction, then in the other direction.

Installation is standard - on fum tape or linen winding with packaging paste

The installation process itself is standard. The valve has a thread. The appropriate fittings are selected for it or a matching thread is cut on the metal pipe.

One important point that those who want to install a thermostat for a heating radiator in apartment buildings should remember. If you have a single-pipe installation, they can only be installed if there is a bypass - a section of pipe that stands in front of the battery and connects the two pipes to each other.

If you have a similar wiring (there may not be a pipe on the right), a bypass is required. The thermostat should be installed immediately behind the radiator

Otherwise, you will regulate the entire riser, which your neighbors will definitely not like. For such a violation, a very substantial fine can be issued. Therefore, it is better to install a bypass (if not).

How to adjust (reconfigure)

All thermostats are factory adjusted. But their settings are standard and may not match your desired parameters. If you are not satisfied with something in the work - you want it to be warmer/colder, you can reconfigure the thermostat for the heating radiator. This must be done with the heating running. You will need a thermometer. You hang it at the point where you will control the state of the atmosphere.

- Close the doors, put the thermostat head in the extreme left position - completely open. The room temperature will begin to rise. When it becomes 5-6 degrees higher than what you want, turn the regulator all the way to the right.

- The radiator begins to cool down. When the temperature drops to a value that you consider comfortable, begin to slowly turn the knob to the right and listen. When you hear the coolant making noise and the radiator starting to warm up, stop. Remember what number is on the handle. It will need to be set to achieve the required temperature.

Adjusting the thermostat for a radiator is not difficult at all. And you can repeat this action several times, changing the settings.

At first glance, purchasing and installing taps for heating radiators is not difficult. But today there are so many different manufacturers and models on the market that an inexperienced buyer comes to a dead end, not knowing which faucet is best to choose. Therefore, before such a purchase, a person needs to ask a specialist for advice or at least listen to general recommendations.

Functions of taps

Any element of the heating system must be periodically adjusted, as well as preventative maintenance. This also applies to radiator taps. If you use them to control the room temperature and coolant flow, you can save on bills.

They also have the following features:

- reducing the volume contained in the coolant system;

- taps release air from the network;

- disconnecting the battery from the system as a whole;

- change in coolant flow.

In some cases, valves for a heating system are simply irreplaceable. For example, with centralized heating in early spring, the heating may not be turned off yet, so the rooms may be very hot due to the increase in temperature outside. In the absence of such a valve, it will not be possible to perform any actions.

Reducing the amount of coolant using taps is carried out to regulate the temperature in each room. It does not matter what heating system is used. The first radiators will always receive more heat than the last ones in the chain. Therefore, by reducing the liquid level in the initial batteries, the temperature can be equalized.

Automatic valves allow you to save even more. If each of them is set to a certain air temperature in the room, then the energy will be used only in the right amount. This allows you to reduce your billing costs by up to 30% or more.

To release air from the system, special valves are used - air valves. They are installed on modern radiators.

In this video you will learn which faucet to choose:

There are the following types of shut-off valves:

- Ball half-turn valves. They are usually made from brass or bronze. There are straight designs and those installed at an angle.

- Valves for balancing radiators. They are also made in straight and angular shapes.

- Valves with thermal heads.

- Air release valves. There are automatic and manual.

Sometimes three-way valves are installed for heating radiators, but such a solution is unjustified, since it will be quite expensive for the home owner.

Ball regulators

The simplest ball valves have only one function and can be in two positions - open and closed. It is impossible to regulate the amount of coolant in the system using such a device, but you can only completely shut off the battery. That is, it cannot be in a “half-closed” state. This option is ideal for centralized heating. In this case, there is still no need to balance the batteries, and there is no point in installing a thermostat, since the quality of the coolant is poor.

Why do you need shut-off and control valves when installing a battery?

In general, this category of devices includes not only faucets of various types, but also various dampers and valves. And the shut-off valves for heating radiators also include plugs that are installed on the holes in the side of the battery.

When installing the battery, it is advisable to use:

- a couple of ball valves - they will be useful to quickly stop the flow of coolant into the battery. For this purpose, a bypass is installed, and shut-off valves are installed on the supply and return pipes;

Bypass will increase the reliability of the heating system

- when connecting the radiator to the system, a special shut-off valve can be used, which provides the ability to quickly drain water.

Among the regulating devices, an automatic thermostat will be useful; it will allow you to change the heat transfer of each battery individually. Thanks to this, you can save on heating costs, and the house will be more comfortable.

Note!. The thermostat is connected to the radiator itself, followed by a shut-off valve, then a bypass tube. Only with this sequence will the system work normally.

Choosing the right model

Which faucet to choose for a private home is primarily influenced by the type of heating system and the required functionality. It may work automatically, or it may require manual adjustment.

The ability to change the temperature in the room depends on the operating principle of the taps, which can be divided into cone and valve taps.

Many people are interested in which taps for heating radiators are best to choose. First you need to pay attention to the quality of the materials. Steel and valves must be of high quality. The durability of the structure will depend on this.

Valves can be divided into several more types:

- Conical. The simplest type of structure. When the rod is moved mechanically by hand, the cross section also changes. The downside is that the gasket wears out quickly.

- Semi-automatic designs with heat regulator. The temperature will change using an automatic sensor. It monitors the coolant temperature and adjusts the cross-section accordingly. The required temperature value is set manually.

- Fully automatic. Here the sensor detects the air temperature in the room, transmits the readings to the control unit, which, in turn, regulates the cross-section of the rods in the batteries. But there are also fully automatic models that can respond not to air temperature, but to the heating level of the coolant.

When selecting elements of the heating system, it is necessary to pay attention to the throughput of the pipes. You should take into account the fact that taps reduce it, so pipes need to be selected with a larger diameter. You can also install a faucet with a larger flow capacity. This may also solve the problem.

Mixing devices

Warm water floor mixing unit

For optimal operation of the heat supply, heating control taps are installed. Their main difference from the models described above is the presence of an automatic water flow control unit. Such structures are most often installed in mixing units.

These types of fittings differ from standard taps in the presence of additional control elements, as well as the number of connected pipes. A standard three-way heating valve has three connecting pipes. Each of them performs its own functions:

To choose the optimal model, you should decide on its purpose, which can be of the following types:

- Organization of automatic control of fluid flow into the radiator or battery. A two-way heating valve is designed for this purpose;

- Installation of the mixing unit. Three-way heating valves are most often used for it.

To understand the operating principle of each of them, you must first understand the specifics of the design. It is this that determines the operational and technical characteristics of these heating components. For full operation of the three-way control valve, it is necessary to connect a thermometer to its control unit.

Two way heating valve

Design of a two-way valve

In essence, this is an ordinary needle valve, in which, instead of a mechanical valve, a block for automatically changing the position of the rod is installed. It is designed for tying heat supply batteries. To be able to respond to the degree of heating of the device, each radiator must be equipped with a heating control valve.

There is a division of models according to the type of control unit. The most common type of two-way heating valve is a thermostat. It has a control element that expands under the influence of temperature. During this process, the rod moves, thereby changing the throughput in this section of the pipe. Such structures are installed for heating radiators.

Thermostat design

However, there is not always a need for such taps for heating pipes. Depending on the required level of regulation, the following types of two-way heating components are distinguished:

- With mechanical control unit . It has markings corresponding to the degree of change in the nominal bore in the pipe. Convenient for manual heating control;

- Servo mechanism with the ability to connect to temperature sensors or a programmer . Such control valves for heating are characterized by maximum control automation.

When choosing, it is important to pay attention to the design of control drives. They can be two-position (open-closed) or with a smooth change in the position of the rod. It all depends on the purpose of the two-way valve for heat supply.

Similar control structures are installed in collectors to automatically regulate the coolant flow. They have proven themselves well in the presence of flow meters.

Three-way valve for heat supply

Operating principle of a three-way valve

One of the types of heat supply control valves are three-way designs. Their main difference from the models described above is the presence of an additional pipe.

To operate, a three-way valve is connected to the supply and return pipes. With the help of the control unit, the position of the damper is changed, thereby regulating the flow of cooled liquid into the supply pipe. This operating principle allows us to solve the following problems:

- Reducing the cost of heating the coolant . Temperature sensors connected to the control units of plastic taps for heat supply automatically change the heating operating mode depending on external factors;

- Stabilization of pressure in the system . In case of a large difference in the degree of expansion of water, the hydraulic resistance will increase. Installing a balancing valve in the heating system will solve this problem;

- Automatic regulation of thermal operating conditions of heating circuits depending on previously configured parameters.

The choice of device control units is completely similar to two-way valves for heating pipes. The only difference is in the shape of the flow control element. If in two-way models it is a rod, then in three-way models a special plate is used. Depending on its position, the quantitative ratio of hot and cold flows changes.

To complete the heating system, it is best to use copper models of mixing taps. But the best choice would be products made of stainless steel.

Reliable manufacturers

A high-quality faucet for a heating system is the key to its long-term operation. When choosing, you must also take into account the manufacturer of the device, since trusted brands will not risk their reputation and produce low-quality products.

First of all, you need to pay attention to the following brands:

- Oventrop (Italy).

- Danfos (Denmark).

- Luxor (Italy).

- Valtek (joint production of Russia and Italy).

Cheaper models are made of silumin. This alloy is quite brittle. For long-term operation of the heating system, it is better not to use these. Instead, quality products are made from brass, steel or bronze.

The world's largest faucet manufacturers use silicone gaskets instead of rubber ones. Silicone does not tend to crack, so such devices last a really long time. Rubber seals lose their elasticity at high temperatures and crumble over time.

Self-installation

How to install the faucet and what scheme to choose depends on the type of shut-off and control valve model.

In most cases, taps are installed as follows:

- With centralized single-pipe heating, two ball valves are installed: one on the inlet line, the second on the outlet line. This design makes it possible to leave the coolant in a separate battery when draining water from the system or when dismantling the radiator for cleaning and periodic maintenance.

- In a nuclear two-pipe system, a thermostat is placed on the input line, and a valve with balancing capability is installed on the output line. It will maintain normal pressure in the system.

- When using a nuclear one-pipe system, a thermostatic valve is placed on the inlet pipe, and a ball valve is placed on the outlet pipe.

Strapping scheme

As a rule, in modern heating systems, the battery connection diagram (piping) looks like this:

- A control valve is installed between the inlet pipe and the battery - this can be a manual valve or a valve with a thermostat.

- A ball valve is installed between the outlet pipe and the radiator.

- A bypass (jumper) is installed in front of the input and output shut-off valves , which allows the coolant to bypass the battery if necessary. The jumper is installed when connecting radiators in series.

As a rule, a ball valve is embedded in the middle of the jumper.

Advice! At the outlet, it is better to install shut-off valves with a drain fitting. This will make draining the battery easier.

Here, in fact, are all the instructions for connecting a heating battery.

Installation of heating elements

Ball elements can be in two positions - open and closed. If they are set to a half-open state, this may lead to damage to the device, as a result of which the faucet may begin to leak.

Before installing such a structure, you must make sure that the operating pressure and ambient temperature will correspond to the parameters of the valve. The tap indicates in which direction the liquid should flow through it. Thus, you need to install a faucet in the system.

Having understood all the parameters of devices for adjusting the temperature of the heating system, you can choose the ideal option that suits your specific needs. The choice is influenced by certain conditions, including financial capabilities and system requirements. If you absolutely need to regulate the air temperature automatically, then you can’t do without a thermostat. And all the additional investments in control valves will pay off, since they will save money in quite large quantities.

Why are cranes needed?

First of all, it should be said that people commonly call a faucet any device for controlling the flow of liquid that has a handle. Technically, it is more correct to call taps shut-off valves.

Moreover, the latter only allows you to completely shut off or open the coolant flow, but not to regulate its flow. Valves and valves are used for regulation.

As a rule, control valves are installed at the entrance to the radiator, which performs the following functions:

- Allows you to disconnect the battery, which may be necessary for various reasons.

- Allows you to shut off the coolant for washing the device or inspection.

- In manual or automatic mode, it regulates the flow of coolant and thereby the temperature of the radiator.

It should be taken into account that different types of fittings may have different functions. Below we will get acquainted with the features and design of all types of taps that are used in conjunction with radiators of the heating system.

Ball valve design diagram