The design of a chimney is complex and responsible.

The efficiency and safety of using the heater depends on correct execution. Not a single device that produces heat can operate normally without a pipe that removes smoke from the room. Smoke contains a huge amount of different gases containing fuel combustion products. The presence of smoke indoors is a sure sign of an erroneous design of the chimney system, which entails the risk of fire and poisoning by combustion products.

In this article we will tell you about backdraft in a chimney, how to prevent its occurrence, as well as how to set up a chimney draft stabilizer.

The principle of operation of the stabilizer

If the draft force in the system begins to exceed its optimal values, then a valve opens in the regulator, which reduces the pressure and thermal lift force due to the air coming from the room and mixing with the flue gases. The valve will remain open until the temperature drops and reaches the optimal level. Next, the valve will automatically close and the chimney system will continue to function properly.

This method of maintaining normal traction is simple and effective. Fuel in a stove or boiler will be burned evenly and consumed economically.

Installing a chimney draft stabilizer provides the following advantages:

- increasing the operational safety of the chimney system;

- reducing the amount of harmful substances released into the atmosphere;

- better air circulation when the valve is kept slightly open;

- the ability to operate on both forced and natural draft;

- uniform combustion of fuel in the boiler, which makes it impossible for the chimney to overheat;

- protection from strong gusts of wind;

- no burning smell in the room;

- increasing the service life of the smoke exhaust channel;

- preventing heat loss;

- possibility of installation in modern low-temperature boilers;

- ensuring fuel savings of 15-20%.

Physical phenomena in the chimney system

The stable operation of a heat source (boiler, stove, etc.) largely depends on the correct setting and adjustment of the combustion mode. One of the factors is sustainable traction. Combustion products (gases, water vapor, mechanical particles) from the combustion space exit through the chimney. The latter is a channel made of fireproof material (brick, stainless steel, ceramics).

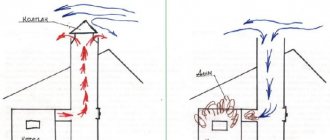

The chimney system can have different sizes, both in height and internal cross-section. It is quite difficult to make a high chimney (10-15 m) with the correct parameters. As a result, phenomena such as unstable mode or “reverse” thrust arise. In the latter case, the direction of movement of combustion products changes in the other direction, into the room. Reasons may include:

- narrowing of the internal channel due to soot, soot, and trapped debris;

- an increase in pressure at the outlet of the chimney during strong gusts of wind (the chimney “blows out”);

- seasonality of the climate, in which there are differences in atmospheric pressure and temperature in cold or warm times;

- the chimney was built in the “wind” shadow of another tall building or nearby trees.

This causes a change in the vacuum of the flue gases. On the other hand, the opposite phenomenon may be observed—increased emission. In this case, the sound in the pipe resembles the roar of a jet engine. By regulating the pressure inside the chimney, a uniform exit of combustion products from the boiler is achieved. For this purpose, a special device is used - a chimney draft stabilizer.

Advantages and disadvantages

Equipping a heat-generating unit with a draft regulator is considered the most effective way to ensure uniform combustion of fuel. This is the key to energy conservation and significant savings in fuel resources. Also, among the advantages of installing a pressure stabilizer in the chimney, the following points are noted:

- the efficiency and safety of the system as a whole is ensured, since the fuel burns evenly and overheating of the chimney is eliminated, which leads to an increase in its service life;

- The efficiency of heating equipment increases, the level of heat loss is leveled, energy savings are up to 15%;

- eliminates the possibility of smoke and fumes entering the room;

- The level of emissions of harmful compounds into the atmosphere is qualitatively reduced.

We are also impressed by the equally impressive capabilities of the chimney stabilizer both with natural draft and with forced draft.

It is noteworthy that the automatic draft force regulator allows you to connect new models of boilers of low-temperature categories to the old chimney system.

This is interesting: Butterflies on the wall in the interior of the apartment - we explain in detail

Operating principle

If draft increases in the chimney system, pressure rises. As soon as it reaches a certain level, the valve is activated. It opens the damper and draws more air from the room. It lowers the temperature inside the chimney, thereby reducing the pressure. As soon as the temperature and pressure drop to the required minimum, the valve closes and the air intake stops. This process allows the flame temperature to be kept within the required range so that the fuel burns at the required rate. There are several positive points that speak in favor of installing a traction stabilizer:

- greater system security;

- increase in service life;

- reduction of harmful emissions;

- less soot settling in the chimney;

- no sudden pressure changes.

Thanks to the traction stabilizer, there is better air circulation. This means that less combustion waste will settle on the walls of the chimney, which will reduce waste on cleaning it. With a stabilizer, you don’t have to worry that in windy weather there may be a sharp drop that will cause the flame to go in the opposite direction. There will no longer be a burning smell in the room where the heating boiler is installed. The temperature inside the chimney will be maintained within acceptable limits. This is important to prevent soot from igniting, which leads to severe fires. That is, the traction stabilizer guarantees additional safety of the entire system.

Design and purpose of the stabilizer

A draft stabilizer is an additional insert on the chimney with a damper, with which you can regulate the intensity of fuel combustion and the draft force in the pipe. A draft stabilizer is installed only on low-temperature heating equipment, where the maximum heating of the exhaust gases does not exceed 500 degrees.

The purpose of the traction stabilizer:

- reduce the rate of removal of furnace combustion products;

- prevent the formation of backdraft in the pipe and the emission of smoke into the room;

- extend the service life of the chimney by reducing the emission temperature;

- increase the fire safety of heating equipment by preventing the emission of sparks and flames from the pipe;

- reduce fuel consumption;

- increase the efficiency of the furnace.

The draft stabilizer is installed in three locations and only in the boiler room:

- The first option is above the furnace outlet pipe on the first vertical section of the pipe. The distance from the stabilizer to the horizontal section is 40-60 cm.

- The second option is at the level of the chimney exit from the stove, but not lower than 40 cm from the floor level.

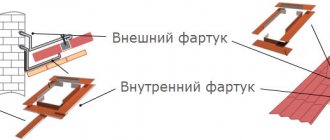

- The third option is shown in the diagram.

The smoke regulator is an additional entrance to the smoke exhaust pipe for air intake. The device is a horizontally oriented pipe, one end of which is closed by a vertical movable damper, and the other is built into the chimney. The damper must exactly coincide with the inner diameter of the pipe so that no air leaks occur in the closed position.

The damper is the main working part of the traction stabilizer. It can be attached to the body on a movable axis in the upper part, which is typical for factory devices. Homemade dampers are usually mounted on an axle through a diameter. To prevent it from tipping inward, clamps are placed at the bottom. The device is mounted on a vertical pipe, without tilting. On a finished sandwich pipe, it is convenient to do this through a regular tee.

Possible problems during installation and ways to eliminate them

- The pipe is not located vertically. Deviations are allowed up to 10 cm per 1 m of product. Ideally, the slope should not exceed 1 cm per 1 m of rolled metal element.

- The pipe does not fit into the smoke duct due to gaps. All gaps must be sealed with a clay-sand mortar or sealant that can withstand heating of the pipe up to 1000 degrees. To fill existing leaky areas, you can use soaked asbestos, heat-resistant sealant or asbestos cord.

When traction is not enough

Methods for determining thrust

If you do not have an anemometer, use one of the popular methods for determining chimney draft:

- Smoke. The most obvious sign of a lack of draft is the presence of a small amount of smoke indoors; a large amount of smoke indicates a high risk of fire and the risk of food poisoning.

- Flame color. By the color of the flame, you can understand the level of draft. If the flame inside the stove has a white tint and cracks when burning, then the draft is very powerful. An orange-red color indicates a lack of traction. If the chimney is made correctly, the flame should have an even golden color fading to yellow.

- With a match. You need to bring a lit match to the heater. If the flame deviates towards the stove, then there is draft. If it remains level, then you can be sure that there is traction, but of average magnitude. When the flame deviates in the opposite direction from the stove, a backdraft occurs in the chimney.

- With a mirror. Another way to check the draft force in the chimney is to place a small mirror against the stove. The occurrence of condensation on the surface of the mirror indicates that smoke removal is difficult.

Attention!

The difference in pressure outside and indoors is the basis for creating draft inside the chimney duct. The temperature in a heated room is higher than outside, and, consequently, the pressure it creates inside the room is greater. Hot air, supported by colder air from below, is squeezed into a zone with lower pressure, that is, into the atmosphere. When measurements are taken in summer, the temperature difference is least striking, therefore the draft will be worse and the measurement results may be low relative to the winter period.

Causes of malfunctions

Once you are sure that there is not enough draft inside the chimney, it is necessary to identify and correct the possible cause. Professionals say the most common causes of smoke duct failures are.

Error in design

To make a choice of chimney pipe, you need to focus on the volume of the firebox. If the size is smaller than the calculated parameter, then a weak chimney will not allow smoke to escape from the room.

Short pipe length

A pipe length of less than 5 m does not make a significant difference between indoor and outdoor pressure, which creates weak draft.

Incorrect placement of the chimney pipe

A master stove maker advises laying the chimney vertically, as tight corners keep smoke inside the chimney, reducing draft.

Long horizontal sections

If when laying the chimney it is not possible to avoid horizontal sections, make sure that their length does not exceed 100 cm, otherwise an amplifier will be needed for this.

Getting into the wind support zone

If there is a tall building near the house, it blocks the chimney from the wind, preventing the normal functioning of the chimney system.

Weather conditions

Often, a decrease in draft occurs due to a decrease in atmospheric pressure, moisture entering the chimney due to rain, fog or snow. But this is not critical, because all these are temporary phenomena.

Causes of malfunctions

After making sure that there is not a sufficient level of draft inside the chimney system, you need to determine and eliminate the possible cause of this defect. Experienced craftsmen claim that the most common causes of failures in smoke exhaust ducts are:

- Design error. The choice of chimney pipe should be made based on the volume of the firebox. If the diameter is less than the calculated parameter, the weak one will not allow smoke to escape from the room.

- Insufficient pipe length. A pipe length of less than 5 m does not provide a significant difference between the pressure indoors and outdoors, which results in weak draft.

- Incorrect placement of the chimney pipe. I advise stove technicians to lay the chimney vertically, as narrow turns trap smoke inside the chimney, reducing draft.

- Long horizontal sections. If, when laying a chimney, you cannot avoid horizontal sections, then make sure that their length is no more than 100 cm. Otherwise, it will need an amplifier.

- Incorrect position relative to the skate. Chimneys are located at the same level or above the roof ridge. A ridge in a windward position sharply reduces the draft force in the chimney.

- Getting into the wind pressure zone. If there is a tall structure next to the house, it blocks the chimney from the wind, preventing the chimney system from functioning normally.

- Weather. Sometimes draft decreases due to a decrease in atmospheric pressure, moisture entering the chimney due to rain, fog or snow. However, these changes are not scary, as they are temporary.

How to make a traction stabilizer with your own hands

To make a traction stabilizer with your own hands, you will need to prepare tools for working with stainless metal and material for making the regulator itself.

To work you will need:

- Welding machine for working with stainless steel. This can be a gas welding machine or an inverter device operating on direct current.

- Stainless steel electrodes diameter 4 or argon for gas welding.

- Grinder, cutting and grinding wheel.

Materials for the manufacture of traction stabilizer:

- Metal sheet made of steel grade AISI 304 (analogue 08Х18Н10) or AISI 321 (analogue 08Х18Н10Т). Metal thickness 10 mm.

- Bolts, nuts, metal rod with a diameter of 10 mm - all made of stainless, heat-resistant steel.

The installation diagram is as follows:

- It is necessary to weld a pipe from a sheet of metal - the regulator body. Calculate the diameter based on the diameter of your chimney. You will need to put the stabilizer on a tee or pipe extending from the main pipe. Therefore, the inner diameter of the stabilizer must match the outer diameter of the tee. Usually it is 115 mm, but it can be more.

- The metal for the body should be cut with the calculation of overlapping welding with a seam width of 1 cm.

- The cut sheet is rolled and welded. The seam is cleaned until smooth on the outside and inside.

- Roll a restrictive barrier at the end of the housing at a distance of 40 mm from the edge. It will serve as a stopper when installing the device on a pipe.

- At the other end of the body, weld stops in the lower part to prevent the damper from tipping inward. At the top or in the middle (depending on the shape of the damper), fastenings for the rotary axis are welded.

- A damper is cut out of metal. Its size is equal to the internal diameter of the outlet of your case, or matches the contours of the outlet if you decide to make it smaller.

- A hole is drilled at the bottom of the damper for the adjusting bolt.

- A rotating axis is welded in the middle (for a symmetrical damper) or in the upper part (for an expanding form).

- Install the damper on the body.

- Install the draft stabilizer on the pipe.

When installing the stabilizer on a pipe, coat the contact points of the pipes with heat-resistant sealant. This will make the connection stronger and more airtight.

Purpose and scope of application

The functionality of the chimney determines such parameters as the quality of room heating, the level of correct energy consumption, and the safety of operation of heat-generating equipment. It is necessary to constantly monitor the draft force in the smoke exhaust duct, since:

- in the absence of draft or weak flow, it is problematic to light a fire,

- backflow of combustion products is fraught with consequences hazardous to health,

- When the intensity of outgoing flows is critical, the level of heat loss increases significantly.

The main reasons for thrust variability are determined by the following factors:

- Fluctuations in atmospheric temperatures. In hot weather, the stream in the chimney overturns and the flows move in the opposite direction. When the outside air is cold, the outflow of gases increases.

- Changes in air pressure. Changing atmospheric pressure parameters affects the intensity of the jet in the gas outlet channel.

- Chimney height parameters. The amount of vacuum at the top point of the smoke exhaust duct depends on the height of the pipe. The more significant this parameter, the stronger the thrust.

- Features of the smoke exhaust duct device. The length, the presence of bends, the roughness of the inner surface, the presence of foreign objects and deposits on the walls cause deterioration in traction.

Equipping the exhaust duct with an automatic regulator allows you to neutralize all the above-mentioned risks and improve the potential of a heat-generating device of any model, including condensing-type devices. Draft stabilizers are widely used in individual heating systems in Moscow and other regions.

Industrial traction stabilizer

Draft Control Models

Today on the market there is a wide variety of models of chimney draft regulators produced by various manufacturers.

Let's look at the most popular and in demand:

- RCO. Models in this series are fixed using crimp clamps and only to a round pipe. They found their application for chimneys with a circular cross-section along the axis of the pipe. The chimney draft stabilizer is installed at the very end of the pipe. Considering the fact that modern chimneys usually have rounded pipes, such regulators have gained wide popularity. Such devices are the easiest to install.

- RCR. This stabilizer is installed directly on the chimney and is secured using special clamps with the possibility of regulation in the range of 120-200 mm and is installed at the boiler outlet. The harsh domestic climate requires the use of such regulators for chimney pipes made of ceramics, steel and asbestos. Chimneys with a draft regulator in the range of 10-35 Pa cannot boast of high quality, however, if necessary, they can be installed.

RCR series chimney draft regulator with adjustable clamp

RCP. With draft regulator in the range of 10-35 Pa. Installation of such a device is carried out by applying and fixing the regulator to a flat surface. The chimney draft regulator is equipped with hidden holes in each corner for mounting.

Chimney draft regulator RCP series for surface mounting

R.C.W. This regulator with a draft regulation range of 10-32 Pa has proven itself as a good draft regulator in stoves, boilers, and fireplaces. Stainless steel is used to make the case, thanks to this you can fix the device with glue or a special solution. You can also use expansion springs and secure it to the ventilation grille.

RCW series chimney draft regulator for brick chimneys

To summarize all of the above, it is worth noting once again that the chimney draft regulator is a very important element of the heating unit, which directly affects the functioning of the entire heating system.

Installation nuances

There are two main ways to install a traction stabilizer. One of them involves placing a stabilizer at the level where the boiler and chimney are connected. It is worth remembering that it must be at least 40 cm above the ground. In the second case, the stabilizer is placed 50 above the place where the boiler is connected to the chimney. There is another option for a traction breaker. It is made in the form of a fungus and can be mounted on gas boilers. The drawings can be viewed below. It is also mounted in the chimney pipe. Part of it has a slight expansion in the form of a fungus. It is under it that there are channels for the flow of air from the room. It performs the same functions as described for the stabilizer above.

Since the factory stabilizer operates in automatic mode, it requires a special sensor that will monitor changes in parameters. It records the temperature of the emitted gases. If it rises and gases accumulate, the sensor transmits a signal to the boiler automation, which automatically stops the gas supply and combustion stops. The principle of its operation is shown in the illustration below.

Ways to increase chimney draft

The purpose of the draft regulator is to extinguish excessive vacuum in the chimney. The stabilizer cannot increase traction. What to do when traction is clearly insufficient?

To increase traction, do the following:

- They check whether the chimney duct is clogged with soot and clean it.

- Check whether there is air access into the room or an air supply from the street to the furnace of the heating unit. If necessary, open a window or install a pipe to take in clean air from the street.

- They analyze whether the pipe is sufficiently insulated and whether the insulation is wet. In the case of modern ceramic or sandwich pipes, the insulation can be considered sufficient; when insulating steel pipes with your own hands, unpleasant surprises are possible. It is also advisable to insulate traditional brick pipes.

- Find out if there is a deflector on the top of the pipe. Often installing a deflector solves the problem.

If all your searches have not led to a solution to the problem, you should invite an experienced heating engineer - family safety comes first.

If you have changed the heating unit to a more modern one (or moved the stove or fireplace), then you must:

- Calculate the minimum length and cross-sectional area of the hog depending on the power of the heating device (see my article about calculating the chimney).

- Consider the required height of the pipe depending on the location relative to the ridge and the zone of wind support of tall buildings and large trees.

- If the chimney is of insufficient height and cross-sectional area, then either build it up or install a smoke exhauster - a special fan. It is installed on the head of the pipe.

- If the old pipe has a cross-section much larger than the design one, this problem can be eliminated by using a gate valve or installing a liner. If the pipe is too long, you can also use a gate.

When replacing an old stove or fireplace with a modern boiler, the pipe will most likely have to be upgraded, since modern boilers have high efficiency, aggressive condensate and low flue gas temperatures. Even modern solid fuel units have a lower smoke point than older wood stoves.

Control and measurement of air vacuum in the chimney

A common way to check whether a chimney is functioning is to place a lit match or lighter near the chimney channel. Sometimes they use a piece of toilet paper and a smoking cigarette instead.

If the flame or smoke is directed into the chimney, there is a vacuum in the air. If the flame is completely motionless, then this means that there is no draft.

Too strong a draft can even extinguish a burning match.

If the light or smoke is directed away from the channel, that is, into the house, it is recognized that there is a rarefaction of air, but it is broken. This phenomenon is called overturned draft, which negatively affects the operation of the heating system.

The normal flow of gases when the thrust is turned over is disrupted

Thrust calculation

Since draft is created due to pressure difference, it is calculated using the formula ∆P = C∙a∙h (1/T0 - 1/Ti), where ∆P is the pressure difference in Pa, a is atmospheric pressure in Pa, h is the height of the pipe in meters, T0 is the absolute external temperature in K, and Ti is the absolute internal temperature in K. C is a coefficient that is taken equal to 0.0342 in calculations.

Depending on the obtained ΔP value, the following air rarefaction levels are distinguished:

- less than 2 Pa - 1st, 2nd or 3rd;

- exactly 2 Pa - 4th;

- more than 2 Pa - 5th or 6th.

There is no point in trying to find out on your own what the traction force is. It is better to use heating equipment in such a way that there is no need to check using formulas and instruments.

Construction of a chimney

When building a chimney with your own hands without special skills and consultation with specialists, its operation may be accompanied by such negative phenomena as draft rupture, excessive draft, and a number of other problems. That is why, when wondering how to properly make a chimney for a gas boiler, or to make a chimney for a gas boiler in a private house with your own hands, you must first contact the appropriate services, where a diagram or design will be made. It will indicate the location where the geyser can be located, what the outlet pipe should be like, whether deflectors should be installed, and what requirements the ventilation duct should meet.

Chimney device

When wondering how to make a chimney for a gas boiler, do not forget that the chimney of a gas water heater must have a draft that supports the normal process of constant combustion. Otherwise, if the draft is insufficient, this may lead to flame extinction and a subsequent explosion of household gas.

Therefore, during construction, you need to pay attention to the chimney pipe, which must have dimensions that comply with the instructions of specialists