Here you will learn:

- What does draft in a chimney depend on?

- How to identify reverse draft

- Causes of reverse thrust

- Eliminating backdraft

- Regular chimney cleaning

- Temporary backdraft

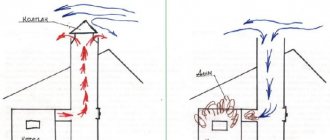

During normal operation of the smoke exhaust system, gas generated as a result of fuel combustion is discharged outside. If the operating mode is incorrect, you may observe the opposite situation. The smoke does not go straight up through the pipeline, as it should, but down, it does not go out into the street, instead it pours into the house - that’s what reverse draft is. And it is not just an unpleasant, but a truly dangerous phenomenon, which, if neglected, leads to a fire hazard in the house, or even to severe carbon monoxide poisoning.

What does draft in a chimney depend on?

The amount of thrust depends on a very large number of factors.

Main Factors

The main factors influencing the movement of waste gases:

- pipe height;

- dimensions of the chimney duct;

- design features (presence of horizontal or inclined sections) location of the pipe head relative to the roof ridge;

- the presence of a flow of fresh air into the room with a boiler or fireplace;

- insulation of chimney walls.

Supporting factors

There are also less important, but also significant factors for increasing or decreasing the flow of flue gases:

- presence of a deflector;

- the channel must be sealed - this is especially important when installing modern chimneys from ready-made elements;

- smoothness or roughness of the internal walls of the chimney;

- soot deposits in the smoke channel;

- mechanical obstacles - closed dampers (dampers), freezing of condensate or ice on the spark arrester or the upper part of the chimney, blocking the cross-section of the channel;

- high ambient temperature (summer);

- strong wind, fog, rain, snow.

How to identify reverse draft

To denote the reverse movement of air flows (not through the chimney, but back into the room), there is a term - overturning the draft. The name speaks for itself: the flow of gases from burning fuel tends back into the room, and not out. There are many videos about this on the Internet with detailed descriptions.

Before each start of heating devices, it is recommended to determine the strength and direction of draft with the ventilation devices turned off (if any are installed).

Traditional methods

- We’ll talk about the factors and reasons below, but now let’s figure out what needs to be done in order to identify the very fact of the thrust overturning:

- if the firebox has a glass door (for example, such an element is found quite often in fireplaces), you can clearly see through the glass how quickly it smokes. One has only to open the door slightly, and a cloud of smoke immediately rushes out, that is, into the room;

- It is enough to attach a sheet of thin paper to the opening of the open firebox and see in which direction it deviates. A smoking cigarette instead of a piece of paper will show the same thing.

Professional methods

There is measuring equipment that allows you to measure the draft in the chimney with maximum accuracy, in pressure units. Indicators within 10-20 Pa are considered normal.

- Measurements are made using a two-way method:

- at the top of the chimney;

- at its base.

However, this technique is hardly relevant for a private home - most people make do with traditional visual methods.

The anemometer does not provide objective information at wind speeds below 1 m/sec. That is, in calm weather there is no point in using such a device.

Visual cues

- If the ratio of combustion and draft processes is normal, then:

- the flame is yellow with a golden tint;

- smoke appears and immediately evaporates into the chimney channel - without jerking, smoothly and at the same time energetically.

A situation where the normal thrust is too high is not good, because the fuel will burn out too quickly. Excessive draft will be indicated by the white color of the flame and the roar in the chimney.

Prevention and testing methods

Before the onset of the heating season, it is imperative to check whether there is air movement in the chimney duct. There are special devices for checking. For example, an anemometer. It allows you to measure flow speed extremely accurately, but this technique costs money. The absence of wind on the street or its speed of less than 1 m/s in itself explains why there is no draft in the chimney.

There are also old proven methods for checking. A lit match should be brought to the firebox and observed where the flame is directed. If it is towards the stove, then this indicates good draft. The fire does not fluctuate - there is no air movement in the chimney. A flame directed in the opposite direction from the firebox is quite obvious evidence of backflow.

The same thing can be seen with a piece of paper . If you attach it to the open opening of the firebox, you will see where it deviates.

How dynamically the air moves and what its direction is can be judged by the color of the flame. If everything is normal, then the fire has a golden color, and the emerging smoke immediately evaporates into the chimney. With very strong draft, the color is dazzling white, and a hum is heard in the pipe. Red indicates problems in the chimney or pipe.

Causes of reverse thrust

Thanks to the pressure difference, the smoke from the stove comes out through the pipe and does not harm people in the room. It was with stoves that people heated their homes for centuries. Backdraft is dangerous because the room will be filled with smoke, which can lead to carbon monoxide poisoning. In addition, sparks flying out along with the smoke can ignite flammable objects located near the stove.

Nowadays, stove heating of houses is becoming a thing of the past. In private homes where there is no central heating, gas heating systems are installed. But backdraft problems in the chimney of a gas boiler can also arise.

In order to create a pressure difference to remove smoke from the combustion of wood, pipes and chimneys are created, but they do not always cope with their functions. The reasons for this can be simple or complex.

Bad weather is one of the reasons for backdraft

Simple causes of backdraft in a chimney are:

- the presence of cold air in the chimney (when the stove has not been heated for a long time, it is cold outside);

- pipe clogging;

- rarefied indoor air;

- unfavorable weather.

Dealing with these problems is relatively simple. If the stove has not been lit for a long time, then when the fire is lit, the room may fill with smoke. But as soon as the heating device heats up, normal smoke removal resumes. A clogged pipe is also quite easy to clean.

It’s worse when the causes of backdraft in the furnace are complex:

- the cross-sectional area of the chimney is disproportionate to the size of the stove;

- incorrect location of the chimney (pipe);

- pipes shorter than 5 m or below the roof ridge;

- bottlenecks in the chimney (pipe);

- the presence of tall trees or buildings near the house.

In this video you will learn about chimney draft:

Any of these reasons for poor draft in the chimney will require disassembling and reworking the heating device. But in order to get rid of this dangerous phenomenon, first of all, it is necessary to identify why the smoke cannot be removed normally.

More complex situations

Coping with the complex causes of air backflow in a furnace is much more difficult. It is possible to correct an incorrectly designed chimney, but only by rebuilding it completely, so it is very important to entrust the design to specialists. It is best that the chimney or pipe be installed strictly vertically.

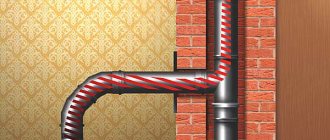

Along a vertical straight pipe, without encountering any obstacles along the way, the smoke will move upward quite dynamically and escape into the atmosphere. Bends, corners, inclined or horizontal sections in the chimney will make it difficult and slow down the outflow. In addition, soot will accumulate in the corners much faster, and this will also contribute to the fact that traction may one day disappear.

The material from which the chimney is made is very important. It is best to use ceramics and bricks. The height of the pipe also matters, which cannot be less than 5 meters. Its inner surface should be smooth. Today there are various devices that can eliminate backdraft. These include :

- chimney deflectors;

- fans;

- smoke exhausters for chimneys;

- rotary turbines;

- chimney weather vanes.

The purpose of using these devices is to increase traction by creating additional air flows. The disadvantage is that in the absence of wind, all these devices are ineffective.

Eliminating backdraft

In some cases, when there is backdraft in the chimney, you can eliminate it yourself.

- This applies to cleaning the chimney from soot and removing foreign objects. You will need a brush and a weight with a cable.

- If there is not enough air, you need to open the window for 10 minutes for ventilation.

- Chimneys in an external wall or external ones need insulation.

- Sometimes in damp weather or after a long break in the operation of the heating device, it is enough to burn a piece of newspaper in the firebox to restore draft.

A good way to eliminate the possibility of reverse thrust is to use various devices. These can be slide valves, deflectors (pictured), chimney weather vanes, smoke fans.

The deflector is always available for sale. The price ranges from 550 to 3800 rubles. The manufacturer provides instructions for use.

Safe and efficient operation of heating units is possible if there is draft in the chimney. At the first sign of backdraft, you need to check the chimney and ventilation ducts. The entry of combustion products into a home is hazardous to health and can threaten people's lives.

Stabilizing devices

During the existence of heating, many devices have been invented that improve the flow of gases in the chimney (see photo):

- rotary turbines - consists of a nozzle and a housing mounted on the head of the chimney. Under the influence of wind, the nozzle rotates and creates an increase in the flow of exhaust gases due to the created dilution;

- electric smoke extractor or smoke fan. With forced draft, you don’t have to worry about tipping over - this is an almost ideal smoke outflow regulator, however, servicing the device on the roof is quite difficult, and the installation of such a structure should be calculated at the drawing stage;

- all kinds of caps can also slightly improve the outflow;

- chimney weather vanes, often installed on wood-burning stoves.

Gate manipulation

Gate is a damper that influences the force and direction of thrust. Typically, during the construction of a stove or fireplace, two dampers are installed. One is located in the chimney, the second is in the stove or in its door. “Play” with the position of these dampers, often this increases traction, and the problem is solved on its own.

Advice! If there is no draft, pay attention to the gate valve. Perhaps it is blocking the chimney, which is why the smoke cannot escape outside and returns back into the room

Using a traction regulator (stabilizer)

This is a special device that creates air flows in the chimney and controls their strength. It stabilizes draft and, among other things, helps save fuel, and also prevents combustion products from entering the room.

Ventilation system

A situation often arises when everything is fine with the chimney, but backdraft still appears in the chimney, what to do then? What is the reason? Most likely, the problem is in the ventilation system, which works according to certain natural patterns.

The density of warm air currents is significantly lower than cold masses, so warm air rushes upward. If at this time the doors or windows are open in the room, then the air masses will be directed precisely into the open openings, and not into the chimney of the heating device. Therefore, you need to make sure that when you turn on the device, all doors and windows to the street are closed.

The internal architecture of the structure also has a huge impact on traction. If there are many doors or windows in a building, or there is a passage to a balcony or stairs to another level, then a draft will certainly arise. Therefore, windows and doors located above the level of the combustion chamber should not be kept open.

A situation often occurs when all the openings are locked, but when the heating device is lit, low-pressure zones attract fresh air flows from the chimney, and as a result, the draft overturns. The problem can be solved by creating the necessary air circulation.

To do this you need:

- install in-wall supply valves;

- equip windows with inlet valves;

- install a forced ventilation device in the window glass;

- open the door, window or vent a little.

The implementation of one of the proposed measures will lead to a decrease in atmospheric pressure in the room and, accordingly, the disappearance of reverse draft.

If a gas water heater is used as a heating device, then there are some nuances:

- the combustion chamber draws air currents from the room;

- oxygen deficiency begins to be felt quite soon;

- air from the chimney will begin to flow back, which will lead to the extinction of the flame and smoke.

In this case, it is worth carefully checking the efficiency of the ventilation system.

The column turns off after a short period of operation.

Most likely the traction sensor has tripped. Check the chimney draft by holding a lit candle.

With good traction (photo above), the spark plug should go out. If the candle does not even deviate towards the chimney, you need to clean it. In addition, check the sealing of the pipes; if there are gaps between the elbows, seal them. This does not apply to the 23-6L model, since it has low power and does not require the installation of a chimney; an open vent or window is sufficient for its operation.

The shutdown factor may be the overheating protection triggered if the output temperature is more than 77 degrees. You need to close the hot water valve, the column will turn off, lower the temperature using the control knobs - reduce the gas pressure, or turn the hot water valve off more. You can turn it on after 1-2 minutes.

The second most frequent occurrence may be a violation of the integrity of the membrane of the water unit; it may tear or become deformed - replace it.

A shutdown can also be caused by a broken flame sensor contact, or by the fact that the sensor electrode comes into contact with burner parts or does not reach the flame. It is necessary to restore contact with the sensor and adjust the position of the electrode.

The temperature reading does not appear on the display. Can be

Regular chimney cleaning

In order to prevent the occurrence of back draft during the heating season, it is necessary to constantly check the cleanliness of the chimney channels before using the stove. The main causes of blockages can be large deposits of soot, peeling of plaster from the inner surface of the chimney walls, and birds accidentally flying into the channel.

To check the cleanliness, you just need to look into the chimney through a special cleaning hatch using a mirror, or just look into the chimney from the roof. If any contamination is found, it must be removed using a special brush or special chemicals, which are commercially available in all specialized stores.

In order to ensure that chimney cleaning is carried out as rarely as possible, it would be best to adopt one of the preventive methods that were passed down to us from our great-grandfathers.

One of these methods involves burning aluminum cans in the furnace every 10-12 fires. It should be noted that the temperature in the oven should be such that the jars burn completely within 5 minutes. In addition, if there is a large amount of soot in the chimney, it is recommended to burn half a bucket of peeled and chopped potatoes in the firebox during combustion.

The starch that will be released during combustion will soften soot deposits, causing it to fall off the walls. From time to time, you can throw rock salt into the combustion chamber, which also allows you to increase the period between cleanings.

Remember: the thrust should not reverse! Otherwise, serious consequences are possible!

If a severe rollover occurs, there is not only the risk of smoke in the building, but also a high probability of generating sparks that can lead to a fire. The presence of reverse draft in the chimney is extremely dangerous not only for the normal functioning of heating equipment, but also for human health. Therefore, if there is a tipover, it is strictly forbidden to use the heating device until the problem is eliminated.

Conclusion

The widespread use of stove heating in our country is explained by the low cost of fuel material and the emergence of efficient equipment with an efficiency of up to 20%. Comparing solid fuel stoves with gas heating equipment, we can conclude that there is no need to build expensive gas pipelines to a house in the village.

If we take into account the costs of obtaining technical conditions for connection, design work and attracting the gas industry trust for construction work, then the tractor driver’s salary is not enough even for a gas meter. And how many problems there are with bureaucrats when coordinating the entire project. Until prices level out, the potbelly stove will be used for heating.

Temporary backdraft

In some cases, backdraft is not a permanent phenomenon, but rather a temporary one. Restoring the normal process will take very little time. Often the main reason is cooling of the stove and chimney. The fact is that during this period of time, cold air accumulates in the cavity of the firebox, which is heavier than heated air, and it is this that interferes with normal draft. As a rule, smoke can completely fill a room in a short time. In such cases, a draft stabilizer installed in the chimney cavity will help get out of this situation.