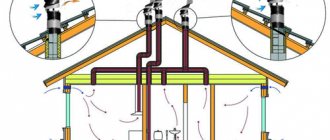

Ventilation device

Now let's look at the general information that is typical for each ventilation system of a private house:

- For natural ventilation systems, it is best to use plastic pipes with a perfectly smooth inner surface. Installation of corrugated pipes is permitted only if supply and exhaust ventilation is planned.

- The fewer bends and curves in the pipeline, the more efficient the system will be.

- It is recommended that all pipelines be laid as short as possible from inlet to outlet.

- If you are building natural ventilation, you need to make exhaust pipes more than 5 meters high. Otherwise the project will be very low. If you cannot provide this height, install fans in the exhaust ducts on the upper floors.

- When forced ventilation, the power of the impellers should be selected so that the amount of supply air is slightly less than the amount of exhaust air. In this case, the pressure in the system will be reduced, which will have a positive effect on the overall indoor climate, as well as on the condition of all building structures.

- With natural circulation, air can be taken from the street or from the basement.

- The optimal amount of air for a room of 40 square meters is about 120 cubic meters per hour.

- Inflow can be carried out in two ways - infiltration, through slot holes and window ventilation, as well as controlled, which occurs through fans installed in pipes and climate control systems.

- Exhaust ducts should be located at a distance of 25 cm from the ceiling.

Advantages of our company

The Vent Center online store has the following advantages:

- a wide range of ventilation equipment from the best Russian and foreign manufacturers;

- rapid production of reinforcing parts with original characteristics (bends, umbrellas, gates, pipes, etc.);

- affordable prices for products of the highest quality;

- fast delivery to any region of the Russian Federation, as well as pickup from a stationary store in Moscow;

- cumulative system of discounts for regular customers and wholesale customers.

Place an order at Vent Center and the result will exceed all your expectations!

Ventilation duct design

Exhaust ventilation in a private house is represented by channels in the wall, the cross-section of which must be at least 38 cm. The entrances are located under the ceiling slab.

The most effective location for such a pipe is considered to be a wall built in the central part of the house. From here it will be easiest to make electrical wiring to all rooms of the house using ordinary plastic pipes with a cross section of 10-12 cm.

It is advisable to have a minimum number of horizontal branches from the main pipe. The more branches, the less draft and weaker air flow. All branches enter into one common pipe and exit through it to the outside.

Remember that the chimney must be lined with at least double brickwork so that in winter it does not freeze at low temperatures and does not cause cooling in a private house with cold air entering the rooms.

The height of the main pipe is calculated according to the rule just above the ridge, otherwise the traction will be impaired. To calculate the correct exit height, draw a straight line from the ridge to the pipe at an angle of 10 degrees, and the latter should not be lower than the drawn straight line.

How to hide an air duct in the kitchen

Plastic channels fit more organically into the design of the room than metal ones. But even they can ruin the look of the kitchen, so most owners prefer to hide this element. There are several ways of such disguise.

- Air duct pipes are hidden under multi-level, suspended or suspended ceilings. For this, a special box is made from drywall, which hides almost the entire system. But this method is only suitable if a major renovation of the kitchen is underway, including replacing the ceiling. If the hood is installed after finishing, then it is unlikely to be hidden under the ceiling covering.

- To mask the pipe air duct, you can purchase or make a special box from PVC or gypsum board. This decorative element can be easily selected or designed to match the finish. In addition, additional lamps can be embedded into the box.

- If you purchase custom-made furniture for the kitchen, you can place the hood in it. To do this, just inform the furniture installation specialist about your desire. The air duct can be permanently built into kitchen cabinets or made in a retractable version. LEROY MERLIN sells ready-made kitchen cabinets for installation above the hood (the choice is huge - about 1,500 varieties). You can select a cabinet above the hood by following the link>>>

- Finally, you can simply paint the duct pipe. If you show your imagination, you can get a completely original decoration for the kitchen.

To ensure that all kitchen ventilation elements are the same color, it is recommended to purchase ready-made kits. Some manufacturers sell their products according to the following scheme: hood + air duct + additional element = effective ventilation in the kitchen.

Particular attention should be paid to the quality of materials. Remember that hoods made from low-grade raw materials or in violation of production technology will last no more than 5 years. At the same time, PVC products from trusted manufacturers are designed for at least 30 years of operation.

Step-by-step instructions for installing a plastic exhaust duct are in the video below. Ask questions about selection and installation in the comments.

Building regulations for ventilation systems

Construction work with the installation of ventilation systems is strictly regulated. For example, for a room with an area of 20 square meters, the performance of the ventilation system should be equal to 3 cubic meters per hour per square meter. For larger rooms, capacity should be calculated at 30 cubic meters per hour per person.

In water supply and kitchen risers, it is necessary to provide an air flow of 110 cubic meters per hour for electric ovens and 140 cubic meters for gas appliances. With a forced ventilation system, these parameters increase.

The ventilation duct installed from the sewer pipe must have a certain diameter, and the standards for all products, fittings and connections used in the work are calculated in detail. Standard values are 20, 15, 12.5 and 10 centimeters. There are individual options for ventilation systems that use elements of other sizes. The diameter of the fittings used in the installation of sewer pipes made of polyvinyl chloride is 20, 16 and 11 centimeters.

Consider that there is a problem with the connection of air exchangers to sewer pipes. The big drawback is the lack of adapters that can solve this problem. It is possible to organize natural ventilation from sewer pipes. But provided that it is a forced type, the process of replacing plastic sewer lines is complicated.

Key elements

The ventilation system for residential and industrial premises will necessarily include the following elements:

- Air ducts. When choosing them, it is important to choose the cross-section and size correctly. A simple profile pipe can be used as this element in an exhaust ventilation system, which is quite easy to install and at the same time has an affordable market price. Rectangular air ducts with a section of 60x120 millimeters or a section of 60x240 millimeters are also in demand.

- Connecting elements, the size of which corresponds to the dimensions of the air ducts. But transition elements can also be used; the need for their use arises in situations where it is necessary to make a high-quality connection of two pipes of different sizes.

- Turns. They are used when you need to change the direction of air ducts and transfer it to another plane.

- Tees are used to equip branches in the air duct system.

Also, when creating a ventilation system, you will also need fastening elements that will allow you to obtain a high-quality connection of all elements of the system and ensure its high reliability, safety and durability. In addition, when installing systems, various auxiliary elements can be used, which are selected based on the type of ventilation and the equipment that will be part of it.

Features of ventilation pipes

The first and main feature of ventilation ducts is that they are designed to conduct air flow. Therefore, all ventilation pipes are made of environmentally friendly materials that in no way affect the air passing through the pipe. On the contrary, sewer pipes are not designed to carry air masses, so this aspect of the manufacturers absolutely cannot be taken into account in the production process.

In any case, for various types of domestic and utility premises - for example, a garage, ventilation from sewer pipes is an excellent and inexpensive solution.

Sewer pipes: pros and cons

There is still no consensus on the advisability of using sewer pipes to install a ventilation system.

Many experts demonstrate the rationality of this decision, while others equally convincingly criticize it. The fact is that plastic, like any other material, has a number of advantages and disadvantages.

Positive aspects of using plastic ductwork in ventilation construction include:

- All plastic pipes (polyvinyl chloride, polyethylene, polypropylene, etc.) are lightweight and durable.

- The ventilation system will have sufficient tightness and strength.

- Plastic products are relatively inexpensive and, unlike metal, are not subject to corrosion.

- Thanks to the variety of shapes and sizes of elements, it is easy to build channels of any configuration.

- The low weight of the products simplifies and reduces the cost of installing air ducts.

Among the disadvantages are the following:

- According to some experts, some harmful substances released by polymers will leak into the room along with the air, so even if manufacturers swear by the excellent environmental friendliness of such pipes, it is better to use plastic only for air extraction.

- Plastic pipes do not have a large margin of safety and are subject to mechanical stress.

- The movement of air masses through plastic pipes inevitably causes friction, which leads to the accumulation of electrostatic charges on the inner walls. The electrified surface begins to behave like a magnet, intensely attracting particles of dust and dirt, on which all types of fungi, microorganisms and mold quickly begin to grow.

Therefore, the construction of a ventilation system from sewer pipes seems justified, first of all, for economic reasons. In addition, such ventilation will have good parameters and will serve properly for decades.

Note: For those who doubt the environmental friendliness of plastic pipes, it is best to build only the exhaust part, from which air infiltration into the room will be completely excluded.

Stainless steel tees

One of the most useful elements for creating a ventilation system is a tee. Its use allows you to create a branching of chimney channels, as well as to merge several pipes. From us you can buy stainless steel tees that meet all GOST requirements. We use only high-quality steel, which ensures the strength of the product and its protection from moisture. Our assortment includes both straight (90 degrees) and oblique (45 degrees) tees, the installation of which will greatly simplify the installation of the chimney.

Which pipes are suitable?

There are several types of pipes for drainage systems:

- plastic. These include polyethylene, propylene and vinyl products;

- cast iron;

- ceramics;

- asbestos cement.

Ventilation of sewer pipes must meet certain requirements:

- light weight. Ducts are installed on walls or ceilings that may not be ready to accept additional load;

- tightness. Air leakage places unnecessary stress on fans and causes drafts indoors;

- easy care, simple maintenance;

- possibility of isolation and jamming.

To install ventilation, it is best to use PVC sockets with a rubber seal. They are available in gray or red. The first ones are used indoors, the second ones are used for installing external sewer pipes. This is the only installation method that does not require additional equipment or skills. If a polyethylene sewer pipe is used for ventilation, welding must be used. This complicates the work, taking away the ability to quickly dismantle or reconfigure sewers.

Dimensions

Sewer parts are available in standard sizes. This is close to typical sewer diameters, but does not allow you to immediately connect to a section of the finished network. The system can be easily assembled from the same type of components, but adapters are required to connect to a standard system.

Channel size range:

- 100 mm;

- 125 mm;

- 150 mm;

- 200 mm, etc.

Size range of sewerage elements:

- 110 mm;

- 160 mm;

- 200 mm, etc.

All components required for installation are available on the market. Special clamps or hangers are used as connectors, which can be purchased at any plumbing store. The only task that is quite difficult to solve on your own will be choosing the diameter. To do this, it is recommended to use an online calculator, of which there are many on the Internet. Before ventilating from sewer pipes, it is necessary to download a fan.

Its parameters will serve as the basis for calculating the size of the ventilation ducts. They are inserted into the calculator and we get the best option for the size and other parameters of the air ducts. All that remains is to buy plastic products of the nearest size and begin installation.

Finally, about the diameter of the ventilation ducts

The most common size of ventilation pipes in the household series is Ø100 mm. In terms of cross-sectional area, it corresponds to a flat plastic air duct 55 x 110 mm or a similar galvanized one. It is easiest to select grilles and fans to match the specified diameter.

When connecting a kitchen hood or other ventilation unit, be guided by the cross-section of the equipment outlet pipe. The ventilation pipe must be at least this size. The shape of the box does not play a special role, although from the point of view of aerodynamics round and oval channels are preferable.

Natural and artificial type

Depending on the type of movement of the supply air mass, ventilation systems are divided into natural and artificial:

- Natural, also called gravity. This occurs due to the difference in density and temperature between the air mass outside the window and the air mass inside the building. Warm, lower-density air rises and is drawn into the vents before being replaced by denser, cooler air from outside the window.

- Artificial or mechanical. They work by constantly stimulating air flow using fans. They are installed on the outlet or on the power, sometimes on the power and on the outlet, but always only in one direction.

The type of gravity ventilation directly depends on atmospheric conditions. In the summer heat, its work spontaneously stops, as the pressure between the indoor and outdoor air equalizes. It happens that in hot weather the air flows in the opposite direction: from the house/apartment to the street.

Natural ventilation does not depend on energy. The program does not include expensive equipment. It is cheaper to install and maintain, but is inferior to forced ventilation in terms of performance and efficiency.

Fresh air enters naturally through cracks in framed windows and doors, through open vents and periodically opening doors. Drainage occurs through closed vents in kitchens and bathrooms.

Apartments in old apartment buildings were naturally ventilated. Nobody was going to mechanize it. Now these apartments, designed for natural ventilation, have sealed plastic windows. Because of this, normal air movement is disrupted, so it is necessary to install a wall fan along with a plastic window in a multi-story building.

Supply or exhaust valves in the wall should be used in private houses where mechanical supply and exhaust ventilation is not provided.

In the case of a valve, the cheapest but most effective way is to provide inflow or outflow. In this case, the entire system will become combined, that is, partially mechanized.

The simplest options for combined ventilation systems, partially mechanized with local fans, include systems with supply or exhaust valves or with kitchen hoods without recirculation with air ducts connected to the ventilation shaft.

Mechanical ventilation is the most expensive and difficult type of system to implement, requiring the inclusion of a recuperator or heater, supply and exhaust ventilation units. Its air ducts are laid behind suspended walls, suspended ceilings, and laid in building structures during the construction of a house.

Of course, if the owner decides to install supply and exhaust ventilation, he will not skimp on material for the ventilation ducts. It is unlikely that he will buy sewer pipes. It is better to purchase plastic air ducts that can be connected to ventilation equipment without any problems or additional tricks.

The device, located in the attic of the house, is responsible for supply and exhaust ventilation. It blows fresh air and sucks out the exhaust mass regardless of weather conditions.

In private homes, exhaust pipes from bathrooms and hoods are either routed separately to the attic or combined into a common air duct inside the building. This reduces the amount of wasted space and the duct reaches the highest point of the roof, providing excellent draft.

The plastic sewer pipe passing through the attic must be lined with thermal insulation. Otherwise, the pipe will collapse due to temperature fluctuations. There will always be hotter air coming out of the kitchen than from the surrounding area, which means the pipe may become warped or lose its seal due to unsteady expansion.

The upper part of the pipe must be equipped with a cap - a ventilation deflector that protects from precipitation.

Deflectors (windproof umbrellas) for the chimney

Stainless steel deflectors are installed at the chimney outlet. They are made in the form of an umbrella with wind protection, and are used to equalize the draft in the pipe when its height is insufficient or during windy weather. The upper part of the deflector structure is also designed to protect the air duct from precipitation and dirt from small birds getting inside. The increase in thrust with an increase in the exhaust air exit speed is carried out due to the Bernoulli effect. This ensures an increase in the efficiency of the entire system. The production of stainless steel in the production of baffles is extremely necessary. The scope of operation requires the following requirements for umbrellas:

- protection from strong gusts of wind and mechanical impacts;

- protection from precipitation (rain, snow), which can cause corrosion;

- long service life under various weather conditions.

Here you will find ventilation umbrellas with wind protection, made of high-quality stainless steel. We offer products in various standard sizes, and we can also make deflectors according to individual measurements.

Calculation of ventilation ducts

Removing impurities and polluted air is a procedure that allows you to maintain optimal humidity in rooms, eliminate unpleasant odors and prevent critical excesses of carbon dioxide levels. To ensure a constant outflow of harmful substances from the premises, a system of air ducts with different parameters in cross-section, height and configuration is created. An extractor hood is provided for the kitchen, bathroom and basement. The project is ensured by the flow of fresh air from the living room windows, special openings in the walls or doors.

Ventilation in a private house from sewer pipes can be installed during the construction phase or erected as a replacement for worn out or damaged sewerage. For installation of air ducts, products of round, rectangular or square cross-section are used. Air ducts must be sized to ensure good drainage of pollutants even under adverse weather conditions.

When performing calculations, the following criteria must be observed:

- channel cross-section – at least 100 mm;

- the total length of horizontal sections is no more than 300 cm;

- number of right angles – no more than 2;

- access for channel cleaning;

- The capacity of the air ducts must ensure ventilation of all residential and auxiliary premises.

If the bathroom and kitchen are far from each other, run them separately. Otherwise, one of the rooms will not have sufficient precipitation.

Self-ventilation, regardless of the installation location, must be carried out in accordance with the requirements of SNiP 2.08.01-89 as amended on April 30, 1993. No. 18-12, No. 2 dated October 11, 1994. No. 18-21 and No. 3 dated June 3, 1999. No. 42.

The exhaust gas system must be installed taking into account these provisions:

- Installation of a fan to ensure forced evacuation of contaminated air is mandatory. Automation functions are added whenever possible.

- Installing a penetrating element through the roof to ensure it is sealed. A ventilation plug is installed behind the penetrating element to protect the channel from precipitation, debris and small animals.

- The difference in height between the air intakes of different devices should not exceed 200 cm. It is prohibited to connect pipes from furnace and heating devices into one pipe.

- The height above the ridge of a pitched roof is 50 cm or more, and above a flat roof - 150 cm.

- The distance to the chimney is at least 200 cm. In cold climates, the supply and exhaust ventilation is insulated to heat the incoming air and prevent the formation of condensation.

To prevent clogging of pipelines with grease and dust, there is a removable fine mesh at the inlets. Cleaning should be done at least once a month.

Priority air exchange volume

Regulatory documents are intended to determine the parameters of natural air circulation. For a living space with an area of 30 m2, the air exchange should be 4.5 m3 of air per 1 m2. With a larger room volume, each person requires 30 m3 of fresh air per hour.

According to the laws of gravity, warm air, saturated with the vapor of our breath and other household fumes, moves upward. This property is taken into account when designing the system. Supply components are located below exhaust components

In the kitchen and bathroom the indicator should be in the range of 110-140 m3/h. For forced ventilation the figures will be higher.

Plastic pipes with a diameter of 160 mm are perfect for arranging ventilation in your home. This parameter provides an air supply of about 30 cubic meters per hour with a duct height of 3 meters. With other indicators, the efficiency will be less.

If it is necessary to increase the throughput, you can increase the cross-section of the air duct and its length. To ensure maximum draft in each room, there should be the same length of ductwork on the same floor.

Installation

Before installing a ventilation system in a private house with your own hands, you need to plan the location of the supply and exhaust air ducts and the direction of air flow. The layout of all ventilation system components must be developed by professionals. Performed according to the following rules:

- The room in which the most polluted air circulates is located at the very end of the ventilation chain.

- The air intake is not in the kitchen or bathroom, but the outlet is in that location.

- The exhaust fan should be located as close to the ceiling as possible and directed upward.

- The entrance and exit should be located as far apart as possible.

Installation begins with the roof, where the main ventilation elements will be located. The ventilation pipe is brought to the roof, rising 50 cm above the ridge. If this condition is not met, the air flow will flow in the opposite direction. The aerator should be placed at the outlet of the pipe to prevent the entry of various deposits.

The air intake pipe is supplied from above and covered with a grille. Then an air intake system is installed, from which air ducts are discharged to all rooms. Roof vent pipes should not be attached at a 90-degree angle, and the attachment points should be carefully sealed.

When using electric fans, check valves should be provided, especially when installing ventilation in bathrooms and kitchens. All ventilation outlets to the interior must be covered with grilles and horizontal sections must be provided to remove moisture. Duct ventilation should not be connected to general ventilation.

Therefore, when using plastic sewer pipes for ventilation, the same disadvantages exist as when using plastic ventilation pipes. The only drawback of sewer pipes is the problem of embedding them into fittings, elbows, and branches of ventilation ducts. A ventilation system made from ordinary plastic pipes is the best option for creating effective air circulation when preparing the appropriate circuit and high-quality installation.

In fact, the sewerage system is such that no unpleasant odor accumulates inside the apartment. Keep in mind that flushing a sewer system creates a vacuum inside, which draws water through the pipes and out of the collection traps found in every fixture in the home. Since the drains are not sealed, the stench will eventually begin to seep into the house and become a nuisance to the people living there. And the smell is so unpleasant that people get irritated and try to find its source so that it can be eliminated as quickly as possible.

First, make sure that the system is equipped with more than one siphon, because these simple sumps are actually hydraulic pumps that prevent the spread of unpleasant odors by maintaining a vacuum inside. It is advisable that the siphon be located downstream of the drain, because it is more reliable. There is another important reason and that is the terrible odor emitted by the sewer system. If there are several bathrooms in the house, and one of them has not been used for a long time, then the water in the installed traps has long dried up, and the vacuum is broken because the valve is not working.

Therefore, it is important to ventilate the system, otherwise the smell will quickly spread throughout the apartment. Standard classic ventilation, even with a forced ventilation fan, is unlikely to save the people in it.

In this case, only a background pipe capable of supplying heated air under pressure will help. It rushes upward, and the smell goes through it directly into the atmosphere.

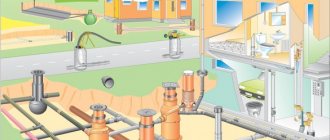

Features of internal wiring

A special feature of the sewerage design is that the basis for the operation of domestic sewers is gravity. Products of human activity move through sewer pipes under the influence of gravity. All channels should have a slope of 1-1.5% to ensure the flow of wastewater from the receiving water to the riser. For example, with a pipe length of 200 cm, the height difference between the pipe outlet and the outlet into the general drain should be 2-3 cm. With each rotation, another 1 cm is added. If these rules are not followed, the pipe will constantly become clogged with waste.

Another nuance is choosing the correct cross-sectional size and plank configuration.

Select plastic sewer pipes of this diameter:

- riser, tee, pipe and toilet pipe - at least 100 mm;

- main pipe from the bathtub, washbasin and kitchen sink – 50 mm;

- washing machine and dishwasher drain – 32 mm.

Since the largest amount of waste comes from the toilet, the distance from the toilet to the riser should be minimal. If it is necessary to change the direction of pipe laying, it is better to use bends at an angle of 45°, as sharp bends can become clogged.

A feature of polymer products is their change in size under the influence of temperature. For example, an increase of 1° results in a 0.5% increase in cell length. This should be taken into account when calculating so that the arches are not attached to the walls. Always allow a tolerance of 1-2 cm to dampen cell expansion. Minor curvature does not affect the strength and tightness.

When cutting semi-finished products, check that the diameter of the pipe corresponds to this value of the fittings used for installing communications. Technical indicators are printed on the products themselves, but it is better to check them in advance, even before installation. Please note that the tightness of the connection is achieved through the use of gaskets. The difference between the inner and outer diameter of the connected links is 2 mm. A small gap can compensate for minor errors in design, marking and assembly.

Other rules for using sewer pipes

When installing a vacuum cleaner on sewer pipes in a private house, it is not advisable to place these pipes and the corresponding exhaust system together. As a rule, this scheme is used when performing work in residential buildings. This is not done in private homes due to the risk of creating a back draft, which can spread various odors throughout the house.

The pipe must be at least 1 meter above the roof. If several systems need to be connected, pipes with diameters proportional to each other must be used throughout the network. It is important to separate the chimney from the ventilation: to achieve maximum fire safety, it is necessary to maintain a distance of at least 2 meters between the stove chimney and the ventilation shaft.

In fact, ventilation can be organized not only from sewer pipes, but also from corrugated pipes. However, due to the large waviness of the internal channel of such pipes, resistance to air masses increases. In this regard, they are used for ventilation in sanitary premises where the length of the duct is very short.

Taking into account all the positive and negative features of sewer pipelines, it is necessary that their installation be carried out after proper calculation. Following the instructions is quite simple to create high-quality, reliable and safe ventilation in a private or residential building. It is best to entrust the work to professionals who will take responsibility for all stages of the work - from the purchase of necessary materials and equipment to their installation and commissioning.

Non-standard ventilation solutions for sewer systems

Non-standard solutions, which at the same time do not contradict safety rules and sanitary requirements, can be a solution if the sewerage system in a private house is installed after the construction of the building itself. In such conditions, the implementation of a classical system can cause certain difficulties.

Installation on the external wall of the house

If the ventilation pipe is laid along the outer wall of the building, it will resemble a regular drain and will not spoil the appearance of the house. The only difference will be the height of the top, which in any case will be higher than the roof level. The most common pipe diameter for sanitary sewer ventilation is 110 mm. When choosing an installation location, comply with the requirements for the permissible distance between the fecal drain and windows (balconies, loggias) given above.

Fence installation

Installing a chimney attached to a fence is almost the same as installing it on an outside wall. The only difference is the greater distance from the building to the ventilation hood. When choosing this option, consider the location of your home and outbuildings on the neighboring property. You don't want your neighbors to be inconvenienced by sewer smell.

Ventilation to the septic tank

A sewer ventilation system in a private house, connected to a septic tank, in some cases may be considered the best solution. According to the law, sewage treatment plants and batteries must be installed at a certain distance from the house (depending on individual conditions - from 5 to 20 meters). This prevents unpleasant odors from entering the house. In addition, it is not difficult to organize a similar application when building a house, repairing or improving living conditions.

Before choosing the most suitable ventilation scheme for the sewer system of a private house, it is necessary to carefully study all the existing conditions and nuances of the sewer system.