If condensation begins to flow down the chimney, it gets into the insulation.

As a result, the sandwich pipe becomes completely unsuitable for use. The product loses its properties and is unable to perform functional duties. Correct assembly of the chimney implies the absence of sealing of internal seams. Combustion products rush upward due to the existing draft. The road inside is blocked by them, condensate begins to flow down the pipe.

The presence of liquid has a negative effect on the chimney. To avoid the formation of condensation in a sandwich pipe, you must first familiarize yourself with the channel structure. This will help minimize the possibility of typical errors occurring when installing this type of system.

Having studied the design of the channel and familiarized itself with its features, it will be possible to choose the right chimney for a specific project.

It should be noted that such a channel for removing combustion products has a rather complex design and has certain negative and positive characteristics.

Why does condensation occur?

The resinous liquid resulting from the combination of oxides and water is called condensate.

As a rule, it is formed when the temperature decreases. After some time, liquid begins to accumulate on the walls of the pipe.

To reduce the appearance of deposits in the sandwich chimney, a special condensate drain is installed. This device has long proven itself on the positive side.

Often the appearance of such a defect is caused by a temperature difference. Condensation can also occur due to precipitation when the outlet is closed.

In addition, liquid in a sandwich chimney is formed by the combined release of carbon dioxide and water vapor and the release of accumulated gases to the outside.

Since the temperature of the walls is much lower than the dew point, resin begins to form and settles inside the structure.

If a condensate drain is installed in the smoke duct, no sticky substance will settle. But, unfortunately, such devices are very rare.

The main reasons for the appearance of deposits:

- incomplete combustion of fuel;

- low temperature of exhaust gases;

- an insufficiently dry or completely raw substance that is a source of energy;

- large difference between outside and inside temperatures;

- poor traction;

- blockage in rolled metal products, which causes combustion of the outlet channel;

- insufficiently heated pipes;

- The design of the device does not correspond to the drawings.

Normal draft appears only with very dry fuel: it completely eliminates the occurrence of condensation. Well-dried wood makes it possible to warm up any device in the shortest possible time.

As a result, the inner surface of the pipe walls will remain clean and free of all kinds of deposits.

What is condensate

The phenomenon is quite common and is known to most owners; after a vaporous state, the element turns into liquid and flows down the walls; to be precise, water droplets are a product of the cooling substance.

Since steam comes out of the chimney pipe, as it cools, especially when it is cold enough outside, liquid forms in the area close to the outlet into the atmosphere.

How to choose the right chimney

The main criteria by which the quality of a chimney system is determined are the following:

- Heat-resistant steel.

- Laser welding.

- It is important that the pipes are connected with expanders. The length of the corrugation should be 600 mm.

- Sheet steel 0.5 mm. For large diameters - more than 1000 mm - the thickness of the product can reach 1 mm.

- For gas heating, the insulation thickness should be 30 mm. When heating rooms using wood, a denser layer is made - 75 kg/m³ with a thickness of 100 mm.

- Availability of branches.

There are several types of pipe cutting:

- plasma;

- laser;

- cold.

Manual cutting of metal is considered the worst. To connect the ends overlapping, butt welding is also used. On the outer contour, which has a colored coating, as an exception, a fold is allowed. The metal melts at the bend, reducing production accuracy.

When using an end connection, continuous welding and a roller apparatus are used.

Fittings of workpieces must have machined end parts, which allows for a good fit of the products. In this case, spot welding is not required.

How to get rid of condensation

To avoid having to spend a lot of money and purchase a new chimney pipe for such nuances, you need to closely monitor and correct the problem in a timely manner. There are several ways to implement it, but you shouldn’t expect a complete absence of savings.

Finished structures are difficult to remake, and this will affect attempts to eliminate excessive moisture; minimizing the phenomenon will be one of the tips.

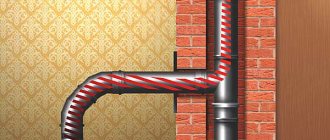

Chimney insulation

Some parts of the device can be improved using special modern materials. The temperature difference can be leveled out by high-quality insulation, the smoke will cool much more slowly and the liquid will no longer accumulate in large volumes.

To maximize the percentage of aired particles, it is necessary to wrap thin-walled steel pipes with thermal insulation material that will be affordable within the family budget. I consider the construction of a brick shaft to be no less effective; it will also perform a useful function.

Choosing the right fuel

If gas equipment is used, then it will not be possible to get rid of the excess; this natural resource produces a lot of steam. Dry fuel, compared to gas, can reduce moisture levels, and if you think rationally, such a solution will significantly save consumption without harming the productivity of the heating system.

Chimney cleaning

It is better to carry out such activities as often as possible, because by eliminating blockages, you can provide a high degree of traction, which is necessary for any type of equipment. The safety of the system directly depends on the permeability of the chimney; accumulations of combustion products harmful to human health when entering the room will cause a lot of harm.

Without proper ventilation, it is pointless to talk about the maximum cross-country ability of units; these are important factors that every owner knows about.

Installation of a steam trap

Modern equipment and devices can help solve difficult situations. This type of device can be called a condensate collector; the component is installed in such a way that if it is full, it can be emptied quite easily.

Keeping this supplement clean is also important. Often such elements are located at the beginning of the chimney or at the turns of the structure.

Chimney installation technology

There are several connection methods. Among them the following are noted:

- bayonet;

- flanged;

- bridge of cold;

- “by condensate”;

- "by the smoke."

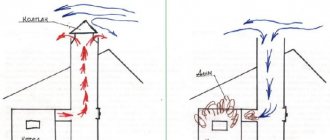

Installation of the pipe “along the smoke” is carried out to prevent carbon monoxide from entering the home.

The “condensate” assembly is used to form liquid that flows down the pipe.

How to make the right choice?

- To properly assemble a chimney, you need to find out what the features of each method are and in what cases it is more reasonable to use it:

- The chimney “by smoke” is assembled according to the following principle - each subsequent section of the pipe is put on top of the already installed one.

The method got its name because the design does not prevent the release of combustion products, but it is only suitable for stoves with high combustion temperatures, when condensation does not form in the chimney.

- The “condensate” chimney differs in that the upper part of the pipe is inserted into the lower part. Such designs are excellent for long-burning heating devices. Since when using such devices there is a high risk of condensation, drops of moisture can freely flow down when assembling the chimney “through the condensate” to be discharged outside.

Assembly of chimneys “by condensate” is more often used.

This installation scheme is necessary for long-burning, smoldering stoves, gas boilers, and long-burning solid fuel boilers.

This method should also be used in cases where most of the pipe runs outdoors. In such cases, moisture appears due to a significant temperature difference. The formation of condensation in the chimney if not assembled correctly can become a serious problem. Accumulations of moisture inside can destroy even stainless steel pipes.

Elements of modular systems

To draw up an installation diagram, purchase components and subsequent assembly, you need to understand what parts are used in a double-circuit chimney. We list the main elements, accompanied by photographs:

- straight sections of sandwich pipes 25, 50, 100 cm long;

- tees at 45, 90°;

- elbows 90, 45, 30 and 15 degrees;

- transitions from a single-wall pipe to a double-wall pipe - “start sandwich”;

- rotary gates (flaps);

- condensate collectors and various heads;

- ceiling passage units (abbreviated PPU);

- support platforms, brackets;

- fastenings – crimp clamps for guy wires;

- pitched roof sealing elements called master flash or “kryza”;

- end caps, skirts.

Note. Here is a partial list of chimney parts. There are direct channels with inspection and condensate drainage, floor stands, inspection hatches, and crosspieces.

Double-layer pipes are connected to other fragments using the socket-profile joining method. In a more accessible language, the connection is called “tenon-groove” or “male-male”, as you like. When manufacturing each shaped part (except for the end parts), a tenon is provided on one side and a groove on the other.

Scheme of installing a chimney along the outer wall of a country house

As an example, we suggest considering the assembly diagram of a wall-mounted sandwich chimney starting from the boiler:

- We connect a single-wall pipe to the output of the heat generator through a coupling, then mount the starting adapter onto the sandwich.

- We connect to the transition a straight section of a double-circuit pipe facing the street. There it is inserted into the tee.

- Below the tee we place an inspection section, then a support platform and a condensate collector. The structure is placed on a wall bracket.

- We rise from the tee in straight sections, fasten it to the wall every 2 meters with sliding brackets, and compress the joints of the elements with clamps.

- At the end of the chimney we install a cone without an umbrella (for a gas boiler), a simple cap or a deflector.

Comment. If a horizontal chimney duct crosses a wooden wall, you need to cut a square opening and install the PPU in accordance with fire safety requirements.

When you need to get around the roof overhang, we use 2 bends at 30 or 45 degrees. We secure the end of the chimney with guy ropes so that it does not sway in the wind, as was done above in the photo. Watch the video for professional installation of a sandwich pipe for a steel furnace:

Sandwich installation diagrams

You can make a chimney from modular sandwich pipes in 3 ways:

- The vertical part is located on the street, attached to the outer wall of the building. The horizontal chimney crosses the external fence, enters the house and is connected to the boiler (stove) pipe.

- The vertical smoke channel passes through the roof, descends into the boiler room and ends with a condensate collector. The heat generator is connected to it by a horizontal pipe.

- The trunk again crosses all roof structures, but is connected to the heater directly, without a pocket or horizontal sections.

Installation diagram of a wall chimney (left) and an internal duct passing through the roof (right)

Note. There are many ways to lay chimneys, but they are all variations of the listed schemes.

The first option is suitable for ready-made houses of any type - frame, brick, log. Your task is to place the boiler against the outer wall, take the sandwich outside, and then secure the main pipe. In terms of financial and labor costs, this is the most profitable way to install a chimney.

Installing a modular system according to the second scheme is much more difficult. In a one-story house, you will have to go through the ceiling and roof slope, arranging fireproof cuts. In a two-story house, the piping will get inside the room and make you think about decorative cladding. But you won’t need to go around the roof overhang and secure the end of the chimney with guy wires.

Chimney design requirements

The chimney must meet certain parameters in order to function correctly.

Requirements for the design of household chimneys for solid fuel and gas boilers are set out in SNiP 41-01-2003:

- the total height of the pipe from the furnace to the top cut of the pipe is more than 5 m;

- the elevation of the chimney above the roof is at least 100 cm;

- elevation above the ridge - 50 cm;

- the length of the horizontal section is no more than 100 cm;

- number of angles per channel - up to 2;

- compensation of horizontal sections - by the same increase in height.

By design, the chimney can be central, exiting vertically from the room through the floor slabs, and wall-mounted, when the pipe is led out directly from the boiler or at a slight elevation from the pipe.

Disadvantages of the “smoke” and “condensation” assembly

Installing a chimney “through condensate” has no significant disadvantages. Then, when assembling a single-circuit chimney “by smoke”, users are faced with a number of disadvantages:

- there is often an unpleasant burning smell in the room;

- fairly rapid destruction of the heat insulator and deterioration of their fire-fighting properties;

- increased risk of destruction of external pipes;

- short service life.

Therefore, it is recommended to choose the “smoke” option only when absolutely necessary.

Prevention: how to eliminate condensation in a chimney with maximum effect

As doctors say, it is easier to prevent than to treat. In our case, preventive measures also play an important role - with their help we can reduce the amount of condensate to a minimum. To do this you need:

- At the design stage, ensure compliance with all rules for organizing the chimney system. During its construction, strictly adhere to the terms of the project.

- Already functioning pipes should be upgraded with thermal insulation or inserts.

- Take all measures to increase draft: install a deflector, rotary turbine or smoke exhauster. Organize reliable air access to the heating unit. Clean the pipe periodically.

- Use dry fuel only.

Frequent mistakes made by beginners when assembling chimneys

When assembling sandwich chimneys, a number of mistakes are made:

- A layer of protective film remains on the products, which causes ignition and fire. Also, when heated, this material releases toxins.

- Improper installation of double-circuit pipes leads to gradual destruction of internal elements and, accordingly, malfunction of the entire structure.

- Performing assembly “through smoke” without a tee for condensate. Thus, a fairly large amount of moisture and resins are released onto the surface of the structure, which causes the soot to smolder.

You can install a chimney for a stove, fireplace or boiler yourself, but it is better to contact a specialist. They will carry out the work strictly according to the rules, guaranteeing reliability and safety throughout the entire period of operation.

Basic rules for using a chimney pipe

Compliance with the rules for the construction and use of a smoke exhaust system allows you to extend its performance. To minimize the occurrence of condensation, the following recommendations should be followed:

- if the chimney structure is installed vertically, then the length of the horizontal elements in it should not exceed 1 m. Moreover, the system should not have sharp corners or inclined straight lines;

- there should be no cracks, protrusions or other defects inside the structure;

- the diameter of the channel must be no less than the diameter of the outlet pipe that comes from the heating equipment;

- during construction, it is necessary to provide the opportunity for convenient and complete cleaning of the entire system;

- The height of the pipe must be selected in accordance with the height of the roof.