Features of the heating cable

The water supply cable is used to ensure that the water in the pipes remains in a liquid state even at subzero temperatures. In fact, it is a regular heating element that converts electrical energy into heat, taking into account the required temperature.

The design features that a heating cable for water supply must have are as follows:

- Multilayer , has several layers of insulation (according to GOST, at least 2).

- Increased flexibility . This allows installation of the cable on a pipeline of any configuration.

- Resistance to external influences and temperature changes.

- Immunity to aggressive conditions . Inside there should be a gasket in the form of a foil screen or copper braid. This avoids short circuits and neutralizes the magnetic field.

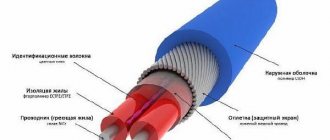

Internal filling of the cable Source koffkindom.ru

To choose the right heating cable, you should consider the main characteristics:

- Sufficient conductivity power for indoor installation per linear meter is 10 W/m.

- If the installation is carried out outdoors, then this figure should be increased to at least 20 W/m.

These nuances should be taken into account when choosing a wire in the same way as other indicators:

- Length . Not only the distance where the product will be laid is measured, but also the footage that will be required to insert the wires into the holes. A significant increase in length can lead to the fact that if the device is shorted or bent, the entire heating system will fail.

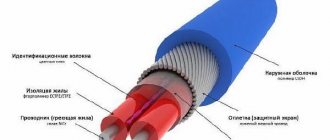

- Number of internal cores . Wires are produced in different thicknesses and have different conductor resistivities. The same diameter may differ in the internal filling, that is, in the number of cores.

Single-core and two-core cable Source sjevi.ru

- Section shape . Round – most often used for outer braiding. Flat - it is convenient to insert such a wire inside the pipe.

The maximum permissible temperature of the wire in the disconnected state should also be taken into account.

How to choose a suitable self-regulating wire

We talked about the principle of operation of a self-regulating heating cable. Let's move on to the next section - we will tell you how to choose a heating wire based on power. For installation inside and outside the pipe, we will use low-temperature samples that heat up to a maximum of +60 degrees. When calculating the heating cable, focus on the following indicators:

It is the number of conductive paths in a cable that affects its maximum output power.

- Internal arrangement when pipes pass underground - the optimal power is 5 W per linear meter;

- External location when pipes pass underground - depending on the depth, you can use samples with a power of 10-15 W/m;

- Any location for outdoor pipes - choose a thin heating cable with a power of 20-30 W.

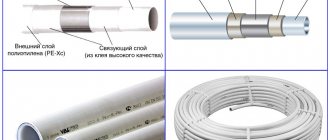

The low-temperature heating self-regulating cable for protecting pipelines from freezing is thin and flexible, so it can be wrapped around water supply pipes without any problems.

Let's now see how long a self-regulating heating cable can be cut. We have already said that its length is an arbitrary indicator. But there are still some restrictions. The maximum recommended length is 80-100 meters, the minimum is 20-30 cm . As for the bending radius, it ranges from 6 diameters.

The cost of a self-regulating heating wire depends on its power, the range is quite large. For example, the price per meter of heating cable 30GSR2 with a power of 30 W/m is about 210-230 rubles. And the 16GSR2 modification with a power of 16 W will cost 180-190 rubles/m. You can buy it in plumbing and heating stores in your city, including construction hypermarkets.

When choosing a self-regulating heating cable, you must remember that it comes in two types:

Special double insulation allows heating cables to be installed directly inside the pipes. However, this option requires more labor-intensive work.

- Technical purpose - it is used for heating water pipes from the outside;

- With safe insulation - it can be laid inside the pipe, as it uses safe fluorine-containing insulation.

When purchasing this or that sample, be sure to check with the seller about the possibility of using a heating cable inside the water supply pipe. Also on sale are universal heating cables in silicone insulation, suitable for heating pipes and working as part of heated floors.

Types of cable

Before installation, it is important to study what heating wires are available and how to install them.

There are two types of cables: resistive and self-regulating.

The difference between them is that when an electric current passes through the cable, the resistive one heats up evenly along the entire length, while the feature of the self-regulating one is that the electrical resistance changes depending on the temperature. This means that the higher the temperature of the section of the self-regulating cable, the lower the current strength will be on it. That is, different parts of such a cable can each be heated to the desired temperature.

In addition, many cables are available with a temperature sensor and automatic control, which significantly saves energy during operation.

A self-regulating cable is more difficult to manufacture and costs more. Therefore, if there are no special operating conditions, then a resistive heating cable is often purchased.

Resistive

A resistive type heating cable for water supply has a budget price.

Cable differences Source teplina.rus

It is divided into several varieties, depending on the design features. Each of them has its own advantages and disadvantages:

| Cable type | pros | Minuses |

| Single-core | The design is simple. It has a heating metal core, copper shielding braid and internal insulation. On the outside there is protection in the form of an insulator. Heats up to a maximum of +65°C. | It is inconvenient for heating pipelines: both opposite ends, which are far from each other, must be connected to the current source. |

| Two-core | It has two cores, each of which is separately insulated. The additional third core is bare, but all three are covered by a foil screen. The external insulation has a heat-resistant effect. It heats up to a maximum of +65°C. | Despite the more modern design, it is not much different from a single-core element. The operating and heating characteristics are identical. |

| Zonal | There are independent heating sections. The two wires are insulated separately, and a heating coil is located on top. The connection is made through contact windows with conductive conductors. This allows heat to be created in parallel. | No shortcomings were found, if you do not take into account the price tag of the product. |

Resistive wires of different types Source yandex.net

Most buyers prefer to lay the wire “the old fashioned way” and purchase a wire with one or two cores.

Due to the fact that a cable with only two cores can be used to heat pipes, the single-core version of the resistive wire is not used. If the owner of the house unknowingly installed it, this threatens to short circuit the contacts. The fact is that one core needs to be looped, which is problematic when working with a heating cable.

If you install the heating cable on the pipe yourself, then experts advise choosing a zonal option for external installation. Despite the peculiarity of the design, its installation will not cause serious difficulties.

Additional features and advantages of zonal cables: stable power, you can cut the product and connect to the power source due to the presence of an end section. Another important nuance in single-core and double-core designs: on sale you can find already cut and insulated products, which eliminates the possibility of adjusting the cable to the optimal length. If the insulating layer is damaged, the wire will be useless, and if damage appears after installation, the entire system will need to be replaced. This disadvantage applies to all types of resistive products. Installation work of such wires is not convenient. It is also not possible to use them for laying inside the pipeline - the head of the temperature sensor gets in the way.

Wire design Source otdelkaexp.ru

See also: Catalog of companies that specialize in electrical engineering.

Another important nuance in single-core and double-core designs: on sale you can find already cut and insulated products, which eliminates the possibility of adjusting the cable to the optimal length. If the insulating layer is damaged, the wire will be useless, and if damage appears after installation, the entire system will need to be replaced. This disadvantage applies to all types of resistive products. Installation work of such wires is not convenient. It is also not possible to use them for laying inside the pipeline - the head of the temperature sensor gets in the way.

Self-regulating

Self-regulating heating cable for water supply with self-regulation has a more modern design, which affects the duration of operation and ease of installation.

The design provides:

- 2 copper cores in a thermoplastic matrix;

- 2 layers of internal insulating material;

- copper braid;

- external insulating element.

It is important that this wire works great without a thermostat. Self-regulating cables contain a polymer matrix. When turned on, carbon is activated, and when the temperature rises, the distance between its graphite components increases.

Self-regulating cable Source moydomik.net

On a note ! Self-regulating wire is more expensive, but these costs will pay off in the future. Pipes can be heated more intensely, using less electricity.

Design and scope of application

Depending on the type and technical characteristics, heating cables are used to heat drains, water and sewer pipes, and tanks. The main purpose is to protect liquids from freezing by increasing the temperature.

Heating systems are relevant for external communications, that is, for use in the ground or in the open air.

The basis of its operation is the ability of the cable to convert electricity into heat. The wire itself cannot transmit energy, as power analogues do. He only accepts it, and then gives off heat to the pipe (tray, gutter, tank, etc.)

Heating systems have one useful ability - zonal application. This means that you can take a set of elements and assemble a mini-system from it for heating a separate area, without connecting to the entire network.

This results in savings in materials and energy. In practice, you can find miniature “heaters” of 15-20 cm, and 200-meter windings.

The main components of the heating cable are the following elements:

- Inner core - one or more. It is made using alloys with high electrical resistance. The higher it is, the greater the specific heat release value.

- Polymer protective shell . Together with plastic insulation, an aluminum screen or copper wire mesh is used.

- Durable PVC outer shell covering all internal elements.

Offers from different manufacturers may differ in nuances - the alloy of the core or the method of protection.

Shielded types are considered more reliable, equipped with foil protection and containing 2-3 cores instead of one. Single-core products are a budget option, which is good for assembling systems for short sections of water supply (+)

To improve the characteristics, the copper braid is nickel-plated, and the thickness of the outer layer is increased. In addition, the PVC material must be moisture resistant and not susceptible to ultraviolet radiation.

Installation methods

Installation work can be carried out in two main ways:

- When the wire is attached to the outside of the pipe.

- When - installed inside it.

Both methods have their own nuances. When choosing a cable laying method, you should also not forget about additional thermal insulation of the pipeline.

External cable installation

You can install the cable outside the pipe along it or around it using the ring (spiral) method.

Linear method

More often, wire installation is carried out linearly, when the cable for heating the water pipe is attached from below. Despite its simplicity, the method has its advantages, the main of which is protection. In this case, the risk of breaking the integrity of the wiring will be minimized, and the heating element will not suffer from mechanical damage from above. The electrical cable should be secured at the bottom. The fixation must be strong. Then the frost will not grab the water supply in case of a sharp drop in temperature.

Fastening along the pipe Source prom.st

On a note ! For fastening it is better to use: aluminum tape. It will increase heat transfer.

Ring method

The spiral method allows you to place the conductor along the outer radius of the pipe. This option is necessary for areas with low temperatures in winter. Due to the circular circulation, the water supply heats up better. The only downside of this method is that it requires a longer cable. To increase heating and properly secure the product, it is important to observe an intersection step no more than 5 cm.

On a note ! If there is a hard-to-reach area, then you can hug it with a small allowance. It is important to wrap the loops in the opposite direction.

Ring winding of heating cable Source www.dobroeteplo174.ru

Installation of individual components when laying cables outside the pipe

If you need to install the cable on separate metal supports, more material will be required to provide better thermal insulation. For this, only a self-regulating wire is used. Difficulty may arise from installing a temperature sensor, which will prevent the structure from overheating. It should be placed at the point where the heating rate is lowest. It is important to maintain the distance of the sensor from the cable line: no closer than a meter.

On a note ! The surface where the device will be installed is first glued with aluminum tape.

Operating principle of cable heating

The use of plastic pipes is increasingly popular, given the fact that such products are rarely destroyed by freezing, since the material of manufacture is plastic in itself. But the heating cable for defrosting plastic pipes is being used more and more actively, since it allows one to avoid large-scale repair work and continue to operate the pipeline.

The heating element in such systems is a wire made of a nichrome-type alloy, covered with a heat-resistant sheath. Drainage wires are located directly in contact with them, the purpose of which is to distribute heat evenly across the cross-section of the cable, which is facilitated by the high thermal conductivity of the material.

These elements are made of copper wires. From the first two components, heat is transferred to an aluminum alloy shell with high thermal conductivity and is evenly distributed over the surface of the conductor. In addition, the aluminum layer gives the heating cable additional strength.

The final coating of the conductor is heat-resistant fluorine-containing plastic. This design of the cable route for heating plastic pipelines ensures its durability and functional qualities.

Video

How to install a self-regulating heating cable inside a water pipe

In addition to the listed components, a signal core with a sensor that responds to a decrease in the temperature of the heating cable and sends a signal to turn on the relay of the heating control circuit is often introduced into the design of the product.

It is advisable to use such a heating structure for plastic pipes for country houses and country houses where people are present periodically.

Connection and thermal insulation

The connection technique is universal, regardless of which wire is used, but there are nuances. The installation of the heating cable is completed by insulating the ends and connecting them to devices and sensors. To work you need to use the following equipment:

- knife;

- pliers;

- side cutter;

- construction hairdryer

First you need to prepare the cable. This will require additional terminals that come with the wire or pipe. Inside the sleeve has a special heat-shrinkable layer that improves the quality of the connection. Instead of a terminal, a special plug can be used. Only after this the end coupling is installed. To do this, first cut off a few centimeters of the outer insulation, then remove the braid, string the sleeve and heat it with a hair dryer so that shrinkage is successful. To be sure, the terminal should be clamped for a few seconds with pliers.

An example of cable installation inside a water supply system Source www.ingeneriya.ru

Nuances of installation work

When the wire is securely fastened inside or outside, it is important to take care of the insulation of the end of the conductor. Experts recommend using heat shrink tubing. This product will perfectly protect the conductors from moisture, which will reduce the risk of short circuits and repair work. We must not forget that the heating part must be connected to the “cold” part.

Connecting wires Source termodar-64.ru

Tips and recommendations from experienced craftsmen:

- If you use two methods of laying wires inside and outside the pipe at once, you can increase the rate of water heating several times, but this will require additional installation costs.

- Heating water pipes with a self-regulating heating cable will allow you to ignore warm sections and direct the current to cold places. It is allowed to be cut, so there will be no problems in installation even in hard-to-reach places. The cable length does not affect heat transfer.

- Resistive wire is half the price, but its service life is much shorter. If a regular two-core cable was installed, you should prepare for the fact that in 5-6 years it will have to be replaced.

- The braid on the wire serves to ground it. You can skip this stage of work, but it is better to become familiar with grounding methods.

Cable installation

How to properly install cable heating of a water supply system?

External installation is carried out by winding the cable or attaching it parallel to the pipe using aluminum tape.

Sewerage and water pipe with a heating cable secured with aluminum tape under thermal insulation

Tip: aluminum reduces heat loss due to infrared radiation and thus helps save energy. For internal installation, a tee with an elastic seal on one of the outlets is used, through which the heating cable is inserted into the pipe.

Pipe for water supply with a heating cable inserted through a tee with a gland

A few nuances:

- A self-regulating cable can be used both to heat the water supply and to prevent defrosting of the sewer system. However, in the latter case, it can only be attached to the outside of the pipe: a cable located inside the drain system will cause frequent blockages;

Sewer heating: the cable is mounted outside the pipe

In addition: the cable heating system is likely to get wrapped around the cable and be damaged when clearing the next blockage.

- The cable can be used to heat a non-buried septic tank or cesspool. However, the cold end connection and end sleeve must not come into contact with the drains. An aggressive environment will not harm the cable insulation, but the heat-shrinkable tube will collapse within one or two seasons;

- For external installation, along with aluminum tape, you have to use polyethylene ties or regular tape to secure the cable. The fact is that aluminum foil cannot boast of high strength.

At sewer bends, the cable is secured with polyethylene ties

Video description

How to ground a water supply is shown in the video:

- Most often, for self-installation, a linear cable laying method is chosen.

- The level of heat transfer directly depends on what pipes are installed in the room. For plastic pipes, this figure will not be high, which means that when installing a heating cable for a water supply system, you will need to wrap the pipes with aluminum foil.

- Before attaching a cable to the outside of a metal pipe, it is important to ensure that there is no rust. If there is one, it requires cleaning and treatment with a special antiseptic. If this is neglected, there is a risk of damage to the insulation in the future.

- If fastening is carried out from the outside, then the distance between the insulating bundles should not be more than 30 cm. If you take a wider step, then after a while the fastening elements will separate.

- In practice, some craftsmen pull two wires at once to increase the heating rate. It is important that there is a small distance between the cables.

- For fastening to plastic, it is better to use special clamps.

Fastening with clamps and thermal insulation in section Source yandex.net

- If you decide to twist the wire in a spiral, then initially the pipe is wrapped with metallized tape.

- To fix the insulation, it is better to use special ties. They can be purchased at any hardware store.

- It is necessary to completely isolate the temperature sensor from the electrical cable to eliminate the risk of short circuit and fire. To do this, it is necessary not only to maintain a distance between these devices, but also to make the insulating gasket with a special material.

- Heating the pipelines with a heating cable using a thermostat will ensure constant temperature maintenance. It is better to install this device next to the electrical panel or directly in it. It would not be superfluous to install an RCD.

Wire with thermostat Source www.elektrikaup.ee

Types of heating cable

For electrical heating of pipelines, 2 types of cords are used:

- resistive;

- self-regulating.

Resistive

When using a resistive type winding, the heat generated when an electric current passes through the conductor is used to heat the pipe material. A feature of the products is a constant heating characteristic, independent of the ambient temperature background.

Stability of operating parameters ensures uniform energy consumption. To reduce heating costs (for example, during thaws or in the spring-autumn period), sensors and a current regulator are introduced into the design of the water pipe heating system.

The resistive type heating cable is made with 1 or 2 cores. Single-core wires are connected to the household AC network from 2 sides. Two-core products are equipped with a connector for connecting to the network or a piece of installation wire with a factory-installed plug.

The opposite side of the cord is closed with a sealed plug (end sleeve). Inside the end element there is a metal insert that ensures the closure of the electrical circuit.

The design of resistive conductors does not provide for cutting the material into sections of the required length. Manufacturers prohibit laying excess wire in coils; it is necessary to mount the entire existing cord onto the pipe section.

When laying resistive elements, it is prohibited to locate the lines next to each other. When placed close to each other or when laying routes intersect, the metal cores overheat and the products fail.

Self-regulating

Operating principle of heating cable

Self-regulating heating cables are built on the basis of a metal-polymer matrix. The operating principle of the heating cord is based on heating a polymer gasket located between 2 conductive wires.

As the temperature increases, the polymer material passes a lower current, which reduces the degree of heating. As the polymer cools, the conducted current increases and the heat transfer of the substance increases. Due to this physical feature of the material, the self-heating cable for water supply automatically regulates the heating temperature of the pipeline or adapter couplings.

Cords with independent heating control can be laid overlapping and next to each other. It is possible to cut the product into sections; there are notches on the outer shell that determine the permissible size of the section.

After separating the required fragment, it is necessary to install a protective end coupling. The disadvantage of the product is the increased cost (compared to resistive elements), but the service life increased to 10-12 years compensates for the increased costs of purchasing the material.

Briefly about the main thing

First of all, it is important to choose the right cable for heating pipelines.

There are self-regulating and resistive types of cable that are used for plumbing. When choosing a cable, pay attention to the number of cores, type of cross-section, heat resistance, length, presence of braid and other characteristics.

For plumbing, a two-core or zone wire is usually used.

Of the methods for installing the wire, it is better to give preference to the external one. The cable should be secured inside the pipe only if it is not possible to install it from the outside. In general, internal and external installation technologies are practically the same, but the second method minimizes the risk of blockages and also increases the service life of the wiring.

Ratings 0

Advantages and disadvantages of using a cable

The key advantage of the resistive system is its lower cost and service life of up to 20 years.

However, there are also disadvantages. As mentioned earlier, a single-core cable is not suitable for laying inside a pipe, and an accidental intersection can damage the entire heating system.

Another drawback is that the resistive cable for water supply is sold in the form of segments of standard length. It cannot be shortened or lengthened. The burned out areas do not change, and the heating power is the same throughout the entire pipe.

The main disadvantage of a self-regulating system is its higher cost. The remaining parameters characterize only the advantages. The self-regulating wire for heating water pipes has reliable protection against overheating of the conductors. It is possible to replace or add a piece of cable. The advantages include the zonal nature of the work. The system independently detects the coolest areas and activates heating on them. The remaining sections are maintained at optimal temperatures.