It is very difficult to ensure uninterrupted water supply in a country house. Residents of such real estate very often experience freezing of the pipeline in winter. To avoid this problem, when installing a water supply, install a cable to heat the water pipe. Such heating systems protect communications from freezing and destruction.

Application of heating cable

Laying a pipeline can be done without heating the water supply and sewerage with a heating cable, if the water supply pipes are buried deep enough and have good thermal insulation.

However, in swampy areas and areas close to water bodies, the groundwater level is very high, which often exposes communications to flooding and freezing. If the pipes are not installed deeply and a self-regulating heating cable is laid, then the communications will be reliably protected.

There are also critical areas that are more susceptible to low temperatures - areas where water and sewer pipes enter the house. The heating cable for heating pipes can only be installed in these places.

Such heating systems have very useful features. For example, the possibility of zonal application. That is, from a set of elements you can assemble a small system for heating a water supply in a separate area, without connecting a self-heating wire throughout the network. There are mini-"heaters" of 20 cm, and maxi-"heaters" of 200 meters.

Depending on the type and technical parameters, the heating cable is used to heat pipelines and drains, tanks for collecting and storing liquids in winter. The main task of the system is to protect the liquid from freezing by warming it up through an increase in temperature.

Installation of the heating cable is possible both in a pipe in the ground, that is, internal, and on a pipeline in the open air, that is, outside.

Thus, if you have a choice between connecting a heating cable or not laying a heating system, then you should definitely take advantage of this opportunity and insure your pipeline from freezing.

Useful tips regarding installation work

There are some recommendations that will help you avoid mistakes when installing or choosing the heating element itself:

- For installation on a pipe with unstable temperatures, it is better to choose a self-regulating cable. It is especially important to take this into account if part of the pipe is in the building, part is laid on the street, and then again enters the building. Heating will require different amounts of heat in different areas. A resistive cable will not only not be able to provide this condition, but will also consume the same amount of electricity, thereby making its use uneconomical;

- Particular attention should be paid to the choice of thermal insulation material for heated pipes. Properly selected insulation will significantly reduce heat and electricity consumption and prolong the life of the cable;

- If you have definitely decided that you will lay the cable over the pipe when winding, be sure to check the permissible bending limits. Otherwise, if the cable is bent beyond the permissible limits, its performance may be impaired;

- If a heating cable is used on domestic pipes, it is imperative to connect it through a current leakage relay. This is necessary to protect against electric shock in the event of damage to the outer insulation of the conductor;

- Selecting the length of the cable when laying it over or inside a pipe is not difficult - it is equal to the length of the pipe with a small margin. However, when winding the cable around a pipe, the length must be calculated as 1.6 - 1.7 of the pipe length;

- Even if you choose a self-regulating cable type, to further minimize energy costs, install a temperature sensor. Set the following parameters on it - turn on at a temperature of +3°C, turn off at +13°C. This mode will also extend the service life of the heaters, because they have a certain operating hours;

- When installing the sensor, it is very important to do it correctly. The main difficulty is to isolate it from the influence of the heater, but at the same time maintain contact with the pipe. Only in this case will it read the correct readings.

Design features of the system

The operating principle is based on the ability of a resistive or self-regulating cable to convert electricity into heat energy. The wiring itself does not transmit energy, as is the case with power analogues, it only receives it, and then the wires heat the object, transferring heat.

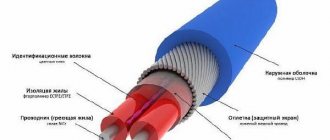

The heating cable for water pipes consists of the following main elements:

- One or more internal conductors with high resistance to electric current; the higher it is, the more heat will be generated.

- The protective shell is made of polymer; insulation in the form of a copper mesh or an aluminum screen is used together with plastic.

- The outer sheath is made of durable PVC, which protects the inner sheath and core.

Cables for heating a water pipe from different manufacturers differ in alloy, design of protective elements, cost and other parameters.

The most reliable is considered to be a heating wire with a foil screen and several cores. Solid wire is a cheaper option and is suitable for connecting a system in a small section of piping as solid wire transfers less heat.

To improve the characteristics, the copper braid is nickel-plated, and the thickness of the outer PVC sheath is also increased. In addition, the outer layer must be moisture-resistant and resistant to ultraviolet radiation so that the protection can withstand both contact with water and exposure to direct sunlight.

Features of anti-freezing

A well with water is made at some distance from the house, so pipes are connected to the house in the country. But even if the water source is in the basement, then even in this case measures are necessary to prevent the water from freezing. In most cases, water freezes not on the section of the pipe that is located underground, but on the section above it.

An equally “weak” zone is the boundary between the subfloor and the room where the water supply is supplied. There are frequent drafts in this place, so the water inside quickly freezes. Conventionally, passive and active methods of pipeline protection are distinguished.

Types of cable heating

The heating cable for sewer and water supply can be one of two types: resistive or self-regulating. Each of them has its own scope of application. So, the first type is more suitable for heating small sections of pipes with a diameter of up to 40 mm, and a self-regulating cable is good for longer sections. Let's look at each type in more detail.

- Resistive has the following principle of operation: current passes through the wires and heats the cable. High current and high resistance contribute to excellent heat dissipation. There are pieces of resistive wire with a constant resistance coefficient. During operation, such a cable gives off an equal amount of thermal energy along its entire length.

Single core wiring is double protected internally and externally insulated. The heater is a single wire that will be connected in a loop-like manner: the wire is connected to the electrical network, then wound around the tube, and then returned back.

A closed loop heating system is usually used for installing “warm floors” and heating roof drains; there is also an option for a plumbing system. Do-it-yourself installation of a heating cable for a water supply system requires double-sided laying of a single-core wire. It is noteworthy that in this case only an external connection is used.

A single-core resistive cable is not suitable for underground installations, since laying a “loop” takes up too much space, and crossing the wiring will lead to overheating.

Wiring with two wires separates their functions: one wire supplies electricity, and the second heats it. The connection diagram is also different: there is no need to create a “loop”, and the cable is connected to electricity at one end, and the other is laid along the pipeline.

The main advantages of resistive cable are its low cost, reliability, ease of installation and long service life (10-15 years). However, there are also disadvantages, among which it is worth highlighting: a fixed length, a high probability of overheating when the wiring is close together, the impossibility of replacing one section and the power cannot be adjusted.

In order not to connect the heating system every time, install a thermostat with a temperature sensor. When the temperature drops below the set value by 2-3 degrees ºC, the thermostat automatically starts the heating device, and as soon as the temperature rises to the set coefficient, the energy is automatically turned off.

- Self-regulating heating cable. This is a universal type of wiring that can be used to heat a roof element, water supply and discharge lines, and containers with various liquids. Such a cable is immediately equipped with a system for adjusting power and heat energy intensity. When the temperature drops below the control value, the system starts heating.

It differs from the resistive model in the presence of a conductive heating matrix that regulates the heating temperature, but with regards to insulation and protection, there are no special differences.

The principle of operation of a self-regulating device is based on the ability to reduce or increase the current, taking into account the resistance indicator. When the resistance increases, the current decreases, which leads to a decrease in power. As a result, the conductor cools down. After the resistance decreases, the current increases and heating begins again.

A self-regulating heating cable for water supply has an important advantage - zonal action. The conductor independently manages his “labor power”: he warms up the cooling areas well and maintains the optimal temperature in those sections where there is no need for strong heating.

The self-regulating heating cable for heating water pipes works constantly, which is very welcome in winter. But when the frosts stop, it is not beneficial for it to always work, therefore, to automate the processes of the conductor, it is equipped with a thermostat linked to the outside temperature. The thermostat for the heating cable will automatically turn off the system when the weather outside is warm enough.

Types of heating cables for water supply

There are two types of heating cables - resistive and self-regulating. Resistive ones use the property of metals to heat up when passing an electric current. In this type of heating cables, a metal conductor is heated. Their characteristic feature is that they always emit the same amount of heat. It doesn’t matter whether it’s +3°C or -20°C outside, they will heat up the same way - at full power, therefore, they will consume the same amount of electricity. To reduce costs in relatively warm times, temperature sensors and a thermostat are installed in the system (the same as those used for electric heated floors).

Structure of a resistive cable

When laid, resistive heating wires should not intersect or be located next to each other (close to each other). In this case, they overheat and quickly fail. Pay close attention to this point during the installation process.

It is also worth saying that resistive heating cables for water supply (and not only) can be single-core or double-core. Two-core ones are more often used, although they are more expensive. The difference is in the connection: for single-core ones, both ends must be connected to the mains, which is not always convenient. The two-core ones have a plug at one end, and at the other end there is a fixed ordinary electrical cord with a plug, which is connected to a 220 V network. What else do you need to know? Resistive conductors cannot be cut - they will not work. If you bought a coil with a section longer than necessary, lay it in its entirety.

This is approximately how heating cables for plumbing are sold.

Self-regulating cables are made of a metal-polymer matrix. In this system, the wires only conduct current, and the polymer, which is located between the two conductors, heats up. This polymer has an interesting property - the higher its temperature, the less heat it releases, and vice versa, as it cools down, it begins to release more heat. These changes occur regardless of the condition of adjacent sections of the cable. So it turns out that it regulates its own temperature, which is why it is called self-regulating.

Structure of a self-regulating cable

Self-regulating (self-heating) cables have many advantages:

- they can intersect and will not burn out;

- they can be cut (there are markings with cutting lines), but then you need to make an end coupling.

They have one drawback - the high price, but the service life (subject to the operating rules) is about 10 years. So these expenses are reasonable.

When using a heating cable for any type of water supply system, it is advisable to insulate the pipeline. Otherwise, heating will require too much power, which means high costs, and it’s not a fact that heating will cope with particularly severe frosts.

Connection methods: inside or outside?

There are two ways to connect the heating cable: outside or inside the pipe. Each option has special types of wires - for outdoor use and for indoor installation, respectively. The recommended connection method is necessarily indicated in the technical specifications for the conductor.

Insulation of pipes from the inside

Heating cable inside the pipe. To begin installation of the heater inside the water main, it must meet the following important requirements:

- high degree of electrical protection, not lower than IP68;

- protective insulation should not release harmful substances;

- final sealed coupling.

To be able to thread the conductor inside, a tee is installed at the end of the water supply, and a cable is inserted into one of the branches through the gland.

Keep in mind that the coupling - the point where the transition between the electrical and heating wire occurs - must be outside the gland and pipe, as it is not designed to function in a wet environment.

Tees for installing heating wiring inside the water supply can be at different outlet angles - 180°, 120°. 90°. With this connection method, the cable is not fixed at all, it is simply tucked inside.

Outdoor heating pipeline

Installing a heating water cable outside the pipe requires a tight fit along the entire circuit. Before installation on a metal pipeline, their surface must be cleaned of rust, welding marks, dust and other dirt that can damage the wire. The cable is laid on the cleaned pipe and secured with plastic clamps or metallized tape every 25-30 cm.

If up to two threads are stretched, then they are attached at a short distance parallel to each other from below, that is, in the most freezing zone. If there are three or more threads stretching at once, then they need to be positioned in such a way that more wires are installed below, but maintaining a certain distance.

Another option for external connection is spiral. It is necessary to wind the wiring with great care, without sudden movements and many bends. This can be done by gradually unwinding the coupling and at the same time winding the freed wire onto the main line, or simply fix the cable with the slack, and only then lay it in a spiral and secure it with metallized tape.

If the pipeline is made of plastic, then you must first stick metallized adhesive tape under the wiring, which will improve the thermal conductivity and increase the heating efficiency. Valves, fittings, tees and other connecting elements require more thorough heating. Therefore, when installing, it is better to make several bends at each connection, but remember the radius of the loops.

In this case, it is necessary to additionally insulate the pipeline. Any type of mineral wool is absolutely not suitable for this, since it loses its properties in a humid environment. It is worth abandoning heat insulators that shrink from gravity if you do not use rigid insulation on top.

A shell made of polystyrene foam in the form of fragments with different diameters is the optimal solution that demonstrates high thermal insulation characteristics: it feels good in a humid environment, does not shrink under weight, and reliably protects.

What are passive methods?

During installation, the water supply at the dacha must be made of pipes made from a special heat-insulating material. Today, these varieties include polyethylene, polypropylene and metal-plastic. It is better to avoid metal pipes altogether.

It is better to choose the diameter of the inlet so that it is as large as possible. Then the wall thickness is greater, which means the thermal insulation is better. In addition, more water accumulates in such a supply; therefore, it will take more time for the temperature inside the pipe to drop below zero.

In winter, water practically does not freeze in insulated pipes with a diameter of 20 mm. (for products made of polypropylene) and 26 mm. (for products made of metal-plastic). For polyethylene, it is better to choose a pipe diameter of 40 mm. In some cases, a larger one is chosen, but it will be more expensive.

Passive heating is carried out through great depth. The water supply is laid in trenches up to 1.5 m. It is important that the pipe is insulated.

Winter water supply at the dacha: new technologies in insulation

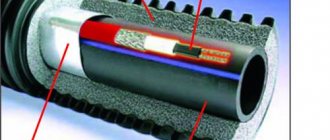

There is an interesting option, a polymer flexible pipe, insulated at the factory. There is a layer of waterproofing on top of the insulation, and along the pipe there is a channel for laying a heating cable. Such pipes are called anti-freeze pipes or insulated pipes. For example, even in the northern regions, it is possible to make winter water supply at the dacha over the surface using ISOPROFLEX-ARCTIC pipes.

Insulated pipes for winter water supply at the dacha

Operating temperature - up to -40°C, operating pressure - from 1.0 to 1.6 MPa, pressure pipe diameter - from 25 mm to 110 mm. It can be laid in a channel or on the surface. They are flexible and supplied in coils of the required length, which allows us to minimize the number of joints.

There is also a new way to insulate the winter water supply at the dacha - liquid thermal insulation or thermal insulation paint. It can be applied to an already installed water supply system, which can be a good solution.

Pipeline insulation

When supplying water to a private house from a well and a borehole, the pipeline can be laid at a very shallow depth - 40-50 cm - this is quite enough. Just laying pipes in such a shallow trench needs to be insulated. If you want to do everything thoroughly, then line the bottom and sides of the trench with some kind of building material - bricks or building blocks. Everything is covered with slabs on top.

An example of laying pipes above the freezing depth in a prepared ditch. The insulation of the water supply is carried out with a special insulation, with a suitable internal diameter

If desired, you can fill in the soil and plant annuals - if necessary, the soil can be easily removed and free access to the pipeline is provided.

Insulation for water pipes

Two types of insulation can be used:

- special energy-saving shells molded in the form of pipes, they are also called “pipe shells”;

- roll material - ordinary insulation in the form of rolls, which is used for walls, roofing, etc.

Thermal insulation for pipes in the form of a shell is made from the following materials:

- Expanded polystyrene - multiple granules are fused together. The result is a fairly rigid and durable material with good thermal insulation characteristics.

- Extruded polystyrene foam - the cells of the material have a closed structure (small balls). This also gives the material water-repellent properties, as well as higher thermal insulation properties. This is one of the best materials with a high degree of insulation, but its disadvantage is its high price.

- Polystyrene foam - one of the variants of expanded polystyrene - has good thermal insulation characteristics, but is characterized by low strength. That's why he needs protection - he can't stand pressure. But it costs a little. If you are laying pipes in a trench with walls made of brick or concrete, it can be used.

Nobody bothers you to play it safe and use two layers of insulation - Polyurethane foam - in terms of characteristics and price, it is between expanded polystyrene and polystyrene foam. This is what is most often used for pipe insulation.

- Foamed polyethylene (such as “Energoflex”) has good characteristics due to the high content of air bubbles.

- Glass wool is a rolled material with good thermal insulation characteristics and a relatively low price. Its disadvantage is that it requires special measures when installing: fiberglass is very prickly, and it is impossible to remove microscopic particles from the skin. You also need a respirator and safety glasses - small particles are volatile and harmful to health.

- Stone wool. It is made from basalt or slag. Basalt wool has the best characteristics, but is expensive. Slag wool is a cheaper material, but its characteristics are worse - you need to take it in greater thickness, which often reduces material benefits to a minimum.

Insulation of water supply pipes in a private house is done using thermal insulation.

Mineral wool - glass wool and stone wool - have one significant drawback: they are hygroscopic. By absorbing water they lose most of their thermal insulation properties. After drying, they are only partially restored. And another very unpleasant moment is that if wet mineral wool freezes, after freezing it turns into dust. To prevent this from happening, these materials require careful waterproofing. If you cannot guarantee the absence of moisture, it is better to use another material.

How to make drip irrigation systems for greenhouses and vegetable gardens with your own hands is written here. There is an article about manufacturers of ready-made drip irrigation kits here.

Manufacturer's choice

In order for the heating cable to serve you for more than one or two years and meet the declared parameters, you need to purchase products from trusted brands. Only in this case the costs of its purchase will be justified. The following manufacturers have earned trust:

- Thermo Industri AB is a Swedish manufacturer that is one of the largest in Europe. For quite a long time the company has been specializing in the production of cable heating systems. This narrow focus can ensure proper product quality and reliability. The production lines are represented by modern equipment. The use of modern technologies allows us to produce heating systems that are safe to use;

- Eltrace is a French manufacturer that adheres to two main criteria for finished products - quality and affordable cost. The company produces a self-regulating type of cable, which, depending on the application, includes two lines. Tubes-heat – for domestic and industrial pipelines. Traceco – for any type of heating systems;

- Thermon and Raychem are brands originating from the USA. The advantages of their products include safety and reliability, economical energy consumption, and convenient installation. It is worth noting that the self-regulating cable of these companies has an international quality control certificate;

- Devi is a manufacturer from Denmark whose products are of high quality. Initially, the company specialized in the production of heating elements for industrial needs. But already in the early 60s, one of the first heating systems based on electric cable was released. The company has extensive experience, which ensures high reliability of their products.

The article was written for the site.

Tags:Pipes