It is very important that the water supply in a private home or country house is provided without interruption, regardless of the time of year. This is especially true in relation to the winter period, when it is freezing outside. Despite the fact that pipes are always laid below the frost line, weak spots are often discovered and the pipes freeze. It is not so easy to get rid of freezing in such conditions, so we have to expect warming. To prevent this from happening, in areas where pipes enter the house, water pipes are heated and insulated. As a rule, a special heating cable is used.

Types of heating cables for heating pipes

There are two types of cables - resistive and self-regulating. Resistive cables work on the principle of heating, depending on the amount of resistance and current. Their peculiarity is that such cables always emit the same amount of heat, regardless of what the outside temperature is. In this case, they always consume the same amount of electrical energy. In order to save any money, you have to install temperature sensors and thermostats.

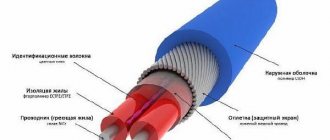

Structure of a resistive cable

The technology for laying resistive cables has some features. Firstly, the conductors should not be located close to one another, much less intersect. If this condition is violated, the system may overheat and fail. Secondly, there are single-core and double-core cables, which is something you need to know about. And most importantly, they cannot be cut, because after such an operation they will not work, so you will have to install the entire cable, regardless of the length of the section that needs protection.

Single-core cables are connected to a 220 V network at both ends, which is sometimes not practical, while double-core cables have a plug on one side and a 220 V electrical plug on the other side.

This is approximately how heating cables for plumbing are sold.

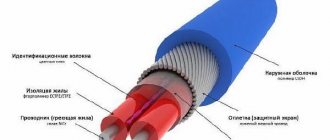

Self-regulating cables have a completely different design, since they are based on a metal-polymer matrix. The wires in such systems only conduct electric current, and the matrix itself is heated, and this polymer has a rather interesting property: the more the matrix heats up, the less heat it emits. When cooling, on the contrary, the matrix begins to increase the amount of heat generated. Because of these properties, the cable is called self-regulating.

Structure of a self-regulating cable

Such products are characterized by a number of positive data:

- Installation methods may vary.

- They can be cut off.

In other words, a self-regulating cable is more practical, despite its high cost. It should be noted that the service life of such cables for heating water pipes is quite impressive (10 years), if used correctly.

On a note! Regardless of the type of heating cable used, the pipeline will have to be carefully insulated. If this is not done, then significant power will be consumed to heat the water supply, so there can be no talk of efficiency.

Self-regulating heating cable https://elektrokhv.ru/

Cable for insulating water pipes - All about insulation and energy efficiency

It is very difficult to ensure uninterrupted water supply in a country house. Residents of such real estate very often experience freezing of the pipeline in winter. To avoid this problem, when installing a water supply, install a cable to heat the water pipe. Such heating systems protect communications from freezing and destruction.

Application of heating cable

Laying a pipeline can be done without heating the water supply and sewerage with a heating cable, if the water supply pipes are buried deep enough and have good thermal insulation.

However, in swampy areas and areas close to water bodies, the groundwater level is very high, which often exposes communications to flooding and freezing. If the pipes are not installed deeply and a self-regulating heating cable is laid, then the communications will be reliably protected.

There are also critical areas that are more susceptible to low temperatures - areas where water and sewer pipes enter the house. The heating cable for heating pipes can only be installed in these places.

Such heating systems have very useful features. For example, the possibility of zonal application. That is, from a set of elements you can assemble a small system for heating a water supply in a separate area, without connecting a self-heating wire throughout the network. There are mini-"heaters" of 20 cm, and maxi-"heaters" of 200 meters.

Depending on the type and technical parameters, the heating cable is used to heat pipelines and drains, tanks for collecting and storing liquids in winter. The main task of the system is to protect the liquid from freezing by warming it up through an increase in temperature.

Installation of the heating cable is possible both in a pipe in the ground, that is, internal, and on a pipeline in the open air, that is, outside.

Thus, if you have a choice between connecting a heating cable or not laying a heating system, then you should definitely take advantage of this opportunity and insure your pipeline from freezing.

Design features of the system

The operating principle is based on the ability of a resistive or self-regulating cable to convert electricity into heat energy. The wiring itself does not transmit energy, as is the case with power analogues, it only receives it, and then the wires heat the object, transferring heat.

The heating cable for water pipes consists of the following main elements:

- One or more internal conductors with high resistance to electric current; the higher it is, the more heat will be generated.

- The protective shell is made of polymer; insulation in the form of a copper mesh or an aluminum screen is used together with plastic.

- The outer sheath is made of durable PVC, which protects the inner sheath and core.

Cables for heating a water pipe from different manufacturers differ in alloy, design of protective elements, cost and other parameters.

The most reliable is considered to be a heating wire with a foil screen and several cores. Solid wire is a cheaper option and is suitable for connecting a system in a small section of piping as solid wire transfers less heat.

To improve the characteristics, the copper braid is nickel-plated, and the thickness of the outer PVC sheath is also increased. In addition, the outer layer must be moisture-resistant and resistant to ultraviolet radiation so that the protection can withstand both contact with water and exposure to direct sunlight.

Types of cable heating

The heating cable for sewer and water supply can be one of two types: resistive or self-regulating. Each of them has its own scope of application. So, the first type is more suitable for heating small sections of pipes with a diameter of up to 40 mm, and a self-regulating cable is good for longer sections. Let's look at each type in more detail.

- Resistive has the following principle of operation: current passes through the wires and heats the cable. High current and high resistance contribute to excellent heat dissipation. There are pieces of resistive wire with a constant resistance coefficient. During operation, such a cable gives off an equal amount of thermal energy along its entire length.

Single core wiring is double protected internally and externally insulated. The heater is a single wire that will be connected in a loop-like manner: the wire is connected to the electrical network, then wound around the tube, and then returned back.

A closed loop heating system is usually used for installing “warm floors” and heating roof drains; there is also an option for a plumbing system. Do-it-yourself installation of a heating cable for a water supply system requires double-sided laying of a single-core wire. It is noteworthy that in this case only an external connection is used.

A single-core resistive cable is not suitable for underground installations, since laying a “loop” takes up too much space, and crossing the wiring will lead to overheating.

Wiring with two wires separates their functions: one wire supplies electricity, and the second heats it. The connection diagram is also different: there is no need to create a “loop”, and the cable is connected to electricity at one end, and the other is laid along the pipeline.

The main advantages of resistive cable are its low cost, reliability, ease of installation and long service life (10-15 years). However, there are also disadvantages, among which it is worth highlighting: a fixed length, a high probability of overheating when the wiring is close together, the impossibility of replacing one section and the power cannot be adjusted.

In order not to connect the heating system every time, install a thermostat with a temperature sensor. When the temperature drops below the set value by 2-3 degrees ºC, the thermostat automatically starts the heating device, and as soon as the temperature rises to the set coefficient, the energy is automatically turned off.

- Self-regulating heating cable. This is a universal type of wiring that can be used to heat a roof element, water supply and discharge lines, and containers with various liquids. Such a cable is immediately equipped with a system for adjusting power and heat energy intensity. When the temperature drops below the control value, the system starts heating.

Installation methods

There are two options for installing the heating cable: it is laid either outside or inside the pipe. In this regard, several types of cables are produced, depending on the installation method. You can learn about the installation method from the technical documentation for the product.

Installation inside the pipe

If installed inside a pipe, the device must meet certain criteria:

- The product must not emit harmful components.

- Have a high degree of electrical protection.

- Sealed end coupling design.

When laying out the pipeline, you should provide an area for installing a heating element. As a rule, a tee is installed at the end of the section and a cable is mounted into one of its branches using a special sealed device - a gland, which must be included in the kit.

An example of installing a heating cable inside a pipe through a gland

Please note that the coupling is not intended for use in wet environments and must therefore be located outside the pipe.

Types of tees for installing a heating cable inside a water supply system

Installation outside the pipe

This installation method also includes some features. Firstly, before installation, the pipes are cleaned of dust, dirt, rust, welding marks, etc. Secondly, the fastening must be carried out so that the heating cable fits tightly to the surface of the pipe. Care should be taken to ensure that there are no elements on the surface that could damage the heating cable. After installation, the cable is fixed every 30 cm using special clamps or special adhesive tape.

Methods for attaching a heating cable to a pipe

When using one or two cables, they are attached at the very bottom, where the coldest zone is. When laying parallel, a certain distance must be maintained, which is especially important for resistive heaters.

There is another installation method - forming a spiral. It should also be recalled that such cables are not intended to form sharp bends, so they should be handled quite carefully. To avoid sharp bends, it is better to use the following recommendations: the cable is wound onto the pipe gradually, as the coil unwinds, or it is attached to the bottom of the pipe with a slack, as indicated in the bottom picture, after which it is additionally tensioned and secured using metallized adhesive tape.

Spiral winding

When heating a plastic water pipe, metallized tape is first glued to the pipe, which increases the efficiency of the system due to good thermal conductivity. As a rule, tees, valves and other fittings require more heat to heat, so in such places it is better to make a few extra loops. In any case, it is necessary to control the bending radii of the cable.

Insulation methods

The process of heating pipelines is accompanied by the formation of condensation, so any insulation, such as mineral wool, is not suitable. When wet, these types of insulation significantly lose their characteristics. If, after getting wet, such insulation also freezes, then after freezing you can forget about this method of insulation altogether.

We should not forget that usually water pipes are simply buried in the ground without being laid in special sewer channels. Many types of insulation shrink, as a result of which they lose their basic characteristics. These types of insulation are also not recommended, despite the fact that they are not afraid of moisture. If a specially laid channel is used, then you can get by with ordinary foam rubber. Otherwise, insulation with a protective casing will be required. Alternatively, you can put a rigid pipe in the form of a plastic sewer pipe on top of the insulation.

An example of insulating a water pipe with a heating cable

There is another type of thermal insulation material - polystyrene foam, which is molded in the form of pipe fragments. It is also called shell. It has excellent thermal insulation properties and resistance to moisture. In addition, it is able to withstand certain types of loads.

Selecting the power of the heating cable

The choice of power depends on a number of factors, such as natural conditions, pipe laying method, pipe diameter, presence of insulation, heating method, etc. In any case, each manufacturer develops tables from which you can easily determine the cable length per 1 linear meter of pipe. At the same time, there are tables for each cable power.

As practice shows, in central Russia, heating 1 meter of pipe from the inside consumes up to 10 W of power, and almost 2 times more from the outside. As a rule, calculations are tied to a specific insulation layer, and the colder the region, the thicker the insulation layer.

Heating cable on a pipe. Installation rules

Self-regulating cable for heating water pipes: installation features

The main places where cables are used for heating pipes are country houses, dachas, garages - all structures where water supply or sewerage runs through places where exposure to negative temperatures can be observed in places or completely. This type of cable is used in the following cases:

- Insulation of the water supply system, part of which runs outside the building;

- Protecting sewers from freezing.

Preventing pipes from freezing is quite simple.

Application of heating cable

Having come across a heating cable for pipes in the assortment of a hardware store, not everyone knows what it is intended for. The use of this device is of great benefit, allowing you to avoid such an unpleasant phenomenon as freezing of the pipeline.

In country houses or cottages, it is almost impossible to avoid laying part of the water supply or sewerage system along the street, and as temperatures drop, there is a very real possibility that water will freeze in unprotected places, which will lead either to a temporary loss of functionality of the pipeline, or to larger-scale consequences expressed in rupture of pipes due to ice.

Before the advent of heating cables in everyday life, they tried to solve the problem of freezing pipelines by organizing the required angle of inclination of the pipes, reinforced with thermal insulation, but the risk still remained. A heating cable will help avoid this.

In order to purchase a suitable cable, you need to know the length of the insulated pipeline and decide how the cable will be laid:

- in a straight line on the surface of the pipe;

- upholster it in a spiral.

Cable laying methods

The latter option provides more intensive insulation and is used if the pipe is subjected to extremely low temperature loads, or sufficient insulation of the pipeline is impossible.

The heating cable may include a temperature relay that will turn on the power when the temperature drops. The price of this product depends on its length, configuration and technical characteristics.

How to install the heating cable?

Installing a cable for heating pipes cannot be called an overly complicated undertaking, and to carry it out it is not at all necessary to call a professional with special equipment. It is enough to have basic skills and a minimum set of tools; the main conditions for a quality installation are accuracy and thoroughness.

A self-regulating cable for heating pipes can be installed:

- Outside the pipeline - this option is more popular.

- Inside the pipeline, in this case additional cable protection is required.

Internal cable installation process

Work can be carried out both on a new water pipeline under construction and on an already functioning one. Cable laying is carried out in several stages; we will consider them in more detail.

If heating is planned on an already operating pipeline, no matter sewer or water supply, first you need to remove the thermal insulation from it and clean the pipe in order to prepare the installation site.

Cabling

The most common way to lay a cable for heating water pipes is to pull the cable in a straight line on the surface of the pipe and fix it with special clamps or electrical tape. In this case, the length of the cable will be equal to the length of the pipeline, but if a method is chosen in which the cable is wrapped around the pipe in a spiral, fixation is not required, you just need to provide a certain length reserve.

Fixing the cable on the pipe

Is it worth installing a thermostat?

Nowadays, issues of saving money in the family budget come to the fore, so no one will overpay, which means that without a thermostat, the operation of the heating system for water pipes will be ineffective and costly. The thermostat turns on the system at a temperature of +3 degrees and turns it off at a temperature of +13 degrees.

When water is supplied from a well, its temperature will not reach +13 degrees, so the system will operate all year round. In the summer, you can turn off the heating, but in spring and autumn, when there is a high probability of frost, this cannot be done.

Whatever one may say, in any case, a thermostat is simply necessary. If you set the shutdown temperature on it to about +5 degrees, then you will have to pay a pittance for electrical energy. In addition, the durability of the heating system increases noticeably, since the cables have a certain working life. The less they work, the more at maximum, the longer they will last.

Heating cable for water supply - connection diagram to the thermostat

Naturally, in this case you will have to correctly position the temperature sensor. It should fit snugly against the pipe, but at the same time it should be reliably isolated from the heating element itself.

As a rule, the thermostat is installed indoors. The device is connected to the house electrical panel via a circuit breaker, 6 amperes and an RCD, with a leakage current of no more than 30 mA.

The heating cable is connected to certain terminals located on the thermostat housing. If several cables are connected, they are connected in parallel. The temperature sensor is connected to other contacts. As a rule, there is a corresponding marking on the body of the device, and the connection diagram is in the passport, so it’s not at all difficult to figure it out. If there is no marking on the device, then it is better not to buy such a product, since it does not meet all the requirements. Most likely it was produced illegally.

How to install a self-regulating heating cable inside a water pipe

Connecting the heating cable