Features of canopies

A profile canopy is a structure that represents a covered area. It can have different shapes and sizes. This structure is used to protect against negative external influences.

A frame for a canopy made of metal profiles is a winning solution. This material is resistant to negative external influences, durable and able to withstand significant loads. Such structures are easy to design and install, which also has economic benefits.

The design of a canopy made from a profile pipe implies the presence of the following elements:

- Foundation . Usually columnar due to low cost and ease of installation.

- Supports . They are vertical load-bearing elements.

- Suspensions . The horizontal part of the frame is formed.

- Slopes . They are lateral connecting elements.

- Rafter system . It is formed from rafters, sheathing, and trusses.

- Roofing _ Made from polycarbonate sheets and profiled flooring.

A canopy made from corrugated pipe is formed from a different set of load-bearing and additional elements. It all depends on its functions, size, configuration, expected loads.

Construction of a covered area Source infotruby.ru

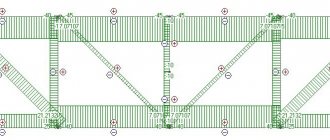

Rafter covering systems of significant size are formed using trusses. They consist of two horizontal pipes, which are connected to each other by vertical (risers) and inclined (braces) elements. Trusses provide the structure with the necessary spatial rigidity and load-bearing capacity.

Materials

Before you move on to drawing up drawings of a canopy with a pitched roof, you should decide what material the frame and the roof itself will be made of.

It is equally important to take into account the size of the canopy, its installation, weight and rules for working with a particular material. Of course, first of all it all depends on personal wishes

For example, you can build a canopy on stilts or from a soft roof.

Frame

There are three types of materials for the frame of the structure.

The metal is galvanized cold-rolled pipes or steel profiles with increased rigidity. In this case, the frame can be standard, complex or forged. This type has a long service life, high quality, and also withstands exposure to natural factors.

Another type of frame is very rare - stone. Of course, this option is time-consuming, but it is also more durable. This design will last 2-3 times longer compared to other types.

Roofs

Currently, among the roofing materials suitable for lean-to sheds, several options stand out.

Classification

Indoor areas are usually divided into several types depending on the type of support and rafter system.

Support type

Types of canopies made of metal profiles according to the type of supports:

- Attached . They are attached to the load-bearing walls of the building. The design implies the presence of additional supports. Such structures are suitable for arranging terraces, entrance areas, and parking lots.

Attached type of canopy Source yandex.net

- Console . The structures have no supports and are fixed to the wall of the building. Additional fixation is provided by special suspensions. Such canopies are most often installed over balconies and entrance areas.

Cantilever canopy Source remont-book.com

- Freestanding . They rest on support posts. They are used to create coverings over parking lots, various playgrounds, and recreation areas.

Free-standing canopy Source polikarbonatvs.com.ua

See also: Catalog of companies that specialize in the design and installation of metal structures

Roof type

The roof is the basis of a suspended structure, the complexity of the construction of which depends on its size and shape. Canopy made of pipes according to the type of rafters:

- Single-pitch . The simplest design that goes well with all roofing materials. When creating a covering for large areas, trusses are used to form a rafter system.

An example of a shed roof Source zakupka.com

- Gable . It has a more complex configuration. Gable canopies made of metal profiles in the courtyard of a private house for large areas are created using trusses in the form of equilateral triangles.

Gable roof Source prom.st

- Shatrov . As the number of roof slopes increases, its calculation becomes more complicated. When creating a structure, precise cutting of the roofing material is necessary. To protect all roof joints, the use of special elements is required.

Hip roof Source landshaftdesign.org

- Arched . It is formed from trusses curved at a certain radius or arched rafter legs. To create the coating, exclusively flexible materials are used. The roof has the shape of an arch or wave.

Arched roof Source stroybat.bel

Installation principle

All types of canopies have the same installation principle. Most often they are installed close to one of the walls.

To attach the canopy to the wall, use a beam of the required length. It is secured using anchors or ordinary dowels. If you want to leave the wall intact, you can install vertical supports close to it.

To make the canopy easier, a straight pitched roof is usually installed. If it is necessary to install a canopy as a decorative element, then it can be made rounded, double, using different styles.

Calculation and creation of drawing

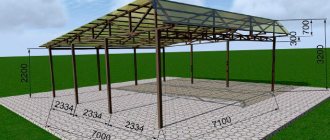

The design of a canopy made of metal structures is necessary to calculate materials and to facilitate subsequent installation. The location of the main and additional elements is noted on the drawing and their dimensions are indicated.

When creating a design project, the following values are taken into account:

- tilt angle (Q);

- rafter length (L).

The angle of inclination of the slopes is selected taking into account the standard snow and wind load (selected for a specific climatic region according to SNiP). The type of roof chosen is also taken into account. A canopy made of corrugated pipe can have slopes that form an angle of 6-15% with the horizontal plane. For other types of structures this figure should be in the range of 22-30%.

Example of a canopy drawing Source prom.st

Area

Construction begins with site preparation, at this stage the following actions are performed:

- clear the area, removing vegetation and debris. If the canopy is intended to protect a resting place or barbecue, fine grass is left;

- particularly prominent mounds and depressions are cut off or filled in, respectively;

- if the area under the canopy is supposed to be concreted, covered with crushed stone or covered with paving slabs, cut off the top layer of soil to a depth of 10 - 15 cm. It contains plant seeds, they would break through the covering;

- carry out markings, noting the location of the supports. The number of supports and the pitch between them are determined by calculation at the design stage. As a result of marking, the outline of a rectangle should appear on the ground. To make sure that the figure is drawn without distortions (due to its large dimensions this is quite likely), measure the lengths of the diagonals: for a rectangle they are equal;

- in the places where the supports are installed, excavations are made with a depth exceeding the soil freezing mark by 10 - 15 cm. If the depth is less, the frozen soil will squeeze out the posts in winter (the force of frost heaving).

Excavations of shallower depth are allowed only in rocky and sandy soils that have draining properties.

Technology of work execution

Sheds made of metal profiles in the courtyard of a private house are installed taking into account generally accepted building codes. The list and scope of work performed also depends on the chosen structural design of the structure.

Single-pitch design

A single-pitch canopy from a profile pipe is made according to the following scheme:

- Preparatory work . The area where the profile pipe carport will be placed is cleared of debris and leveled.

- Marking . The installation locations of the support pillars are indicated.

Marking a columnar foundation Source yandex.net

- Foundation . A hole with a depth of at least 60 cm and a diameter of 25 cm is dug under each pillar.

- Installation of racks . Each pipe, which acts as a rack, has a “heel” - a special strip - welded to the bottom. The element is installed in the design position, after which the free space in the hole is filled with concrete mixture.

- Frame strapping . The racks are connected along the contour using horizontally oriented elements.

- Creation of farms . Two pipes located along the legs of the structure are welded. The hypotenuse is measured, a piece of pipe of the required size is cut off, and then welded in the right place. Cross members are welded between the leg and the hypotenuse to increase the spatial rigidity of the structure.

- Installation of additional fasteners . When creating a canopy from a profile pipe, a horizontal strip is welded to each smaller leg of the truss. Holes are made in it, which will allow you to subsequently attach the structure to the wall of the house.

Frame installation Source ad-cd.net

Kinds

According to its design, the building has various methods of execution. It all depends on the purpose of the canopy, the material and the personal preferences of the owner. Today, you can build an extension in various ways, taking into account the selected material. Metal or wood can be used to construct supports. The roof frame is made in the same way. But you can see what wood-like metal siding looks like here.

The versatility of corrugated sheeting is that there is no need to adjust the ceiling to the fastenings

(It is also worth paying attention to how the pediment is covered with corrugated sheets). This is due to the fact that the edges of the sheet are concentrated very close and this is quite enough to fix the iron sheet

The cladding around the perimeter can also be different. The attached structure is open, trimmed with boards with windows, and presented in the form of a terrace.

But what kind of canopies and awnings there are over the entrance can be seen here.

In the video there is a canopy made of corrugated sheets adjacent to the house:

https://youtube.com/watch?v=RxbGI0EqdnM

Canopies made of polycarbonate can have different designs. The most common ones include:

- arched;

- single-pitched;

- gable.

The difference between them lies in the complexity of installation and the amount of material used.

But what types of polycarbonate carports there are, and how they can be made, this information will help you understand.

Arch

This polycarbonate canopy option has a rather attractive appearance. To attach it to a house, you need to have significant construction experience, because this design is distinguished by its complexity.

Canopy arch made of corrugated sheets adjacent to the house

They arise for the reason that the roof straps to which the corrugated sheeting is to be fixed must be presented in a curved shape. And to obtain such a bend, special equipment is used.

Single-pitch canopy

This type of corrugated sheet extension does not require special experience or the use of special equipment

But at the same time, increased attention will be required when choosing the correct angle of inclination of the roof.

Single-pitch canopy

Thanks to it, the canopy will not be subject to constant accumulation of snow in winter, and the sheathing will be freed from unnecessary pressure. A polycarbonate canopy over a porch can look exactly the same.

bbb77658765d88a0938f3bf98f404168.jpe

Gable canopy

This design is a full-fledged roof. To obtain such a canopy, one corrugated sheet will not be enough. A gable roof can be used when a spacious open-type summer kitchen is required. There is also another roofing option - multi-slope. This type of construction is the most difficult to implement. Only professional builders can make it.

Gable canopy

If we talk about the dimensions of the canopy, then their choice should take into account the load and purpose of the structure. The canopy adjacent to the house should not be large, otherwise the wall will not be able to withstand the load. If this canopy is over the porch, then it should not be very small. But the carport is calculated taking into account its size. But you can see what the texture of the wall looks like under the plaster here.

If the car is small, then it can fit under a structure of at least 2.3 x 5.5 m. For an SUV or truck, you will have to find a load with dimensions of 3.5 x 6.6 m. It is also worth considering the height of the canopy. The optimal parameter is 2.3 m. But for a gazelle this will not be enough. As the height of the canopy increases, the likelihood of rain and snow getting under the extension increases.

Maybe

Video description

More information about how to install metal canopies from metal structures to a house is described in this video:

Gable

The gable structure is being built according to a similar technological scheme. The only difference is the roof design. Trusses, which are equilateral triangles, are used as rafter legs. Inside the structure there are always vertical and inclined elements that provide additional rigidity.

If a canopy for a house made of metal profiles is made using corrugated sheets, special screws are used to attach the sheets to the sheathing. They are installed without pre-drilling holes and ensure a tight connection due to the presence of a rubber gasket.

The joint of sheets on a gable roof is closed with a special ridge strip. It is attached using the same screws to the upper groove of the corrugated sheet.

Manufacturing of sheathing

A wooden sheathing is placed on the trusses, on which the roofing covering is installed. The easiest and most reliable way is to lay a simple metal profile flooring. It is reliable, quite durable, and relatively inexpensive. The use of polycarbonate sheets for the manufacture of canopy roofing is also widespread today. In addition, no one has canceled slate, and you can also use sheets of polymer. To ensure that wooden sheathing lasts longer, wooden structures should be treated with antiseptic preparations. The polycarbonate roof is laid directly over the girders of the truss.

Additional recommendations

Canopies made of metal profiles in the courtyard of a private house or public building are made taking into account the following rules:

- Before laying the foundation, you need to find out the depth of soil freezing for a specific area. The pillars should be buried no higher than this level. This will guarantee the strength and durability of the structure.

- All elements of the metal frame must be coated with a special primer and paint. This will prevent the material from being destroyed by moisture.

- Arches for a canopy from a profile pipe are made using special equipment that helps bend the metal to the desired radius. It is impossible to do this on your own.

- To fix pipes with a diameter of up to 25 mm, you can use the crab system. These are special clamps that provide simultaneous connection of several frame elements.

An example of using a crab system Source greenhouse-yaroslavl.rf

- To connect elements from a profile pipe, in addition to welding, you can use bolted connections. They are no less durable and can withstand significant loads.

Variety of metal profiles

A metal profile is not only corrugated sheeting, but a whole range of finished metal products that are produced by metal rolling enterprises. In addition to corrugated sheeting, metal profiles also mean a number of steel elements:

- non-profiled metal sheets;

- solid bars - reinforcement of various sections;

- sectional hollow steel - pipes of different sections, an excellent frame option for lightweight

- canopy or canopy;

- shaped beams - channels, I-beams, corners.

It is from these rolled elements that the awnings, canopies and gazebos we are talking about today are most often built.

Briefly about the main thing

A carport made of metal profiles is the optimal solution from a constructive, functional and aesthetic point of view. Also, such structures are excellent for arranging covered areas for recreation, games, sports, for decorating terraces and entrance areas.

Such structures consist of a foundation, racks, hangers, slopes, rafter system and roof. Depending on the type of support, they can be free-standing, cantilevered or attached. According to the type of roof used, such structures are divided into single-pitched, gable, arched, and hipped.

It is best to entrust the calculation and installation of the canopy to professionals. This will allow you to get a reliable design that will last for many years.

Ratings 0

Advantages

The key features of a fence made of polypropylene pipes are its resistance to various weather conditions and temperature changes, as well as minimal maintenance requirements, which may be required even less frequently than once a year. Plus, you can forget about the corrosion process that is harmful to iron.

Let's look at a few more positive points:

- A fence made of plastic pipes will not be damaged by frost;

- It is easy to install and is not demanding to operate;

- Time will not spoil its appearance;

- Not exposed to ultraviolet radiation;

- Easy to clean from most types of dirt;

- And most importantly, its creation will not require large investments, since PVC pipes are several times cheaper than metal.

The only drawback can be the “unnaturalness” of plastic pipes, which may not appeal to lovers of environmentally friendly materials.

Decorating the fence

The main purpose of the fence is still warning and protective functions, but every owner would like to stand out from the general background. And a house or summer cottage always begins with its fence, so the desire to decorate it is quite understandable.

Supports and spans

The most daring ideas can be realized to improve the plastic structure. The finishing of the enclosing structure can be done with the help of vinyl decorations, and the supports are protected and at the same time decorated with caps of various shapes, made in imitation of natural material.

Decoration can also be called low fences for flowers or a front garden. A variety of product colors and installation methods allow you to create inimitable masterpieces.

Some important tips

- If reinforcement is used as supports, but the bottom trim can be made of boards. It will be much easier to attach fabric or tarpaulin to them. Yes, and then disassemble the structure too.

- Plastic pipes can become the basis not only for the gazebo frame. It is easy to make original summer furniture from them (armchairs, chairs, benches, flower stands).

Photo: furniture made of polypropylene pipes

- When the project also includes flooring, it is better not to attach its base to the bottom trim. It is recommended to mount separate posts, and then lay timber logs on them and cover them with boards on top.