If you use gas cylinders at home, then you probably know that safety should come first. Agree, nothing adds confidence more than peace of mind for yourself, your loved ones and property. In this sense, everything is decided by the gasket on the gas cylinder - a very cheap and simple remedy. The safety of using the equipment directly depends on its quality and size. It would be nice to protect yourself from explosion, destruction or possible fire, wouldn't it?

We will tell you about the requirements for gaskets and the rules for their use. You will find out what sizes, types they come in, and what features they have depending on the materials used. Together with this information, it will be easier for you to make a choice whether to buy a new or replace the old seal.

Gaskets are used on many connections. In the gas industry, seals are used on cylinders, hoses, and pipelines. This is done for the sake of safety and to minimize fuel losses. Read the article and find out more about it.

What are cylinder gaskets for?

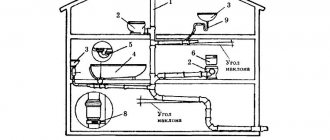

They are used as sealing parts at the points of connection of the valve (faucet) to the neck of the gas cylinder and to the reducer. In the first case, the seal is mounted on the tank body and in a horizontal position, in the second - between the valve fitting and the gearbox, vertically. There are also gaskets inside the valve: under the flywheel, in the unit body and in its valve.

The seal eliminates or prevents gas leakage. Rubber gaskets increase tightness, improve mechanical characteristics, and keep connection parts in working condition. You cannot do without oil seals in rooms with small or no windows, rooms with stagnant air, and unventilated areas.

Gaskets improve the performance of gearboxes. The latter are connected when gas is supplied through a hose to reduce or stabilize pressure. In the process, the usual indicator of 16-50 or the maximum of 150-250 atmospheres reaches values from 1 to 16, and the probability of an explosion increases compared to the state when the cylinder is not used. The seal reduces the risk.

After prolonged use of the cylinders, the seals become deformed. They are changed about as often as cylinder taps.

In addition to sealing gaskets, transportation gaskets are used with gas cylinders: the rings are placed on the wide part of the body, in 2 places.

Reducers for gas cylinders, hoses. Selection and installation.

The pressure in a household gas cylinder can vary within fairly wide limits depending on the composition of the gas (the percentage of propane in it) and the ambient temperature. To operate a gas stove or other gas equipment, a certain pressure is required. Moreover, the pressure for gas appliances is very low. This was invented specifically for safety reasons.

| Here is a selection of materials: IN Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning |

To obtain low pressure from high pressure inside the cylinder, a reducer

- a device that maintains stable outlet pressure regardless of the inlet pressure.

The gas reducer is screwed directly onto the cylinder (also for safety reasons, to minimize the length of communications under high pressure). On the cylinder and on the pressure nut of the gearbox there is a left-hand thread. So you need to screw it in the direction in which we usually unscrew it.

A gasket is installed between the reducer and the cylinder. These gaskets are usually made of special synthetic materials or genuine leather. But I use silicone gaskets. Silicone gaskets seal more reliably, but they are flammable. In the event of a fire, such a gasket will burn out, gas will leak, and an explosion will occur. So the use of such gaskets is prohibited by standards. The gearbox nut should be tightened moderately. Both insufficient tightening (gas will pass through) and overtightening (you can damage the gasket, nut, cylinder or reducer) are dangerous. A sign of normal tightening is the rigid fixation of the gearbox on the cylinder, but the force that must be applied for further tightening remains small.

Propane has virtually no odor. So its leak is very difficult to detect. To solve this problem, special aromatic, foul-smelling additives are added to it. Gas leaks become easily diagnosed.

The problem is that the rubber gas pipes that are usually used to connect the reducer to the gas stove leak gas a little. The volume of this leak is so insignificant that the standards allow it. But the pipe gradually begins to smell quite intensely of these same flavors. This makes diagnosing a leak very difficult. I tried to buy imported hoses, but the effect is the same, only after a longer time. Gradually I began to use silicone hoses. Silicone hose has two disadvantages. It is not reinforced (the pressure is small, but for some reason the rubber hoses are reinforced), and it really likes to bend and cut off the gas supply. The ideal solution was to place a silicone tube of a diameter suitable for the reducer inside a thick rubber reinforced gas hose. You need to choose a hose of suitable thickness so that the silicone tube fits easily into it. We coat the tube with Vaseline. We push it inside the hose. We put the ends on the gearbox and the fitting from the plate and tighten them with clamps.

Materials for seal

Paronite, rubber and fluoroplastic are used in production.

Due to its adhesiveness, paronite tightly fills cracks and gaps. The connections are specially protected with graphite so that the material does not stick to them. Biological and climatic factors have little effect on paronite, and a sealant with mineral additives will survive contact with aggressive hydrocarbons. As the ideal size of the washer is exceeded, its effect becomes minimal.

Rubber is used because of its elasticity and ability to restore shape. Other properties include amorphousness and elasticity. The latter indicator increases with the ambient temperature. Hardness is controlled by the degree of vulcanization, plasticizers and fillers.

Seals are made of nitrile butadiene rubber with an upper temperature limit of +120...+130 °C and fluorine rubber, which can withstand up to +150...+200 °C.

Fluoroplastic exhibits resistance to chemical and corrosive processes. The material was also found to have weather resistance, heat and frost resistance. Due to low gas permeability, fluoroplastic began to be used in private homes and household gas distribution systems. After ignition, it quickly dies out, and the friction coefficient is in the range of 0.4–0.05 at a load of 1–20 kgf/cm².

In practice, silicone profiles are also used, but general safety standards prohibit installing the material on gas and fire equipment. Silicone seals reliably, exhibits high temperature resistance, but is highly flammable.

Types of gas flexible hoses

The current market offers a fairly extensive list of gas hoses. In addition to the material, you will also need to choose a manufacturer. And in this case it is better not to save. The item is bought once and for a long time. Having saved 500 rubles, you can then spend a lot on health and repairs if the pipe starts leaking gas. Therefore, let’s first look at the varieties.

Rubber-fabric

It has many advantages that allow it to be used in a gas system:

- easy installation;

- good flexibility;

- low cost;

- various sizes;

- excellent electrical insulation.

The disadvantage of such rubber parts is poor rigidity. Today, the industry produces hoses from a special material of high elasticity. Therefore, their service life can reach 10 years.

Very important! The connection must only be made with a special gas hose. It is forbidden to use water hoses, especially homemade ones. The cost of such hoses usually does not exceed $7

The cost of such hoses usually does not exceed $7.

Bellows metal

Professional gas fitters consider it the most suitable for gas systems. The service life of such hoses can be more than 25 years. It connects to a gas stove without any difficulty. Bellows systems can be connected to boilers and water heaters, and they are completely safe.

If you have a gas stove equipped with electric ignition in your kitchen, in order to connect the bellows device, a special insulating connection is created between it and the tap.

This type of hose bends freely and can withstand high pressure, reaching 6 atmospheres. It can withstand significant temperature changes ranging from -50 degrees to heating up to 200 degrees. The main disadvantage of a bellows hose is its cost. It is many times higher than similar gas connections.

The advantages of such bellows metal systems include:

- made of stainless steel;

- complies with GOST;

- meets all technical requirements;

- protected from any mechanical influences by a special polymer coating;

- able to withstand any mechanical impact;

- the warranty period exceeds 30 years;

- withstands voltage of 1500 Volts.

Oxygen

It can also be connected to gas stoves, but you need to take into account several very important points:

- The internal diameter must exceed 16 millimeters;

- The surface in contact with oxygen must be well cleaned of oil. Otherwise, the hose will overheat and material damage will occur.

The advantages of oxygen hoses include the following characteristics:

- withstands high pressure. It can reach 20 atmospheres;

- very simple installation;

- low cost;

- rich assortment;

- does not conduct electric current.

Range of sizes and gasket models

The effectiveness of a gas cylinder gasket depends on its size and the dimensions of the unit. In the case of transport rings, the inner diameter should be slightly smaller than the diameter of the cylinder. For sealing rings inside connections, exact matching dimensions are important.

Washers for external structures are selected according to the outer and inner diameter. All types of sealing gaskets are subject to heavy loads, so their compatibility with equipment depends on pressure indicators.

Rings for necks and reducers have a flat configuration. Their sizes are regulated by GOST 15180-86. The document described the parameters of flat elastic gaskets made of fluoroplastic, paronite, rubber and materials based on them. Standardized products seal flanges and connecting parts, which are elements of the gas cylinder valve and various fittings.

The size range of gaskets corresponds to the nominal bore (DN, Dу) in millimeters and the nominal pressure (PN, Pnom, Pu) in MPa. Both indicators are also called nominal.

The first displays the internal diameter of the structural element through which the gas moves. The nominal pressure acts as a conditional indicator, which was established based on strength calculations at a temperature of +20 °C.

Dimensions of sealing gaskets according to GOST:

| Nominal diameter (DN), mm | Nominal pressure (PN), MPa | Outer diameter of gasket (D), mm | Inner diameter of gasket (d), mm |

| 10 | 0,1 – 0,63 | 38 | 14 |

| 10 | 1,0 – 4,0 | 45 | 14 |

| 15 | 0,1 – 0,63 | 43 | 20 |

| 15 | 1,0 – 4,0 | 50 | 20 |

| 20 | 0,1 – 0,63 | 53 | 25 |

| 20 | 1,0 – 4,0 | 60 | 25 |

| 25 | 0,1 – 0,63 | 63 | 29 |

| 25 | 1,0 – 4,0 | 69 | 29 |

| 32 | 0,1 – 0,63 | 75 | 38 |

| 32 | 1,0 – 4,0 | 81 | 38 |

| 40 | 0,1 – 0,63 | 85 | 45 |

| 40 | 1,0 – 4,0 | 91 | 45 |

| 50 | 0,1 – 0,63 | 95 | 57 |

| 50 | 1,0 – 4,0 | 106 | 57 |

| 65 | 0,1 – 0,63 | 115 | 75 |

| 65 | 1,0 – 4,0 | 126 | 75 |

Requirements for sealing products

The gasket must correspond to the drawing. Shape displacement is allowed within the limits indicated in special tables.

Do not place washers with cracks, bubbles or porosity on the working surfaces (P). In the case of non-working ones (NR), only gaskets with cracks are not used, but exceptions are made for other parameters.

On surfaces of both types, gaskets with some defects can be installed if they do not exceed the permissible values:

- Imprint on the surface of the product. With depth, length and width allowed for the gasket size.

- A chip up to 0.3-1.5 mm long, depending on the thickness of the seal.

- Pressing out up to 0.3-1.5 mm high. The value also depends on the thickness of the washer.

- Depressions, elevations and inclusions. Up to 0.3-5 mm.

- Under-formation. Up to 0.3-5 mm, based on the thickness of the gasket.

- Retracted edge. With a size of up to 0.3-1 mm.

Before installation, the gaskets are cleaned of dirt and dust and the target surface is prepared in the same way. The rings are fastened without shock loads, with short stretching.

The condition of the sealing gasket can be determined by the unit in which it is installed. After changing the unit or removing the product itself, it is subject to further use if the appearance remains unchanged and the dimensions are maintained.

The criteria also apply to seals and transport rings for propane gas cylinders of 2, 5, 10, 12, 15, 20, 27, 40, 50 liters and more. Products for methane cylinders of 47, 50, 67, 80, 85, 96, 100, 123, 132, 160 and 185 liters fall under the standards.

Similar products

PTFE gasket MasterPof set 4 pcs

Delivery of online orders

Goods ordered in the OBI online store are delivered throughout St. Petersburg and the Leningrad region within 50 km from the Ring Road. Delivery costs are automatically calculated when placing an online order, based on the weight of the product and delivery area.

Minimum order amount for free delivery:

We will deliver your order free of charge if the delivery address is located in the first delivery zone for online orders, and also:

- > 3,000.00 ₽ — for orders weighing up to 5.0 kg

- > 8,000.00 ₽ — for orders weighing up to 30.0 kg

The courier service delivers small-sized orders (weighing up to 30 kg) to the buyer’s door, large-sized ones to the entrance (gate, gate) of the house. Delivery includes free unloading of goods from the vehicle and their transfer within 10 m.

Delivery date and time

Next day delivery is available when ordering before 6:00 pm. You will be offered a choice of one of two 7-hour delivery intervals:

- — from 10:00 to 16:00

- — from 15:00 to 22:00

If you want to reduce the waiting period, you can choose one of the 3-hour delivery intervals for an additional fee:

- — from 10:00 to 13:00 +350.00 ₽.

- — from 13:00 to 16:00 +300.00 ₽.

- — from 16:00 to 19:00 +300.00 ₽.

- — from 19:00 to 22:00 +350.00 ₽.

Rescheduling the date and changing the delivery time interval is possible no later than 24 hours before the previously agreed date and time.

You can learn more about the operating conditions of the courier service in the section Delivery of online orders.

Gasket replacement procedure

Changing the O-ring on the body neck often coincides with replacing the valve. The gasket is updated if a problem with it or the faucet is identified.

They resort to replacing the valve if:

- it is not possible to move the flywheel, it has become more difficult to turn it;

- there is deformation of the valve or its parts;

- there is a smell of gas in the room;

- The scheduled technical inspection did not take place.

Gaskets are changed with a precise algorithm of actions. First, the cylinder itself is taken as far as possible from buildings. The valve flywheel is slowly unscrewed, after which the gas is released. The valve is carefully removed, smoothly and without damaging the housing.

The condensate remaining in the cylinder is poured out. Then simple technical steps remain: install a new gasket, another valve (if necessary). Finally, check for leaks.

Independent manipulations are prohibited by the rules, but in extreme cases and if you have the skills, you don’t have to wait for specialists. Some types of valves can be partially disassembled indoors and without releasing gas, for example, to replace internal seals.

Replacing the gasket between the valve and the gearbox will take less time. It will be enough to close the flywheel, disconnect the gearbox and install a seal between its nut and the valve fitting.

Some gearboxes do not operate through a valve, but directly from the cylinder. In this case, it should be taken outside to release the gas.

Checking the tightness of gas connections

After installing the reducer (after each filling of the cylinder), it is necessary to check the tightness of the connection and the reducer itself. Gearboxes wear out over time and may begin to leak gas. The easiest way to check for leaks is to use bubble liquid. We apply it to the joints, to the gearbox itself and to the joints of the tubes with the gearbox and fitting. Open the cylinder valve. If there is a leak, bubbling will appear.

(read more...) :: (to the beginning of the article)

| 1 | 2 | 3 |

:: Search

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared. Subscribe to the news to stay informed.

If something is unclear, be sure to ask!Ask a question. Discussion of the article. messages.

How to find out how much gas is in the cylinder? Pressure after filling and during operation How to find out how full the cylinder is. What gas pressure is guaranteed during replacement? What is the relationship between the pressure in a propane tank and the amount of gas remaining? How to determine whether the cylinder was completely filled or deceived? Read more…

Hello. I wanted to buy a gas gun using mains gas, but there wasn’t enough pressure and the gun wouldn’t light up. I called to find out the gas pressure in the main, but the gas service did not give an answer. Tell me what (which compressor device) can pump 2.5 atmospheres for a gas gun. Is this possible, thanks for your help Read the answer...

If there is no centralized gas pipeline, is it possible to use a cylinder to connect a gas water heater? Read the answer...

I changed the reducer on the gas cylinder, and when the valve was opened, gas under high pressure came out through the burners. I installed the old reducer again, but now, with the valve slightly open and the burners turned off, gas is escaping. When ignited with a match, a short flash occurs. What to do? There is a smell of gas. Read the answer...

Tell me, the cylinder should be closed after each use, or for long-term non-use Read the answer...

Can the reducer under pressure gradually unscrew from the cylinder? Read the answer...

Where to buy o-rings for a gas cylinder valve Read the answer...

Functions of the gas reducer when the cylinder is empty. Read the answer...

More articles

Heating with gas cylinders, bottled liquefied gas, propane, pro... I share my experience of heating a house with bottled gas...

Gas reducer. Principle of operation. Device. Adjusting the output yes... How the gas reducer works. Operating principle. How to adjust the pressure on...

Stove tap malfunctions. Why does the fire go out and not be regulated? ... Review of kitchen gas stove malfunctions. Weak or too strong combustion,...

Knitting. Openwork style, Openwork freshness, Oriental sweetness, Openwork... How to knit the following patterns: Openwork style, Openwork freshness, Oriental sweetness...

Knitting. Leaf in a figured frame, Cheerful diamonds, Openwork rows... How to knit the following patterns: Leaf in a figured frame, Cheerful diamonds, A...

Knitting. Rows of flowers. Braided raspberry. Drawings. Pattern patterns... How to knit the following patterns: Rows of flowers. Braided raspberry. Detailed information...

Knitting. Horizontal hatching. Curls. Starry sky. Drawings. With... How to knit the following patterns: Horizontal hatching. Curls. Starry sky...

Knitting. Birch leaves. Airiness. Drawings. Pattern patterns... How to knit the following patterns: Birch leaves. Airiness. Detailed instructions...

Conclusions and useful video on the topic

Eliminating gas leaks using available tools and replacing the internal valve gasket:

Gas cylinder seals should be replaced at the first sign of damage or loss of seal. They are made from highly flammable materials such as paronite, fluoroplastic and special rubber. Rings are produced for containers and units of any size, so there is no doubt about the quality of the seal.

In hardware stores there are gaskets for gas cylinders of 12, 27, 50 liters and containers with less common sizes. The cylinders themselves should be stored outside residential buildings, apartments and technical floors, away from escape routes.

Write comments on the topic of the article, ask questions, exchange important information. If you bought a gasket for a gas cylinder, tell us what material you purchased the product from and whether you are satisfied with its quality. The communication block is located below.

Some materials can be used as a replacement for paronite, depending on operating conditions.

Paronite is a cushioning sheet material. It is produced by pressing rubber, asbestos and powder components. The material has found wide application in many areas - the gas industry, in the arrangement of hot and cold water supply, in metalworking and electronics, in the oil and gas and chemical industries and in many other areas. Paronite should be used with caution in systems where there are sudden temperature changes.

Kinds

Connecting hoses for household appliances are necessary in every home. In order to carry out the process of connecting them to gas stoves, water heaters or boilers, it is worth using some additional elements, such as an adapter, gaskets and much more.

Dielectric insert

The dielectric coupling is a cut-off fitting, which helps protect the centers of devices that consume gas from stray current and its influence. This node is very important and effective. It is installed at the junction of the taps and connections to the device that consumes gas. The insert is also fixed between gearboxes and gas meters. In case of its absence, the performance of the devices suffers from stray current, since they are quite susceptible to current surges.

But a spark may also form in the pipeline, which will cause a fire. That is why the installation of dielectric inserts is mandatory according to the safety rules for using gas equipment.

Currently, there are several types of this device.

- Dielectric couplings with threaded ends. Their installation occurs between gas pipelines and devices that run on blue fuel.

- Dielectric bushings. These devices are in the form of inserts that do not conduct current. Installation of bushings is carried out at the junction of gas pipeline parts.

Clamp

The main purpose of the worm clamp is reliable fixation, as well as tightness during the process of connecting gas equipment, which uses a rubber hose and fittings. The material for the manufacture of clamps is galvanized steel, which provides the element with strength, durability and ease of installation. Thanks to the above features, clamps ensure tightness of systems.

This type of components has different types of cross-sections, so they can be selected in accordance with the cross-section of pipelines. The worm clamp design has the form of a solid steel strip, which must be put on the hose, and then clamped using an adjustment screw. Some clamps have additional parts that contribute to a tighter connection.

Tee

When laying PVC pipelines, it is often necessary to separate the flows. This function is performed by tees, which look like pipeline fittings. The gas tee can be straight or transitional. Judging by the method of connection to the pipe - welded, threaded.

The stamped version has the ability to withstand from –30 to +3000 degrees Celsius. They are made from pipes that have no seams. Welded products, in turn, are made from sheet steel and welded at the seams. There is a classification of tees according to the type of fastening:

- welded;

- flanged;

- threaded

Rubber gasket

Quick-release rubber flange gaskets are also called wafer gaskets. They look like a rubber ring and are used to seal and improve the tightness of a flange connection.

Paronite or fluoroplastic – which is better?

For natural gas, only gaskets made from paronite are installed . Despite the fact that the gas pressure is low, in this case the fire hazard plays a decisive role. If a fire occurs, paronite gaskets will give additional time to burn out, while fluoroplastic may “leak” from the normal heating of a nearby gas burner. In this regard, the main parameters for choosing paronite gaskets are based on operating temperature, speed and catastrophic failure.

For plumbing work, it is more advisable to replace paronite with fluoroplastic . It withstands high temperatures, aggressive environments and high pressure. The fluoroplastic gasket is the most inert material under operating conditions, for example, a heated towel rail. Consequently, it will ensure the durability of the structure.

Paronite or silicone?

Compared to silicone, paronite is more heat-resistant, while silicone is advisable to use at low temperatures. Silicone gaskets are used for pipelines with low pressure and relatively low temperature characteristics . They are used when arranging the internal water supply system in a room.

At temperatures above 150 degrees, silicone can only be used for a short time. If there is insufficient or no oxygen supply to the system, this material softens - porosity appears and hardness decreases, therefore, the strength of the product decreases. If the design assumes the above conditions, it is recommended to use paronite gaskets.

Our production:

- 2.196

- 2.82

To increase the mechanical strength of paronite, metal mesh reinforcement can be used. The resulting material is called ferronite or, as defined by GOST, reinforced paronite (PA).

Paronite gasket (GOST 481-80) is divided into several types, suitable for different types of connections:

- seal for flanges;

- gas seal;

- for radiators;

- for water.

produces and sells paronite gaskets for the oil and gas industry, public utilities, metallurgical industry, food industry, for repair and construction tasks, trading houses, shops.

Paronite or cardboard?

For installation in the engine system, it is better to use paronite . It is not corroded by synthetics, while cardboard is corroded by water if it is not tightened tightly. In addition, paronite can always be tightened, and cardboard only needs to be replaced.

Compared to cardboard, paronite is a more preferable option. Gaskets made from cardboard are not used in the gas system and water supply system due to their “low” technical characteristics.

JSC Tambov ATI - manufacturer of paronite gaskets

Our company produces gaskets from any materials - paronite (asbestos and beasbestos), fluoroplastic, thermally expanded graphite, TMKShch rubber, MBS and cardboard, including for individual orders. For questions regarding purchase or production request, please contact the sales department by multi-channel phone in Moscow +7 (495) 789-69-88.

If you use gas cylinders at home, then you probably know that safety should come first. Agree, nothing adds confidence more than peace of mind for yourself, your loved ones and property. In this sense, everything is decided by the gasket on the gas cylinder - a very cheap and simple remedy. The safety of using the equipment directly depends on its quality and size. It would be nice to protect yourself from explosion, destruction or possible fire, wouldn't it?

We will tell you about the requirements for gaskets and the rules for their use. You will find out what sizes, types they come in, and what features they have depending on the materials used. Together with this information, it will be easier for you to make a choice whether to buy a new or replace the old seal.

Gaskets are used on many connections. In the gas industry, seals are used on cylinders, hoses, and pipelines. This is done for the sake of safety and to minimize fuel losses. Read the article and find out more about it.

Safety precautions

Any installation work carried out with gas appliances requires mandatory compliance with all safety requirements. The connected flexible hose must always be in front of your eyes. It is strictly forbidden to close it. It must always be located in a place accessible for visual inspection.

It is prohibited to use a gas hose of non-standard sizes. They must comply with existing regulations.

The hose does not need to be painted, as paint may cause it to crack quickly. If you want to make the appearance of the sleeve more beautiful, you can cover it with self-adhesive paper.

The rubber hose is directly connected to the tap if it is located on the outlet. If the thread has non-standard dimensions, an adapter may be used.

When operating gas equipment, it is very important to comply with safety rules and existing operating standards. The fire safety of gas-fired installations depends on this

What are cylinder gaskets for?

They are used as sealing parts at the points of connection of the valve (faucet) to the neck of the gas cylinder and to the reducer. In the first case, the seal is mounted on the tank body and in a horizontal position, in the second - between the valve fitting and the gearbox, vertically. There are also gaskets inside the valve: under the flywheel, in the unit body and in its valve.

The seal eliminates or prevents gas leakage. Rubber gaskets increase tightness, improve mechanical characteristics, and keep connection parts in working condition. You cannot do without oil seals in rooms with small or no windows, rooms with stagnant air, and unventilated areas.

Gaskets improve the performance of gearboxes. The latter are connected when gas is supplied through a hose to reduce or stabilize pressure. In the process, the usual indicator of 16-50 or the maximum of 150-250 atmospheres reaches values from 1 to 16, and the probability of an explosion increases compared to the state when the cylinder is not used. The seal reduces the risk.

After prolonged use of the cylinders, the seals become deformed. They are changed about as often as cylinder taps.

In addition to sealing gaskets, transportation gaskets are used with gas cylinders: the rings are placed on the wide part of the body, in 2 places.

Connecting a gas stove yourself

This type of cooperation will be convenient for both us and you.

Most often, we use UDI-GAS bellows hoses. These hoses can be used for:

— work with the gas network of heating systems, household heating equipment systems that operate from gas lines and cylinders;

— work with liquid fuel coolants (TOSOL);

— work of household appliances with non-aggressive liquids of different temperatures.

The following supplies will be used when installing this type of hose:

— AISI 316L hose made of austenitic stainless steel;

— end fittings welded to the hose, also made of stainless steel, AISI 303 marking;

— union nuts made of stainless steel or nickel-plated brass;

— gaskets for aluminum nuts.

The installation provides that the hose can withstand temperatures from -50 to 130 degrees, a critical pressure of 33 atmospheres with a nominal pressure of 11 atmospheres.

This equipment allows us to guarantee you the safety and long service life of the installation. Don't joke with the gas hose; invite an experienced technician to install it. A craftsman for whom connecting a gas hose is nothing new.

Views: 6560

Materials for seal

Paronite, rubber and fluoroplastic are used in production.

Due to its adhesiveness, paronite tightly fills cracks and gaps. The connections are specially protected with graphite so that the material does not stick to them. Biological and climatic factors have little effect on paronite, and a sealant with mineral additives will survive contact with aggressive hydrocarbons. As the ideal size of the washer is exceeded, its effect becomes minimal.

Rubber is used because of its elasticity and ability to restore shape. Other properties include amorphousness and elasticity. The latter indicator increases with the ambient temperature. Hardness is controlled by the degree of vulcanization, plasticizers and fillers.

Seals are made of nitrile butadiene rubber with an upper temperature limit of +120...+130 °C and fluorine rubber, which can withstand up to +150...+200 °C.

Fluoroplastic exhibits resistance to chemical and corrosive processes. The material was also found to have weather resistance, heat and frost resistance. Due to low gas permeability, fluoroplastic began to be used in private homes and household gas distribution systems. After ignition, it quickly dies out, and the friction coefficient is in the range of 0.4–0.05 at a load of 1–20 kgf/cm².

In practice, silicone profiles are also used, but general safety standards prohibit installing the material on gas and fire equipment. Silicone seals reliably, exhibits high temperature resistance, but is highly flammable.

Range of sizes and gasket models

The effectiveness of a gas cylinder gasket depends on its size and the dimensions of the unit. In the case of transport rings, the inner diameter should be slightly smaller than the diameter of the cylinder. For sealing rings inside connections, exact matching dimensions are important.

Washers for external structures are selected according to the outer and inner diameter. All types of sealing gaskets are subject to heavy loads, so their compatibility with equipment depends on pressure indicators.

Rings for necks and reducers have a flat configuration. Their sizes are regulated by GOST 15180-86. The document described the parameters of flat elastic gaskets made of fluoroplastic, paronite, rubber and materials based on them. Standardized products seal flanges and connecting parts, which are elements of the gas cylinder valve and various fittings.

How to choose?

For a gas hose, you should choose only high-quality components, since safety depends on them. That is why you should give preference only to products that have quality certificates.

When choosing a dielectric coupling, you should first determine the diameter of its thread:

- 15 mm;

- 20 mm;

- 25 mm.

Thanks to the above types of threads, the installation of couplings occurs absolutely accurately, since at present couplings with other indicators are not used. The user can also select the ideal insert for the gas pipeline based on the type of connection:

- “barrel”, when the two ends are equipped with external threads;

- “barrel”, when one end has an internal and the other external thread;

- “coupling” - two sides are equipped with internal threads.

Among the trusted manufacturers of high-quality dielectric bushings are the following brands: TuboFlex, Lavita, as well as the Viega Sanpress 2267-22X1 and Viega G3 Sanpress 2267-20X1 models.

Worm-worm hose clamps can have one or more auxiliary clamps. These elements can be considered tapes and screws

When choosing a device, you should pay attention to the clamping force of the screw, that is, if it is pressed weakly, it can jump over the thread, and if it is pressed too hard, it will spin. Clamps are not universal, so it is worth choosing the right device for each type of hose

For example, ABA Nova is suitable for hard reinforced hoses, and Shoru A is suitable for silicone hoses with increased softness.

When choosing a tee for a 9 mm gas hose, you should give preference to a device made of brass. This type of tee is quite popular nowadays, as it facilitates simple branching into several gas consumers. An ideal complement to it would be a worm clamp.

When choosing gaskets for a gas hose, most consumers prefer rubber ones. The purchase of this type of device is due to its advantages:

- low gas permeability;

- high fatigue strength;

- resistance to abrasion;

- at an affordable price.

Requirements for sealing products

The gasket must correspond to the drawing. Shape displacement is allowed within the limits indicated in special tables.

Do not place washers with cracks, bubbles or porosity on the working surfaces (P). In the case of non-working ones (NR), only gaskets with cracks are not used, but exceptions are made for other parameters.

On surfaces of both types, gaskets with some defects can be installed if they do not exceed the permissible values:

- Imprint on the surface of the product. With depth, length and width allowed for the gasket size.

- A chip up to 0.3-1.5 mm long, depending on the thickness of the seal.

- Pressing out up to 0.3-1.5 mm high. The value also depends on the thickness of the washer.

- Depressions, elevations and inclusions. Up to 0.3-5 mm.

- Under-formation. Up to 0.3-5 mm, based on the thickness of the gasket.

- Retracted edge. With a size of up to 0.3-1 mm.

Before installation, the gaskets are cleaned of dirt and dust and the target surface is prepared in the same way. The rings are fastened without shock loads, with short stretching.

The condition of the sealing gasket can be determined by the unit in which it is installed. After changing the unit or removing the product itself, it is subject to further use if the appearance remains unchanged and the dimensions are maintained.

The criteria also apply to seals and transport rings for propane gas cylinders of 2, 5, 10, 12, 15, 20, 27, 40, 50 liters and more. Products for methane cylinders of 47, 50, 67, 80, 85, 96, 100, 123, 132, 160 and 185 liters fall under the standards.

Gasket replacement procedure

Changing the O-ring on the body neck often coincides with replacing the valve. The gasket is updated if a problem with it or the faucet is identified.

They resort to replacing the valve if:

- it is not possible to move the flywheel, it has become more difficult to turn it;

- there is deformation of the valve or its parts;

- there is a smell of gas in the room;

- The scheduled technical inspection did not take place.

Gaskets are changed with a precise algorithm of actions. First, the cylinder itself is taken as far as possible from buildings. The valve flywheel is slowly unscrewed, after which the gas is released. The valve is carefully removed, smoothly and without damaging the housing.

The condensate remaining in the cylinder is poured out. Then simple technical steps remain: install a new gasket, another valve (if necessary). Finally, check for leaks.

Independent manipulations are prohibited by the rules, but in extreme cases and if you have the skills, you don’t have to wait for specialists. Some types of valves can be partially disassembled indoors and without releasing gas, for example, to replace internal seals.

Replacing the gasket between the valve and the gearbox will take less time. It will be enough to close the flywheel, disconnect the gearbox and install a seal between its nut and the valve fitting.

Some gearboxes do not operate through a valve, but directly from the cylinder. In this case, it should be taken outside to release the gas.

Mandatory Precautions

Before replacing the gas cylinder valve, precautions must be taken. Work must be carried out in such a way as to protect people from potential hazards and keep the equipment in working condition.

The following precautions are used when preparing to replace a gas valve:

- The remaining contents of the cylinder can only be vented in an open space. An exception can be made only for nitrogen, air and argon.

- The work area should be well ventilated, although it is advisable to carry out work outside.

- There should only be one closed gas cylinder within the workplace.

- The flywheel must be unscrewed slowly to prevent electrification.

- You can begin replacing the valve only after the pressure in the cylinder and outside has been completely equalized.

When screwing the valve into the cylinder, fum tape or special lubricants are used, which provide increased tightness and strength of the connection. When replacing a faucet, such seals greatly complicate the process of dismantling it. To solve this problem, you can heat the valve with a hairdryer.

There is no need to save on gas fum tape, because high-quality material will eliminate the need to twist the valve due to gas leaks

You can heat the shut-off valves only after bleeding the gas from the cylinder and closing the tap. In this case, the procedure is safe and will not lead to unpredictable situations.

An alternative to a hairdryer is to wrap a cloth around the valve and then pour boiling water over it. With this heating method, any suitable plug should be screwed onto the outlet fitting to prevent water from entering there.

After taking all precautions and warming up the shut-off valves, you can begin to unscrew the valve, which can be a difficult task at home. If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work

If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work.

Conclusions and useful video on the topic

Eliminating gas leaks using available tools and replacing the internal valve gasket:

Gas cylinder seals should be replaced at the first sign of damage or loss of seal. They are made from highly flammable materials such as paronite, fluoroplastic and special rubber. Rings are produced for containers and units of any size, so there is no doubt about the quality of the seal.

In hardware stores there are gaskets for gas cylinders of 12, 27, 50 liters and containers with less common sizes. The cylinders themselves should be stored outside residential buildings, apartments and technical floors, away from escape routes.

Write comments on the topic of the article, ask questions, exchange important information. If you bought a gasket for a gas cylinder, tell us what material you purchased the product from and whether you are satisfied with its quality. The communication block is located below.

How to choose the right gas hose

It is necessary to purchase such devices only in special stores that have certificates for each product.

Very important! Never buy Chinese hoses. Even their licensed sleeves are made of especially thin rubber

It becomes unusable very quickly. A large number of fakes are produced in the country, which are difficult to distinguish from the real ones.

The gas hose braid should have a yellow mark. It is placed only on the gas hose; on the water hose, a blue-red line is placed.

All hoses come in different sizes to accommodate a wide range of connections. The most common range is one to two meters. Usually, fastening threads are made with dimensions of 1/2″–3/4″.

The ends can be equipped with two nuts. The so-called nut-nut, sometimes a nut with a fitting. This hose is called a “nut-fitting”. A nut with an internal thread is called a female; a fitting with an external thread is called a male.