Blowing pipes for the winter

One of the important elements in the garden is the water supply.

Without watering, especially in dry summers, it is quite difficult to grow a good harvest. Mulch helps retain moisture in the soil, but this moisture must still be added to the soil. Therefore, periodic watering of plants is necessary. To organize irrigation in a garden plot, a water supply system of one of three types is made. The first type of plumbing is its absence. Along the border of the garden plot there is a common water supply system, in which there is a tap for watering the plot. The advantage of such a system is that there are no pipes on the site and they do not interfere. The downside is that you need to carry a long, heavy hose from the tap, which damages the plants and destroys the beds.

The second type of water supply is above ground. The pipes are located on the surface of the garden plot. Plus - the system is easy to install, it is easy to drain water from it for the winter. The downside is that the pipes get in the way.

The third type of water supply is underground. The pipes are located underground at a depth of more than 30 cm.

Plus, the pipes don’t get in the way. Disadvantages - more labor-intensive and expensive construction of the system, the need to remove water for the winter.

Despite the disadvantages, underground water supply is more preferable for a garden plot, especially if landscaping is done on it.

Water can be supplied to each bed and the plants can be watered on them with a hose or a drip irrigation tape can be installed.

You can also place underground hidden water points on the site, covered with lids. We connect hoses or irrigation devices to the points during watering.

When installing underground water supply, it is optimal to use polypropylene pipes that are resistant to freezing in winter. That is, if water remains in them and turns into ice, then the pipe expands under the influence of ice. And when the ice melts in the spring, it narrows, but remains intact.

However, it is better to remove water from the pipes in the fall. If only for the reason that in the spring the ice in the pipe will not melt immediately and the pipes will not be able to be used at this time. For example, in 2014, the pipes thawed only on May 5th.

There are two ways to remove water from pipes.

The first is to lay the pipes at an angle when installing the water supply system and install a tap at the lowest point to drain the water in the fall.

The second is to blow air through the pipes. A household compressor will not work here, as it has weak outgoing air pressure. Over a long pipe length, the pressure decreases greatly and water is practically not blown out of it.

To ensure guaranteed water removal, you need to connect to the system with a pipe with a diameter of 12-34 inches and high air pressure. It's easy to do it yourself. You will need: a membrane expansion tank for the heating system, fittings, a compressor for the car, a piece of hose and clamps.

The essence of blowing pipes is as follows: we pump air into the expansion tank with a compressor, then we connect the tank with a hose to the water supply system and supply air from the tank into it. At the same time, water flies out noisily from open taps. Family members and neighbors within a radius of three hundred meters must be warned about this in advance.

The expansion tank is a metal container in which a membrane is located - a rubber container. When heated, water in the heating system expands and fills the membrane. The expansion of water is restrained by air pressure, which is pumped into the gap between the membrane and the tank body. Air is pumped through a valve at the end of the tank using a car compressor.

A membrane prevents us from using the tank to blow out pipes. We unscrew the tank flange, remove the membrane and screw the flange into place. Next, screw the tap onto the flange thread. If the thread is inch, then first install adapter 1-34.

Then the tap and place an adapter on it to connect the hose. We install the same adapter on any faucet of the water supply system. Next, we put the hose on the adapters and clamp them securely using clamps. It is important! When you open the tap, air under high pressure enters the hose, and if it is not secured, it can be torn off the adapter. And this is fraught with minor injury.

So, the hose was installed and securely fastened. Next, we connect a car compressor to the tank valve and pump air into it to a pressure of 6-8 bar.

Then we open the taps in the water supply system and open the tap on the tank. Air noisily enters the pipes and blows water out of them.

When organizing purge, you need to take into account that the longer the pipes in the system, the more air will be needed to purge them. The amount of air depends on the volume of the expansion tank. The larger the tank, the larger the system can be purged with it.

If you have a pipe 5-15 meters long, then a tank with a volume of 20-30 liters will be enough. Longer lengths will require tanks of 50-100 liters. Or you can use a smaller tank, but blow out the long system in parts.

In my opinion, it is better to immediately purchase an expansion tank of 80-100 liters and permanently install it somewhere in the workshop. You will have your own compressor station providing you with high pressure air. Moreover, an ordinary automobile pump will act as a compressor. You never know where you need high pressure air! Blow out the water from the pipes, blow out the air filter, etc.

Foreign objects

You shouldn’t be surprised, but various objects get inside the “snail” and they block the pump impeller. As a result, the water drainage does not work. Pulls them into the gap between the cuff and the drum.

This happens due to improper use:

- foreign objects remain in pockets;

- small items are placed without bags.

Most often, the pump's operation is blocked by the following things:

- socks;

- descendants;

- toothpicks;

- teaspoons;

- metal paper clips and pins;

- bra underwire.

You need to unscrew the cap, then pull out the concentrator. After this, remove foreign objects.

Do you wash your shoes in the machine?

Oh yes! No

Air purging

Unlike water, which is a practically incompressible liquid, air has very high compressibility. It is this property that allows it to be used in shock absorbers. But the high degree of air compressibility requires the use of a sufficiently powerful compressor for effective blowing; a car compressor is not suitable for these purposes. With a long pipe length, the pressure of the pumped air quickly drops, which does not allow the remaining water to be effectively blown out.

Blowing the water supply after draining the tap

To blow out the water supply system, pressure and air flow are important.

Do not use too powerful compressors, since the pipes used for internal wiring are designed for a maximum pressure of 8-10 atmospheres. To blow through a complex and extensive water supply system in a multi-story cottage, a large volume of air will be required.

Blockage

First you need to check the sewer system. Quite often, in old buildings, such as Soviet five-story buildings, pipes become clogged. And if the washing machine is not connected correctly, then it simply cannot drain the water.

To do this, disconnect the hose from the sewer and direct it to the bathroom or a large bucket. Then it starts a separate draining program. If the water came out, then the problem was in the sewer.

Otherwise, you need to clean the drain hose. To do this, tilt the washing machine on its side.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! To prevent water from getting on the electronic unit, always place it on the left side!

Then we disconnect the drain hose from the pump, having first removed the iron clamp. We take it out and clean it under running water. We put it back.

Are you using citric acid?

Oh yes! No

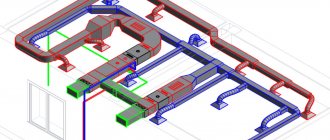

Equipment: what to blow with?

If you cannot find a powerful compressor, you can use the property of air to accumulate kinetic energy during compression. In other words, to blow out the water supply we will use a receiver, a compressed air storage device. For these purposes, we will use a hydraulic accumulator, which is designed to stabilize the water supply to taps and can hold air under pressure of up to 10 atmospheres. The procedure is as follows: a car compressor gradually pumps air into the bulb or membrane of the hydraulic tank, the hydraulic tank is connected to the water supply system through a hose, open all the taps at the water intake points and turn on the air supply from the hydraulic tank. We will see the effect of purging - water will come out of the pipes under pressure, quickly and with great noise.

The main causes of air jams

If air pockets occur, check the tightness of the connections.

The appearance of bubbles in water supply lines is associated with an internal physico-chemical reaction or penetration from the outside. In the first case, gas escapes from the water flow itself, because approximately 30 grams of air are dissolved in 1000 liters of water. The release of a gaseous substance occurs faster if the liquid flows slowly and if it is heated. It is for this reason that voids and cavities occur much more often in hot water pipes. In the second case, air from the external environment leaks into the main networks.

The main reasons for the appearance of air from outside in the water supply system of a private home:

- when the liquid level decreases, air can be sucked in through the non-return valve;

- the fitting elements with rubber sealing parts are poorly covered, depressurization occurs at the joints;

- the air in the water supply lines was not removed from the first start-up of the system.

In vertically directed pipes, air rises upward or is absorbed throughout the cavity. In horizontal ones, it accumulates in the highest places, which is unfavorable for the entire system.

The destruction of air bubbles occurs at a flow speed of a quarter of a meter per second. If it is smaller, the traffic jams may remain in one place for a long time.

Compressor types

Compressors operating on various principles can be used to purify water pipes.

different types of air compressors

Piston compressor

Air is compressed in piston cylinders, a direct analogy is the compression of the combustible mixture in an internal combustion engine. Low price, simple design, maintainability. High noise level during operation, impossibility of long-term operation.

Screw compressor

I pump air into two complex-shaped screws in parallel rotation. Low noise level during operation. Low friction between the screws ensures low power consumption. High energy efficiency - a large volume of pumped air per unit of energy spent. The cost is higher than piston compressors, repairs are only carried out under specialized service conditions.

Scroll compressor

Compact size, convenient for use in small spaces, relatively low productivity.

Diaphragm compressor

Similar to a piston, but instead of a metal piston a thin membrane is used. The membrane is driven by a crank mechanism. Low pressure generated, not very high level of performance.

industrial compressor

Compressors are often equipped with a small receiver. This is a durable steel tank in which compressed air is stored. The presence of a receiver allows you to increase the pressure to high values, which the compressor itself cannot provide, and organize a supply of air. As a result, we get an effective replacement for an expensive, powerful compressor.

The compressor is always equipped with a pressure gauge and control means. This is necessary to monitor and correct pressure levels. After purging the water supply system, all drain valves located at the lower points of different pipe branches should be left open.

Mechanical damage to the pump

Mechanical failures can also cause the failure of the fecal pump. So, if any part of the unit mechanism breaks off, it may well jam the working blades of the pump. To check and confirm/refute this point when repairing the pump, you need to rotate the blades by hand. If they spin easily, then the reason is not a breakdown. If the blade rotates with difficulty, then more complex repairs of the unit and its disassembly will be necessary.

Important: a difficult-to-rotate impeller may be the result of a failure of the bearing system.

Stages of purging water pipes

All pipeline purging is divided into several successive stages:

- We turn off the water and disconnect the purged system from the external water intake source.

- We drain the water from it.

- We twist the plugs, disconnect the plumbing fixtures and other appliances.

- We remove visible blockages.

- We connect the compressor pipe to one edge of the pipe.

- Turn on the compressor.

- We observe the other edge of the pipe. We turn off the compressor only after all the water has flowed out.

- For insurance, you can repeat this procedure in the opposite direction.

- After disconnecting the compressor, during conservation, both edges of the pipeline are closed with plugs, which prevents it from clogging. If the water supply continues to be used, all plumbing and appliances are connected to it, and water is supplied through it.

In this way, it is possible to efficiently bleed the summer water supply and prepare it for the winter, or carry out a high-quality cleaning of it.

Expert advice

Do not use sulfuric acid (such as battery fluid) to clean pipes - it is unsafe to use and produces toxic compounds that can leach into drinking and shower water.

A favorite remedy for home plumbers, vinegar and baking soda are not effective for cleaning pipes.

Before cleaning, you should try to determine whether the entire system is clogged or whether only part of it is clogged - that should be cleaned.

Water meters can only be cleaned by flushing. You cannot clean it with a cable or chemically - you can damage the meter.

If there is a lot of plaque and it cannot be cleaned, it means that the meter is already 12-15 years old and you should think about replacing it.

After disassembling and reassembling part of the network, it is necessary to carry out hydraulic tests - fill the network with water and carefully check all joints for leaks.

Compressors and their variants

Let us consider in more detail the possible options for this equipment, which differ in individual characteristics.

Here, air is compressed in piston cylinders according to the operating principle of an internal combustion engine. The advantage of this type is the simplicity of the design, its maintainability and low cost. The disadvantage is the limited operating time and noise of this process.

This type is distinguished by its small dimensions and low productivity. Its work occurs as a result of the interaction of two helices. Such equipment is suitable for blowing short-length pipes with small diameters.

The operating principle of such a device is based on the parallel rotation of two special screws. Due to low friction, this process requires little electricity and is characterized by low noise.

On the other hand, it should be noted the high productivity of this design. He is able to create sufficient pressure. Due to the complexity of the design, such products are very expensive and difficult to repair.

This type is similar to the piston design. A membrane is used instead of a piston. Its features are low efficiency and low pressure. To increase power, a small receiver is used in which compressed air is stored.

As a result of the combined work of these two elements, low-power equipment is capable of creating high pressure. This way you can significantly save your family budget. After all, to purify the water supply of a private house or cottage, there is no need to buy powerful equipment.

Danger of air bubbles in the pipeline

Water hammer can rupture a pipe

Bubbles, especially large ones, can destroy even strong elements of the highway. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning. Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles.

Making your own compressor

In order to blow out pipes for the winter, it is not necessary to purchase factory-made equipment. You can make it yourself, using available materials. For this you will need:

- take a canister, equip it with a water hose and fitting;

- the edge of the disconnected water supply is connected to the hose;

- a car pump is connected to the fitting;

- using a pump, pressure is created in the canister, which pushes water out of the pipes.

Naturally, the power of such a manual device will be insufficient, but it will be enough to blow through pipes of small diameter and length. The advantage of such a device is its independence from electricity and other power sources.

Preventing blockages

There is virtually no real prevention of blockages. It is necessary to periodically clean the inlet strainers and the mixer filter from debris and scale, and rinse or clean the pipes. Removing debris has a surprisingly good effect on the pressure in the system. Metal pipelines still become overgrown with calcium deposits and rust.

If plastic pipes are regularly clogged, it means that there are a lot of mechanical impurities in the water - this is a sign of an emergency condition of the main networks. If such problems arise, you should contact the water utility (and possibly higher authorities).

Recommendations

Comments 69

Good idea, I forgot to drain it the second fall, but strangely enough the pipes are intact, but I have 20 and I realized that you have 34

no difference. tees with 3/4 threads are also available for the 20th pipe. I chose the 3/4 thread because it is more difficult to insert a nipple into the 1/2″ plug.

I wish there were more Kulibins like this. thanks for the advice

I also blow out all the pipes at the dacha before frosts, only the device is a little different and with a receiver, it seems more effective to me. www.google.com/url?q=http…rPjpOfttRY_KRa8Ob4Kfsym0g I’ve been using it for 3 years now and not a single pipe has broken.

We’ve been doing this for a long time too, the only pumping station we have is 20 meters from the house, and it takes a long time for one person to run, but for two people it takes 15 minutes, from the house and from watering... In the house through a mixer: one monitors the pump, the second opens the tap...

I worked on landscaping and did watering. For the winter, the water was removed using a compressor and receiver. A regular pump won’t get it all out, although there will be a little left, and maybe it won’t tear it.

I use a compressor, nothing has broken in four years, HDPE pipe

but I don’t kick it out...it rips, of course after the winter...I patch it with rations of fresh pieces of pipe...I’m just too lazy to cut 40 meters in the fall, collect it, put it somewhere. But it rips in only three to five places. this is less in terms of soldering than the entire cut mainline and soldered again

I do this: Since the pipe is slightly sunk into the ground so as not to get in the way underfoot, in the fall I buy the most inexpensive antifreeze and pour it into the pipes from the house through the taps and shower hose, in turn cold to the supply pipe and hot to the bottom point where the drain krantik. Then I use a pedal pump to blow out the residue. 2 liters of antifreeze diluted in half is enough for the eyes. I pour the rest into the sink and shower siphons. In the spring, I pumped water into the pipes, washed 20 liters into a bucket and that’s it. To prevent farts from vomiting: this is industrial water, wash the dishes or use the water heater in the shower. At the inlet there is a filter with resin. For 7 years, no one was poisoned. ))) I get something to drink from the well.

Pump up the pressure and quickly release it through the far tap - water mixed with air comes out.

HDPE with a blue stripe doesn’t really care about the frost, you just need to open the taps. Otherwise, you can’t get all the water out; there will be sagging in the pipes and it will return there.

But the sellers say that if there is no slope, it will tear in 2-3 years...

Trusting the seller means not respecting yourself.

A guy already wrote here... PVC pipe and no problems with defrosting and freezing. Just leave the taps open in time. It’s inexpensive... Why all these hemorrhoids?

So don't do it. If you don't need it, don't do it. What's the problem? Do you want to prove to me that the pipe is not bursting? Well, prove it. I'm vomiting and I made this device for myself. It's inexpensive, you say? This adapter costs 5 rubles. This, dude, turns me on - if you come up with something, there will definitely be people who will crap everything. Like, what the heck, we’ll buy it, they have it in China, etc. If you don’t want to, don’t do it, no one is forcing you, aphids, done for yourself! Thanks for understanding.

Are you an idiot? Do you have a spring exacerbation? Where did you find sir in my text? I won’t prove anything to the idiot, no one’s pvc vomits, the idiot does. Yes, write as much as you like, fuck...

don’t do nonsense all the water from a hose or pipe in this way you won’t be able to squeeze out air lighter than water at a certain moment the air will begin to come out of the pipe passing through the pipe on top of the water if there is no slope then you won’t be able to remove all the water from the pipe

They will pump more air... Ahahaha

exactly, use a pump to expel the water so that the pipes don’t burst)

I laid a reinforced garden hose in the ground and forgot about the frozen pipes.

I would do it under the pump; it pumps air faster, but it seems to me that my father-in-law and I also drain the dead poultice, just unscrew it like you did and first insert the electric pump from the boat into the exhaust pipe, and that’s it.

And here the pumping speed does not matter. Excess pressure will still be created and will displace the water. However, I repeat, this is an idea. I implemented it this way, but you can at least adapt a turbine from a rocket engine - it’s up to you, however.

I’m not offended, I’m saying how we do it, and it’s right that whoever wants to do it the way he wants.

And here the pumping speed does not matter. Excess pressure will still be created and will displace the water. However, I repeat, this is an idea. I implemented it this way, but you can at least adapt a turbine from a rocket engine - it’s up to you, however.

I also pumped it up with an auto-compressor at the highest point of the water supply, and went around opening the taps. For five years, not a single impulse.

Stages of conservation of street water supply and automatic watering systems

Street water supply in dachas is often located above the ground or at a depth of up to 0.5 m. Therefore, such systems must be emptied before winter frosts, otherwise the resulting ice will break all the pipes.

It is especially important to blow out all metal pipes, since threaded connections quickly burst in the cold. PVC pipes are not so afraid of frost, but the water still needs to be removed from them; a compressor will also do an excellent job with this task.

Do not forget to remove water from storage tanks for irrigation, outdoor showers and other containers. All ball valves must be left open, then they will easily survive the winter and can be used in the future.

Recommendations

It makes sense to leave the devices open for a while and let the moisture dry out. This can be done indoors where there is no wind and dust does not fly. This requirement is especially significant for equipment that is sensitive to solid particles. Breakage will not happen, but the abrasive will damage the mechanical components.

It is necessary to drain any water from flexible hoses that may remain in the kinks. To do this, the hose must be lifted sequentially until liquid stops flowing from the end hole. There is nothing complicated. The main thing is to show a little attention, and the spring mood will not be overshadowed by anything.

Devices for creating winter water supply

The main devices are:

- pipes;

- surface or submersible pump;

- drain valve;

- pressure switch;

- hydraulic accumulator;

- water heating cable.

Pipes for winter water supply

It is better to choose polypropylene pipes, because they have a number of advantages:

- do not rust;

- durable (up to 50 years);

- low thermal conductivity;

- low weight;

- easy to install;

- acoustically isolated.

Installation is performed by thermal welding, which ensures the integrity and safety of the entire system.

Surface or submersible pump for winter water supply

The best option would be to use a submersible pump. It supplies water well to the system and is economical.

You need to choose the brand yourself, which depends on the depth of the water source and the type.

Natural cooling of the engine is carried out automatically, and during operation it does not create any noise.

Drain valve for winter water supply

The valve is installed after the pump, and the water can be drained into a source or into a well.

You can build a bypass pipe instead of the drain valve. This option is good when the winter water supply is located near the house.

Pressure switch for winter water supply

The device is necessary to maintain the pressure in the water supply within a certain range.

When the maximum pressure is reached, the relay will turn off the pump. If the pressure drops to a minimum, the relay will close the contacts and the pump will resume operation.

Hydraulic accumulator for winter water supply

This device will protect the water supply from water hammer and stabilize the pressure.

If the electricity suddenly goes out, you will still have water, since the water that has accumulated in the tank will enter the system.

It is better to use a hydraulic storage tank with a membrane.

Winter water heater

In practice, storage water heaters cope best with this process.

The power and volume of the boiler must be selected based on your water consumption. Typically, for a family of 5 people, 100 liters with a power of 2.5 kW is enough.

If winter water supply is carried out near the house, then you will need a water heating cable. It can be placed in the basement or under the floor.

Features and algorithm of actions when starting a pumping station

Installation, grounding and startup of the pumping station must be carried out by a specialist who is authorized and qualified to carry out this work. If this condition is met, there will be no reason to refuse warranty repairs if the pump breaks down. However, a competent and skilled man can independently connect the station by reading the instructions and observing safety precautions.

The pumping station is installed in an insulated room and is protected from exposure to negative temperatures or flooding. Considering the noise level of the unit, it is necessary to place it away from living rooms or provide a soundproof casing, which, by the way, can simultaneously serve as insulation. The station must be rigidly fixed to a concrete base or steel frame. Requires 220 V power supply.

Before starting a new pumping station for the first time, it is necessary to check the air pressure in the accumulator. It should be within 1.4-1.7 atm. for small containers up to 25 l; 1.7-1.9 atm. for larger ones. For measurements, an autopump with a pressure gauge is used; it can also pump air through the valve if necessary.

To properly start the pumping station for the first time, the following work should be done step by step:

- Place the station on a hard, flat surface and secure it.

- Check the hydraulic accumulator. When the tank is empty, the standard pressure is 1.5 atm. If it is more, you need to bleed the air through the nipple, less - pump it up.

- At the initial suction point, install a check valve with a coarse filter mesh on the pipe and lower it into the water intake. The angle of inclination of the suction line from the pump to the source must be 10 degrees or more to the horizon. For suction, rigid metal or HDPE pipes are used, as well as reinforced hoses with a diameter of 25-32 mm.

- Connect the suction line to the inlet pipe on the housing.

- Connect the pressure line through the connecting piece.

- Fill the pump and suction pipe with water: open the filling hole on the body, closed with a plug or valve; pour until the liquid begins to flow back; close tightly.

- Connect the power cable to a grounded outlet and press start.

- Open the nearest tap to bleed any remaining air from the water supply.

- After 3-5 minutes of pump operation, water should flow from the tap. If this does not happen: turn off the station, refill water, start again.

Nature of the problem

The processes that occur with pipelines at the moment of freezing are quite complex, but we will try to explain them to you using simple examples. When you understand the reasons for breakouts in the spring, when everything thaws, you will understand how to protect yourself from such problems.

The main problem of any pipeline in winter is its carrier. Or rather, the media is not a problem when the system is operated as intended. We are, of course, talking about proper temperature control, normal pressure, etc.

However, in winter, at the same dachas, or in country houses where the owners are absent regularly, the temperature constantly drops.

You're not going to burn fuel to heat just the water supply. The temperature drop is constant, and in the coldest times of the year its level can drop to negative values.

What happens to the water supply system in this case? If it's dry, then nothing. The pipes don’t care what the temperature is outside or inside. Some types of plastic tolerate critical temperatures less well, but in the end no serious problems arise.

It’s a different matter when the pipes are not empty and there is carrier left in them. This could be water if we are talking about a water pipe, gas, etc.

A decrease in temperature also affects the condition of the carrier. At one point he will freeze. You probably know what happens to water when it freezes - it changes in volume. When defrosting, the reverse process occurs.

As a result, the greatest pressure is placed on the pipe material. Something must dampen the energy from the expansion of water.

In addition, the icing of water on the walls itself does not have the best effect on the structure of the water supply system. It is possible that microcracks, weakened areas, etc. may appear after several freezing cycles. Weaknesses will not make themselves felt immediately. But over time, you will definitely hear about them.

Mobile compressor for pipe blowing

How to get rid of such problems? Yes, very simple. The water supply needs to be prepared before winter. Namely, use a compressor to blow through the pipes. The compressor will remove and completely clean the pipes of media, leaving behind a dry shell.

Where is purging used?

An equally important point concerns specific areas where a compressor as a blowing device is simply necessary.

The fact is that it’s not just the water supply that needs to be cleaned before winter. Quite the contrary, there are fewer questions about the water supply system, especially internal, that is, domestic.

Be that as it may, it is always warmer inside a room than outside; in order for the temperature inside to drop to negative values, a “wild frost” is needed. Although, this certainly happens.

A much more common case is damage to systems:

- external automatic watering;

- a water pipeline that runs along the street, for example, to neighboring houses;

- pipelines inside unheated premises;

- water supply supplying the pool;

- automatic animal feeders;

- for pumps and pumps.

All of them also need pre-purge with a compressor.

How to provide for the possibility of draining water in advance at the construction stage

To quickly drain water without stopping the operation of the entire system circuit, tees and valves are installed in front of any water heating or similar equipment. External or internal pipes should be laid with a slight slope; a tap is installed at the lowest point of the contours for emergency or scheduled drainage.

In well-designed heating systems, such taps are installed before and after each heat exchanger (Mayevsky taps) and at the lowest point of the return line leading to the boiler.

In water supply systems from wells, the drain valve is located not only at the lowest point, but also between the check valve and the hydraulic accumulator. All taps and tees are freely accessible.

How to insulate a well

Modern wells are made from reinforced concrete rings. This is a material with high thermal conductivity, and it will freeze. There is a particularly high risk of freezing in shallow wells, with a water level no higher than 1.1 - 1.2 meters, and in wells located in cold regions.

In regions with a temperate climate, it is enough to simply close the well tightly for the winter, or make a reliable house on top without cracks - the cold penetrates through the cracks, falls down and thus freezes the shaft.

Protasevich Consultant FORUMHOUSE

In a tightly closed well, the rings in frost are approximately 0.5-0.7 meters below ground level. The concrete rings themselves will not “conduct” the cold to the bottom.

But insulation of wells is also welcomed in the Moscow region. Frozen water in a well can damage pumping equipment, displacement of rings, and discrepancies in the joints between them.

Wells that are not insulated for the winter are more likely to need repairs.

If you have a blind area, you can insulate it too.

You can buy a ready-made “shell” for insulating wells, or you can insulate the structure with polystyrene foam or extruded polystyrene foam (these options are used by FORUMHOUSE members more often than others.

Well protection

To prevent ice from forming in the well, its lid and head must be insulated with any material with low thermal conductivity. Boards or timber work well; in addition to protection, they will give an aesthetic appearance to your well. When insulating, the constant temperature in the well will not drop below +5 C o.

You can also insulate the walls of the well with foam plastic or other similar material. This will provide additional protection against freezing. Insulation with foam plastic is carried out to a depth of 1.5-2 meters (the level of soil freezing in your region + 0.5 meters).

Wells and wells with drinking water that will not be used in winter can be cleaned of fungus and other formations. Cleaning is carried out using special antiseptic agents that can be bought in pharmacies. The treatment should be carried out according to the instructions and after completion the water should be pumped out. By spring, the cleaned wells will be filled with fresh drinking water.

The process of preparing household appliances for the winter period

The boiler is disconnected from the power supply and the access to water is blocked. After cooling, the water is removed from the device using a drain tap, and if it is not available, do this using a drain hose, having first unscrewed the screw on the safety valve. Then you need to loosen the nut on the outlet hose, which will allow air to enter and remove water from the boiler.

Remaining water from dishwashers, as well as washing machines, is removed from the drain hole, most often located on the front panel at the bottom of the equipment. For this purpose, place a container under the drain, open it and remove the water.

Have you ever left your dacha or country house for the winter, moving to the city, where it is much more convenient? Surely yes. At least in our area there are few people who like to freeze at their dachas in winter, especially considering the average temperature in January.

The problems faced by owners of unheated premises in winter are always the same and relate mostly to water supply systems.

For any pipeline, it doesn’t have to be a water supply, dropping the ambient temperature to below zero is a big problem. If you do not prepare the system before winter, then on sunny spring days you will be in for a not very pleasant surprise.

Blowing heating pipes with a compressor