A gutter on the roof of a house is an absolutely necessary thing. The roof itself cannot cope with the function of draining water: most of the moisture ends up on the wall, is partially absorbed, and partially goes down, being absorbed by the foundation. It is clear that in such conditions not a single building will last long enough.

The traditional and trouble-free method of arranging drainage is galvanized steel pipes.

Types of drainage systems according to the criterion of their installation method

A drain line can be installed using several methods

:

1. Installation of drainage systems from the inside will not spoil the appearance of the facades, since the drainage elements are located from the inside of the room.

2. External installation of a drainage system, where liquids are discharged through a gutter to an external pipeline. The design of the external drainage line involves the presence of a suspended or wall-mounted gutter, vertical drainage products and drainage elements, with the help of which the elements of the drainage network are joined horizontally and vertically. If simple products for the drainage system are used when installing liquid drains, then the appearance of the room may suffer, and the operational process will be complicated by the fact that the drain will regularly freeze, so it is necessary to create heating mechanisms for the drains. For these purposes, it is necessary to install a system that prevents icing of the drain, in order to avoid failure of the entire drainage system and a complete cessation of wastewater drainage.

3. The drainage line is located in combination. When installing the ceiling, you must keep in mind the required slope of the roof and gutters in the direction of the drainage holes, which should be throughout the entire roof and evenly located in its lowlands.

The gap between the funnels and the parapet and other parts of the room, in accordance with building codes and regulations, is at least 0.5 meters.

Types of drainage pipes according to material criteria and the distinctive nuances of their installation

Technical features of galvanized steel drainage products

We recommend: Installation of drainpipes

To install a drainage system, in most cases, galvanized products are used, from which, using two sheet blanks, they create pipelines suitable for supplying water, narrow channels that collect sediment and discharge it, as well as funnels. It must be taken into account that products made of galvanized steel and other structural parts are quite noisy; in addition, such a structure is impractical and very heavy.

Even after preventive measures are taken, the joining areas are not resistant to rust. It is because of this that it is better to replace steel sheets with the most durable and lightweight option, one that does not require painting, that is, aluminum products.

Today, the market offers a wide variety of drainage systems, which differ in the method of obtaining water resources and fasteners, the device itself and the shape. Nowadays, manufacturers create funnels, gutters, and pipes for drains from copper, galvanized steel, coated with polymer substances, and from polyvinyl chloride.

Characteristic features of plastic drainage products and the main nuances of their installation

Plastic gutters are new to the construction industry, but already occupy a leading place in popularity. The main advantage of plastic drainage is considered to be a high level of resistance to aggressive environments, ultraviolet radiation, chemical attack, and corrosive formations.

When the temperature regime changes from outside, plastic pipes (they are also used for heating systems and water supply systems) do not lose their flexibility and plasticity properties.

The widespread use of gutters made of polyvinyl chloride can be explained by the fact that they have a decorative appearance and a wide range. Their production involves the use of a special technological machine. They have also found their application in the internal sewer system.

A large selection of colors and excellent performance properties of polyvinyl chloride material distinguish it from metal products.

The advantages of polyvinyl chloride drainage include:

:

1. Compliance with affordable prices and high quality characteristics;

2. High level of resistance to high and low temperatures (their fluctuations);

We recommend: How to defrost a water supply: advice from professionals

3. Not subject to deformation processes and corrosive formations;

4. Resistant to external blockages and contamination inside the product;

5. Easy to use installation process;

6. In case of rainfall, they provide sound insulation;

7. Flexible system that allows you to install the most unconventional drainage systems.

Fixation of gutters and other parts of the polyvinyl chloride structure is carried out using glue or using rubber sealing rings, which ensures strength qualities, from a mechanical point of view, and a high level of tightness.

Due to its quality characteristics, plastic drainage systems are widely used not only in low-level buildings, but also in multi-level construction.

It must be remembered that you cannot make a combination of seals, namely a rubber and adhesive connection.

Plastic gutters can change dimensions with temperature fluctuations, due to the fact that the material tends to have a high expansion rate. In drainage, in accordance with state quality standards, in order to level out changes, the presence of special parts is provided that tend to expand, that is, they compensate for them. Installation of such parts is carried out in areas provided by the manufacturer.

Cable heating of drainpipes

Ice on the roof surface can occur for two reasons: due to temperature differences between night and daytime and the installation of a warm roof. to prevent ice formation . Among all its types, cable is the most widespread. There are two types:

- resistive cable consisting of a metal core and insulation. Such heating is characterized by constant resistance and constant power;

- The self-regulating cable consists of a matrix. This is automated heating, regulated depending on changes in operating conditions (drop in temperature, etc.).

In order for heating to be effective, the cable is installed in the entire area susceptible to ice formation:

- It covers gutters, and the cable should have a power of 200 to 300 W per 1 m².

- It is installed on the drain pipe to warm up the funnels and the outlet part of the product. The cable in the pipe should consist of two cores, each of which gives 20-30 W per 2 lm.

- Heating is provided in the roof valleys. There should be 250-300 W per square meter of valley.

- To protect the roof eaves, the cable is laid in a snake along the edge of the eaves. Its installation is calculated in such a way as to eliminate the formation of cold zones.

When installing cable heating, you should avoid drilling the roofing to avoid leakage.

Heating of roof edge and gutter with electric cable

It is more advisable to use different types of wall mounts.

How to calculate drainage?

The calculation of the drainage system occurs according to the following steps:

- Determine background information:

- measure the height of the building from the ground to the eaves overhang, the length of the eaves on all slopes to calculate the length of the gutters;

- determine the distance from the ground to the drain to find out the length of the pipes;

- calculate the roof area for each slope, and then sum the value. If the roof is rectangular, use the formula S=B×L, in which: S is the roof area (m²), B is the width of the slope (m), L is its length along the eaves (m).

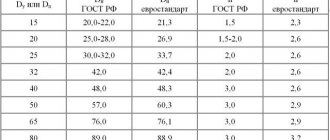

- Choose plastic or metal pipes and gutters. The cross-section and diameter of the drainpipes depends on the roof area. For example, for slopes up to 200 m², a gutter with a width of 130 mm and a pipe with a width of 100 mm are used.

- Select drainage system components: wall mount, clamps, holder, etc. They can be metal or plastic.

- Perform calculations based on initial data:

- Calculate the number of gutters and corners for fastening to the wall using the formula N = L+3.0 m, in which N is the number of gutters, and L is the perimeter of the cornice, 3.0 m is the standard length of the product;

- Calculate the clamps or holder using the formula N = (L-0.3)/i + 1, in which L is the length of the gutter along the cornice, i is the installation step of the holder;

- Calculate the length of the pipes using the formula: N=(H-0.25-H +L)/L_tr, in which H is the height from the eaves to the ground level; 0.25 - distance from ground level to drain; H—swan neck size; L_tr—length of the drainpipe section; L is the length of the swan neck insert.

The holder is mounted in increments of 2 m for house heights up to 10 m and 1.5 m for house heights higher than 10 m.

Features of installation of a drainage system (video)

Advantages of products made of galvanized steel coated with a polymer substance

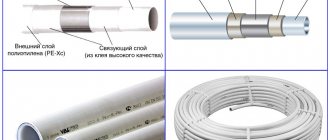

Installing a drainage system that includes a galvanized steel pipe coated with polymer is an alternative option made from new materials. A layer of plastic is applied to the galvanized product and other parts of the drain on both sides, as it can withstand temperatures ranging from 50 degrees to +120 degrees and increase the mechanical strength of the entire system.

Such designs are presented in round and rectangular sections. The advantage of such structures is their low expansion coefficient compared to plastic products. Therefore, the use of special expansion elements is not required. Specially coated galvanized steel pipes can be snapped together for easy drain line installation.

The drainage system includes a gutter, galvanized products, a clamp and other fasteners. Gutters can be from 2 meters to 6 meters long. Gutters are installed using supports.

We recommend: Rubber pipes for slurry pipelines

Functional purpose of the drain

Let's figure out what internal and external drains are, what their role is and the fundamental difference from each other in a residential building.

To do this, you need to start with the main purpose of the drain as an engineering structure, which is to drain rain and melt water from the roof of a residential building.

But since we live in a climatic zone characterized by seasonal changes in weather conditions, the drain is subject to requirements for trouble-free operation all year round.

So, with sudden changes in external temperatures, an internal drainage system is the most convenient and practical.

Advice! If a traditional pitched or gable roof is being designed, then it will be cheaper to design an electric heating system for the external drainage. If the roof is flat (in use), then it is preferable to install an internal drainage system.

It should also be noted that internal water drainage systems are more suitable for flat roofs, since the internal drainage funnel is also located inside the building structure.

If the roof has a different shape (single-pitched, gable, broken, gable or hipped), then to arrange a drainage system with an internal location, it should be designed differently, or an external drainage system should be provided.

Design of an internal roof water drainage system

Structurally, the melt and rainwater drainage system consists of three parts:

- Upper part (catchment);

- Internal part (riser);

- Lower part (release).

Roof funnel

The upper part of the system is nothing more than a funnel with a protective cover in the form of a mesh or lathing that protects against large debris (branches, leaves) getting inside.

Internal drain funnels are installed at the lowest point of the roof surface and are connected to the drain pipe, forming a sealed connection.

The internal part of the roof drainage system is a vertically installed drain pipe, colloquially referred to as a “riser”, running inside the building and serving to drain water from the roof of the building.

The lower part, called the outlet, is used to remove water from the drainage system either into a storm drain or outside the home.

Installation of external drainage

An external drain is installed according to a design that specifies the proportional number of elements of the drainage system. For example, 2 funnels and elbows, 8 drain pipes, 1 mark, 7 fastenings, gutters around the perimeter of the house with fastenings, connections and plugs.

- First, the gutter fastenings are installed. The gutters should have a slope of 3-5º towards the funnels;

- Then funnels are placed;

- Then the gutters are assembled, laid in place and connected to the funnels;

- Then the eastern pipes are installed. Installation is carried out from bottom to top.

Related articles: Everything you need to know about the Arduino water flow sensor